What can cause this? (I may have an answer)

Posted by dlc60

|

What can cause this? (I may have an answer) May 23, 2017 06:22PM |

Registered: 7 years ago Posts: 619 |

I just started having issues with my Kossel printer that are puzzling. Basically, even though I am using the same filament temperature and the same bed temperature AND the same filament, suddenly it stopped adhering to the bed. Hmm. This kind of problem comes up often it seems. The last time the hot end heater element had come unscrewed a tiny bit.

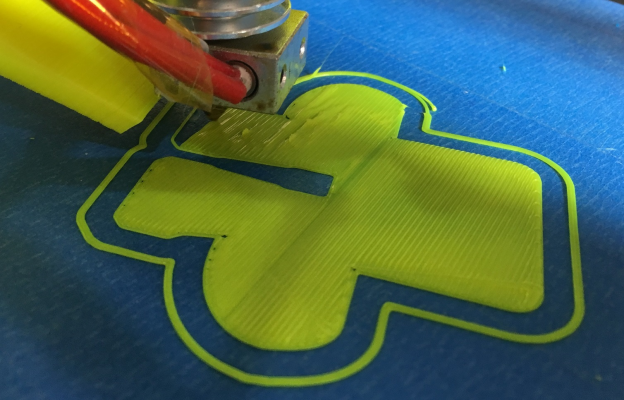

This is what a "raft" looks like on its first layer.

A couple of sections even looked burned again - No, the heater is NOT unscrewed. The operator may be...

What would make something look like that, the rippled area not adhering? I tried making the print height 80% of normal, extruding 20-50% more material, slowing down the print speed...

I think that I figured it out. The one other symptom of the printer was that the fan was very loud and there was more vibration to the system than usual.

Do you see it yet?

The potential solution is the hot end cooling fan.

I inadvertently tapped the fan with a tool when I was replacing a part cooling fixture on my end effector. In doing so I broke off a fan blade (the fan was running). This unbalanced the fan so much that it started vibrating a lot and apparently lost a lot of rotational velocity. Enough so that the feeder tube was clearly not being cooled down enough, which caused a filament extrusion problem(?). I have an "all metal" hot end and it didn't completely block up for this, but it looks like it had an adverse affect on the print! I will post confirmation of my find this evening when I get home and see if my afternoon print job came through.

More as I know it.

DLC

This is what a "raft" looks like on its first layer.

A couple of sections even looked burned again - No, the heater is NOT unscrewed. The operator may be...

What would make something look like that, the rippled area not adhering? I tried making the print height 80% of normal, extruding 20-50% more material, slowing down the print speed...

I think that I figured it out. The one other symptom of the printer was that the fan was very loud and there was more vibration to the system than usual.

Do you see it yet?

The potential solution is the hot end cooling fan.

I inadvertently tapped the fan with a tool when I was replacing a part cooling fixture on my end effector. In doing so I broke off a fan blade (the fan was running). This unbalanced the fan so much that it started vibrating a lot and apparently lost a lot of rotational velocity. Enough so that the feeder tube was clearly not being cooled down enough, which caused a filament extrusion problem(?). I have an "all metal" hot end and it didn't completely block up for this, but it looks like it had an adverse affect on the print! I will post confirmation of my find this evening when I get home and see if my afternoon print job came through.

More as I know it.

DLC

|

Re: What can cause this? (I may have an answer) May 23, 2017 06:44PM |

Registered: 8 years ago Posts: 601 |

|

Re: What can cause this? (I may have an answer) May 23, 2017 10:04PM |

Registered: 13 years ago Posts: 1,797 |

my guess is feedstock pressure is not consistent, either feedstock is binding, or bed is not level. keep in mind first level is often over extruded, and back pressure is often quite high. this is why first layer is often printed at slower speed or a higher temp, and at a thicker layer height,

make sure 1st layer speed never exceeds 10-15mm/s depending on temp and extruder type until you know how well your machine can do a first layer. for example heated beds can have 1st layers put down faster.

make sure 1st layer speed never exceeds 10-15mm/s depending on temp and extruder type until you know how well your machine can do a first layer. for example heated beds can have 1st layers put down faster.

|

Re: What can cause this? (I may have an answer) May 24, 2017 02:18AM |

Registered: 8 years ago Posts: 5,232 |

The gap between heatsink and heater block is pretty small and the block surface isn't insulated. Maybe the heatsink gets to much parasitic heat from below?

I'd insulate the block with cotton wool pads ( makeup-remover pads from the drugstore ) and kapton tape.

The other possible reasons have been said.

I'd insulate the block with cotton wool pads ( makeup-remover pads from the drugstore ) and kapton tape.

The other possible reasons have been said.

|

Re: What can cause this? (I may have an answer) May 24, 2017 07:05AM |

Registered: 8 years ago Posts: 413 |

I have some suspicions that water absorption causes this. It is only a suspicion.

You are clearly extruding enough material for it to "squish" and its obviously hot enough to flow and to bond with its neighbour. So why does it not stick to the bed?

Hence I suspect there are small bubbles trapped under the filament that expand and cause it to lift.

You are clearly extruding enough material for it to "squish" and its obviously hot enough to flow and to bond with its neighbour. So why does it not stick to the bed?

Hence I suspect there are small bubbles trapped under the filament that expand and cause it to lift.

|

Re: What can cause this? (I may have an answer) May 24, 2017 09:41AM |

Registered: 8 years ago Posts: 601 |

Quote

MCcarman

I have some suspicions that water absorption causes this. It is only a suspicion.

You are clearly extruding enough material for it to "squish" and its obviously hot enough to flow and to bond with its neighbour. So why does it not stick to the bed?

