Nichrome wire temperature sensing

Posted by LoboCNC

|

Nichrome wire temperature sensing May 28, 2017 02:48PM |

Registered: 10 years ago Posts: 564 |

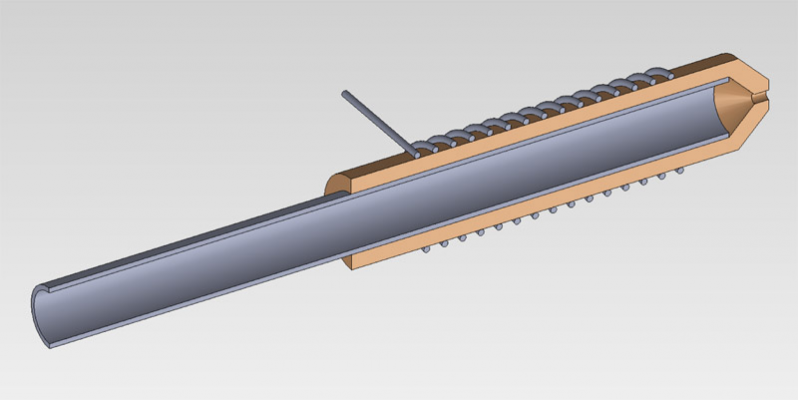

Has anyone tried using a single nichrome wire for both heating and temperature sensing of the hot-end? It seems that many types of resistance wires have a relatively high resistance change with temperature (although not as dramatic as thermistor) that could be used to sense the temperature during the off-cycle when the wire is not actively driven. This would eliminate the need mount a thermistor or thermocouple at the business end of the heater block.

What I am envisioning is an ultra-low thermal mass hot-end (just nichrome wire wrapped around a small diameter tube) similar to the on-going induction heater discussion:

Edited 1 time(s). Last edit at 05/28/2017 02:52PM by LoboCNC.

What I am envisioning is an ultra-low thermal mass hot-end (just nichrome wire wrapped around a small diameter tube) similar to the on-going induction heater discussion:

Edited 1 time(s). Last edit at 05/28/2017 02:52PM by LoboCNC.

|

Re: Nichrome wire temperature sensing May 28, 2017 04:55PM |

Registered: 7 years ago Posts: 11 |

I think the issue here would be that the nichrome wire will be significantly warmer, than the rest of the construction.

As you want things to heat up quickly, and heat transfers faster, the greater the temperature difference.

So reading off the temperature of the nichrome wire would not give any useful information.

As you want things to heat up quickly, and heat transfers faster, the greater the temperature difference.

So reading off the temperature of the nichrome wire would not give any useful information.

|

Re: Nichrome wire temperature sensing May 28, 2017 05:36PM |

Registered: 10 years ago Posts: 564 |

Quote

Skrogh

I think the issue here would be that the nichrome wire will be significantly warmer, than the rest of the construction.

As you want things to heat up quickly, and heat transfers faster, the greater the temperature difference.

So reading off the temperature of the nichrome wire would not give any useful information.

If the nichrome wire is wrapped directly onto the thermally conductive cylinder (maybe anodized aluminum?), it will never get that much hotter than the cylinder surface. Also, the thermal time constant of the wire would probably well less than a second, so you should be able to get a pretty good temperature reading after only a very short off time.

|

Re: Nichrome wire temperature sensing May 28, 2017 06:57PM |

Registered: 12 years ago Posts: 1,450 |

The idea has possibilities but I think that nichrome is not a good candidate. Nichrome has a very high resistivity, about 120 x 10-8 Ωm this means that you don't need a lot of material to give your required resistance. Little material = little surface area = not much area to conduct the heat from the wire - the point that Skrogh made. The second point is that nichrome has quite a low temperature coefficient of resistance, 4 x 10-4/°C which means that better electronics are needed. Nickel is the best common material that I know of with a resistivity of 6.8 x 10-8 Ωm and a tempco of 6.4 x 10-3/°C.

Anodised aluminium may work as an insulator but would be likely to be too thin and some insulation would be needed between the turns of wire. A possible answer would be to use a glass frit to enamel the outside of the heated part and a second layer to insulate between the turns of wire.

Mike

Anodised aluminium may work as an insulator but would be likely to be too thin and some insulation would be needed between the turns of wire. A possible answer would be to use a glass frit to enamel the outside of the heated part and a second layer to insulate between the turns of wire.

