What Do People Want In A CNC?

Posted by Trakyan

|

What Do People Want In A CNC? February 26, 2018 04:28PM |

Registered: 7 years ago Posts: 507 |

I'm doing a university project at the moment, the first part is some "market research" or just to find out what people want.

I'm looking to make a CNC platform, mostly intended for routing/milling. It'll be something like the MPCNC, but with a more liberal license and freedom to use the source files. I'm looking to improve rigidity, make a few design simplifications and get rid of some unnecessary parts (i.e. single motor per axis). Since I can't make a competitive, high end machine, I'm aiming for low cost introductory machines.

If you've got a CNC, or you want a precision machine for metalworking, this is not for you, I'll be straightforward. I'm looking at people who want to get into CNC but have a very strict budget, several thousand dollar machines or even machines like the x-carve and shapeoko are too expensive. 3d Printers really spiked in popularity after machine costs fell into the several hundreds, not several thousands, even if quality wasn't completely spectacular at the time. I'm looking to do something similar for CNC.

Any thoughts or feedback? Anyone in the "want to get into CNC but have a small wallet" boat?

EDIT: Mods, if this is inappropriate for the forum or in the wrong place, please delete.

Edited 1 time(s). Last edit at 02/26/2018 04:49PM by Trakyan.

I'm looking to make a CNC platform, mostly intended for routing/milling. It'll be something like the MPCNC, but with a more liberal license and freedom to use the source files. I'm looking to improve rigidity, make a few design simplifications and get rid of some unnecessary parts (i.e. single motor per axis). Since I can't make a competitive, high end machine, I'm aiming for low cost introductory machines.

If you've got a CNC, or you want a precision machine for metalworking, this is not for you, I'll be straightforward. I'm looking at people who want to get into CNC but have a very strict budget, several thousand dollar machines or even machines like the x-carve and shapeoko are too expensive. 3d Printers really spiked in popularity after machine costs fell into the several hundreds, not several thousands, even if quality wasn't completely spectacular at the time. I'm looking to do something similar for CNC.

Any thoughts or feedback? Anyone in the "want to get into CNC but have a small wallet" boat?

EDIT: Mods, if this is inappropriate for the forum or in the wrong place, please delete.

Edited 1 time(s). Last edit at 02/26/2018 04:49PM by Trakyan.

|

Re: What Do People Want In A CNC? February 26, 2018 05:43PM |

Registered: 9 years ago Posts: 465 |

Well, Amazon.ca has some small CNC mills in the $400 CAD range. I guess that puts them in under the $300 USD range.

These seem to be reasonably decent little machines, cast aluminum chassis so rigidity is unlikely to be a problem for the smallish projects (175mm X 175mm) that they're made for. These are likely to be very good at small sized projects, PCB milling or other tasks that people want a small cheapish CNC mill to do. I'm considering buying one, because it can do the small precision parts that would allow a larger version to be built.

Why I haven't bought one:

1. Size. 7" by 7" isn't enough to guarantee long term usefulness. Even 12" by 12" would do a lot to reassure me that I could use it for more useful projects, and as a guideline, I would use the ability to handle a 1 cubic foot subwoofer box as a guideline for "I'd definitely go for that." which means being able to cut a part that is 13.5" to a side. (allowing 0.75" each side for thickness of material to maintain a 12" interior dimension.) So allowing for 1/8" as a tool path, probably 14" of movement in the X and Y planes would be what I'd want.

2. Actually, that's about it. I don't have a problem with the price point, the tooling availability is okay, the height range is quite reasonable, and quality of machine seems good. The tool speed may be a bit slow, and it may not be able to cut full depth in one pass, but hey, I can wait for a 3D printer to make small stuff, this is hardly going to be worse.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

These seem to be reasonably decent little machines, cast aluminum chassis so rigidity is unlikely to be a problem for the smallish projects (175mm X 175mm) that they're made for. These are likely to be very good at small sized projects, PCB milling or other tasks that people want a small cheapish CNC mill to do. I'm considering buying one, because it can do the small precision parts that would allow a larger version to be built.

