Another kit, another set of problems.

Posted by SupraGuy

|

Another kit, another set of problems. December 18, 2017 01:34PM |

Registered: 9 years ago Posts: 465 |

Back when I got my i3 kit, I put up a topic asking "Are all these kits this bad?"

Well, I've run out of patience with trying to fix the i3 up. It's not capable of making parts that would make it better, which is frustrating. It's also degraded over time, and I finally gave up on it about a year and a half ago when it could no longer manage a semblance of a circle.

So, earlier this month, I picked up another kit off of Amazon. It's a plywood frame printer, found here: [github.com]

The price was good, and I was happy with the quality of the parts. Assembly was mostly easy, a couple of steps would have been MUCH easier with another set of hands. I damned near lost the bearings for the Y drive/slave axles more than once, and the step where you install the Y drive belts was missing, but I figure that if you're competent to use one of these, it's not hard to do. Also, unlike the old kit that I had, it actually came with all the screws and nuts that you need to assemble it, so I didn't need to scrounge for stuff.

Aside from one of the linear bearings being noisy, the parts in the kit were good. The print bed is nice and large, the X and Y axes move smoothly and precisely, and the auto levelling bed is a nice feature.

Everything looked good, until it's time to print. The plastic just doesn't stick to the unheated bed.

Also from Amazon, I bought a piece of tempered glass about 8.5" square, but it arrived shattered. I sent it back for a refund.

I tried the 3M painters' tape, with and without hairspray. no luck, I just get a mass of plastic curled around the hotend. The closest that I've managed is with a piece of glass from a dollar store picture frame (Which is what I used on the heated bed from my i3 clone) taped to the print surface and liberally coated with hairspray. The plastic would stick to that about long enough for it to make a couple of circuits, but would then move before the first layer of a small print was done, let alone a larger one. ABS seemed better than PLA, which I thought was odd, since I always had more problems with ABS adhering than PLA before.

Given that it's December, I'll admit that my house isn't as warm as it could be. Still, probably as warm as it's likely to be in midsummer when I'll have air conditioning running.

I'm thinking that the next stage will be doing something like a heated chamber. Since the printer is almost enclosed already, with the front and top open, I'll need a cap for the top that still allows the filament to feed, and the print head to move around, a cover for the front that allows access to the control panel will be the other part. not sure what I'll use for a heater element. It would be nice to keep the power consumption to a reasonable level. I thought about picking up a hair dryer at a thrift store (Well, even new they're not terribly expensive.) I don't figure that I need 1875W of heat, but I'm less sure of how much I do need. I've seen other heat chambers that use a hair dryer as a heat source, but I don't know if they use the full power of the hair dryer to provide it. I'd hoped that this wouldn't be a necessary step, but I'm kind of frustrated at this inability to get a print off of this new printer.

Ultimately, I'd like to have both printers up and running, but I need the new one in order to get the old one working. Once the old one is working again, It at least has the heated bed.

So in exchanging an old printer for a new one, it seems that I've just swapped problems.

All in all though, considering what a piece of junk my old kit was, the overall build issues are much less. I have high hopes for this little box in terms of build quality and capability.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

Well, I've run out of patience with trying to fix the i3 up. It's not capable of making parts that would make it better, which is frustrating. It's also degraded over time, and I finally gave up on it about a year and a half ago when it could no longer manage a semblance of a circle.

So, earlier this month, I picked up another kit off of Amazon. It's a plywood frame printer, found here: [github.com]

The price was good, and I was happy with the quality of the parts. Assembly was mostly easy, a couple of steps would have been MUCH easier with another set of hands. I damned near lost the bearings for the Y drive/slave axles more than once, and the step where you install the Y drive belts was missing, but I figure that if you're competent to use one of these, it's not hard to do. Also, unlike the old kit that I had, it actually came with all the screws and nuts that you need to assemble it, so I didn't need to scrounge for stuff.

Aside from one of the linear bearings being noisy, the parts in the kit were good. The print bed is nice and large, the X and Y axes move smoothly and precisely, and the auto levelling bed is a nice feature.

