Help with design for 2nd printer

Posted by Phuzzy112

|

Help with design for 2nd printer February 03, 2018 12:30AM |

Registered: 6 years ago Posts: 3 |

Hi All,

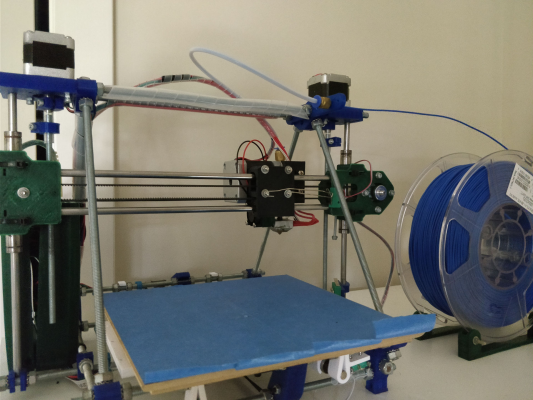

I have had a long-standing love for the idea of 3D printing, but never had the money, time, or access to materials to build one. Until a few months ago, all I had was a dream that one day I would build my very own Huxley.

Well...

So ... yea...

Except for the print bed made from MDF and painters tape, the slightly damaged M5 Z-screws and the massive wobble ghosting I get from the giant block of BPS v2 that I have bolted to the thing, the only big problem I have with this printer is the 150x120x50 print envelope.

Nah... who am I kidding? I love this little thing You can tell from the print colors that demonstrate its multiple generations of "upgrades".

You can tell from the print colors that demonstrate its multiple generations of "upgrades".

But seriously... 150x120x50 is ridiculous. I need something bigger. This is where you all come in: I have so many ideas in my head, but no real ideas how to tie them all together, or even if they belong together.

So here goes:

1.) I am looking to build something that fits inside a extrusion frame no bigger than 500x500x500.

2.) I have no access to a machine shop of any kind, and very few hand tools for metalworking. I would prefer printed parts (if viable) or simple metal parts where applicable. However...

3.) I am not comfortable with a mostly printed printer. I have seen how much PLA flexes in the links on my Huxley and think its just a bad idea to print supports for a printer. I might be OK doing some ABS, but...

4.) This new printer will live in a cupboard in my study, so I will not be printint anything exotic or high-temperature. I considered engineering it for ABS printing, but I am now thinking that I might not be able to do more than a few very simple ABS prints to start with. I think if I do things right, I might be able to print some basic parts in PLA to get running, then print ABS replacements later on... maybe....

5.) I cannot CAD. Pretty much at all. I do want to change this though, so would like whatever printer I end up with to be able to spit out plastic pretty rapidly. Fast printing means less time from screen to print and therefore more design time.

That said, I am torn between a design modeled on the Voron, or the German RepRap X400.

Opinions?

I know and understand Cartesian printers, but it seems CoreXY is the way to go if you want something fast. Is this true? And does it make any difference if I use a Bowden or direct feed extruder?

I can work with smooth rods and linear bearings, but would like to do something with rails. Is it worth the cost?

I have had a long-standing love for the idea of 3D printing, but never had the money, time, or access to materials to build one. Until a few months ago, all I had was a dream that one day I would build my very own Huxley.

Well...

So ... yea...

Except for the print bed made from MDF and painters tape, the slightly damaged M5 Z-screws and the massive wobble ghosting I get from the giant block of BPS v2 that I have bolted to the thing, the only big problem I have with this printer is the 150x120x50 print envelope.

Nah... who am I kidding? I love this little thing

You can tell from the print colors that demonstrate its multiple generations of "upgrades".

You can tell from the print colors that demonstrate its multiple generations of "upgrades". But seriously... 150x120x50 is ridiculous. I need something bigger. This is where you all come in: I have so many ideas in my head, but no real ideas how to tie them all together, or even if they belong together.

So here goes:

1.) I am looking to build something that fits inside a extrusion frame no bigger than 500x500x500.

2.) I have no access to a machine shop of any kind, and very few hand tools for metalworking. I would prefer printed parts (if viable) or simple metal parts where applicable. However...

3.) I am not comfortable with a mostly printed printer. I have seen how much PLA flexes in the links on my Huxley and think its just a bad idea to print supports for a printer. I might be OK doing some ABS, but...