Why I haven't bought one:

1. Size. 7" by 7" isn't enough to guarantee long term usefulness. Even 12" by 12" would do a lot to reassure me that I could use it for more useful projects, and as a guideline, I would use the ability to handle a 1 cubic foot subwoofer box as a guideline for "I'd definitely go for that." which means being able to cut a part that is 13.5" to a side. (allowing 0.75" each side for thickness of material to maintain a 12" interior dimension.) So allowing for 1/8" as a tool path, probably 14" of movement in the X and Y planes would be what I'd want.

2. Actually, that's about it. I don't have a problem with the price point, the tooling availability is okay, the height range is quite reasonable, and quality of machine seems good. The tool speed may be a bit slow, and it may not be able to cut full depth in one pass, but hey, I can wait for a 3D printer to make small stuff, this is hardly going to be worse.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: What Do People Want In A CNC? February 26, 2018 06:26PM |

Registered: 7 years ago Posts: 507 |

Could you link one of them? I've seen some relatively cheap chinese CNC engravers in that price range, but they've used aluminium extrusions not cast aluminium. Another thing is that with these machines, it's not the rigidity of the frame/extrusions they use that's the bottleneck for rigidity, it's the relatively thin end supported rails. These are fine for printing and engraving but produce sub par milling results.

The machine I'm planning to build will be for larger scale routing/milling. The one I plan to build for myself will have upwards of a meter square cutting area. That being said, just like the MPCNC it'll just depend on the length of tubing you use.

EDIT: This is the sort of thing I think woodworkers would find useful. An easy way to cut out large and relatively complex shapes. I plan to use it for cutting out longboard decks, furniture panels, bike frames and bits and so on. Not so much for PCBs and the like.

Edited 1 time(s). Last edit at 02/26/2018 06:30PM by Trakyan.

The machine I'm planning to build will be for larger scale routing/milling. The one I plan to build for myself will have upwards of a meter square cutting area. That being said, just like the MPCNC it'll just depend on the length of tubing you use.

EDIT: This is the sort of thing I think woodworkers would find useful. An easy way to cut out large and relatively complex shapes. I plan to use it for cutting out longboard decks, furniture panels, bike frames and bits and so on. Not so much for PCBs and the like.

Edited 1 time(s). Last edit at 02/26/2018 06:30PM by Trakyan.

|

Re: What Do People Want In A CNC? February 26, 2018 08:41PM |

Registered: 7 years ago Posts: 249 |

|

Re: What Do People Want In A CNC? February 26, 2018 08:55PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: What Do People Want In A CNC? February 26, 2018 11:16PM |

Registered: 7 years ago Posts: 507 |

@Dust, I'm on the same boat there, I want to make sure it will CNC aluminium (albeit not at the same rate as a cast iron behemoth). Though this will mostly depend on the size and length of tubing used in the build. Large diameter, short tubes will make it more rigid and will increase it's milling capabilities. The MPCNC can mill aluminium so I don't see why my slightly bulked up design wouldn't manage.

@prot0typ1cal, That'll probably add a fair bit to the cost of any machine, and I can't think of a cheap way to do this. Feel free to point me in some direction you might like to see implemented.

EDIT: Personally, I've found collets to be one of the more user friendly options.

Edited 1 time(s). Last edit at 02/26/2018 11:18PM by Trakyan.

@prot0typ1cal, That'll probably add a fair bit to the cost of any machine, and I can't think of a cheap way to do this. Feel free to point me in some direction you might like to see implemented.

EDIT: Personally, I've found collets to be one of the more user friendly options.

Edited 1 time(s). Last edit at 02/26/2018 11:18PM by Trakyan.

|

Re: What Do People Want In A CNC? February 26, 2018 11:35PM |

Registered: 8 years ago Posts: 1,671 |

Have you built a Printer yet? I dont remember any pictures.

I want CNC, but I'd be happy with good manual mill or lath or combo for a while.

I'd like something like this for starters, as they are local, but the college bought from them and said they where Crap

couldnt get a decent finish, so it makes me wonder what finish would look like from something even cheaper.

