Is this too much for a A4988 Stepper driver?

Posted by eatumup

|

Is this too much for a A4988 Stepper driver? July 14, 2017 06:58PM |

Registered: 11 years ago Posts: 48 |

I have some extra A4988 drivers for a project im doing. I am using these stepper motors to spin model airplane props real slow. Its a display piece so they wont be pulling any weight or trying to make it fly or anything. Just creating motion.

The steppers came with no datasheet. Across the coil i show 10ohm resistance. I am not worried if they turn in sync or not.

I was thinking that I would wire the 4 motors in series and drive them from the one a4988 driver. Would this be too much for a single driver? I have a 9v power source for the a4988.

Im not real good with the math as in I don't have a good grasp on how/when to use what expression. My initial thought says that id be asking 3.6a of the a4988. Is that right?

The steppers came with no datasheet. Across the coil i show 10ohm resistance. I am not worried if they turn in sync or not.

I was thinking that I would wire the 4 motors in series and drive them from the one a4988 driver. Would this be too much for a single driver? I have a 9v power source for the a4988.

Im not real good with the math as in I don't have a good grasp on how/when to use what expression. My initial thought says that id be asking 3.6a of the a4988. Is that right?

|

Re: Is this too much for a A4988 Stepper driver? July 14, 2017 08:37PM |

Registered: 11 years ago Posts: 335 |

The coil resistance is effectively irrelevant as the a4988 will regulate current itself. I would probably start with all four motors in parallel and set the a4988 to like 0.2A. Go up to 0.6A if they need more power to turn, and you can keep increasing the current if they are still cold.

I am not confident the motors are suitable for this application. They have an 18 degree step angle (regular motors have 1.8 degree) so their low speed performance will be very rough; maybe it will work out with sufficient micro-stepping.

Test without the props first.

Edited 1 time(s). Last edit at 07/14/2017 08:38PM by 691175002.

I am not confident the motors are suitable for this application. They have an 18 degree step angle (regular motors have 1.8 degree) so their low speed performance will be very rough; maybe it will work out with sufficient micro-stepping.

Test without the props first.

Edited 1 time(s). Last edit at 07/14/2017 08:38PM by 691175002.

|

Re: Is this too much for a A4988 Stepper driver? July 14, 2017 09:09PM |

Registered: 6 years ago Posts: 1,863 |

lets take a look.

If you have 10 ohms in series x 4 steppers you have a total of 40 ohms

9 volts divided by 40 ohms equals .225 amps you have 2.25 volts across each stepper.

Now in parallel 10 Ohms in parallel x 4 steppers equals 2.5 ohms, 9 volts divided by 2.5 ohms equals 3.6 amps

A4988 Datasheet states 2A max.

I would place each 2 steppers in parallel in series with 2 steppers in parallel which would look like a single 10 ohm stepper.

([10 ohms stepper in parallel with a 10 ohm stepper equals 5 ohms] is series with [10 ohms stepper in parallel with a 10 ohm stepper equals 5 ohms]) equals a 10 Ohms circuit.

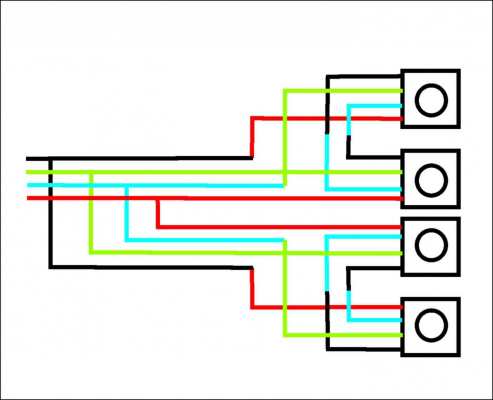

So lets say the first image each stepper is 2 steppers in parallel or is actually the second image you would have 2 steppers in parallel in series with 2 steppers in parallel or a 10 Ohm stepper wire configuration.

Edited 4 time(s). Last edit at 07/14/2017 09:15PM by Roberts_Clif.

