Need help with print banding

Posted by gadittri

|

Need help with print banding May 19, 2017 08:34PM |

Registered: 10 years ago Posts: 80 |

Hi all,

I have been battling this issue for a long time and can't figure it out. I have a custom built Core XY with a 5mm pitch ball screw for my Z axis and a 1.9 degree stepper with a 2:1 reduction. It appears repeatable about every 12-13 layers at 2.5 layer height. My bed and extruder temps are very stable and only varying by .2 degree or so. I have tried different rolls of filament but all have been Micro Center's Inland filament. The layers appear very well aligned and feels smooth to the touch. It doesn't matter what model I print because they all show this signature. Forgot to mention that I use Simplify 3D.

Edited 1 time(s). Last edit at 05/19/2017 08:37PM by gadittri.

I have been battling this issue for a long time and can't figure it out. I have a custom built Core XY with a 5mm pitch ball screw for my Z axis and a 1.9 degree stepper with a 2:1 reduction. It appears repeatable about every 12-13 layers at 2.5 layer height. My bed and extruder temps are very stable and only varying by .2 degree or so. I have tried different rolls of filament but all have been Micro Center's Inland filament. The layers appear very well aligned and feels smooth to the touch. It doesn't matter what model I print because they all show this signature. Forgot to mention that I use Simplify 3D.

Edited 1 time(s). Last edit at 05/19/2017 08:37PM by gadittri.

|

Re: Need help with print banding May 20, 2017 12:08AM |

Registered: 10 years ago Posts: 80 |

I am thinking of purchasing another rolled ball screw but don't want to end up with the same issue. Anyone have any luck with these chinese ball screws?

I am now using a 1605 5mm pitch and curious if the 1604 4mm pitch would help. I would prefer a name brand nsk but can't justify the hundreds of dollars.

[www.ebay.com]

I am now using a 1605 5mm pitch and curious if the 1604 4mm pitch would help. I would prefer a name brand nsk but can't justify the hundreds of dollars.

[www.ebay.com]

|

Re: Need help with print banding May 20, 2017 10:28PM |

Registered: 10 years ago Posts: 80 |

I did some more testing on my Z axis using a digital indicator. I switched from 1/16 stepping to 1/4 stepping which made no difference. I homed the Z and issued a G1 Z30 and then zeroed out my indicator. I then homed the Z again and issued the G1 Z30 which the indicator still read 0.00mm. This tells me my stepper motor is not skipping steps and my homing is very repeatable. I then stepped the stage up 1mm at a time from 0 to 20mm and here are the results:

0

1.03

2.06

3.04

4

5

6.02

7.04

8.02

8.99

9.99

11.01

12.05

13.01

13.98

14.98

15.99

16.01

17.04

18

18.97

19.97

I am using a C7 precision ball screw and I guess this is an acceptable error for this grade of ball screw. I may just forked out the money for a name brand Kuroda or NSK precision ground screw if I knew it would fix my issue.

0

1.03

2.06

3.04

4

5

6.02

7.04

8.02

8.99

9.99

11.01

12.05

13.01

13.98

14.98

15.99

16.01

17.04

18

18.97

19.97

I am using a C7 precision ball screw and I guess this is an acceptable error for this grade of ball screw. I may just forked out the money for a name brand Kuroda or NSK precision ground screw if I knew it would fix my issue.

|

Re: Need help with print banding May 21, 2017 03:15AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Need help with print banding May 21, 2017 08:39AM |

Registered: 13 years ago Posts: 1,797 |

the issue: something is causing the feedstock to appear change color.

what can cause color change? particles, or a break down in feedstock thru temp, or an uneven deposited layer, or possibly something else.

is your print head clean?

does printing part at a lower temp change effect?

does printing part slower change banding effect?

are the layers all the same height?

can you print part out without slowdown for cooling?

what happens if you lower extrusion settings by 5% (perhaps the layers are too wide for the type of nozzle to smash them flat)

my guess is that there are two things going on.

1 dirty feedstock with no sponge in place to keep it clean.