Mike

|

Re: Nichrome wire temperature sensing May 28, 2017 07:20PM |

Registered: 10 years ago Posts: 564 |

Quote

leadinglights

The idea has possibilities but I think that nichrome is not a good candidate. Nichrome has a very high resistivity, about 120 x 10-8 Ωm this means that you don't need a lot of material to give your required resistance. Little material = little surface area = not much area to conduct the heat from the wire - the point that Skrogh made. The second point is that nichrome has quite a low temperature coefficient of resistance, 4 x 10-4/°C which means that better electronics are needed. Nickel is the best common material that I know of with a resistivity of 6.8 x 10-8 Ωm and a tempco of 6.4 x 10-3/°C.

Anodised aluminium may work as an insulator but would be likely to be too thin and some insulation would be needed between the turns of wire. A possible answer would be to use a glass frit to enamel the outside of the heated part and a second layer to insulate between the turns of wire.

Mike

Nickel wire does sound like a much better choice - thanks. As for anodizing, you can get a thicker hard-anodizing, so I think by itself could be made to work reliably. It is also extremely hard and unlikely to punch through with the wire. And as a bonus, it would make for a very long-lasting nozzle.

|

Re: Nichrome wire temperature sensing May 28, 2017 07:45PM |

Registered: 7 years ago Posts: 270 |

|

Re: Nichrome wire temperature sensing May 29, 2017 01:37AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Nichrome wire temperature sensing May 29, 2017 07:37AM |

Registered: 8 years ago Posts: 3,525 |

I don't know if it helps but there are thermostatic controlled e-cigarettes which must use something similar. They don't have any type of thermocouple in the heater cartridges they only have two contacts.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Nichrome wire temperature sensing May 29, 2017 08:14AM |

Registered: 9 years ago Posts: 487 |

You might be able to monitor the resistance of the coil while it's on by monitoring the current, the trick would be eliminating fluctuations due to supply voltage variation.

I believe that some heaters use a positive temperature coefficient to maintain a designed temperature. With PTC element as the temperature increases the resistance increases and the current drops reaching a equilibrium at a temperature that can be set when the heater is designed. If something starts to cool the heater then the resistance drops, current increases and resists the disturbance from the set point. Very simple but only usable at one temp (for a given voltage)

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

I believe that some heaters use a positive temperature coefficient to maintain a designed temperature. With PTC element as the temperature increases the resistance increases and the current drops reaching a equilibrium at a temperature that can be set when the heater is designed. If something starts to cool the heater then the resistance drops, current increases and resists the disturbance from the set point. Very simple but only usable at one temp (for a given voltage)

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Nichrome wire temperature sensing May 29, 2017 09:19AM |

Registered: 11 years ago Posts: 5,780 |

The OP's drawing looks a lot like the hot-ends in my CubeX Duo printer. They are not very good. I don't know if the volume for molten filament is too large or the heat zone is too long, but they drool continuously. The wire has some sort of glass fiber insulation wrapped around it, and the coils are covered with some sort of cement like substance. They commonly fail shorted to the aluminum tube. I've taken a couple of dead ones apart and it looks like they develop hot spots that burn through the glass fiber insulation and let the bare wire contact the aluminum. If they do that in a couple spots, it's all over. The thermistor leads are insulated with teflon sleeves and set in a groove in the tube, and the nichrome wire is wrapped right over them. Crazy!

In order to insulate the nichrome wire from itself and the tube, you need some sort of electrical insulator that can withstand high temperatures. But that means it's going to be a thermal insulator too. That means the wire is going to operate at a much higher temperature than the aluminum tube and plastic you're melting. The wire gets longer when it heats up (18 um/m C or so). If you wrapped it tightly around the tube when it was cold, when it heats up the coils are going to loosen, reducing the heat transfer to the tube. That is how hot spots develop. Using a short piece of heavy gauge wire would minimize that problem, but a short piece of heavy gauge wire has low resistance so you'll need to operate it at a low voltage or very high intermittent current to keep the average power at a reasonable number.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In order to insulate the nichrome wire from itself and the tube, you need some sort of electrical insulator that can withstand high temperatures. But that means it's going to be a thermal insulator too. That means the wire is going to operate at a much higher temperature than the aluminum tube and plastic you're melting. The wire gets longer when it heats up (18 um/m C or so). If you wrapped it tightly around the tube when it was cold, when it heats up the coils are going to loosen, reducing the heat transfer to the tube. That is how hot spots develop. Using a short piece of heavy gauge wire would minimize that problem, but a short piece of heavy gauge wire has low resistance so you'll need to operate it at a low voltage or very high intermittent current to keep the average power at a reasonable number.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Nichrome wire temperature sensing May 29, 2017 12:42PM |