Hopefully I will get the Cube Milling at some point, but i'd rather not spend another 500 quid to find out its crap.

SORRY GUYS THIS [PcAAOSww5Raetsm" target="_blank" rel="nofollow">www.ebay.co.uk]

forgot to add link

They also do a slightly bigger one (or better spec, cant remember) for 2k.

Best to get them to demo the unit to see if they can achieve decent results,

but you would think better than any profile framed machine.

Edited 3 time(s). Last edit at 02/27/2018 02:26AM by MechaBits.

I want CNC, but I'd be happy with good manual mill or lath or combo for a while.

I'd like something like this for starters, as they are local, but the college bought from them and said they where Crap

couldnt get a decent finish, so it makes me wonder what finish would look like from something even cheaper.

Hopefully I will get the Cube Milling at some point, but i'd rather not spend another 500 quid to find out its crap.

SORRY GUYS THIS [PcAAOSww5Raetsm" target="_blank" rel="nofollow">www.ebay.co.uk]

forgot to add link

They also do a slightly bigger one (or better spec, cant remember) for 2k.

Best to get them to demo the unit to see if they can achieve decent results,

but you would think better than any profile framed machine.

Edited 3 time(s). Last edit at 02/27/2018 02:26AM by MechaBits.

|

Re: What Do People Want In A CNC? February 27, 2018 01:04AM |

Registered: 9 years ago Posts: 483 |

This should give you all the specs you need

p.s. I built my CNC router for under $500 with most of that in the VFD and the spindle motor. I used 25mm unsupported rails for a usable build area 18"x15". The carriages were made by casting polyurethane around bushings. The frame is MDF with tensioning rods. The design is based on MicroCarve's work. I routinely do aluminum on it.

Edited 1 time(s). Last edit at 02/27/2018 01:14AM by etfrench.

p.s. I built my CNC router for under $500 with most of that in the VFD and the spindle motor. I used 25mm unsupported rails for a usable build area 18"x15". The carriages were made by casting polyurethane around bushings. The frame is MDF with tensioning rods. The design is based on MicroCarve's work. I routinely do aluminum on it.

Edited 1 time(s). Last edit at 02/27/2018 01:14AM by etfrench.

|

Re: What Do People Want In A CNC? February 27, 2018 01:57AM |

Registered: 8 years ago Posts: 1,671 |

do you get a nice finish on it?(did you do the suction table? that was good and didnt seem to be a mega machine) I dont mind a tool for roughing out shapes that dont need super precision and I wouldnt mind spending the extra time/passes needed to get a good finish or use of small tools.

Edited 2 time(s). Last edit at 02/27/2018 02:57AM by MechaBits.

Edited 2 time(s). Last edit at 02/27/2018 02:57AM by MechaBits.

|

Re: What Do People Want In A CNC? February 27, 2018 03:45AM |

Registered: 11 years ago Posts: 528 |

when it comes to small desktop I think Myfordboy on youtube nailed it and he pimped the hell out of his banggood offering, he got a whole series of vid of whats involved and a home metal shop to help... but if this is just for a learning exercise into the software involved in cnc operation then aint it a case competing with those small rigs like this which from all accounts just aint that good.

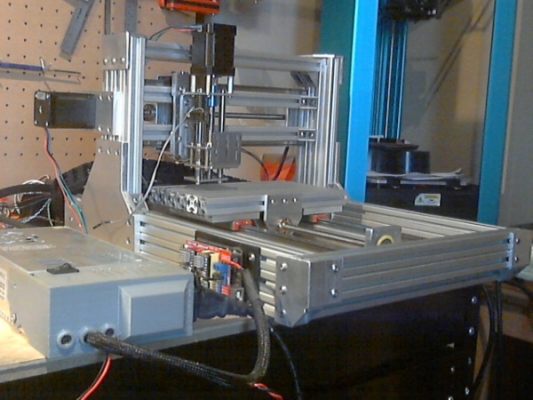

my play rig! for learning the software and grbl

am in the process of saving to swap out those mgn rails and building a stronger Z axis but its been fun

Edited 3 time(s). Last edit at 02/27/2018 04:01AM by jinx.

my play rig! for learning the software and grbl

am in the process of saving to swap out those mgn rails and building a stronger Z axis but its been fun

Edited 3 time(s). Last edit at 02/27/2018 04:01AM by jinx.

|

Re: What Do People Want In A CNC? February 27, 2018 05:01AM |

Registered: 6 years ago Posts: 1,007 |

First, please don't call that a CNC, there are just computer driven wood routers.