4.) This new printer will live in a cupboard in my study, so I will not be printint anything exotic or high-temperature. I considered engineering it for ABS printing, but I am now thinking that I might not be able to do more than a few very simple ABS prints to start with. I think if I do things right, I might be able to print some basic parts in PLA to get running, then print ABS replacements later on... maybe....

5.) I cannot CAD. Pretty much at all. I do want to change this though, so would like whatever printer I end up with to be able to spit out plastic pretty rapidly. Fast printing means less time from screen to print and therefore more design time.

That said, I am torn between a design modeled on the Voron, or the German RepRap X400.

Opinions?

I know and understand Cartesian printers, but it seems CoreXY is the way to go if you want something fast. Is this true? And does it make any difference if I use a Bowden or direct feed extruder?

I can work with smooth rods and linear bearings, but would like to do something with rails. Is it worth the cost?

|

Re: Help with design for 2nd printer February 03, 2018 04:34AM |

Registered: 12 years ago Posts: 799 |

Quote

Phuzzy112

I know and understand Cartesian printers, but it seems CoreXY is the way to go if you want something fast. Is this true? And does it make any difference if I use a Bowden or direct feed extruder?

Core X/Y can go fast, but if you want to go faster Ultimaker typ X/Y is your choice.

It has the most lightest granty and more important, both axes do have the same weight.

Weight in general is a critical factor to printing fast, therefore when printing fast a Bowden is good, but does not come with some down sides.

A direct extruder can extrude more precisely, if you want to print filigrane and small parts a direct extruder is better (and as light as possible).

If you have to print more larger parts, than a bowden is also a good choice.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

|

Re: Help with design for 2nd printer February 03, 2018 08:50AM |

Registered: 7 years ago Posts: 507 |

1)That's not a small envelope, you shouldn't have trouble fitting a decent sized printer in there (350-400mm in each axis depending on how much you try and squeeze things, though how often you'll use such a large volume is questionable, especially if you want fast prints)

2)Printed parts are sturdy enough for most applications as long as you design them big and bulky enough. Geometry plays a big part in how stiff and strong a part is and you can do a lot more with the geometry of a 3d printed part than, let's say, a sheet metal bracket. With no machine shop and limited tools (hacksaw and a drill?) you'll have trouble making accurate metal parts for your machine, you'll likely be better off printing parts.

3)If you think PLA is flexible, you'll be disappointed to find out ABS is not more rigid than PLA. PLA is actually one of the more rigid plastics we print with. Want it stiffer? Make it thicker.

4)?

5)Well, if you want to design your own printer, this is a problem. Also, if you want to use it for prototyping as you say, it's probably going to be an issue. There are lots of free programs out there for CAD with tutorials to go with them. Fusion 360 has gotten pretty popular since autodesk released a free version, FreeCAD is an open source alternative but most discussion I've seen around it (the discussions are quite old) state it's a bit buggy and crash prone. I haven't used it long enough to encounter the bugs and crashes, but I have run into the other criticism it faces, it's not very intuitive and it's a jack of all trades, master of none. It can do a fair bit more beyond mechanical CAD, but that makes it more confusing (and cluttered) for those not interested in those features. OpenSCAD is a script based modeler, I quite like it but it's not for everyone. Solvespace is another open source GUI based CAD program, it's not exactly fully featured but it's dead simple to pick up and learn. There is OnShape which is cloud based, too. All of these have a number of guides and tutorials online, but I personally like to learn a program by designing a part in it. It forces me to learn the learn the basics and makes me use them, and I can pick up on the extras and peripherals as I go along and need them rather than in one giant dump.

If you want to go fast, I'd say go for a bowden extruder. No printer likes hurling around a heavy extruder at speed, and a lighter bowden setup is much easier on the mechanics. Other than that, go for something with minimal moving mass (i.e. stationary motors) like CoreXY, or the crossed axis design the ultimaker uses. CoreXY has slightly simpler mechanical construction imo, but I personally don't like that the axis are coupled together. The crossed axis gantry has one translating rod (if you use linear rods) for a moving axis, whereas a coreXY would need two moving x rods. The crossed axis motion system does have to rotate at least on of the perimeter rods per axis though, so because of this I don't know if it ends up with less moving mass overall. You can avoid rotating the perimeter rods at the expense of longer belt paths, so there's that if you really want minimal moving mass. The extra belt stretch you'd get can be negated with slightly wider belts. I personally think the weight of the effector will matter more than the nitty gritty of whether coreXY or crossed axis gantries have less moving mass.