2 over extruded layers

Edited 1 time(s). Last edit at 05/21/2017 08:44AM by jamesdanielv.

what can cause color change? particles, or a break down in feedstock thru temp, or an uneven deposited layer, or possibly something else.

is your print head clean?

does printing part at a lower temp change effect?

does printing part slower change banding effect?

are the layers all the same height?

can you print part out without slowdown for cooling?

what happens if you lower extrusion settings by 5% (perhaps the layers are too wide for the type of nozzle to smash them flat)

my guess is that there are two things going on.

1 dirty feedstock with no sponge in place to keep it clean.

2 over extruded layers

Edited 1 time(s). Last edit at 05/21/2017 08:44AM by jamesdanielv.

|

Re: Need help with print banding May 21, 2017 12:56PM |

Registered: 10 years ago Posts: 80 |

Thanks for the suggestions and I will print a rectangular tower when I get a chance. PETG is all I print with now since ABS was causing me sore throats and was tired of the cracking and warping that goes along with it.

Yes, I do use a sponge to wipe the filament and it sure does catch a lot of dust. Just can't figure out why it would be so repeatable every so many layers if it was over extruding. The tower test suggestion would tell us a lot since the layers would be the same throughout the print.

Yes, I do use a sponge to wipe the filament and it sure does catch a lot of dust. Just can't figure out why it would be so repeatable every so many layers if it was over extruding. The tower test suggestion would tell us a lot since the layers would be the same throughout the print.

|

Re: Need help with print banding May 21, 2017 02:21PM |

Registered: 8 years ago Posts: 601 |

My first guess would be temperature fluctuations but you said you checked that. What happens if you change the thermistor in bed and hotend? Or use bang bang/pwm?

If it's the ball screw it should be visible under a microscope or macro lens.

Does anything obstruct the filament path at all? Could it be the filament becoming tight on the spool and then uncoiling a bit?

If it's the ball screw it should be visible under a microscope or macro lens.

Does anything obstruct the filament path at all? Could it be the filament becoming tight on the spool and then uncoiling a bit?

|

Re: Need help with print banding May 21, 2017 08:00PM |

Registered: 10 years ago Posts: 80 |

I am using PWM for my hotend and my bed. My bed is a 3/8" piece of aluminum with a 1/16" PEI piece glued down to the aluminum.

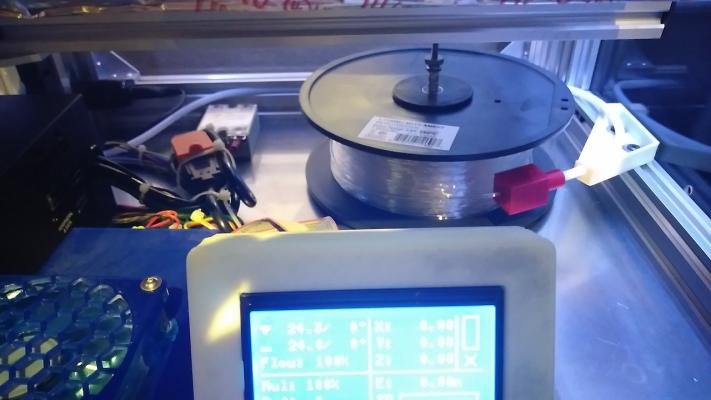

The filament idea could be a possibility because every once and a while I hear a pop as the filament catches on the spool or under another wrap of filament. I have my spool mounted horizonally on ball bearing spindles (spool itself turns very easily) The filament runs through a foam sponge and then through 4' of 4 ID X 6 OD teflon tubing to my 5:1 direct drive extruder. I wish my printer allowed me to mount the spool vertical but I have all my sides enclosed and not enough space.