Here is a CNC: [www.youtube.com]

Edited 2 time(s). Last edit at 02/27/2018 05:10AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Here is a CNC: [www.youtube.com]

Edited 2 time(s). Last edit at 02/27/2018 05:10AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: What Do People Want In A CNC? February 27, 2018 05:18AM |

Registered: 11 years ago Posts: 528 |

computer driven routers?? aint that a box that connects a series of computers together with a connection to the web?Quote

MKSA

First, please don't call that a CNC, there are just computer driven routers

don't be such an angry IMP have some coffeeee

second I referred to my effort as a play thing, so no need to add words and my final goal is to CNC route circuit board, So it still be CNC,CNC,CNC as in wiki

how many of us gonna afford or even fit that Ytube link into our caves? or are you implying that only industry have the right to use the term CNC.

Edited 1 time(s). Last edit at 02/27/2018 05:25AM by jinx.

|

Re: What Do People Want In A CNC? February 27, 2018 05:47AM |

Admin Registered: 16 years ago Posts: 13,884 |

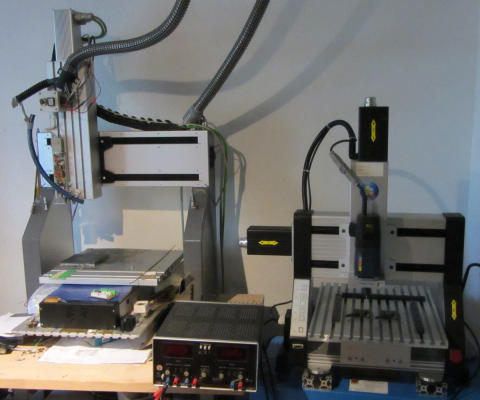

... this are two of my actual "medium sized CNC's":

Have and had other types and components too, but mostly focussed on high precision in the micron- to sub-micron range

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Have and had other types and components too, but mostly focussed on high precision in the micron- to sub-micron range

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: What Do People Want In A CNC? February 27, 2018 05:55AM |

Registered: 7 years ago Posts: 507 |

MKSA needs to look up what C(Computer)N(Numerical)C(Control) stands for. I'll admit I used the term incorrectly in my OP, but really it just means a machine which can move a tool head that is controlled via a computer, it says nothing of what that toolhead is. It could be a wood router, extruder or laser for all anyone cares. It's just there is an unspoken consensus that CNC is synonymous with a CNC Mill.

Besides, the machine I'm planning to build is going to be build on a budget. Currently looking at around $250 USD for a machine with around 1mx1m cutting area, and that's with a "fancy" controller board. Why so cheap? Because, looking at my wallet, the $1000 machine I had planned was well out of my price range :-). That machine in the video looks spectacular, but it's completely useless to me since I can't afford it and am no closer to having a machined part than if I asked the work piece really nicely to get itself in shape for me.

After all, the best tool for the job is the one you can afford.

Besides, the machine I'm planning to build is going to be build on a budget. Currently looking at around $250 USD for a machine with around 1mx1m cutting area, and that's with a "fancy" controller board. Why so cheap? Because, looking at my wallet, the $1000 machine I had planned was well out of my price range :-). That machine in the video looks spectacular, but it's completely useless to me since I can't afford it and am no closer to having a machined part than if I asked the work piece really nicely to get itself in shape for me.