2)Printed parts are sturdy enough for most applications as long as you design them big and bulky enough. Geometry plays a big part in how stiff and strong a part is and you can do a lot more with the geometry of a 3d printed part than, let's say, a sheet metal bracket. With no machine shop and limited tools (hacksaw and a drill?) you'll have trouble making accurate metal parts for your machine, you'll likely be better off printing parts.

3)If you think PLA is flexible, you'll be disappointed to find out ABS is not more rigid than PLA. PLA is actually one of the more rigid plastics we print with. Want it stiffer? Make it thicker.

4)?

5)Well, if you want to design your own printer, this is a problem. Also, if you want to use it for prototyping as you say, it's probably going to be an issue. There are lots of free programs out there for CAD with tutorials to go with them. Fusion 360 has gotten pretty popular since autodesk released a free version, FreeCAD is an open source alternative but most discussion I've seen around it (the discussions are quite old) state it's a bit buggy and crash prone. I haven't used it long enough to encounter the bugs and crashes, but I have run into the other criticism it faces, it's not very intuitive and it's a jack of all trades, master of none. It can do a fair bit more beyond mechanical CAD, but that makes it more confusing (and cluttered) for those not interested in those features. OpenSCAD is a script based modeler, I quite like it but it's not for everyone. Solvespace is another open source GUI based CAD program, it's not exactly fully featured but it's dead simple to pick up and learn. There is OnShape which is cloud based, too. All of these have a number of guides and tutorials online, but I personally like to learn a program by designing a part in it. It forces me to learn the learn the basics and makes me use them, and I can pick up on the extras and peripherals as I go along and need them rather than in one giant dump.

If you want to go fast, I'd say go for a bowden extruder. No printer likes hurling around a heavy extruder at speed, and a lighter bowden setup is much easier on the mechanics. Other than that, go for something with minimal moving mass (i.e. stationary motors) like CoreXY, or the crossed axis design the ultimaker uses. CoreXY has slightly simpler mechanical construction imo, but I personally don't like that the axis are coupled together. The crossed axis gantry has one translating rod (if you use linear rods) for a moving axis, whereas a coreXY would need two moving x rods. The crossed axis motion system does have to rotate at least on of the perimeter rods per axis though, so because of this I don't know if it ends up with less moving mass overall. You can avoid rotating the perimeter rods at the expense of longer belt paths, so there's that if you really want minimal moving mass. The extra belt stretch you'd get can be negated with slightly wider belts. I personally think the weight of the effector will matter more than the nitty gritty of whether coreXY or crossed axis gantries have less moving mass.

|

Re: Help with design for 2nd printer February 03, 2018 04:40PM |

Registered: 9 years ago Posts: 294 |

I built a coreXY, CBOT, designed by Carl Fenick and posted on openbuilds.

I was also looking to replace a 2up, which was a piece of garbage that I had somehow figured out how to modify it well enough to print parts for a new printer.

I stumbled upon Carl's design and immediately fill in love with it. Apparently, so did a lot of other people as shown by the size of his forum. He has moved it to Google+ and Alan posted a design mod similar to mine using 3 screws - called a Triplebot. It had been adapted to direct drive but mine is the original Bowden. I am in the process of updating to a AL bed, full heater and Piezo bed leveler. Carl's design is very stable and scalable. Just change the size of the rails, Which is the most expensive item and probably still only available from Openbuilds.

The only thing I changed was the cantilevered platform to a 3 screw design, and I shrunk the width by 2". I also have the front where his back is so the motors are in the rear.

May mods to the plastic exist, but IMHO they are way overkill. I changed the bottom corner supports to my own i piece design, which I posted, but there is one version that must use a whole roll of plastic. TOO MUCH. Mine is extremely solid with Carl's original parts. It shakes the table, but nothing internal flexes. My version measures 430mm deep, 530mm wide, 560mm high for a 305x305x305 build. Motors hang out the back about an additional 50mm and the bouden tube clears approx. another 200mm.

Check it out.

I was also looking to replace a 2up, which was a piece of garbage that I had somehow figured out how to modify it well enough to print parts for a new printer.

