Launching a new build plate

Posted by andornot

|

Re: Launching a new build plate July 14, 2017 03:17PM |

Registered: 8 years ago Posts: 193 |

Quote

andornot

Having problems with my website so i am unable to upload pictures to the beds, 8 inch £7.50 + vat and 12" £14.50 + vat and delivery. PM me if you want to order them and i will sort it out.

OK thanks. Will be a couple if weeks before I'm ready. Will let you know when I'm ready

|

Re: Launching a new build plate July 16, 2017 03:42PM |

Registered: 10 years ago Posts: 97 |

The link to my beds is:

[www.andornot.co.uk] 12" square AndOrNot build plate

[www.andornot.co.uk] 8" square AndOrNot build plate

Regards

Andrew

[www.andornot.co.uk] 12" square AndOrNot build plate

[www.andornot.co.uk] 8" square AndOrNot build plate

Regards

Andrew

|

Re: Launching a new build plate July 16, 2017 04:16PM |

Registered: 11 years ago Posts: 528 |

|

Re: Launching a new build plate July 16, 2017 05:03PM |

Registered: 8 years ago Posts: 141 |

|

Re: Launching a new build plate July 17, 2017 01:47PM |

Registered: 8 years ago Posts: 117 |

|

Re: Launching a new build plate July 17, 2017 02:01PM |

Registered: 8 years ago Posts: 3,525 |

Not tried it for sure, but put a black substrate under it, and I can see no reason why not, its fairly transparent and no graphics to affect the consistency of readings across the surface.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 17, 2017 04:38PM |

Registered: 10 years ago Posts: 97 |

I have send a sample David to try with his IR sensor, hopefully soon he will give you all feedback.

@rgn01 it does include an adhesive like Lokbuild and Printbite.

Edited 1 time(s). Last edit at 07/17/2017 04:38PM by andornot.

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

@rgn01 it does include an adhesive like Lokbuild and Printbite.

Edited 1 time(s). Last edit at 07/17/2017 04:38PM by andornot.

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

|

Re: Launching a new build plate July 18, 2017 03:48PM |

Registered: 11 years ago Posts: 528 |

@ Andornot

wondering about this " if you require custom graphics " could be fun personalising the surface but how much for example would this add to the cost of a 8" plate

Edited 1 time(s). Last edit at 07/18/2017 03:57PM by jinx.

wondering about this " if you require custom graphics " could be fun personalising the surface but how much for example would this add to the cost of a 8" plate

Edited 1 time(s). Last edit at 07/18/2017 03:57PM by jinx.

|

Re: Launching a new build plate July 18, 2017 05:08PM |

Registered: 10 years ago Posts: 97 |

@ jinx, maybe you could print your own personalised surface with paper or another material and stick it to the back of my print bed material and then stick a 3m double sided adhesive to this, also available from my website in 8 inch and 12 inch.

Just an idea, i will give a try and post the outcome.

Andrew

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

Just an idea, i will give a try and post the outcome.

Andrew

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

|

Re: Launching a new build plate July 20, 2017 04:58AM |

Registered: 11 years ago Posts: 528 |

Well I just about completed my review with PLA rebel review I've not had a PLA print fail once out the 10 or so prints if you looking for at remote printing and need a reliable surface this is it, if your print fail it want be because adhesion to the bed. and thanks to Andrew and the team for the opportunity to review this build plate

|

Re: Launching a new build plate July 20, 2017 06:03AM |

Registered: 8 years ago Posts: 3,525 |

Great review Jinx.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 20, 2017 08:18AM |

Registered: 11 years ago Posts: 528 |

that aint how I imagined it work a paper print attached to glue side would/possible look crap and distorted and loose the transparency as a whole, am googling how T shirt graphics applied ! my thinking is/was that you take the blank surface then apply the graphics then the glue backing that leave clean sharpish image,, the killer downside to it is if the ink cook and bubble creating an uneven surface.Quote

AndorNot

@ jinx, maybe you could print your own personalised surface with paper or another material and stick it to the back of my print bed material and then stick a 3m double sided adhesive to this, also available from my website in 8 inch and 12 inch.

IS THERE ANY T-shirt makers in the house!

this vinyl looks interesting but damn intensive on details.