After all, the best tool for the job is the one you can afford.

|

Re: What Do People Want In A CNC? February 27, 2018 05:59AM |

Registered: 11 years ago Posts: 528 |

|

Re: What Do People Want In A CNC? February 27, 2018 06:29AM |

Registered: 11 years ago Posts: 528 |

from what I've been reading your budget low for the size of machine you planning even with ali offering, its gonna get eaten on a good set of ball screws, nema 23 and a spindle " hope am wrong and good luck with the build"Quote

Trakyan

Currently looking at around $250 USD for a machine with around 1mx1m cutting area

|

Re: What Do People Want In A CNC? February 27, 2018 07:18AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Trakyan

MKSA needs to look up what C(Computer)N(Numerical)C(Control) stands for. I'll admit I used the term incorrectly in my OP, but really it just means a machine which can move a tool head that is controlled via a computer, it says nothing of what that toolhead is. It could be a wood router, extruder or laser for all anyone cares. It's just there is an unspoken consensus that CNC is synonymous with a CNC Mill.

Besides, the machine I'm planning to build is going to be build on a budget. Currently looking at around $250 USD for a machine with around 1mx1m cutting area, and that's with a "fancy" controller board. Why so cheap? Because, looking at my wallet, the $1000 machine I had planned was well out of my price range :-). That machine in the video looks spectacular, but it's completely useless to me since I can't afford it and am no closer to having a machined part than if I asked the work piece really nicely to get itself in shape for me.

After all, the best tool for the job is the one you can afford.

I perfectly know about these.

Just that by labeling these routers (like in wood routers, not the network router ! BTW, it happens I have worked with all of them

) it is misleading.

) it is misleading.Indeed, many believes they will be able with these flimsy machines to do real metal work which the first CNC were designed for.

And no, the best tool is the one that can do the job. Now, to be able to do the job with a good, low cost tool requires a lot of expertise. Do a search for metal scraping to see the miracle these guys can do with the simplest of tool. Quite useful to get a real flat print bed and cheap too

Better buy a used good stuff than cheap junk.

Junkyards are full of good stuff too.

Edited 1 time(s). Last edit at 02/27/2018 07:20AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: What Do People Want In A CNC? February 27, 2018 09:38AM |

Admin Registered: 16 years ago Posts: 13,884 |

Quote

jinx

VDX you got a build blog for them, like the small one on the right, " got a vid of it in action". while researching I realised I should have gone with a static bed rather than moving the job back and forth but used what I had in the scrap box!

... don't have a video of the smaller CNC - but here videos of some of my other machines "in action"

[vimeo.com]

[vimeo.com]

[vimeo.com]

[vimeo.com]

[vimeo.com]

[vimeo.com]

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: What Do People Want In A CNC? February 27, 2018 10:10AM |

Registered: 11 years ago Posts: 335 |

Quote

Trakyan

3d Printers really spiked in popularity after machine costs fell into the several hundreds, not several thousands, even if quality wasn't completely spectacular at the time. I'm looking to do something similar for CNC.

I respect the idea here, but the low-end CNC market has been around much longer than the consumer 3d printer market, and is constrained by basic physical requirements such as rigidity and mass.

Shapeoko and the like started with exactly that idea five years ago. You aren't reprap displacing six figure Stratasys machines, reprap is already here and the low hanging fruit has already been picked. The only remaining ways to dramatically reduce costs are through manufacturing and volume. Gluing together the cheapest set of parts you can buy off Aliexpress isn't going to revolutionize hobby CNC.

I spent some time playing with an lightweight design built from two layers of sheet metal separated by a viscoelastic gel several years ago, the reality is that you have to come up with really weird stuff to make even marginal gains in design. People have been building the basic machine tools for hundreds of years.

Don't get me wrong though, this can still be a great university project. I just wouldn't rack up credit card debt to finance the kickstarter.

|

Re: What Do People Want In A CNC? February 27, 2018 10:43AM |

Registered: 9 years ago Posts: 465 |

I used to hang around a lot in DIY places. DIY video projectors (I've built several) and some of the DIY CNC machines. There are some decent ones out there for reasonable costs. Usually what kills it for me is the cost of getting things shipped. I have several affordable designs around if I can ever bootstrap it to cut the parts.