Registered: 10 years ago Posts: 564 |

Quote

the_digital_dentist

The OP's drawing looks a lot like the hot-ends in my CubeX Duo printer. They are not very good. I don't know if the volume for molten filament is too large or the heat zone is too long, but they drool continuously. The wire has some sort of glass fiber insulation wrapped around it, and the coils are covered with some sort of cement like substance. They commonly fail shorted to the aluminum tube. I've taken a couple of dead ones apart and it looks like they develop hot spots that burn through the glass fiber insulation and let the bare wire contact the aluminum. If they do that in a couple spots, it's all over. The thermistor leads are insulated with teflon sleeves and set in a groove in the tube, and the nichrome wire is wrapped right over them. Crazy!

In order to insulate the nichrome wire from itself and the tube, you need some sort of electrical insulator that can withstand high temperatures. But that means it's going to be a thermal insulator too. That means the wire is going to operate at a much higher temperature than the aluminum tube and plastic you're melting. The wire gets longer when it heats up (18 um/m C or so). If you wrapped it tightly around the tube when it was cold, when it heats up the coils are going to loosen, reducing the heat transfer to the tube. That is how hot spots develop. Using a short piece of heavy gauge wire would minimize that problem, but a short piece of heavy gauge wire has low resistance so you'll need to operate it at a low voltage or very high intermittent current to keep the average power at a reasonable number.

The CubeX hot-end does sound a little sketchy. I wouldn't want to rely on separate insulation; I would wrap bare wire right onto the hard-anodized cylinder. At about 0.05mm thick, the anodized layer shouldn't offer a lot of thermal resistance. The wire would need to be wrapped in a single layer with some separation between wraps - maybe in a very shallow thread cut into the cylinder OD. Then it would need to be encapsulated in something like high-temp gasket compound. Good point about the thermal expansion. Over a nominal 200c temperature change, it will expand by about 0.3%, so it would need to be stretched by at least 0.3% during wrapping to maintain contact at elevated temps.

|

Re: Nichrome wire temperature sensing May 29, 2017 01:17PM |

Registered: 11 years ago Posts: 5,780 |

Oh yeah, one other failure mode was the heater wire burning through the teflon insulation on the thermistor leads, shorting the heater power to the thermistor. That causes all sorts of weird behavior and can destroy the thermistor input on the controller board if you're aren't lucky.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Nichrome wire temperature sensing May 29, 2017 04:25PM |

Registered: 7 years ago Posts: 11 |

If you really do want to try this approach out, why not get a commercial tubular ceramic heater?

The [deltaprintr.com] has one, but I've seen the heater type on both Aliexpress and Alibaba.

You will still face the issue of the coil being significantly warmer, than what you are trying to control the temperature of - namely the plastic in the extruder.

The [deltaprintr.com] has one, but I've seen the heater type on both Aliexpress and Alibaba.

You will still face the issue of the coil being significantly warmer, than what you are trying to control the temperature of - namely the plastic in the extruder.

|

Re: Nichrome wire temperature sensing May 29, 2017 05:33PM |

Registered: 10 years ago Posts: 564 |

Quote

Skrogh

If you really do want to try this approach out, why not get a commercial tubular ceramic heater?

The [deltaprintr.com] has one, but I've seen the heater type on both Aliexpress and Alibaba.

You will still face the issue of the coil being significantly warmer, than what you are trying to control the temperature of - namely the plastic in the extruder.

I'd be tempted to try a ceramic heater, but crucial to the sensing is having the heater wire in intimate contact with the heater block. Ceramic heaters have the wire embedded in a block of ceramic, which as you point out, won't be particularly accurate for sensing. I'd also like to keep the overall thermal mass to a minimum, which would require integrating the nozzle with the heater cylinder as show in my original post. I like DjDemonD's idea of looking at how e-cigarettes are constructed and controlled.

If I can find a place that'll do a tiny anodizing job for a reasonable price, I might go ahead and give this a shot.

Edited 1 time(s). Last edit at 05/29/2017 05:35PM by LoboCNC.

|

Re: Nichrome wire temperature sensing May 30, 2017 08:42AM |

Registered: 7 years ago Posts: 11 |

Without knowing too much about E-cigs, I would assume that the goal of temperature control in them is to be able to dump as much energy into the atomizer, without melting the filament (heater), as possible. So then the temperature of the filament is the control state of interest.

In the hotend it is not the temperature of the heater that is of interest ('long as it doesn't melt or burn), but the plastic.

