Infills with a bigger second nozzle, how?

Posted by swatti

|

Infills with a bigger second nozzle, how? July 04, 2017 08:01AM |

Registered: 6 years ago Posts: 6 |

I print big, very big and nearly all my prints have 100% infill simply due to durability... Aaaand they have quite a lot of small surface-details there and here.

All that turns into ~30-40 hour prints simply due to infilling and me no likey. Sooo, i thought i'd get a second, larger nozzle to do the infills faster. Worked that far.

Problem is, the small areas are now left hollow where the bigger nozzle wont fit.

How do i infill those small areas with the small nozzle and the big open areas with the large nozzle?

Currently using Simplify3D. Dual Volcanos, chimera. 0.4mm and 1.2mm nozzles.

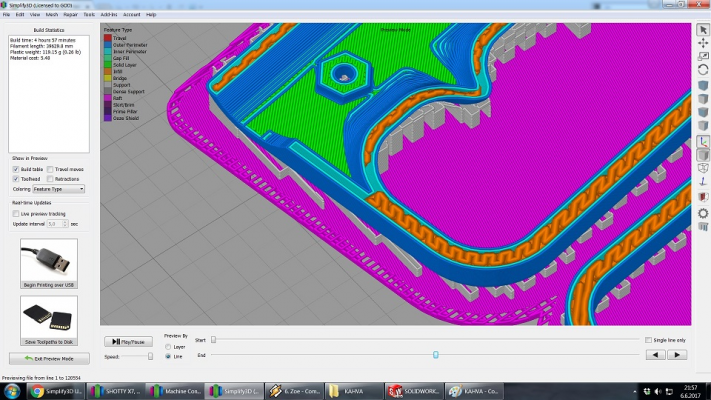

Notice the small areas left hollow in the pic.

All that turns into ~30-40 hour prints simply due to infilling and me no likey. Sooo, i thought i'd get a second, larger nozzle to do the infills faster. Worked that far.

Problem is, the small areas are now left hollow where the bigger nozzle wont fit.

How do i infill those small areas with the small nozzle and the big open areas with the large nozzle?

Currently using Simplify3D. Dual Volcanos, chimera. 0.4mm and 1.2mm nozzles.

Notice the small areas left hollow in the pic.

|

Re: Infills with a bigger second nozzle, how? July 04, 2017 08:46AM |

Registered: 8 years ago Posts: 3,525 |

If this was slic3r I would have no idea how to do the infill with the second head, but the infill overlap can be specified in percentage terms. Increasing this would surely eliminate some of the gaps, but might affect some of the small details effectively over-extruding in those areas. I wonder if S3D has a similar setting?

I have no idea if all the objects you print have large flat bases with detail on top, but why not print the base separately using your big nozzle and bond the more detailed portion on afterwards?

Edited 2 time(s). Last edit at 07/04/2017 08:50AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

I have no idea if all the objects you print have large flat bases with detail on top, but why not print the base separately using your big nozzle and bond the more detailed portion on afterwards?

Edited 2 time(s). Last edit at 07/04/2017 08:50AM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Infills with a bigger second nozzle, how? July 04, 2017 09:13AM |

Registered: 8 years ago Posts: 487 |

I think he's printing on top of a raft (purple), support in white, perimeters in blue, infill orange and top layers in green.

I have no experience with S3D but in slic3r you can specify that the infill is done with a separate extruder, you can also specify how small an area should be before it's ignored for infill.

Have you tried printing an extra perimeter rather than trying to get 100% infill density? in my experience infill is really only needed to support horizontal layers, if you want strength bump up the number of perimeters, you'll save massively on time, not to mention filament.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

I have no experience with S3D but in slic3r you can specify that the infill is done with a separate extruder, you can also specify how small an area should be before it's ignored for infill.

Have you tried printing an extra perimeter rather than trying to get 100% infill density? in my experience infill is really only needed to support horizontal layers, if you want strength bump up the number of perimeters, you'll save massively on time, not to mention filament.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Infills with a bigger second nozzle, how? July 04, 2017 06:08PM |

Registered: 7 years ago Posts: 267 |

|

Re: Infills with a bigger second nozzle, how? July 04, 2017 08:59PM |

Registered: 9 years ago Posts: 483 |

|

Re: Infills with a bigger second nozzle, how? July 05, 2017 08:47AM |

Registered: 6 years ago Posts: 6 |

Perimeters alone wont work. Even 3 perimeters flex a lot and making more takes a long while.