Looked at the Amazon kit that I was thinking about: Amazon,ca

I guess it's cut plate, not cast, but it's not extrusion, either. It's also got a smaller working area than I had initially read.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

Looked at the Amazon kit that I was thinking about: Amazon,ca

I guess it's cut plate, not cast, but it's not extrusion, either. It's also got a smaller working area than I had initially read.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: What Do People Want In A CNC? February 27, 2018 02:28PM |

Registered: 7 years ago Posts: 507 |

|

Re: What Do People Want In A CNC? February 27, 2018 02:43PM |

Registered: 11 years ago Posts: 528 |

recall the same thing seeing a review with broken parts.Quote

Trakyan

From what I know, those are plastic plates, not aluminium. I saw a couple of video reviews and people said it's plastic, plus it cracked like plastic.

VDX that is some inspiring work there in the vids the Movtex-xy vid "thought that was quite ingenious method of travel on the Y axis would that hold up for a spindle?

Edited 1 time(s). Last edit at 02/27/2018 02:51PM by jinx.

|

Re: What Do People Want In A CNC? February 27, 2018 03:02PM |

Registered: 12 years ago Posts: 1,450 |

When most people use the term Milling they are thinking of cutting metal on a three axis machine, particularly where there is some depth in the Z direction. My own take on it is that real milling machines can be made at a low cost that will cut metal accurately but this can only be done with small size machines. I don't think that a 3 axis milling machine designed to work in the region of 100mm each in X, Y and Z need be particularly expensive as it could use beefier versions of parts from the 3D printer world like 12mm round bars and LM12UU linear bearings. Acme leadscrews could be used if the design allows for rapid replacement when they wear (as they will). The most significant things would be a decent spindle motor which could run up to 20,000RPM or maybe more and a decent way to lubricate the tools. Every doubling of the axis size means 8 times and the price will try to go up by this ammount or more - it even may be worthwhile looking at smaller sizes to reduce costs.

Is a 100mm cube a useful size? I think so as I have made very many parts in aluminium and brass, along with a few in steel on a Proxxon MF70 modified for CNC and this has a useable volume 44mm by 130mm by 100mm.

A passing thought is that some quite large milling machines were made with granite loaded epoxy for the frames as it gives a lot of mass and is almost as strong as cast iron.

Mike

Is a 100mm cube a useful size? I think so as I have made very many parts in aluminium and brass, along with a few in steel on a Proxxon MF70 modified for CNC and this has a useable volume 44mm by 130mm by 100mm.

A passing thought is that some quite large milling machines were made with granite loaded epoxy for the frames as it gives a lot of mass and is almost as strong as cast iron.

Mike

|

Re: What Do People Want In A CNC? February 27, 2018 05:05PM |

Admin Registered: 16 years ago Posts: 13,884 |

Quote

jinx

VDX that is some inspiring work there in the vids the Movtex-xy vid "thought that was quite ingenious method of travel on the Y axis would that hold up for a spindle?

... not stiff enough for "serious metal working", but more than enough for a high-speed sindle with millbits <3mm diameter for wood, plastic ... and even for grinding some millimeters into aluminum

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: What Do People Want In A CNC? February 28, 2018 01:06AM |

Registered: 7 years ago Posts: 507 |

I don't plan to use ballscrews, I'm thinking belts should be fine as long as I keep feed rates realistic.

@MKSA, A tool that can do a job is no good to me if I can't afford it. It might as well be a fairly tail. And even second hand machines of the type you're talking about are way out of most people's price range. Where I live, these sorts of tools aren't common to begin with so second hand ones are even less common.

For the record, I'm not saying the machine I'm building will revolutionize anything, or be a substitute or expensive machines. All I'm saying is that it will provide an affordable entry point. We'll see how successful I am, but for now I'm aiming for a rock bottom cost machine that does the job. It won't be as fast or as accurate, but with any luck it will work.