Hence I suspect there are small bubbles trapped under the filament that expand and cause it to lift.

If it is too squished, the new bead being laid down will push out and away from the other lines, causing it to 'bubble'. Since the error accumulates, the new bead can actually be forced over by more then the width of the nozzle meaning the tip can't 'iron' it down as well.

I have had problems with PLA and ABS with too much moisture, but the first layer still looks the same. Adhesion can be affected but not this obviously. Also, you would hear a lot of popping and cracking.

Edited 1 time(s). Last edit at 05/24/2017 09:41AM by Origamib.

|

Re: What can cause this? (I may have an answer) May 24, 2017 10:48AM |

Registered: 7 years ago Posts: 619 |

Quote

Origamib

Quote

MCcarman

I have some suspicions that water absorption causes this. It is only a suspicion.

You are clearly extruding enough material for it to "squish" and its obviously hot enough to flow and to bond with its neighbour. So why does it not stick to the bed?

Hence I suspect there are small bubbles trapped under the filament that expand and cause it to lift.

If it is too squished, the new bead being laid down will push out and away from the other lines, causing it to 'bubble'. Since the error accumulates, the new bead can actually be forced over by more then the width of the nozzle meaning the tip can't 'iron' it down as well.

I have had problems with PLA and ABS with too much moisture, but the first layer still looks the same. Adhesion can be affected but not this obviously. Also, you would hear a lot of popping and cracking.

Your "too squished" idea resonates, I will have to experiment with that.

This is very interesting. I DO hear "crackling" with this PLA, I have not been able to locate its origin. I have also seen voids, kind of like zits, but in reverse, in some layers. This filament has different characteristics than my other filaments and seems to like a higher temperature. It also tends to "curl" more than my others.

This one (Tianse yellow PLA) works best at .3mm heights for fast "crude" prints. I have used it as low as 0.15 successfully, but only after slowing everything WAY down. In short, sometimes I have to chisel this off my bed, at others, it just won't stick. Can a PLA filament be that variable across the spool?

I keep my PLA in their bags with their desiccant, but that stuff does not last forever. I am considering keeping them in a large plastic crate with a bucket of kitty litter (desiccant) to keep them dry - I live in Colorado, there is not much humidity here.

thanks,

DLC

|

Re: What can cause this? (I may have an answer) May 24, 2017 11:14AM |

Registered: 8 years ago Posts: 601 |

I highly doubt you have humidity issues in your spools in Colorado...

I keep my spools in large Tupperware boxes filled with orange/green desiccant. It changes colour when it has taken on too much water, and then I bake it in the oven to renew it. Silica gel can also be baked to renew it but you won't know when. its ready. The popping is the moisture in the filament boiling, expanding and finally released as steam out the nozzle. This can cause zits and over/under extrusion for a very small distance afterwards. For it to cause layer issues like this, your nozzle would probably sound like a kettle boiling!

Do you use a pcb heater? If so, these warp with every heating and cooling cycle and can put the bed off quite dramatically after only a few prints. 4 point levelling has a similar issue. Maybe invest in a better bed. I use 5mm tooling plate.

Edited 1 time(s). Last edit at 05/24/2017 11:14AM by Origamib.

I keep my spools in large Tupperware boxes filled with orange/green desiccant. It changes colour when it has taken on too much water, and then I bake it in the oven to renew it. Silica gel can also be baked to renew it but you won't know when. its ready. The popping is the moisture in the filament boiling, expanding and finally released as steam out the nozzle. This can cause zits and over/under extrusion for a very small distance afterwards. For it to cause layer issues like this, your nozzle would probably sound like a kettle boiling!

Do you use a pcb heater? If so, these warp with every heating and cooling cycle and can put the bed off quite dramatically after only a few prints. 4 point levelling has a similar issue. Maybe invest in a better bed. I use 5mm tooling plate.

Edited 1 time(s). Last edit at 05/24/2017 11:14AM by Origamib.

|

Re: What can cause this? (I may have an answer) May 24, 2017 02:08PM |

Registered: 7 years ago Posts: 619 |

Quote

Origamib

I highly doubt you have humidity issues in your spools in Colorado...

I keep my spools in large Tupperware boxes filled with orange/green desiccant. It changes colour when it has taken on too much water, and then I bake it in the oven to renew it. Silica gel can also be baked to renew it but you won't know when. its ready. The popping is the moisture in the filament boiling, expanding and finally released as steam out the nozzle. This can cause zits and over/under extrusion for a very small distance afterwards. For it to cause layer issues like this, your nozzle would probably sound like a kettle boiling!

Do you use a pcb heater? If so, these warp with every heating and cooling cycle and can put the bed off quite dramatically after only a few prints. 4 point levelling has a similar issue. Maybe invest in a better bed. I use 5mm tooling plate.

I do use an aluminum bed with an integrated heater. I print my PLA with the bed a 60 C. I am using the "auto leveling" (g-code 29) which hits 17 points. In the vast majority of cases this works fine - but it can be improved upon. I am considering adding a glass top to get rid of bed "hot spots" and be more reliably level.

After replacing the fans the really nasty "blistering" effect on the bed went away. I still have adhesion problems on some spots of the bed, but I am willing to bet that it has to do with bed leveling issues. I have a delta kossel printer, these have tendencies to go concave or convex, although I have mine pretty well dialed in. There is always room for improvement.

I have picked up a lot of ideas with this thread folks, I thank you for the attention and hope to give back to the group whenever I actually discover or do something worthy.

DLC

Sorry, only registered users may post in this forum.