Looking for a specific alternative to Mic-6 bed plate, requirements listed.

Posted by klcjr89

|

Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 25, 2017 05:35AM |

Registered: 6 years ago Posts: 207 |

Hello, I am on the search for a new bed material that is a good thermal insulator, thinner with less mass, and also won't warp much. If possible, I would like the warp to be the same as Mic-6 or less, or slightly more, as long as the warp is repeatable given the same temperatures for each print. It also needs to be as flat as possible off the shelf with no machining involved preferably because surface grinding is a little beyond my means.

It also needs to be mounted with no through holes piercing the top of the build plate surface. Another requirement: the thermistor needs to read the temperature between the build surface substrate and the build plate. Thermistors are too thick to put under the subtrate, so I wonder if a stud mount thermistor flush with the top of the build plate would work? I don't want to take the reading on the bottom of the plate, that's the whole idea of using a less thermally conductive plate. Ceramic is brittle and I have no idea how flat it comes stock.

Now you may be asking why, well I am experimenting with something that I am in need of the above specs. Thought about using borosilicate glass, but that might be iffy figuring out a mounting method to utilize the most print area (also drilling and tapping becomes sketchy for the stud mount thermistor), and Titanium or 304 stainless is a decent insulator compared to Aluminum, but it will have more surface deflection for a thinner piece compared to the 1/4" Mic-6 that I use. For a 1/4" piece of Titanium or 304 the weight would be too much and also the price.

Would appreciate insight into some possible subtrates. As you can see I have alot of requirements to look for but there's room for slight compromises. Right now it looks like I have to use Mic-6 and drill and tap the plate to mount it to the carriage plate with studs, but the issue is that I do not want to heat the build plate up, hence the need for a less thermally conductive build plate.

Thanks!

Edited 9 time(s). Last edit at 09/25/2017 05:54AM by klcjr89.

It also needs to be mounted with no through holes piercing the top of the build plate surface. Another requirement: the thermistor needs to read the temperature between the build surface substrate and the build plate. Thermistors are too thick to put under the subtrate, so I wonder if a stud mount thermistor flush with the top of the build plate would work? I don't want to take the reading on the bottom of the plate, that's the whole idea of using a less thermally conductive plate. Ceramic is brittle and I have no idea how flat it comes stock.

Now you may be asking why, well I am experimenting with something that I am in need of the above specs. Thought about using borosilicate glass, but that might be iffy figuring out a mounting method to utilize the most print area (also drilling and tapping becomes sketchy for the stud mount thermistor), and Titanium or 304 stainless is a decent insulator compared to Aluminum, but it will have more surface deflection for a thinner piece compared to the 1/4" Mic-6 that I use. For a 1/4" piece of Titanium or 304 the weight would be too much and also the price.

Would appreciate insight into some possible subtrates. As you can see I have alot of requirements to look for but there's room for slight compromises. Right now it looks like I have to use Mic-6 and drill and tap the plate to mount it to the carriage plate with studs, but the issue is that I do not want to heat the build plate up, hence the need for a less thermally conductive build plate.

Thanks!

Edited 9 time(s). Last edit at 09/25/2017 05:54AM by klcjr89.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 05:38AM |

Registered: 6 years ago Posts: 207 |

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 10:30AM |

Registered: 11 years ago Posts: 335 |

I would recommend carbon fiber or fiberglass plate, but I think you will have a very hard time getting alternative materials that are as flat as MIC6. If you probe the bed flatness isn't as critical as repeatability anyways.

You can drill composites with carbide bits and a lot of water but in general its probably easier to epoxy components to the bottom of the plate.

I think CF has reasonable thermal conductivity, but it will certainly be lower than aluminum. Some commercial printers use CF beds to save weight.

You can drill composites with carbide bits and a lot of water but in general its probably easier to epoxy components to the bottom of the plate.

I think CF has reasonable thermal conductivity, but it will certainly be lower than aluminum. Some commercial printers use CF beds to save weight.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 10:40AM |

Registered: 12 years ago Posts: 1,450 |

Just a bit of lateral thinking. If you don't want to heat the build plate up how about printing one. The principal advantage is that you could design it with a supporting structure so that it could be made both rigid and light. With most available materials you may have to lap the front surface smooth and would definitely have to have some sort of film to prevent sticking.

Mike

Mike

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 10:53AM |

Registered: 6 years ago Posts: 207 |

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 03:01PM |

Registered: 11 years ago Posts: 5,780 |

My printers don't require adjustment and they have MIC6 beds and use microswitches for zeroing (actually one has an opto interruptor). If you build the printer well enough that it doesn't need frequent readjustment, why on earth would you go to the trouble of adding and calibrating autoleveling to do the initial set-up? You won't be saving any effort, time, or money that way. Your extruder carriage will be forever dragging around a bed sensor and its cable for a single use. Hmmm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 04:04PM |

Registered: 7 years ago Posts: 249 |

Garolite.

There's plenty of types for consideration.

G7 high temp, flame retardant has the highest thermal resistance, while G11 offers the highest thermal insulation.

G10/FR4 you can get with ground precision flat surfaces, with comparable tolerances to MIC-6 or ATP-5.

I'm using 1/2" CE to insulate under my heated bed. Though you will still get heat creep, that is, the garolite will eventually heat up.

If you want a true insulator, ceramic is the best.

Calcium silicate sheets typically starts at 1/2" thick (40lb per cu ft is best), while ceramic fiber sheets are less prone to cracking with normal handling and are available down to 3/16" thick.

There's plenty of types for consideration.

G7 high temp, flame retardant has the highest thermal resistance, while G11 offers the highest thermal insulation.

G10/FR4 you can get with ground precision flat surfaces, with comparable tolerances to MIC-6 or ATP-5.