Everything looked good, until it's time to print. The plastic just doesn't stick to the unheated bed.

Also from Amazon, I bought a piece of tempered glass about 8.5" square, but it arrived shattered. I sent it back for a refund.

I tried the 3M painters' tape, with and without hairspray. no luck, I just get a mass of plastic curled around the hotend. The closest that I've managed is with a piece of glass from a dollar store picture frame (Which is what I used on the heated bed from my i3 clone) taped to the print surface and liberally coated with hairspray. The plastic would stick to that about long enough for it to make a couple of circuits, but would then move before the first layer of a small print was done, let alone a larger one. ABS seemed better than PLA, which I thought was odd, since I always had more problems with ABS adhering than PLA before.

Given that it's December, I'll admit that my house isn't as warm as it could be. Still, probably as warm as it's likely to be in midsummer when I'll have air conditioning running.

I'm thinking that the next stage will be doing something like a heated chamber. Since the printer is almost enclosed already, with the front and top open, I'll need a cap for the top that still allows the filament to feed, and the print head to move around, a cover for the front that allows access to the control panel will be the other part. not sure what I'll use for a heater element. It would be nice to keep the power consumption to a reasonable level. I thought about picking up a hair dryer at a thrift store (Well, even new they're not terribly expensive.) I don't figure that I need 1875W of heat, but I'm less sure of how much I do need. I've seen other heat chambers that use a hair dryer as a heat source, but I don't know if they use the full power of the hair dryer to provide it. I'd hoped that this wouldn't be a necessary step, but I'm kind of frustrated at this inability to get a print off of this new printer.

Ultimately, I'd like to have both printers up and running, but I need the new one in order to get the old one working. Once the old one is working again, It at least has the heated bed.

So in exchanging an old printer for a new one, it seems that I've just swapped problems.

All in all though, considering what a piece of junk my old kit was, the overall build issues are much less. I have high hopes for this little box in terms of build quality and capability.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Another kit, another set of problems. December 18, 2017 03:46PM |

Registered: 9 years ago Posts: 978 |

PLA should stick OK to blue painter's tape without a heated bed or chamber. Wiping the blue painter's tape with alcohol makes it a bit stickier.

I'm guessing the issue is with the bed-sensing... probably it's set a smidgen too high. If it was me, I'd turn off all the bed-levelling and sensing stuff (IMHO it's more trouble than it's worth) and manually set the bed height and level & flat, as below. Even if you do use bed-leveling and height-sensing, doing this is still a good idea because it simplifies debugging of other printing issues.

1. Move the nozzle down by hand at one corner of the bed until it grips a piece of paper held between it and the bed. You should be able to just slide the paper to and fro but still feel the grip.

2. Move the nozzle to an adjacent corner without moving it up or down (being careful in case the bed is actually higher at this next corner than at the previous one... if it is, wind the bed down at that corner until it is clear). Adjust the *bed* so that paper is gripped as above.

3. Move the nozzle to the next corner and repeat step 2. If your bed has 4 adjusting screws (one at each corner), adjust the 4th one the same as this one.

4. Check at the middle of the bed.

5. Repeat steps 1-4 -- the paper should be gripped at all corners and the middle without needing any adjustment.

If the bed isn't *flat* (i.e. 3 corners are good, but the middle and/or the 4th corner isn't), build up any low areas with layers of tape. Or put a piece of flat glass on the bed, but use blue tape on it. You can check flatness with a straightedge.

This leveling & flattening should last for many, many prints.

Each time you turn the printer on, you will need to do the height setting once, as per step 1 but at the centre of the bed.

With bed-leveling turned off, your Z motor should be disabled whilst printing (except when actually raising/lowering), so you can tweak the height by turning the Z-screw by hand. On each print, tell your slicer to generate a couple of skirts, which will allow you to do the tweaking before the actual object starts printing.

To turn off the bed-levelling and height sensing, remove any G28 or G29 commands in your slicer (in Slic3r it is in Printer Settings/Custom G-code/Start G-code).