Edited 1 time(s). Last edit at 07/20/2017 08:56AM by jinx.

|

Re: Launching a new build plate July 20, 2017 12:52PM |

Registered: 8 years ago Posts: 193 |

|

Re: Launching a new build plate July 23, 2017 01:40PM |

Registered: 10 years ago Posts: 97 |

|

Re: Launching a new build plate July 26, 2017 02:26PM |

Registered: 10 years ago Posts: 97 |

I am offering an Introductory offer on my bed material for the Reprap community of 20% off, discount code: "20reprap"

Links below to the bed plates

12" AndOrNot Build Plate

8" AndOrNot Build Plate

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

Links below to the bed plates

12" AndOrNot Build Plate

8" AndOrNot Build Plate

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

|

Re: Launching a new build plate July 26, 2017 05:58PM |

Registered: 8 years ago Posts: 601 |

Looks great! Any chance on an instructable on how to cut it? Is it similar to acrylic or glass where you score and snap?

Also, have you found any materials that won't print on this? The list of materials sounds extensive enough for day to day printing anyway so will be buying this regardless

How do you clean this surface? Can you use acetone?

Edited 1 time(s). Last edit at 07/26/2017 08:15PM by Origamib.

Also, have you found any materials that won't print on this? The list of materials sounds extensive enough for day to day printing anyway so will be buying this regardless

How do you clean this surface? Can you use acetone?

Edited 1 time(s). Last edit at 07/26/2017 08:15PM by Origamib.

|

Re: Launching a new build plate July 26, 2017 06:01PM |

Registered: 8 years ago Posts: 601 |

Quote

jinx

that aint how I imagined it work a paper print attached to glue side would/possible look crap and distorted and loose the transparency as a whole, am googling how T shirt graphics applied ! my thinking is/was that you take the blank surface then apply the graphics then the glue backing that leave clean sharpish image,, the killer downside to it is if the ink cook and bubble creating an uneven surface.Quote

AndorNot

@ jinx, maybe you could print your own personalised surface with paper or another material and stick it to the back of my print bed material and then stick a 3m double sided adhesive to this, also available from my website in 8 inch and 12 inch.

IS THERE ANY T-shirt makers in the house!

this vinyl looks interesting but damn intensive on details.

Preferably you would want to put it directly to the plastic and then apply adhesive. Have you considered water transfers? I use them for printed stuff all the time.

|

Re: Launching a new build plate July 27, 2017 04:15AM |

Registered: 11 years ago Posts: 528 |

thats sounds like a belting plan " like the old airfix graphs or those temporary tats." googling right now thou am faced with a wall of hydro dipping at the mo. If you got a link too an how to make custom graphics I really appreciate it thanks.Quote

Origamib

Preferably you would want to put it directly to the plastic and then apply adhesive. Have you considered water transfers? I use them for printed stuff all the time.

No fan of hydro dipping its an ecological disaster in the waiting if it ever takes off "we be drinking petroleum as clowns throw the waste in the sinks... needs more cofffeee

"How do you clean this surface? Can you use acetone?"

unless Andrew say differently , using ABS be handy to have some form of acetone or the likes around with a flat palette knife... PLA fine come away clean thou cheap heavy filled pigment filament can leave stain.

|

Re: Launching a new build plate July 27, 2017 04:34AM |

Registered: 10 years ago Posts: 97 |

To clean the bed do not use acetone, alcohol based fluid are ok to use. I need to write a blog on website on its use, if you have any questions just ask.

Andrew

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

Andrew

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

|

Re: Launching a new build plate July 27, 2017 05:10AM |

Registered: 11 years ago Posts: 528 |

its been/ongoing pleasure, been a real eye opener, "I thought these print surfaces was just a rich man gimmick!"Quote

AndorNot

Jinx thanks for the review of the printer build plate.

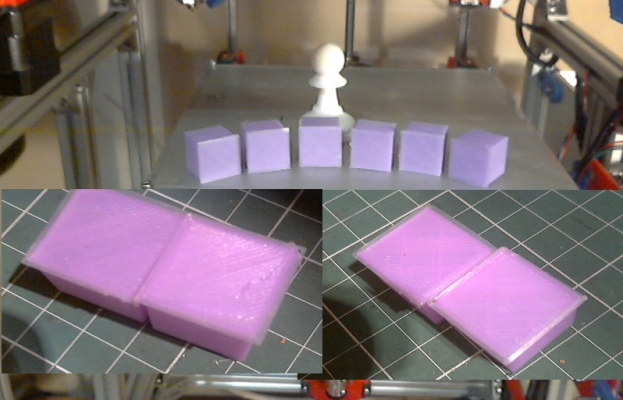

random cubes over the week belting first surface "well look closer at the left pic, but that was my failure rather than the surface" I just wouldn't get that repeatability with gluestick or Ktype first time everytime.

just waiting on on fila sample to test others.