I'l just spit it out. These are AIRSOFT gun parts. Fielded components that take a few hits every now and then. They cant have any hollow sections.

Can Slic3r use both nozzles to do infills? I cant test it for a couple days, im on the move.

I'l just spit it out. These are AIRSOFT gun parts. Fielded components that take a few hits every now and then. They cant have any hollow sections.

Can Slic3r use both nozzles to do infills? I cant test it for a couple days, im on the move.

|

Re: Infills with a bigger second nozzle, how? July 05, 2017 09:12AM |

Registered: 8 years ago Posts: 5,232 |

You can assign solid infill to the small nozzle and regular infill to the big one. Then define the threshold where slic3r uses solid infill.

Unfortunately this won't work where a single infill area has narrow and wide shape. You'd have to live with gaps or use a smaller nozzle and live with the longer print time.

I haven't tried it yet, but if you print only 10-15% infill without solid top infill, you could fill it later with epoxy resin. That would be quite tough stuff.

Edited 1 time(s). Last edit at 07/05/2017 09:16AM by o_lampe.

Unfortunately this won't work where a single infill area has narrow and wide shape. You'd have to live with gaps or use a smaller nozzle and live with the longer print time.

I haven't tried it yet, but if you print only 10-15% infill without solid top infill, you could fill it later with epoxy resin. That would be quite tough stuff.

Edited 1 time(s). Last edit at 07/05/2017 09:16AM by o_lampe.

|

Re: Infills with a bigger second nozzle, how? July 05, 2017 10:36AM |

Registered: 8 years ago Posts: 487 |

I routinely print with four perimeters, sometimes as many as six or eight. It's true that adding perimeters will slow things down but you'll still save time over solid infill.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

Idris

{Precision Piezo} Accurate, repeatable, versatile z-probe plus piezo discs, endstop cables, pt100, 50w heaters.

|

Re: Infills with a bigger second nozzle, how? July 05, 2017 02:58PM |

Registered: 8 years ago Posts: 3,525 |

Have you considered making the part hollow and filling them with something like resin?

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Infills with a bigger second nozzle, how? July 06, 2017 04:22PM |

Registered: 7 years ago Posts: 249 |

You may not have to switch nozzles.

It's possible to print 0.1 and 0.3 layer heights with a 0.4 nozzle.

Unfortunately I've only seen this option for supports via the Makerbot slicer. Model as 0.1 and supports as 0.3

Be cool if you can do this for perimeters and infill, with or without nozzle (print head) swaps.

doh, nm. Didn't read the op clearly.

Just add a few more perimeters, the small gaps between the perimeter and infill won't effect much as far as strength.

Edited 1 time(s). Last edit at 07/06/2017 04:25PM by prot0typ1cal.

It's possible to print 0.1 and 0.3 layer heights with a 0.4 nozzle.

Unfortunately I've only seen this option for supports via the Makerbot slicer. Model as 0.1 and supports as 0.3

Be cool if you can do this for perimeters and infill, with or without nozzle (print head) swaps.

doh, nm. Didn't read the op clearly.

Just add a few more perimeters, the small gaps between the perimeter and infill won't effect much as far as strength.

Edited 1 time(s). Last edit at 07/06/2017 04:25PM by prot0typ1cal.

|

Re: Infills with a bigger second nozzle, how? July 06, 2017 05:39PM |

Registered: 8 years ago Posts: 3,525 |

Slic3r can do combine infill every x layers which should in theory with 0.1mm perimeter layers only print infill every 3rd layer (with a 0.4mm nozzle) I've never tried it as I rarely print 0.1 or lower. I'm not sure if you could print 0.2mm perimeters and get away with infill every other layer with a 0.4mm nozzle, though a 0.5mm nozzle would allow this, and possibly save you half of the infill time. That being said for the strongest parts you want taller layers so 0.2mm are out anyway.

Edited 1 time(s). Last edit at 07/06/2017 05:40PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

Edited 1 time(s). Last edit at 07/06/2017 05:40PM by DjDemonD.

Simon Khoury

Co-founder of [www.precisionpiezo.co.uk] Accurate, repeatable, versatile Z-Probes

Published:Inventions

|

Re: Infills with a bigger second nozzle, how? July 07, 2017 01:13AM |

Registered: 9 years ago Posts: 483 |

Sorry, only registered users may post in this forum.