Going out on a limb here, but I think that hairspray will have limited benefit for PLA. It will work a little because it's kindof sticky in itself, but will work better for ABS because it contains acetone, which is an ABS solvent.

The glass you want is borosilicate glass (aka Pyrex). This has a lower coefficient of thermal expansion than ordinary glass, so is less likely to break when one part is heated (by depositing hot plastic on it) more than the rest.

Beware that screws through plywood will gradually loosen and your print quality will drop. Regular tightening of screws and belts is necessary. Over-tightening these screws will damage the plywood and hasten the printer's demise. Over time, the holes in the plywood will open and things will become sloppy, regardless of how tight your screws are. I think that a metal frame is a worthwhile investment.

I'm guessing the issue is with the bed-sensing... probably it's set a smidgen too high. If it was me, I'd turn off all the bed-levelling and sensing stuff (IMHO it's more trouble than it's worth) and manually set the bed height and level & flat, as below. Even if you do use bed-leveling and height-sensing, doing this is still a good idea because it simplifies debugging of other printing issues.

1. Move the nozzle down by hand at one corner of the bed until it grips a piece of paper held between it and the bed. You should be able to just slide the paper to and fro but still feel the grip.

2. Move the nozzle to an adjacent corner without moving it up or down (being careful in case the bed is actually higher at this next corner than at the previous one... if it is, wind the bed down at that corner until it is clear). Adjust the *bed* so that paper is gripped as above.

3. Move the nozzle to the next corner and repeat step 2. If your bed has 4 adjusting screws (one at each corner), adjust the 4th one the same as this one.

4. Check at the middle of the bed.

5. Repeat steps 1-4 -- the paper should be gripped at all corners and the middle without needing any adjustment.

If the bed isn't *flat* (i.e. 3 corners are good, but the middle and/or the 4th corner isn't), build up any low areas with layers of tape. Or put a piece of flat glass on the bed, but use blue tape on it. You can check flatness with a straightedge.

This leveling & flattening should last for many, many prints.

Each time you turn the printer on, you will need to do the height setting once, as per step 1 but at the centre of the bed.

With bed-leveling turned off, your Z motor should be disabled whilst printing (except when actually raising/lowering), so you can tweak the height by turning the Z-screw by hand. On each print, tell your slicer to generate a couple of skirts, which will allow you to do the tweaking before the actual object starts printing.

To turn off the bed-levelling and height sensing, remove any G28 or G29 commands in your slicer (in Slic3r it is in Printer Settings/Custom G-code/Start G-code).

Going out on a limb here, but I think that hairspray will have limited benefit for PLA. It will work a little because it's kindof sticky in itself, but will work better for ABS because it contains acetone, which is an ABS solvent.

The glass you want is borosilicate glass (aka Pyrex). This has a lower coefficient of thermal expansion than ordinary glass, so is less likely to break when one part is heated (by depositing hot plastic on it) more than the rest.

Beware that screws through plywood will gradually loosen and your print quality will drop. Regular tightening of screws and belts is necessary. Over-tightening these screws will damage the plywood and hasten the printer's demise. Over time, the holes in the plywood will open and things will become sloppy, regardless of how tight your screws are. I think that a metal frame is a worthwhile investment.

|

Re: Another kit, another set of problems. December 18, 2017 03:49PM |

Registered: 8 years ago Posts: 1,671 |

persevere make sure bed is as flat as possible, (i use a silver rizzla) so its just grabbing at all points, when it sticks to blue tape it really sticks, i'd say glass is for heated bed (but I think some ppl can make it stick to it cold), also if the filament is bad like one roll i had it wouldnt stick. print slow and over extrude if need be, and baby step nozzle lower or higher as you lay down the brim.

|

Re: Another kit, another set of problems. December 18, 2017 06:21PM |

Registered: 9 years ago Posts: 465 |

I thought that the tape should be okay. Kind of floored by that.