I stumbled upon Carl's design and immediately fill in love with it. Apparently, so did a lot of other people as shown by the size of his forum. He has moved it to Google+ and Alan posted a design mod similar to mine using 3 screws - called a Triplebot. It had been adapted to direct drive but mine is the original Bowden. I am in the process of updating to a AL bed, full heater and Piezo bed leveler. Carl's design is very stable and scalable. Just change the size of the rails, Which is the most expensive item and probably still only available from Openbuilds.

The only thing I changed was the cantilevered platform to a 3 screw design, and I shrunk the width by 2". I also have the front where his back is so the motors are in the rear.

May mods to the plastic exist, but IMHO they are way overkill. I changed the bottom corner supports to my own i piece design, which I posted, but there is one version that must use a whole roll of plastic. TOO MUCH. Mine is extremely solid with Carl's original parts. It shakes the table, but nothing internal flexes. My version measures 430mm deep, 530mm wide, 560mm high for a 305x305x305 build. Motors hang out the back about an additional 50mm and the bouden tube clears approx. another 200mm.

Check it out.

|

Re: Help with design for 2nd printer February 03, 2018 05:06PM |

Registered: 10 years ago Posts: 14,672 |

Have you considered building a Delta printer? Depending on how much height you have in your cupboard and how much print area you really need, it might be a good option. A build area of 300mm diameter is relatively straightforward, and 400mm wouldn't be difficult.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help with design for 2nd printer February 03, 2018 07:54PM |

Registered: 6 years ago Posts: 3 |

Thanks for the feedback everyone!

I actually really like the crossed X/Y thing that Ultimaker does, but I initially discounted it as a gimmick that just makes lots of noise (I know some people who spend lots of time around Ultimakers that complain about the noise pretty much every time they are brought up in discussion). If they are worth it, I might just do that then. Can anyone recommend a build?

Yup, thought as much, but wanted to be sure. Also, thanks for the CAD advice!

Wait, so it looks like the C-bot became the D-bot?

I did look at the D-bot back when I started getting interested in doing a Core-XY build, but I found many places saying I should rather be looking at the Voron due to its documentation. I think I should have a closer look now that you pointed out the OpenBuilds links.

Yea, for a little while. I do technically have the space for it if I move some things around. I guess I am just not sold on how well they would do with small prints and dual colors. Its also another case where I know and understand X and Y planes and the Delta idea is just completely different. The Core-XY i can still kind of wrap my head around, but Delta is a massive jump for me. Don't get me wrong, I would like to do one one day so that I can learn more about them, but I am not sure today is that day.

Regarding the overall size and the print envelope: I am really hoping to one day be able to print random props like a Mjolnir, Fallout Laser Rifle or a Space Marine Heavy Boltor. This means more print space is good in my mind. I can offset the long print times by obtaining a 1.0 nozzle

Quote

Chri

Core X/Y can go fast, but if you want to go faster Ultimaker typ X/Y is your choice.

I actually really like the crossed X/Y thing that Ultimaker does, but I initially discounted it as a gimmick that just makes lots of noise (I know some people who spend lots of time around Ultimakers that complain about the noise pretty much every time they are brought up in discussion). If they are worth it, I might just do that then. Can anyone recommend a build?

Quote

Trakyan

With no machine shop and limited tools (hacksaw and a drill?) you'll have trouble making accurate metal parts for your machine, you'll likely be better off printing parts.

Yup, thought as much, but wanted to be sure. Also, thanks for the CAD advice!

Quote

ruggb

I built a coreXY, CBOT, designed by Carl Fenick and posted on openbuilds.

Wait, so it looks like the C-bot became the D-bot?

I did look at the D-bot back when I started getting interested in doing a Core-XY build, but I found many places saying I should rather be looking at the Voron due to its documentation. I think I should have a closer look now that you pointed out the OpenBuilds links.

Quote

dc42

Have you considered building a Delta printer?

Yea, for a little while. I do technically have the space for it if I move some things around. I guess I am just not sold on how well they would do with small prints and dual colors. Its also another case where I know and understand X and Y planes and the Delta idea is just completely different. The Core-XY i can still kind of wrap my head around, but Delta is a massive jump for me. Don't get me wrong, I would like to do one one day so that I can learn more about them, but I am not sure today is that day.