@MKSA, A tool that can do a job is no good to me if I can't afford it. It might as well be a fairly tail. And even second hand machines of the type you're talking about are way out of most people's price range. Where I live, these sorts of tools aren't common to begin with so second hand ones are even less common.

For the record, I'm not saying the machine I'm building will revolutionize anything, or be a substitute or expensive machines. All I'm saying is that it will provide an affordable entry point. We'll see how successful I am, but for now I'm aiming for a rock bottom cost machine that does the job. It won't be as fast or as accurate, but with any luck it will work.

|

Re: What Do People Want In A CNC? February 28, 2018 02:45AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Trakyan

I don't plan to use ballscrews, I'm thinking belts should be fine as long as I keep feed rates realistic.

@MKSA, A tool that can do a job is no good to me if I can't afford it. It might as well be a fairly tail. And even second hand machines of the type you're talking about are way out of most people's price range. Where I live, these sorts of tools aren't common to begin with so second hand ones are even less common.

For the record, I'm not saying the machine I'm building will revolutionize anything, or be a substitute or expensive machines. All I'm saying is that it will provide an affordable entry point. We'll see how successful I am, but for now I'm aiming for a rock bottom cost machine that does the job. It won't be as fast or as accurate, but with any luck it will work.

What is a "fairly tail" ?????

Edited 1 time(s). Last edit at 02/28/2018 02:46AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: What Do People Want In A CNC? February 28, 2018 03:19AM |

Registered: 9 years ago Posts: 483 |

|

Re: What Do People Want In A CNC? February 28, 2018 05:56PM |

Registered: 7 years ago Posts: 507 |

@MKSA, I meant a fairy tale. A machine I can't afford is absolutely useless to me.

@etfrench, I'd rather not I'd quickly get ripped apart for using steel tubing from the hardware store as a linear guide. I'm going to build it anyway, I want/need a CNC and this is what I can afford. My initial plans were for a CNC built out of 2080 aluminium extrusions and steel plate. This was going to cost me around $1000 USD. For someone in my situation, I can't justify spending that much on a single machine even if I had the money.

I'd quickly get ripped apart for using steel tubing from the hardware store as a linear guide. I'm going to build it anyway, I want/need a CNC and this is what I can afford. My initial plans were for a CNC built out of 2080 aluminium extrusions and steel plate. This was going to cost me around $1000 USD. For someone in my situation, I can't justify spending that much on a single machine even if I had the money.

@etfrench, I'd rather not

I'd quickly get ripped apart for using steel tubing from the hardware store as a linear guide. I'm going to build it anyway, I want/need a CNC and this is what I can afford. My initial plans were for a CNC built out of 2080 aluminium extrusions and steel plate. This was going to cost me around $1000 USD. For someone in my situation, I can't justify spending that much on a single machine even if I had the money.

I'd quickly get ripped apart for using steel tubing from the hardware store as a linear guide. I'm going to build it anyway, I want/need a CNC and this is what I can afford. My initial plans were for a CNC built out of 2080 aluminium extrusions and steel plate. This was going to cost me around $1000 USD. For someone in my situation, I can't justify spending that much on a single machine even if I had the money.

|

Re: What Do People Want In A CNC? February 28, 2018 08:27PM |

Registered: 9 years ago Posts: 483 |

|

Re: What Do People Want In A CNC? February 28, 2018 11:57PM |

Registered: 7 years ago Posts: 507 |

I know the design isn't ideal/the best, but it will work. I'm proceeding with the design because I know it is good enough, even if it isn't the absolute best. Same reason someone might buy a second hand. If it didn't accomplish "good enough", then I wouldn't go ahead with it. This is for the same reason I have a manual screwdriver instead of an impact driver, and why I have an el cheapo bike from a walmart equivalent instead of some bleeding edge carbon-fibre-electric-built-in-LEDs-seat-warmer-self-driving-gps bike. They both do the job and are "good enough" even if they aren't the best.

By the way, is this funky fella what I should take a look at?

[en.wikipedia.org])

By the way, is this funky fella what I should take a look at?

[en.wikipedia.org])

Sorry, only registered users may post in this forum.