Experimenting with filament drive pulley

Posted by gadittri

|

Experimenting with filament drive pulley March 22, 2018 02:49PM |

Registered: 10 years ago Posts: 80 |

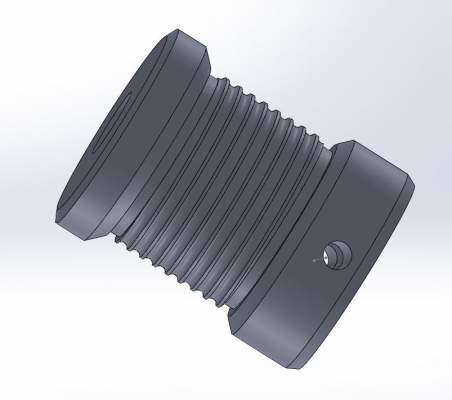

I am currently using 20 tooth GT2 pulleys on my core XY and wanted to experiment with using specta 65lb fishing braid. My printed model looks great but the string is walking up or down on the pulley depending on direction which is not good. I thought if there is a groove on top and bottom the string would track parallel with one another but not the case. Has anyone tried this and what am I doing wrong?

|

Re: Experimenting with filament drive pulley March 22, 2018 03:01PM |

Registered: 10 years ago Posts: 80 |

|

Re: Experimenting with filament drive pulley March 22, 2018 05:19PM |

Registered: 7 years ago Posts: 507 |

I'm quite a fan of spectra for budget reasons. There isn't really a way to stop it from walking up/down the spool, it's just what happens because of the way it gets wound on/off the spool. What you could do is add a bevel to the sides so the walking string falls back into the spool but then it tends to get tangles.

EDIT: Is that a helix or straight rings you've made on your spool? Straight rings wouldn't work since the string is wound in a helix. And a helix only really encourages walking. I just remembered a thread a while ago on a 3D printer called "lander" which tried to overcome this problem. It had the string spool onto a sort of screw which was threaded onto a nut. The string walks in one direction but the thread moves equally in the other so the string coming off the spool doesn't move along the spool's axis.

Edited 1 time(s). Last edit at 03/22/2018 05:22PM by Trakyan.

EDIT: Is that a helix or straight rings you've made on your spool? Straight rings wouldn't work since the string is wound in a helix. And a helix only really encourages walking. I just remembered a thread a while ago on a 3D printer called "lander" which tried to overcome this problem. It had the string spool onto a sort of screw which was threaded onto a nut. The string walks in one direction but the thread moves equally in the other so the string coming off the spool doesn't move along the spool's axis.

Edited 1 time(s). Last edit at 03/22/2018 05:22PM by Trakyan.

|

Re: Experimenting with filament drive pulley March 22, 2018 05:41PM |

Registered: 10 years ago Posts: 80 |

It is a helix with .5mm deep grooves. It just seems like the filament windings should stay in place as one side feeds and the other end pulls when using a helix. I will play around with it using deeper grooves and maybe a helix the full length. This is the beauty of 3D printing is to print these parts for pennies.

|

Re: Experimenting with filament drive pulley March 23, 2018 03:19AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Experimenting with filament drive pulley March 23, 2018 03:45AM |

Registered: 8 years ago Posts: 5,232 |

If I get the headline right, you want to build a remote driven extruder by spectra wire?

I thought about this a while back, because the cable driven seem too stiff for my liking.

The walking problem of spectra line could be overcome, if you had a big pulley with the line wrapped around only once ( 180-300° wrap )

The groove would have a narrow V-shape that really clamps the line to get enough friction.

The big pulley on the extruder side is no problem, but the stepper side would need a gear reduction.

I thought of guiding the spectra line through small PTFE tubes or bicycle brake tubes. The tubes must be able to handle the tension required for spectra line.

The only problem I saw: there is no closed loop spectra line....and a knot would probably cause issues.

I thought about this a while back, because the cable driven seem too stiff for my liking.

The walking problem of spectra line could be overcome, if you had a big pulley with the line wrapped around only once ( 180-300° wrap )

The groove would have a narrow V-shape that really clamps the line to get enough friction.

The big pulley on the extruder side is no problem, but the stepper side would need a gear reduction.

I thought of guiding the spectra line through small PTFE tubes or bicycle brake tubes. The tubes must be able to handle the tension required for spectra line.

The only problem I saw: there is no closed loop spectra line....and a knot would probably cause issues.

Sorry, only registered users may post in this forum.