For bed leveling, I do have the build platform level without any need for software leveling. Not that I don't trust it, but... I don't trust it. Still, visually it does appear to have about the appropriate gap for the first layer (0.25mm) which is what I used for my i3. Of course the i3 had a heated bed. I would have rather not used the glass. It does occur to me that I only really checked the Z height carefully after setting the offset when I had the glass in place, since I really didn't want the print head hitting the glass and breaking it, if only because cleaning up broken glass is a royal pain.

Still, visually it does appear to have about the appropriate gap for the first layer (0.25mm) which is what I used for my i3. Of course the i3 had a heated bed. I would have rather not used the glass. It does occur to me that I only really checked the Z height carefully after setting the offset when I had the glass in place, since I really didn't want the print head hitting the glass and breaking it, if only because cleaning up broken glass is a royal pain.

I think that I'll want to do something about a heated bed eventually. The build platform for this kit seems a bit complicated. There's a big aluminum plate which has the drive screw nut and linear bearings bolted to it. That has a triangular plate attached at 3 points by spring loaded bolts. the build plate attaches at the same 3 points with strong magnets. This makes the build plate fairly easy to remove, which is kind of nice, though I'd worry about debris interfering with the mount if I were to remove it a lot. The plate has 3 notches in it for the nozzle at the 3 leveling points so that the nozzle won't hit the build plate where the probe is sensing the build plate position. The probe is about 1.5mm above the nozzle with it tightened into the feed tube. I like that, as it means that the probe shouldn't hit the model as it's built.

So what I'll need to to do is replicate the shape of the build plate, but have connectors for power and a thermistor. I can source rare earth magnets to connect it to the platform okay. Or else I might just do away with the lower platform and connect it directly via springs/bolts to the aluminum plate. Might as well simplify a little.

The picture frame glass is a risk. I did buy a piece of tempered glass, but as I said, it arrived shattered. The picture frame glass was only supposed to be a stop-gap 3 years ago when I got the i3, and I meant to get a piece of tempered glass then. I didn't, and I've only broken one piece of cheap dollar store picture frame glass over more than 2 years of use (It broke because I dropped it while taking it out to clean off the ABS/acetone slurry I'd been using for large thin ABS prints.)

The spools of PLA and ABS both are ones that I had used with the i3. They've been stored in a sealed plastic storage box. I wouldn't say air-tight though, so it's possible that they've been exposed to moisture, which I understand can affect the properties of the plastic. Maybe my PLA spools (I have 3) are no good anymore.

Well, more troubleshooting to do. Maybe I'll have more news tomorrow.

For bed leveling, I do have the build platform level without any need for software leveling. Not that I don't trust it, but... I don't trust it.

Still, visually it does appear to have about the appropriate gap for the first layer (0.25mm) which is what I used for my i3. Of course the i3 had a heated bed. I would have rather not used the glass. It does occur to me that I only really checked the Z height carefully after setting the offset when I had the glass in place, since I really didn't want the print head hitting the glass and breaking it, if only because cleaning up broken glass is a royal pain.

Still, visually it does appear to have about the appropriate gap for the first layer (0.25mm) which is what I used for my i3. Of course the i3 had a heated bed. I would have rather not used the glass. It does occur to me that I only really checked the Z height carefully after setting the offset when I had the glass in place, since I really didn't want the print head hitting the glass and breaking it, if only because cleaning up broken glass is a royal pain.I think that I'll want to do something about a heated bed eventually. The build platform for this kit seems a bit complicated. There's a big aluminum plate which has the drive screw nut and linear bearings bolted to it. That has a triangular plate attached at 3 points by spring loaded bolts. the build plate attaches at the same 3 points with strong magnets. This makes the build plate fairly easy to remove, which is kind of nice, though I'd worry about debris interfering with the mount if I were to remove it a lot. The plate has 3 notches in it for the nozzle at the 3 leveling points so that the nozzle won't hit the build plate where the probe is sensing the build plate position. The probe is about 1.5mm above the nozzle with it tightened into the feed tube. I like that, as it means that the probe shouldn't hit the model as it's built.

So what I'll need to to do is replicate the shape of the build plate, but have connectors for power and a thermistor. I can source rare earth magnets to connect it to the platform okay. Or else I might just do away with the lower platform and connect it directly via springs/bolts to the aluminum plate. Might as well simplify a little.