The filament idea could be a possibility because every once and a while I hear a pop as the filament catches on the spool or under another wrap of filament. I have my spool mounted horizonally on ball bearing spindles (spool itself turns very easily) The filament runs through a foam sponge and then through 4' of 4 ID X 6 OD teflon tubing to my 5:1 direct drive extruder. I wish my printer allowed me to mount the spool vertical but I have all my sides enclosed and not enough space.

|

Re: Need help with print banding May 21, 2017 10:59PM |

Registered: 10 years ago Posts: 80 |

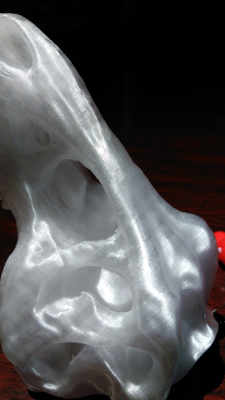

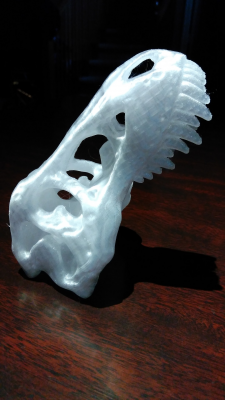

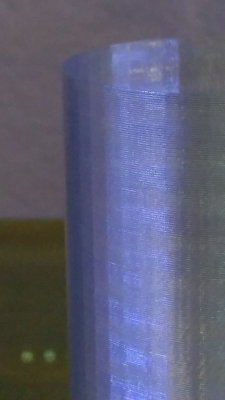

I made sure the filament did not bind throughout the print but I am convinced its my Z axis for it to be so repeatable. I haven't printed a thin wall model in a long time so I know my tuning needs some work. This was printed at 240 with Micro Center's Inland Natural PETG. Temp recommendations are from 230-250 on the spool. I have a Kuroda 12-2 ball screw on the way to try out.

|

Re: Need help with print banding May 22, 2017 02:16AM |

Registered: 8 years ago Posts: 5,232 |

A single wall object with natural PETG should be almost transparent.

You either print to fast or the temperature is not spot on.

As I'm testing a new print surface ( LokBuild ) and have some transparent PETG left over, I give it a try today and post my settings.

A CoreXY with only one ballscrew can have other issues with z-height consistency, like wobbling or tilting bed frame. Can you rule that out?

Edited 1 time(s). Last edit at 05/22/2017 02:24AM by o_lampe.

You either print to fast or the temperature is not spot on.

As I'm testing a new print surface ( LokBuild ) and have some transparent PETG left over, I give it a try today and post my settings.

A CoreXY with only one ballscrew can have other issues with z-height consistency, like wobbling or tilting bed frame. Can you rule that out?

Edited 1 time(s). Last edit at 05/22/2017 02:24AM by o_lampe.

|

Re: Need help with print banding May 22, 2017 06:36AM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Need help with print banding May 22, 2017 07:10AM |

Registered: 8 years ago Posts: 5,232 |

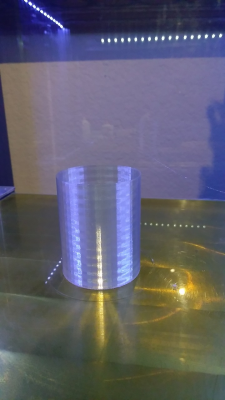

Here's my cube. Print started at 245°C and 35mm/s, but as you can see the corners aren't perfect. I had to slow down to 22mm/s and then experimented with temps. But 240°C seems to give best transparency.

|

Re: Need help with print banding May 22, 2017 07:19AM |

Registered: 8 years ago Posts: 413 |

|

Re: Need help with print banding May 22, 2017 07:25AM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Need help with print banding May 22, 2017 09:47AM |