Edited 1 time(s). Last edit at 07/27/2017 05:12AM by jinx.

|

Re: Launching a new build plate July 28, 2017 04:48AM |

Registered: 8 years ago Posts: 601 |

Quote

jinx

thats sounds like a belting plan " like the old airfix graphs or those temporary tats." googling right now thou am faced with a wall of hydro dipping at the mo. If you got a link too an how to make custom graphics I really appreciate it thanks.Quote

Origamib

Preferably you would want to put it directly to the plastic and then apply adhesive. Have you considered water transfers? I use them for printed stuff all the time.

No fan of hydro dipping its an ecological disaster in the waiting if it ever takes off "we be drinking petroleum as clowns throw the waste in the sinks... needs more cofffeee

"How do you clean this surface? Can you use acetone?"

unless Andrew say differently , using ABS be handy to have some form of acetone or the likes around with a flat palette knife... PLA fine come away clean thou cheap heavy filled pigment filament can leave stain.

I use water transfer sheets from Amazon. You just print on them from your normal inkjet printer and then spray them with clear lacquer to stop the ink running. Cut it out, pop it in water and then slip away from the backing on to your desired surface. seal again with lacquer to keep it in place. 3-5 coats of lacquer makes a really strong surface. If this was your print surface I would try to do this to the back of the print surface and then apply the adhesive instead of the final coats of lacquer. Then stick it to desired print bed material (aluminium, glass etc).

|

Re: Launching a new build plate July 28, 2017 08:32AM |

Registered: 6 years ago Posts: 1,863 |

All build plates surfaces are much too expensive, and over glamorized. I purchased a similar surface for my 3D Printers and it is difficult to get anything to stick to it.

I cover my expensive build surface with Vinyl Transfer Paper Tape, similar to blue painters tape comes in 300yard rolls. With widths that will cover any build plate in one pass.

And it comes with different adhesion low, medium and high tack, have a Vinyl Transfer Tape with a plastic covering of different styles and lengths.

The Sample tape set come with a mere 10 yards of tape for your testing without having 300 yards of tape you may not use.

videos showing how easy it is to use

At a cost of .10cents per covering, which last for dozens of prints.

Installing Vinyl Transfer Paper (video shows old aluminum build plate)

[youtu.be]

Will Vinyl transfer paper Hold my Part

[youtu.be]

Edited 3 time(s). Last edit at 07/28/2017 08:54AM by Roberts_Clif.

I cover my expensive build surface with Vinyl Transfer Paper Tape, similar to blue painters tape comes in 300yard rolls. With widths that will cover any build plate in one pass.

And it comes with different adhesion low, medium and high tack, have a Vinyl Transfer Tape with a plastic covering of different styles and lengths.

The Sample tape set come with a mere 10 yards of tape for your testing without having 300 yards of tape you may not use.

videos showing how easy it is to use

At a cost of .10cents per covering, which last for dozens of prints.

Installing Vinyl Transfer Paper (video shows old aluminum build plate)

[youtu.be]

Will Vinyl transfer paper Hold my Part

[youtu.be]

Edited 3 time(s). Last edit at 07/28/2017 08:54AM by Roberts_Clif.

|

Re: Launching a new build plate July 28, 2017 10:34AM |

Registered: 8 years ago Posts: 3,525 |

Hi Roberts_clif,

This sounds interesting what can you print on it and what temperatures do you use?

If a print surface is easy to use, lasts a long time and is cheap enough like AndOrNot surface promises to be then it's worth it.

I use printbite currently and it's not a case of replacing it every few dozen prints I've had a piece going for 2 years. So at £20-£30 its not bad value for zero hassle for years.

But I'm keen to see what the alternatives are.

Edited 1 time(s). Last edit at 07/28/2017 10:44AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

This sounds interesting what can you print on it and what temperatures do you use?

If a print surface is easy to use, lasts a long time and is cheap enough like AndOrNot surface promises to be then it's worth it.

I use printbite currently and it's not a case of replacing it every few dozen prints I've had a piece going for 2 years. So at £20-£30 its not bad value for zero hassle for years.

But I'm keen to see what the alternatives are.

Edited 1 time(s). Last edit at 07/28/2017 10:44AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Launching a new build plate July 28, 2017 12:49PM |

Registered: 10 years ago Posts: 97 |

Nice idea, but is the maximum temperature the tape can handle?

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

Quote

Roberts_Clif

All build plates surfaces are much too expensive, and over glamorized. I purchased a similar surface for my 3D Printers and it is difficult to get anything to stick to it.

I cover my expensive build surface with Vinyl Transfer Paper Tape, similar to blue painters tape comes in 300yard rolls. With widths that will cover any build plate in one pass.