The picture frame glass is a risk. I did buy a piece of tempered glass, but as I said, it arrived shattered. The picture frame glass was only supposed to be a stop-gap 3 years ago when I got the i3, and I meant to get a piece of tempered glass then. I didn't, and I've only broken one piece of cheap dollar store picture frame glass over more than 2 years of use (It broke because I dropped it while taking it out to clean off the ABS/acetone slurry I'd been using for large thin ABS prints.)

The spools of PLA and ABS both are ones that I had used with the i3. They've been stored in a sealed plastic storage box. I wouldn't say air-tight though, so it's possible that they've been exposed to moisture, which I understand can affect the properties of the plastic. Maybe my PLA spools (I have 3) are no good anymore.

Well, more troubleshooting to do. Maybe I'll have more news tomorrow.

|

Re: Another kit, another set of problems. December 20, 2017 12:23PM |

Registered: 9 years ago Posts: 465 |

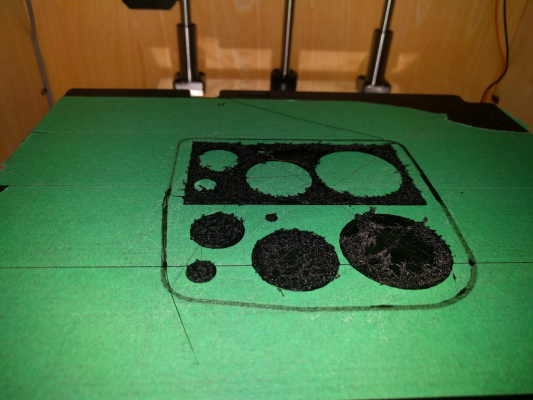

Well, it looks like I'm having some Z axis problems. I'm not hearing anything that sounds like missed steps, but there's definitely some weirdness going on. Print below was PLA extruded at 200 deg C.

I took time to really solidly level the bed. I locked the platform in place so that there could be no interference from the firmware, and adjusted the mounting screws so that the print head will drag a sheet of printer paper around. Carefully set the offset as per the instructions that came with the printer. First sign, it seems to wander. The print head itself can't do that, and the probe is solidly mounted, so it should not, but it appears to do so. I can repeat the same process, and sometimes I get about ~1.5mm, and it can be up to 1.9mm. It is not dependent on t e X/Y coordinates, it's the same everywhere.

I'm not hearing anything from the Z motors that sounds like missed steps, but I suspect that this is a problem. Not 100% sure though.

One of the problems is that I can set the offset, and when I move the printer to it's "0" Z position, it looks right, but at the start of the Gcode print routine, it's supposed to be at 0.2-0.25mm, and there's a clear gap between print head and bed that looks to be over 1mm. This happens when the print bed rises up from a Z of ~5mm.

After wasting all of my blue tape (Didn't have much left) I did a quick and dirty job with cheap dollar store painter's tape, and then manually adjusted the Z axis, and got a print started. Obviously, this is sub-optimal, but since the steps/mm setting seemed appropriate. Mathematically, it's perfect, and it seems reasonable. for fairly large values where the Z axis is set. I had hoped that once the print was started that it would run normally. Oops. The result was as is in the picture there.

At the end of the print, the LCD reports Z=2, but there's maybe a bit more than 1mm between the print head and the bed, and it's been doing terrible things to the print job. The skirt is uneven because that's where I was messing with getting the starting Z height where I wanted it.

So given that once moving the Z axis moves at very close (error <1%) to the expected distance, it seems that the error is much larger for small moves. I'd think that this would be an acceleration or jerk setting somewhere, that it's too high, and the motor is missing steps when trying to make small adjustments.