Never the less, I'm keen on seeing your results. It might be possible to include some sort of feed forward, to correctly estimate the plastic temperature.

In the hotend it is not the temperature of the heater that is of interest ('long as it doesn't melt or burn), but the plastic.

Never the less, I'm keen on seeing your results. It might be possible to include some sort of feed forward, to correctly estimate the plastic temperature.

|

Re: Nichrome wire temperature sensing May 30, 2017 09:58AM |

Registered: 12 years ago Posts: 1,450 |

I don't see any great theoretical problem. If you think of the heater as a combination of a heat source, a joining compound and a heat sink (the hotend tube) then the power being delivered to the heater is known by the voltage times the current; the temperature drop from the heater element through the joining compound to the hotend tube should be fairly proportional to the power in much the same way as the drop from a power transistor to a heatsink is rated, in °C per Watt. Since the temperature of the heater element can be calculated from the element resistance then the hotend tube temperature has the same relationship to the plastic temperature as in a normal hotend.

I think that practical realization should follow this fairly well as long as the maximum power when the heater is on is not excessive and the thermal conductivity between the element and the metal body of the heatsink is good. If this were not the case then other effects such as heat being radiated away rather than going through the thermal joining part and possibly non-linear electrical resistance may be a big problem.

As with many things, it may be possible to work it out accurately enough to know if it will or won't work, but the working out is often harder and more error prone than simply trying it.

Mike

I think that practical realization should follow this fairly well as long as the maximum power when the heater is on is not excessive and the thermal conductivity between the element and the metal body of the heatsink is good. If this were not the case then other effects such as heat being radiated away rather than going through the thermal joining part and possibly non-linear electrical resistance may be a big problem.

As with many things, it may be possible to work it out accurately enough to know if it will or won't work, but the working out is often harder and more error prone than simply trying it.

Mike

|

Re: Nichrome wire temperature sensing May 30, 2017 10:33AM |

Registered: 7 years ago Posts: 270 |

'heater wire' hot end is on my try-it list. I consider resistance temperature sensing a non issue - if it does not work - I'll be fine with a thermistor. Big hurtles are mechanical fixing of the heating wire to the nozzle and thermal conductivity and capacity of it. I plan on using 32 or 36Ga Kanthal (temco ire in UK?) wire attached longitudinally (S pattern) while using a combination of high temperature paint/fiberglass paper and self fusing silicone tape for keeping it firmly attached to the nozzle.

EDIT:

photos from [builders.reprap.org] (not mine of course)

Edited 1 time(s). Last edit at 05/30/2017 04:24PM by newbob.

EDIT:

photos from [builders.reprap.org] (not mine of course)

Edited 1 time(s). Last edit at 05/30/2017 04:24PM by newbob.

|

Re: Nichrome wire temperature sensing May 31, 2017 04:16AM |

Registered: 8 years ago Posts: 3,525 |

Quote

Skrogh

If you really do want to try this approach out, why not get a commercial tubular ceramic heater?

The [deltaprintr.com] has one, but I've seen the heater type on both Aliexpress and Alibaba.

You will still face the issue of the coil being significantly warmer, than what you are trying to control the temperature of - namely the plastic in the extruder.

The heater on a deltaprintr mini hotend works very well, but they do have to place their thermistor in a hole in the side of the nozzle in order to actually measure nozzle temperature. Its quite a nice idea really as this is a much better approximation of the filament temperature, even if it is less secure than e3d's approach to thermistors.

Edited 1 time(s). Last edit at 05/31/2017 04:16AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Nichrome wire temperature sensing May 31, 2017 09:54PM |

Registered: 10 years ago Posts: 39 |

I'd love to see a simple lightweight hot end too. I want say some reprapper was looking into sensing the heating element a few years ago. (In fact, this whole thread feels 5-10 years old.)

If weight is the primary concern, PT100 sensors can be quite small, light and have a small time constant. Just to pick a random part, the Heraeus M222 Pt 100 is < 4 mm^3 and good to 500C. (part 32208548) The wires will weigh more than the sensor!

My own plan for a lightweight hot end would be a Luer lock glue dispensing tip, with copper heat sink fins brazed on (braze the nozzle and Luer lock on too). Then insulate (sodium silicate dip?), spiral wrap with a nichrome wire next to a glass fiber, and dip again and coat with thermal insulation. Haven't figured the ideal spot for the sensor.

Too far down my build list, I'm afraid.

Plus side is it gives you a highly polished stainless steel barrel and a fly weight form factor. Downside is it probably crumples on the first curled print it meets, and has a non interchangeable nozzle. (Although I suppose you could braze on some threads near the tip for a more standard nozzle.)