And it comes with different adhesion low, medium and high tack, have a Vinyl Transfer Tape with a plastic covering of different styles and lengths.

The Sample tape set come with a mere 10 yards of tape for your testing without having 300 yards of tape you may not use.

videos showing how easy it is to use

At a cost of .10cents per covering, which last for dozens of prints.

Installing Vinyl Transfer Paper (video shows old aluminum build plate)

[youtu.be]

Will Vinyl transfer paper Hold my Part

[youtu.be]

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

|

Re: Launching a new build plate July 28, 2017 01:43PM |

Registered: 6 years ago Posts: 1,863 |

Quote

andornot

Nice idea, but is the maximum temperature the tape can handle?

Have had more failed prints in one day, with a build plates surface than I have ever had on the paper surface currently using.

Will use what works. And As you can see in my video vinyl transfer paper works well is inexpensive, and you can see it holds very well.

What is the max temperature for Painters Tape. Have never seen it on any spec sheet an this material is used daily.

Edited 1 time(s). Last edit at 07/28/2017 01:47PM by Roberts_Clif.

|

Re: Launching a new build plate July 28, 2017 02:27PM |

Registered: 10 years ago Posts: 97 |

I am interested in this material as i have a range of bed materials i sell through my website, where would i purchase it from to give it a go.

I am currently testing other materials, my aim is to drive down the prices of add-ons and consumables and make it more affordable for everybody.

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

I am currently testing other materials, my aim is to drive down the prices of add-ons and consumables and make it more affordable for everybody.

www.andornot.co.uk, selling new products, including smoothie boards and other useful parts for 3D Printers:

AndOrNot buildplate launched, available in 6 inch, 8 inch, 12 inch and 17 inch square introductory discount code "20reprap"

And Or Not Build Plates

|

Re: Launching a new build plate July 28, 2017 02:45PM |

Registered: 8 years ago Posts: 117 |

|

Re: Launching a new build plate July 28, 2017 03:13PM |

Registered: 6 years ago Posts: 1,863 |

Have not tried all can't say, I do know that all Blue Painters Tape is not the same. Bought some painters tape once, it fell off the walls before I could paint.

However most Vinyl Sign retailers sell a sampler set of their material at a fraction of the cost. This includes the Transfer Tapes.

They sell 10 yard sample rolls.

RTape

Edited 4 time(s). Last edit at 07/28/2017 09:04PM by Roberts_Clif.

However most Vinyl Sign retailers sell a sampler set of their material at a fraction of the cost. This includes the Transfer Tapes.

They sell 10 yard sample rolls.

RTape

Edited 4 time(s). Last edit at 07/28/2017 09:04PM by Roberts_Clif.

|

Re: Launching a new build plate July 29, 2017 04:40AM |

Registered: 11 years ago Posts: 528 |

Quote

origamib

I use water transfer sheets from Amazon. You just print on them from your normal inkjet printer and then spray them with clear lacquer to stop the ink running. Cut it out, pop it in water and then slip away from the backing on to your desired surface. seal again with lacquer to keep it in place. 3-5 coats of lacquer makes a really strong surface. If this was your print surface I would try to do this to the back of the print surface and then apply the adhesive instead of the final coats of lacquer. Then stick it to desired print bed material (aluminium, glass etc).

Thanks for that, hope to give that a go soon

|

Re: Launching a new build plate July 30, 2017 01:52AM |

Registered: 8 years ago Posts: 888 |

Quote

jinx

that aint how I imagined it work a paper print attached to glue side would/possible look crap and distorted and loose the transparency as a whole, am googling how T shirt graphics applied ! my thinking is/was that you take the blank surface then apply the graphics then the glue backing that leave clean sharpish image,, the killer downside to it is if the ink cook and bubble creating an uneven surface.Quote

AndorNot

@ jinx, maybe you could print your own personalised surface with paper or another material and stick it to the back of my print bed material and then stick a 3m double sided adhesive to this, also available from my website in 8 inch and 12 inch.

IS THERE ANY T-shirt makers in the house!

this vinyl looks interesting but damn intensive on details.

Maybe something like THIS works for you? Just an example for inspiration

Gruß

Siggi

Geeetech I3 Pro B 8mm Acryl - Mega 2560 - Ramps 1.4 - TMC2100 - MK42 - E3DV6-Clone 0,4 - SSR 522-1dd60-40 (A-Senco) - Marlin RC8Bugfix 26.12.2016 - Repetier Host - Windows 7 64 Bit

Vulcanus mit Linearschienen

Anycubic i3 Mega

Sorry, only registered users may post in this forum.