In general, the steps/mm setting for the X and Y axis that the controller came pre-programmed with seems to be dead on. The rectangle is supposed to be, and indeed is 50mm by 100mm. The circles are nicely circular, and the size for the voids closely matches the size of the plugs. There's a mismatch of about a half mm, which I can deem acceptable for a first print. this is closer than I was ever able to get my i3 clone to manage, even before it started being unable to deal with circles. The steps/mm for the extruder was under-extruding by about 4%. This SHOULDN'T be critical, but I did change that from the LCD, where I can access the parameters. I am not sure how to change the firmware for this printer, as it's not the same idea of having an arduino and needing to upload a sketch in quite the same way as my i3 was. For the i3, I could do whatever I wanted, and not just setting the parameters that the UI directly allows. there are certainly a couple of parameters that I'd like to be able to change that the UI doesn't allow, like having a max temp of the hotend at 245. Anything more than that and the printer shuts down, even if it's just momentary, so I can't set the extrude temp above about 230. (Pre-programmed ABS preheat to 240 often triggers max temp/shutdown, which is super annoying.) Well, I suppose that I don't want it any hotter than that if the hotend uses PTFE in its makeup. I could run nylon with an extrude temp of 260 in my i3. The firmware is Marlin (1.1.0, I think, it displays for a moment on power up)

For the mess that the printer made starting from the 0.75mm layer, I think that I can blame the Z axis. There seems to be some under extrusion, but that can be blamed on inadequate clearance between nozzle and print surface. At this point, I still can't make a full decision on the final print quality.

There's only one acceleration setting that I can get to without computer access to the firmware. The UI allows you to set it, as well as some max settings for movement.

I don't mind the Z axis being slow, as that's not a major factor in print times, but I'd rather that the X and Y axis can move fairly quickly, so I don't want to set the acceleration to low, and it seems to be fine for handling X/Y moves with default settings. Can I set those parameters in Slic3r? It seems to me that I had to slow down the Z axis on my i3 as well, because it would de-sync the pair of Z motors, but I had access to the firmware more directly for that one.

Anyway, it'd be nice to get the troubleshooting portion of this over with, so that I can start using the printer.

I took time to really solidly level the bed. I locked the platform in place so that there could be no interference from the firmware, and adjusted the mounting screws so that the print head will drag a sheet of printer paper around. Carefully set the offset as per the instructions that came with the printer. First sign, it seems to wander. The print head itself can't do that, and the probe is solidly mounted, so it should not, but it appears to do so. I can repeat the same process, and sometimes I get about ~1.5mm, and it can be up to 1.9mm. It is not dependent on t e X/Y coordinates, it's the same everywhere.

I'm not hearing anything from the Z motors that sounds like missed steps, but I suspect that this is a problem. Not 100% sure though.

One of the problems is that I can set the offset, and when I move the printer to it's "0" Z position, it looks right, but at the start of the Gcode print routine, it's supposed to be at 0.2-0.25mm, and there's a clear gap between print head and bed that looks to be over 1mm. This happens when the print bed rises up from a Z of ~5mm.

After wasting all of my blue tape (Didn't have much left) I did a quick and dirty job with cheap dollar store painter's tape, and then manually adjusted the Z axis, and got a print started. Obviously, this is sub-optimal, but since the steps/mm setting seemed appropriate. Mathematically, it's perfect, and it seems reasonable. for fairly large values where the Z axis is set. I had hoped that once the print was started that it would run normally. Oops. The result was as is in the picture there.

At the end of the print, the LCD reports Z=2, but there's maybe a bit more than 1mm between the print head and the bed, and it's been doing terrible things to the print job. The skirt is uneven because that's where I was messing with getting the starting Z height where I wanted it.

So given that once moving the Z axis moves at very close (error <1%) to the expected distance, it seems that the error is much larger for small moves. I'd think that this would be an acceleration or jerk setting somewhere, that it's too high, and the motor is missing steps when trying to make small adjustments.