Registered: 10 years ago Posts: 80 |

|

Re: Need help with print banding May 22, 2017 11:24PM |

Registered: 10 years ago Posts: 80 |

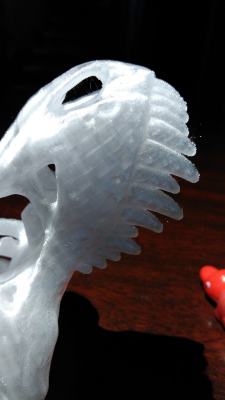

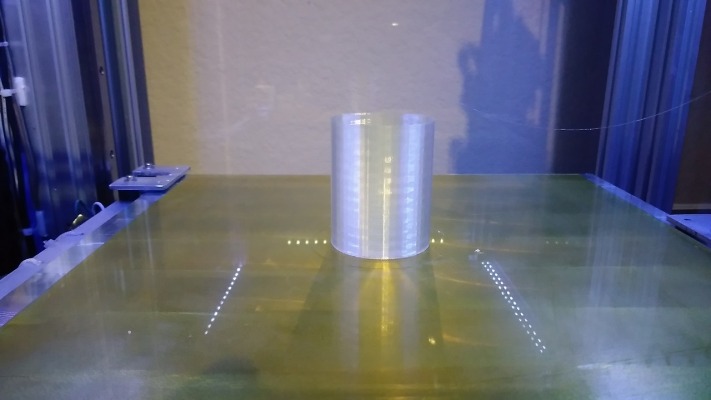

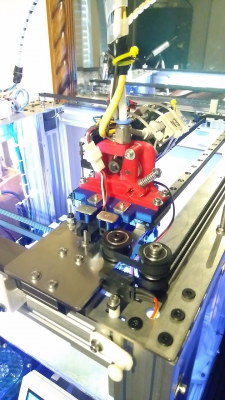

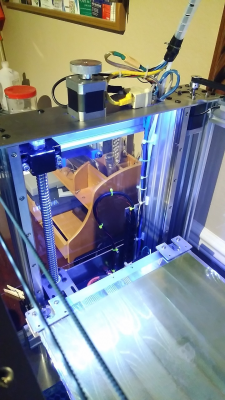

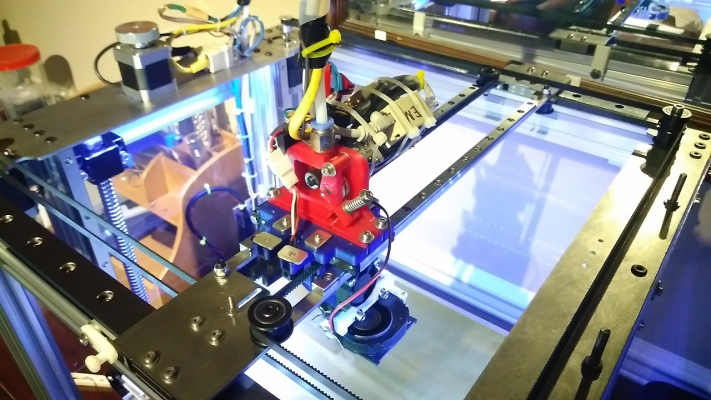

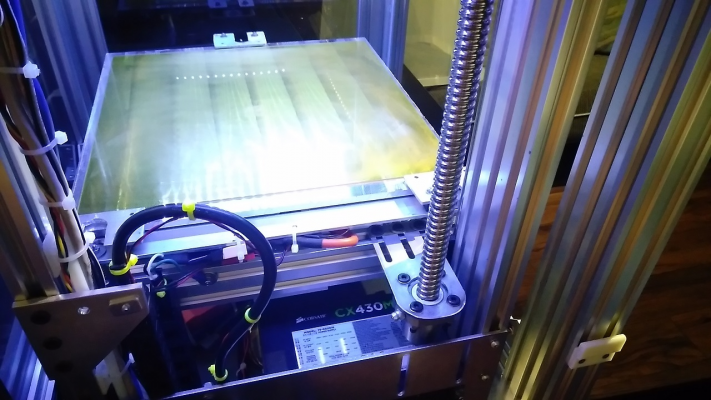

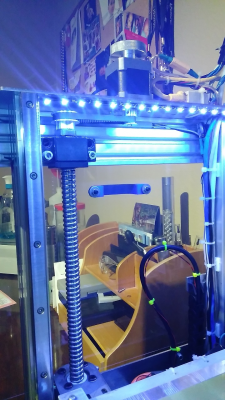

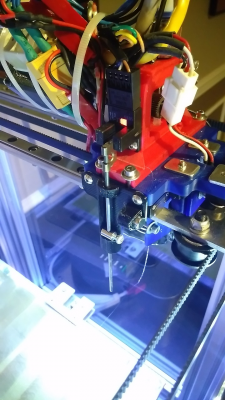

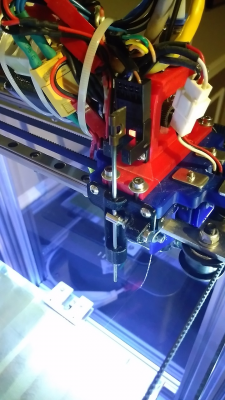

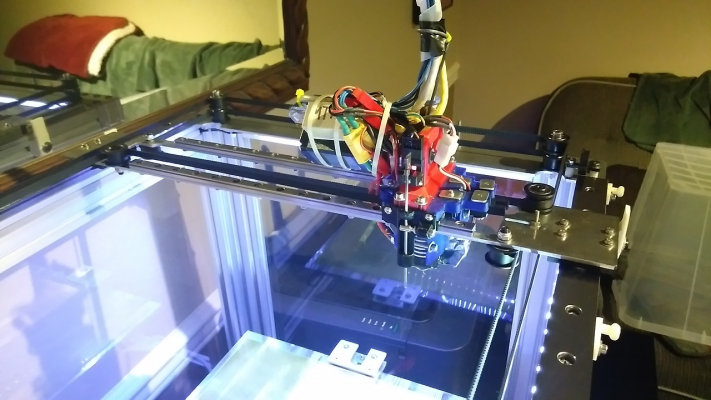

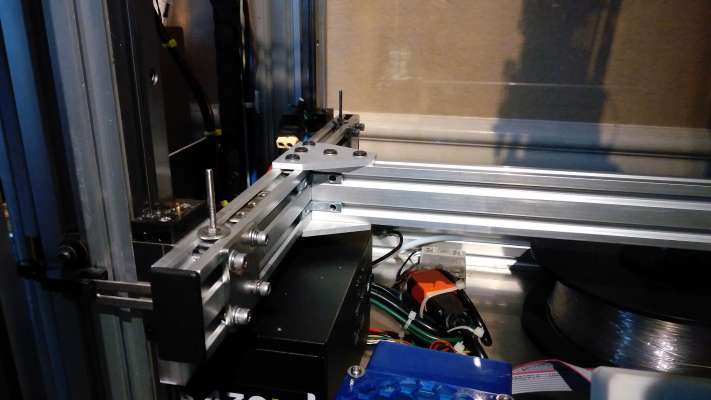

I tightened my belts up and slowed my print speed from 50 to 30. I printed a single wall cylinder in vase mode which had no starts or stops between layers. This will be a good before and after test piece when I replace my ball screw this weekend. The layers look pretty good but can actually feel the slight imperfections. I also took some pictures of my setup as requested. My printer weighs est. 50lbs and is a beast to move around but holds its position if moved (do not have to re-level)

|

Re: Need help with print banding May 22, 2017 11:36PM |

Registered: 10 years ago Posts: 80 |

Here are some more pictures. Check out my simple auto level solution. I usually never use it except to manually check the level at 3 points. The magnet holds it up out of the way until I need to use it.

|

Re: Need help with print banding May 23, 2017 08:15AM |

Registered: 8 years ago Posts: 413 |

That's an impressive build.

Put some marks on the gears in the Z drive and look to see if the layer changes match the gear positions. Any eccentricity of the gears will change the Z height a small amount. I mean that the gear on the top of the Z screw may be slightly off centre.

The pictures of the tower seem to show the layers are misaligned. Looks like you are using the Z screw for bed position control as well and what looks like one of the corner verticals.

If the Z screw is eccentric it would move the bed. Can't really be a bent shaft as its the same all the way up the print. Seems unlikely this is the problem as it looks like your bearings are on the outer diameter of the shaft.

Put some marks on the gears in the Z drive and look to see if the layer changes match the gear positions. Any eccentricity of the gears will change the Z height a small amount. I mean that the gear on the top of the Z screw may be slightly off centre.

The pictures of the tower seem to show the layers are misaligned. Looks like you are using the Z screw for bed position control as well and what looks like one of the corner verticals.