If you have 10 ohms in series x 4 steppers you have a total of 40 ohms

9 volts divided by 40 ohms equals .225 amps you have 2.25 volts across each stepper.

Now in parallel 10 Ohms in parallel x 4 steppers equals 2.5 ohms, 9 volts divided by 2.5 ohms equals 3.6 amps

A4988 Datasheet states 2A max.

I would place each 2 steppers in parallel in series with 2 steppers in parallel which would look like a single 10 ohm stepper.

([10 ohms stepper in parallel with a 10 ohm stepper equals 5 ohms] is series with [10 ohms stepper in parallel with a 10 ohm stepper equals 5 ohms]) equals a 10 Ohms circuit.

So lets say the first image each stepper is 2 steppers in parallel or is actually the second image you would have 2 steppers in parallel in series with 2 steppers in parallel or a 10 Ohm stepper wire configuration.

Edited 4 time(s). Last edit at 07/14/2017 09:15PM by Roberts_Clif.

|

Re: Is this too much for a A4988 Stepper driver? July 14, 2017 09:17PM |

Registered: 11 years ago Posts: 48 |

Thank you all for the input. This is why I came to ask. For whatever reason i love messing with this stuff but struggle with the math in design.

Running tests with a single motor i have been able to slow them down enough to do what I need. I had a really hard time finding the "right" motor. these are on the edge of being able to fit where I need them. other motors that had better steps were ether offset output shaft, too big, or regular dc with noisy gear redux.

Im a bit confused. So are you saying to go ahead and use a single a4988 like id like to but run two pairs of motors? That is each pair or set of 2 motors wired together as in image 1, then tie those pairs together as in image 2 at the a4988 output?

Edited 1 time(s). Last edit at 07/14/2017 09:20PM by eatumup.

Running tests with a single motor i have been able to slow them down enough to do what I need. I had a really hard time finding the "right" motor. these are on the edge of being able to fit where I need them. other motors that had better steps were ether offset output shaft, too big, or regular dc with noisy gear redux.

Quote

Roberts_Clif

lets take a look.

If you have 10 ohms in series x 4 steppers you have a total of 40 ohms

9 volts divided by 40 ohms equals .225 amps you have 2.25 volts across each stepper.

Now in parallel 10 Ohms in parallel x 4 steppers equals 2.5 ohms, 9 volts divided by 2.5 ohms equals 3.6 amps

A4988 Datasheet states 2A max at 35volts

I would place each 2 steppers in parallel in series with 2 steppers in parallel which would look like a single 10 ohm stepper.

[10 ohms stepper in parallel with a 10 ohm stepper equals 5 ohms] is series with [10 ohms stepper in parallel with a 10 ohm stepper equals 5 ohms] equals a 10 Ohms circuit.

[attachment 96231 Parallel-series.jpg]

So lets say the first image each stepper is 2 steppers in parallel or is actually the second image you would have 2 steppers in parallel in series with 2 steppers in parallel or a 10 Ohm stepper wire configuration.

Im a bit confused. So are you saying to go ahead and use a single a4988 like id like to but run two pairs of motors? That is each pair or set of 2 motors wired together as in image 1, then tie those pairs together as in image 2 at the a4988 output?

Edited 1 time(s). Last edit at 07/14/2017 09:20PM by eatumup.

|

Re: Is this too much for a A4988 Stepper driver? July 14, 2017 10:20PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Is this too much for a A4988 Stepper driver? July 14, 2017 10:28PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Is this too much for a A4988 Stepper driver? July 14, 2017 10:40PM |

Registered: 11 years ago Posts: 48 |

Quote

Roberts_Clif

They will wire together like this.

[attachment 96235 Parallel.jpg]

Ahh I see now! Sorry to have you draw it out further. I was just having trouble wrapping my head around it. I wasn't going to even worry about the opposite direction bit,. but you took care of that. Thank you very much for taking the time to spell that out for me.

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 03:06AM |

Registered: 10 years ago Posts: 14,672 |

Roberts is ignoring the fact that A4988 drivers are constant current, and these drivers are designed to work with a supply voltage much higher than the motor voltage. For example, in 3D printers it is usually to choose motors rated at about 3V with a supply voltage of 12V of 24V. The driver uses chopper control to limit the current to the motors.