In general, the steps/mm setting for the X and Y axis that the controller came pre-programmed with seems to be dead on. The rectangle is supposed to be, and indeed is 50mm by 100mm. The circles are nicely circular, and the size for the voids closely matches the size of the plugs. There's a mismatch of about a half mm, which I can deem acceptable for a first print. this is closer than I was ever able to get my i3 clone to manage, even before it started being unable to deal with circles. The steps/mm for the extruder was under-extruding by about 4%. This SHOULDN'T be critical, but I did change that from the LCD, where I can access the parameters. I am not sure how to change the firmware for this printer, as it's not the same idea of having an arduino and needing to upload a sketch in quite the same way as my i3 was. For the i3, I could do whatever I wanted, and not just setting the parameters that the UI directly allows. there are certainly a couple of parameters that I'd like to be able to change that the UI doesn't allow, like having a max temp of the hotend at 245. Anything more than that and the printer shuts down, even if it's just momentary, so I can't set the extrude temp above about 230. (Pre-programmed ABS preheat to 240 often triggers max temp/shutdown, which is super annoying.) Well, I suppose that I don't want it any hotter than that if the hotend uses PTFE in its makeup. I could run nylon with an extrude temp of 260 in my i3. The firmware is Marlin (1.1.0, I think, it displays for a moment on power up)

For the mess that the printer made starting from the 0.75mm layer, I think that I can blame the Z axis. There seems to be some under extrusion, but that can be blamed on inadequate clearance between nozzle and print surface. At this point, I still can't make a full decision on the final print quality.

There's only one acceleration setting that I can get to without computer access to the firmware. The UI allows you to set it, as well as some max settings for movement.

I don't mind the Z axis being slow, as that's not a major factor in print times, but I'd rather that the X and Y axis can move fairly quickly, so I don't want to set the acceleration to low, and it seems to be fine for handling X/Y moves with default settings. Can I set those parameters in Slic3r? It seems to me that I had to slow down the Z axis on my i3 as well, because it would de-sync the pair of Z motors, but I had access to the firmware more directly for that one.

Anyway, it'd be nice to get the troubleshooting portion of this over with, so that I can start using the printer.

|

Re: Another kit, another set of problems. December 20, 2017 02:15PM |

Registered: 7 years ago Posts: 558 |

Quote

SupraGuy

Anyway, it'd be nice to get the troubleshooting portion of this over with, so that I can start using the printer.

I hate to be the bearer of bad news, but if you truly wanted a printer to take out of a box and use, a kit was the wrong thing to get. Its also one of those things you get what you pay for.

I spent $350 on a kit to start with, but after realizing it's limitations, I've probably spend upwards of $1000 on it on upgrades to get it to a functional machine with very little trouble. And over the course of my upgrades with excess parts (because amazon wouldn't let me only buy 2 bearing I got 30), I ended up building 3 additional machines that I also upgraded with 32bit controllers. And based on my own experience, when my company wanted to invest in a 3D printer we started with a budget of nothing less than $10,000 to make sure we got a machine that didn't have to be upgraded to become a solid unit.

|

Re: Another kit, another set of problems. December 20, 2017 02:25PM |

Registered: 8 years ago Posts: 1,671 |

Is it me or does this bed look Wonky

Maybe your beds bouncing.

Maybe your beds bouncing.

|

Re: Another kit, another set of problems. December 20, 2017 06:57PM |

Registered: 9 years ago Posts: 978 |

Quote

SupraGuy

Carefully set the offset as per the instructions that came with the printer. First sign, it seems to wander. The print head itself can't do that, and the probe is solidly mounted, so it should not, but it appears to do so. I can repeat the same process, and sometimes I get about ~1.5mm, and it can be up to 1.9mm. It is not dependent on t e X/Y coordinates, it's the same everywhere.

So given that once moving the Z axis moves at very close (error <1%) to the expected distance, it seems that the error is much larger for small moves. I'd think that this would be an acceleration or jerk setting somewhere, that it's too high, and the motor is missing steps when trying to make small adjustments.

My thinking is that the height that your Z sensor trips at is variable. Maybe you can slow down the speed at which it moves towards the bed whilst probing? But it could be that your physical presence changes the electrical fields and such-like, so that your proximity to the sensor changes the height? As I said, I don't trust those things. Have you tried printing without using the Z probe at all?

|

Re: Another kit, another set of problems. December 21, 2017 10:35AM |

Registered: 9 years ago Posts: 465 |

@PDBeal: Obviously I'm not averse to doing a bit of tweaking. It is also worth noting that this printer is a part of what is supposed to be a solution to getting the old one to be a more solid platform. Still, there's a difference between debugging/troubleshooting and tweaking. I'd like to be done with the first portion to the point where I get useable printing done, which will continue to be able to use some tweaking.