Regarding the overall size and the print envelope: I am really hoping to one day be able to print random props like a Mjolnir, Fallout Laser Rifle or a Space Marine Heavy Boltor. This means more print space is good in my mind. I can offset the long print times by obtaining a 1.0 nozzle

|

Re: Help with design for 2nd printer February 04, 2018 02:18AM |

Registered: 7 years ago Posts: 507 |

They'll still take quite a whilee even with a big nozzle. As for the ultimaker, I imagine it would be quieter since it uses bushings rather than linear bearings. There are some community builds based on the ultimaker lile the eustathios. I think the ultimakers use drv stepper drivers which are probably the source of the noise complaints, you wont have that issue if you just use different stepper drivers. Drv drivers have a couple of issues with lost microsteps and stepper whine. I can't think of any noise issues that would be coming from the motion system.

|

Re: Help with design for 2nd printer February 04, 2018 02:21AM |

Registered: 10 years ago Posts: 14,672 |

Small prints are just fine on deltas, but dual extrusion is tricky.

If you are looking to do dual colour prints, consider using either a Diamond hot end, or dual independent X carriages.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If you are looking to do dual colour prints, consider using either a Diamond hot end, or dual independent X carriages.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Help with design for 2nd printer February 04, 2018 11:00AM |

Registered: 9 years ago Posts: 294 |

|

Re: Help with design for 2nd printer February 04, 2018 11:12AM |

Registered: 9 years ago Posts: 294 |

the variations of the CBOT are the TripleBOT (like mine, but my belt config is better), and the DBOT. I think some parts of the DBOT are a little overkill. There are also modded parts that can be used on any, but again, things like those huge bottom braces are really way over the top. All of the docs you need are posted on Openbuilds. Because there are so many pages Carl moved it to Google+, which makes individual threads of topics, which I guess is good and bad.

Since I shrunk my width, I modeled the whole think in Sketchup to make sure everything fit and worked properly. My source for the steppers is listed in the Openbuilds forum - search for my posts (ruggb). Also the bottom corners I created. I think there is also a warning about the lead screws from Openbuilds that I posted. I managed to cut mine in 1/3 sections and everything fit, but my bottom brackets are different, otherwise one 1M screw would not be long enough.

Since I shrunk my width, I modeled the whole think in Sketchup to make sure everything fit and worked properly. My source for the steppers is listed in the Openbuilds forum - search for my posts (ruggb). Also the bottom corners I created. I think there is also a warning about the lead screws from Openbuilds that I posted. I managed to cut mine in 1/3 sections and everything fit, but my bottom brackets are different, otherwise one 1M screw would not be long enough.

|

Re: Help with design for 2nd printer February 04, 2018 08:07PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Help with design for 2nd printer February 05, 2018 05:56AM |

Registered: 6 years ago Posts: 3 |

Thanks again for the advice everyone! It has really helped.

So after a good few hours of checking and re-checking designs and looking over a few more, I have settled on building a D-bot. I chose it because its based on a pretty solid 2040 chassis design that I think will last very well. The way the Core-XY movement is attached to the chassis also makes me think I should be able to fit the Ultimaker style or classic X-Y movements if I wanted to later on. It is extremely well documented too - the build manual is more comprehensive than most other printers I have seen.

The Triple-C-Bot three screw bed is perfect, and I really would like to be able to combine it with the D-bot. After reading its build thread, I also think I will be going directly for PETG for the chassis prints.

For the business end, I am looking at a E3D legends pack so that I can try the Chimera and Cyclops for multi-color printing, probably fed via Titans over bowden. Control will be a Duet, because Bed levelling using multiple independent Z motors is just an amazing and idea and something I really need in my life.

I will put some photos up somewhere if anyone is interested

So after a good few hours of checking and re-checking designs and looking over a few more, I have settled on building a D-bot. I chose it because its based on a pretty solid 2040 chassis design that I think will last very well. The way the Core-XY movement is attached to the chassis also makes me think I should be able to fit the Ultimaker style or classic X-Y movements if I wanted to later on. It is extremely well documented too - the build manual is more comprehensive than most other printers I have seen.

The Triple-C-Bot three screw bed is perfect, and I really would like to be able to combine it with the D-bot. After reading its build thread, I also think I will be going directly for PETG for the chassis prints.

For the business end, I am looking at a E3D legends pack so that I can try the Chimera and Cyclops for multi-color printing, probably fed via Titans over bowden. Control will be a Duet, because Bed levelling using multiple independent Z motors is just an amazing and idea and something I really need in my life.

I will put some photos up somewhere if anyone is interested

Sorry, only registered users may post in this forum.