The page you linked to gives the motor voltage as 3V to 5V. If the resistance is 10 ohms then the peak current draw per phase will be 0.3 to 0.5A per phase at 3V and 5V respectively. So if you connect all 4 motors in parallel, the current draw will be 1.2 to 2.0A. You will not be using the motors to drive a significant load, so 1.2A will be plenty. Therefore I suggest you connect all 4 motors in parallel, and set the A4988 module to about 1A to 1.2A current.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The page you linked to gives the motor voltage as 3V to 5V. If the resistance is 10 ohms then the peak current draw per phase will be 0.3 to 0.5A per phase at 3V and 5V respectively. So if you connect all 4 motors in parallel, the current draw will be 1.2 to 2.0A. You will not be using the motors to drive a significant load, so 1.2A will be plenty. Therefore I suggest you connect all 4 motors in parallel, and set the A4988 module to about 1A to 1.2A current.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 07:28AM |

Registered: 6 years ago Posts: 1,863 |

Quote

eatumup

I have some extra A4988 drivers for a project im doing. I am using these stepper motors to spin model airplane props real slow. Its a display piece so they wont be pulling any weight or trying to make it fly or anything. Just creating motion.

The steppers came with no datasheet. Across the coil i show 10ohm resistance. I am not worried if they turn in sync or not.

I was thinking that I would wire the 4 motors in series and drive them from the one a4988 driver. Would this be too much for a single driver? I have a 9v power source for the a4988.

Im not real good with the math as in I don't have a good grasp on how/when to use what expression. My initial thought says that id be asking 3.6a of the a4988. Is that right?

Not ignoring the fact that A4988 is a constant current driver. Not good build practice to place 4 steppers in parallel across one a4988 and following his guidelines "I have a 9v power source for the a4988".

In short it is too easy to adjust above max current for the a4988 causing meltdown, with a max current draw of 900 milliamps this will never happen.

This configuration allows for a 4.5 volt head voltage across each stepper. Which will allow for any torque required to spin the steppers.

Arranging the steppers in parallel will jump the current above the operation limits. Arranging the steppers is series will drop the current below the operating limits.

This was the only way to make the project work using a single A4988 driver with a 9volt supply.

Using a single A4988 driver he can adjust the limits from minimum current to a max current of 0.900 amps, without risk of burning the a4988 out.

9 volts divided by 10 ohms equals 0.900 amps.

Individual stepper current draw is 4.5 volts divided by 10 ohms equals 450 milliamps.

Edited 2 time(s). Last edit at 07/15/2017 07:41AM by Roberts_Clif.

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 08:49AM |

Registered: 6 years ago Posts: 1,863 |

When you run more than one stepper off one driver it is risky business. This messes up microstepping and anti-resonance circuits.

Steppers are essentially generators which means they constantly fight each other in series or in parallel circuits, pushing, pulling and shoving like siblings.

And with a 5% tolerance per stepper this gives 10% for two and a 20% max tolerance for four steppers, would not trust a plane in the air with this tolerance.

Companies parallel to keep cost down. Although this is generally a really bad ideal when using them to make precision parts.

Steppers are essentially generators which means they constantly fight each other in series or in parallel circuits, pushing, pulling and shoving like siblings.

And with a 5% tolerance per stepper this gives 10% for two and a 20% max tolerance for four steppers, would not trust a plane in the air with this tolerance.

Companies parallel to keep cost down. Although this is generally a really bad ideal when using them to make precision parts.

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 10:00AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Roberts_Clif

When you run more than one stepper off one driver it is risky business. This messes up microstepping and anti-resonance circuits.

Steppers are essentially generators which means they constantly fight each other in series or in parallel circuits, pushing, pulling and shoving like siblings.

And with a 5% tolerance per stepper this gives 10% for two and a 20% max tolerance for four steppers, would not trust a plane in the air with this tolerance.