@MechaBits: Yeah, those pictures are terrible. There could be more stability to the bed platform, but in general it's not bad.

@frankvdh: The probe in this case is a microswitch, same as the endstops, so my presence or absence has nothing to do with it.

I ran another few sets, and I believe that I have that issue straightened out. Still don't have any good prints, but I have some answers.

I thought that the extruder was underfeeding, so I bumped that up, but that was actually wrong. Should have left that alone until I solved the Z axis problem first. Well, I know better, but sometimes I get ahead of myself.

I ran through a taller print, and went to eat dinner and watch a movie while it ran. When the print finished, the display was reading Z=20, and there was what I will only describe as a mess on the bed, with the print head still only about a mm or so away. I went to the "move Z axis" control and set it to 100mm, at which point it moved smoothly. To about 100mm Z height. Sending it to 200mm height, and it was about right. Send it back to 0 and the print nozzle is a sheet of paper away from the bed. At no point has the Z probe touched anything. This means that the printer really does know where it actually is, even though it was obviously wrong about the Z height while printing. So it seems to be a matter of degree. If I change the Z height by a larger number, say 1mm or more, it moves, but when under GCode control moving in very small increments, of 0.3mm or less, it moves much less or not at all.

I tried again, with the print speed slowed down. No good. Even at 40% speed, the results are the same, they just take longer to get.

So I started looking through the parameters. Acceleration for X and Y was set to 2000, but for Z it was set really low, at 100. I bumped it up to 1000, and now it works, but since I had messed with the E steps/mm, now I have some over-extrusion problems, but I can fix those.

So it looks like the big problems are done, and now I can use the printer. Time to start tweaking, then I can use it to rebuild the old printer.

Even with the over-extrusion, this printer is showing accuracy better than I ever got from the old one.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

@MechaBits: Yeah, those pictures are terrible. There could be more stability to the bed platform, but in general it's not bad.

@frankvdh: The probe in this case is a microswitch, same as the endstops, so my presence or absence has nothing to do with it.

I ran another few sets, and I believe that I have that issue straightened out. Still don't have any good prints, but I have some answers.

I thought that the extruder was underfeeding, so I bumped that up, but that was actually wrong. Should have left that alone until I solved the Z axis problem first. Well, I know better, but sometimes I get ahead of myself.

I ran through a taller print, and went to eat dinner and watch a movie while it ran. When the print finished, the display was reading Z=20, and there was what I will only describe as a mess on the bed, with the print head still only about a mm or so away. I went to the "move Z axis" control and set it to 100mm, at which point it moved smoothly. To about 100mm Z height. Sending it to 200mm height, and it was about right. Send it back to 0 and the print nozzle is a sheet of paper away from the bed. At no point has the Z probe touched anything. This means that the printer really does know where it actually is, even though it was obviously wrong about the Z height while printing. So it seems to be a matter of degree. If I change the Z height by a larger number, say 1mm or more, it moves, but when under GCode control moving in very small increments, of 0.3mm or less, it moves much less or not at all.

I tried again, with the print speed slowed down. No good. Even at 40% speed, the results are the same, they just take longer to get.

So I started looking through the parameters. Acceleration for X and Y was set to 2000, but for Z it was set really low, at 100. I bumped it up to 1000, and now it works, but since I had messed with the E steps/mm, now I have some over-extrusion problems, but I can fix those.

So it looks like the big problems are done, and now I can use the printer. Time to start tweaking, then I can use it to rebuild the old printer.

Even with the over-extrusion, this printer is showing accuracy better than I ever got from the old one.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Another kit, another set of problems. December 21, 2017 08:05PM |

Registered: 7 years ago Posts: 507 |

Sorry, only registered users may post in this forum.