Or, if you went with a longer tube, you could have two heating zones, with the part above the heat sink held just below Tg. This minimizes the amount of heat the filament needs to absorb in the hot end, boosting maximum flow rate.

If weight is the primary concern, PT100 sensors can be quite small, light and have a small time constant. Just to pick a random part, the Heraeus M222 Pt 100 is < 4 mm^3 and good to 500C. (part 32208548) The wires will weigh more than the sensor!

My own plan for a lightweight hot end would be a Luer lock glue dispensing tip, with copper heat sink fins brazed on (braze the nozzle and Luer lock on too). Then insulate (sodium silicate dip?), spiral wrap with a nichrome wire next to a glass fiber, and dip again and coat with thermal insulation. Haven't figured the ideal spot for the sensor.

Too far down my build list, I'm afraid.

Plus side is it gives you a highly polished stainless steel barrel and a fly weight form factor. Downside is it probably crumples on the first curled print it meets, and has a non interchangeable nozzle. (Although I suppose you could braze on some threads near the tip for a more standard nozzle.)

Or, if you went with a longer tube, you could have two heating zones, with the part above the heat sink held just below Tg. This minimizes the amount of heat the filament needs to absorb in the hot end, boosting maximum flow rate.

|

Re: Nichrome wire temperature sensing June 01, 2017 05:17AM |

Registered: 12 years ago Posts: 1,450 |

Quote

newbob

'heater wire' hot end is on my try-it list. I consider resistance temperature sensing a non issue - if it does not work - I'll be fine with a thermistor. Big hurtles are mechanical fixing of the heating wire to the nozzle and thermal conductivity and capacity of it. I plan on using 32 or 36Ga Kanthal (temco ire in UK?) wire attached longitudinally (S pattern) while using a combination of high temperature paint/fiberglass paper and self fusing silicone tape for keeping it firmly attached to the nozzle.

............

Hi newbob,

Please don't abandon resistance temperature sensing too early. With care the junction between the wire of the heater and the metal of the hotend tube can be as low as 1.8°C per Watt and this can be mathematically quite predictable, certainly waaay simpler than the geometry of a Delta printer. If you had thought of trying resistance sensing then Kanthal is a poor choice as it has a low temperature coefficient of resistance. Many "vaping" wires are available for e.g. from "The Crazy Wire Company" in the U.K., typical of these are Nickel Iron Wire with a fairly high resistiveity and high TCo as [www.wireandstuff.co.uk] and also Nickel with a low resistiveity and high TC as [www.wireandstuff.co.uk]

Mike

|

Re: Nichrome wire temperature sensing June 01, 2017 12:53PM |

Registered: 7 years ago Posts: 270 |

Quote

leadinglights

Quote

newbob

'heater wire' hot end is on my try-it list. I consider resistance temperature sensing a non issue - if it does not work - I'll be fine with a thermistor. Big hurtles are mechanical fixing of the heating wire to the nozzle and thermal conductivity and capacity of it. I plan on using 32 or 36Ga Kanthal (temco ire in UK?) wire attached longitudinally (S pattern) while using a combination of high temperature paint/fiberglass paper and self fusing silicone tape for keeping it firmly attached to the nozzle.

............

Hi newbob,

Please don't abandon resistance temperature sensing too early. With care the junction between the wire of the heater and the metal of the hotend tube can be as low as 1.8°C per Watt and this can be mathematically quite predictable, certainly waaay simpler than the geometry of a Delta printer. If you had thought of trying resistance sensing then Kanthal is a poor choice as it has a low temperature coefficient of resistance. Many "vaping" wires are available for e.g. from "The Crazy Wire Company" in the U.K., typical of these are Nickel Iron Wire with a fairly high resistiveity and high TCo as [www.wireandstuff.co.uk] and also Nickel with a low resistiveity and high TC as [www.wireandstuff.co.uk]

Mike

Hi. I think effective thermal interface between heater wire and the nozzle is a much bigger challenge and without it resistance temperature sensing would be pointless - so I'm trying to figure it out first. Of course, it does not mean that both challenges cannot be worked on in parallel...

I already have 36AWG Kanthal wire and I like that it's pliable, stays in place and I only need few inches (about 15 Ohms) of it so it's easier to manage. With that said I think 32AWG Kanthal would have been more suitable as it would allow for twice of the surface contact while still maintaining narrow heated area.

Edited 1 time(s). Last edit at 06/01/2017 12:56PM by newbob.

Sorry, only registered users may post in this forum.