I'm using 1/2" CE to insulate under my heated bed. Though you will still get heat creep, that is, the garolite will eventually heat up.

If you want a true insulator, ceramic is the best.

Calcium silicate sheets typically starts at 1/2" thick (40lb per cu ft is best), while ceramic fiber sheets are less prone to cracking with normal handling and are available down to 3/16" thick.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 06:00PM |

Registered: 6 years ago Posts: 207 |

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 06:33PM |

Registered: 6 years ago Posts: 207 |

Quote

prot0typ1cal

Garolite.

There's plenty of types for consideration.

G7 high temp, flame retardant has the highest thermal resistance, while G11 offers the highest thermal insulation.

G10/FR4 you can get with ground precision flat surfaces, with comparable tolerances to MIC-6 or ATP-5.

I'm using 1/2" CE to insulate under my heated bed. Though you will still get heat creep, that is, the garolite will eventually heat up.

If you want a true insulator, ceramic is the best.

Calcium silicate sheets typically starts at 1/2" thick (40lb per cu ft is best), while ceramic fiber sheets are less prone to cracking with normal handling and are available down to 3/16" thick.

The ceramic would appear to be heavy assuming it really is 40 lbs per foot? I'm not good with math.

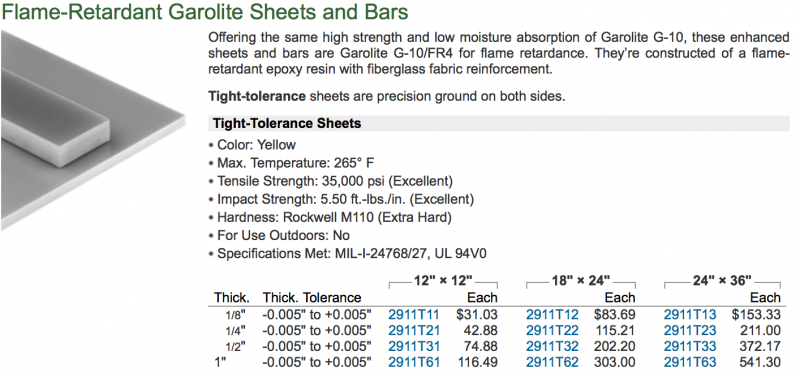

As for the Garolite, what size thickness should I choose? I am looking at the tight-tolerance sheets on McMaster-Carr.

Ideally the thinner the better, but I do need to take into account printing at least a whole spool's worth of plastic (1kg) onto it and the bend deflection.

Should I pick 1/4" or something else? Photo of what's available:

Edited 2 time(s). Last edit at 09/26/2017 06:38PM by klcjr89.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 26, 2017 08:02PM |

Registered: 6 years ago Posts: 207 |

I have ordered the 1/4" thick precision ground Garolite, which will be a 1.32 lb weight reduction over Mic-6 of the same thickness. The flatness tolerance is equivalent to Mic-6.

The plate deflection with the same applied mass and area is only 5.33 microns more than Mic-6 (about the size of a red blood cell).

Edited 2 time(s). Last edit at 09/26/2017 08:05PM by klcjr89.

The plate deflection with the same applied mass and area is only 5.33 microns more than Mic-6 (about the size of a red blood cell).

Edited 2 time(s). Last edit at 09/26/2017 08:05PM by klcjr89.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 27, 2017 07:10AM |

Registered: 6 years ago Posts: 207 |

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 27, 2017 10:20AM |

Registered: 11 years ago Posts: 335 |

Quote

klcjr89

I have ordered the 1/4" thick precision ground Garolite, which will be a 1.32 lb weight reduction over Mic-6 of the same thickness. The flatness tolerance is equivalent to Mic-6.

Where are you seeing a flatness tolerance? The McMaster page only shows thickness, although I'm sure flatness will be quite good.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 27, 2017 10:28AM |

Registered: 6 years ago Posts: 207 |

Quote

691175002

Quote

klcjr89

I have ordered the 1/4" thick precision ground Garolite, which will be a 1.32 lb weight reduction over Mic-6 of the same thickness. The flatness tolerance is equivalent to Mic-6.

Where are you seeing a flatness tolerance? The McMaster page only shows thickness, although I'm sure flatness will be quite good.

It says both sides are precision ground so I assumed they would be as flat as possible if they are parallel to each other. Probably the same as mic-6

Edited 1 time(s). Last edit at 09/27/2017 10:29AM by klcjr89.

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 27, 2017 12:47PM |

Registered: 7 years ago Posts: 249 |

Ground sheets are usually within .003" per foot flatness, which is pretty damn good.

One thing to look out for is they can be stress deformed if placed under heavy loads for extended periods, but the same can be said of MIC-6.

My 1/2" CE had a .03" bow because I left 50 lbs of weights on it for a week while I was load testing my Z axis before I got my ATP-5. Yea, stupid me :p

One thing to look out for is they can be stress deformed if placed under heavy loads for extended periods, but the same can be said of MIC-6.

My 1/2" CE had a .03" bow because I left 50 lbs of weights on it for a week while I was load testing my Z axis before I got my ATP-5. Yea, stupid me :p

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 27, 2017 02:18PM |

Registered: 11 years ago Posts: 5,780 |

If you just want the sensor to bump the bed plate surface, why not mount the zero switch so that it bumps the bed surface? It won't matter if it's conductive or not, and it won't matter if you swap bed plates.

Edited 1 time(s). Last edit at 09/27/2017 02:19PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 09/27/2017 02:19PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Looking for a specific alternative to Mic-6 bed plate, requirements listed. September 27, 2017 05:41PM |

Registered: 6 years ago Posts: 207 |

Sorry, only registered users may post in this forum.