If the Z screw is eccentric it would move the bed. Can't really be a bent shaft as its the same all the way up the print. Seems unlikely this is the problem as it looks like your bearings are on the outer diameter of the shaft.

|

Re: Need help with print banding May 23, 2017 09:55PM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Need help with print banding May 23, 2017 11:40PM |

Registered: 10 years ago Posts: 80 |

I already started making mods in preparation for a different ball screw to install so unable to run anymore tests. I held up the print from last night and the bands line up pretty well with my current ball screw. I don't know why this would be causing this because it rolls fairly smoothly. Now what do I use to cut a 21mm hole in 11ga stainless without mangling it to hell? I ordered some step bits but am skeptical about them for cutting stainless.

Thanks all, I will post an after picture with my used ball screw from ebay.

Thanks all, I will post an after picture with my used ball screw from ebay.

|

Re: Need help with print banding May 24, 2017 12:02PM |

Registered: 8 years ago Posts: 3,525 |

Frustrating problem as that looks like a great machine. I can't make out from the images the z axis configuration, I presume it has one ballscrew and is cantilevered? It is constrained by linear rails, if so how many?

I can't see a cantilevered bed (if it is one) or a bed with 3 or 4 rails to guide it but only one ballscrew, being completely level as it travels which would easily cause the banding it seems you've ruled out most/all of the other possible causes. Its not severe as it's big and heavy and I'm sure it seems quite rigid. My corexy bed with twin 8mm smooth rods to guide it and belts to lift it one on each side, does not produce that banding.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I can't see a cantilevered bed (if it is one) or a bed with 3 or 4 rails to guide it but only one ballscrew, being completely level as it travels which would easily cause the banding it seems you've ruled out most/all of the other possible causes. Its not severe as it's big and heavy and I'm sure it seems quite rigid. My corexy bed with twin 8mm smooth rods to guide it and belts to lift it one on each side, does not produce that banding.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Need help with print banding May 24, 2017 01:44PM |

Registered: 10 years ago Posts: 80 |

Yes it is frustrating because I have so much money in this. I could have bought a cheaper mid grade printer and had better quality but I wouldn't have learned as much. What is more frustrating is the layers used to look really good but don't know if switching to petg filament made it more profound than before. I used to print abs only and never really noticed this I guess.

I use only two rails for the z axis which is mounted on the same side as the single ball screw. They are high quality nsk brand linear rails and it is surprising very rigid. I then use a 3 point leveling to attach the print bed to the Z sub frame (20x40 extrusions).

Edited 1 time(s). Last edit at 05/24/2017 02:08PM by gadittri.

I use only two rails for the z axis which is mounted on the same side as the single ball screw. They are high quality nsk brand linear rails and it is surprising very rigid. I then use a 3 point leveling to attach the print bed to the Z sub frame (20x40 extrusions).

Edited 1 time(s). Last edit at 05/24/2017 02:08PM by gadittri.

|

Re: Need help with print banding May 24, 2017 02:04PM |

Registered: 8 years ago Posts: 3,525 |

Maybe the least difficult fix if it is going to be very problematic to add a different ballscrew is to look at Digital Dentist's belt system. I use belts and they work, You could probably add something like that more easily than drill that stainless steel. And you would be lifting from two sides, so two belt attachments and two rails.

Edited 1 time(s). Last edit at 05/24/2017 02:05PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 05/24/2017 02:05PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Need help with print banding May 24, 2017 02:16PM |

Registered: 7 years ago Posts: 270 |

|

Re: Need help with print banding May 24, 2017 05:01PM |

Registered: 10 years ago Posts: 80 |

I thought about that also but the weight would always be constant applied so even it it did flex under weight it shouldn't change (not certain for sure though). I am making the new ball screw closer to the Z frame. This should minimize the flex if any, it is 11ga stainless and feels super rigid.

|

Re: Need help with print banding May 25, 2017 01:53AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Need help with print banding May 25, 2017 03:11PM |

Registered: 10 years ago Posts: 80 |

Something I should have tried before taking it apart was to set the Z axis motor to enabled between layers. I currently have it set to turn off the motor between layers and it may possibly be walking itself with the motor off. I have the new screw installed, just waiting on a 8mm bore pulley and a smaller belt.

|

Re: Need help with print banding May 25, 2017 04:16PM |

Registered: 10 years ago Posts: 770 |

Sorry, only registered users may post in this forum.