Companies parallel to keep cost down. Although this is generally a really bad ideal when using them to make precision parts.

I agree with you that in general, connecting stepper motors in parallel is a bad idea when using constant-current drivers, because they won't necessarily share the currents equally. I would never do it where precision is required. Whereas connecting stepper motors in series (using constant-current drivers again) is reasonable IMO if they are sharing the same load, for example multiple Z motors in a 3D printer, provided that the supply voltage is high enough to handle the combined voltage drop + back emf of all of them so that the driver chip really can provide a constant current.

In this particular application, series connection is not an option because the voltage drop at low speeds is already 3 to 5V per motor. As the application is not critical and the loads are light, I think parallel connection is most likely to work best because it provides the drivers with the voltage headroom needed to control the current well. It is certainly possible that the motors may not share the current very equally, but as the loads are light I suspect that won't matter.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 10:24AM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 05:15PM |

Registered: 11 years ago Posts: 48 |

Wow, I got a lot from the discussion from Robert_Clif and dc42! Thank you for having that conversation. The scope of this project is just making the motors spin slowly without overloading something.

To this If I were doing anything with precision, like my 3d printer I wouldn't even consider this. I would be using a driver per motor. However, in this case I am not actually flying this thing. It will just be a static display mounted to a stick. I dont expect it to run more than 10 or 20 seconds after the go button is pressed.

That said I think your point is essential to anyone reading this. Steppers are often used for precision control in my experience. however, my application does not care about any sort of precision. So to anyone reading this post in research for their own project please consider that nothing in this application is relying on those steppers

Quote

Roberts_Clif

When you run more than one stepper off one driver it is risky business. This messes up microstepping and anti-resonance circuits.

Steppers are essentially generators which means they constantly fight each other in series or in parallel circuits, pushing, pulling and shoving like siblings.

And with a 5% tolerance per stepper this gives 10% for two and a 20% max tolerance for four steppers, would not trust a plane in the air with this tolerance.

Companies parallel to keep cost down. Although this is generally a really bad ideal when using them to make precision parts.

To this If I were doing anything with precision, like my 3d printer I wouldn't even consider this. I would be using a driver per motor. However, in this case I am not actually flying this thing. It will just be a static display mounted to a stick. I dont expect it to run more than 10 or 20 seconds after the go button is pressed.

That said I think your point is essential to anyone reading this. Steppers are often used for precision control in my experience. however, my application does not care about any sort of precision. So to anyone reading this post in research for their own project please consider that nothing in this application is relying on those steppers

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 05:30PM |

Registered: 11 years ago Posts: 335 |

I'd just like to point out that I find it extraordinarily unlikely that stepper motors weighing 9g each are intended to survive the currents being talked about in this thread. I could not find a PM15S-020 motor with 10 ohm coil resistance, but the other motors of that series are designed for 100-150mA.

|

Re: Is this too much for a A4988 Stepper driver? July 15, 2017 08:56PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Is this too much for a A4988 Stepper driver? July 16, 2017 04:12AM |

Registered: 7 years ago Posts: 103 |

|

Re: Is this too much for a A4988 Stepper driver? July 16, 2017 08:27AM |

Registered: 10 years ago Posts: 14,672 |

Quote

slippyr4

Surely a simple DC motor with integrated gearbox is going to be a much better solution for this problem? Using a stepper for this is over engineering it quite a bit.

That might be a simpler solution, however at $1 each, using those stepper motors is hardly overkill.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is this too much for a A4988 Stepper driver? July 16, 2017 08:55AM |

Registered: 8 years ago Posts: 601 |

Have you considered an AC motor? I found one in an old laminating machine that originally cost about £20. All you have to do is wire it up to mains and it spins at around 5~6 revolutions per minute. I'm not sure what the motor number is, but I can look it up if you need it. I currently use mine for a photogrammetry scanner turntable. I use it to rotate the item while a camera automatically takes photos.

The motor I salvaged also had some nice plastic gears on it.

The motor I salvaged also had some nice plastic gears on it.

Sorry, only registered users may post in this forum.