Thoughts on a beginner CNC

Posted by Trakyan

|

Re: Thoughts on a beginner CNC April 19, 2018 03:42AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Thoughts on a beginner CNC April 19, 2018 11:04AM |

Registered: 8 years ago Posts: 1,671 |

MKSA took the words right outa my mouth, I didnt post the video's to show a preference, just how to build it, how big it needs to be,

I also never said I would build what they built for 2k(certainly not the tool changer), but feel its a much more realistic budget to create a useful machine, a base machine to build on.

But as you asked, I would like a Mill before a Lathe, but a friend needs a Lathe, and it is the logical first step(easier), with the Mill attachments to follow.

Last month I went to see a Sherline(lathes & mills) & Taig, which where for sale on ebay, I told my mate I had a feeling I wanted to leave with both a Mill & Lathe, and pass the lathe to my friend...but things never worked out that way. The guy came to my home first, and saw my developments...I talked him through a few things, my logic, the price of pieces, etc... he was blown away by the £1 heatsink.

Who knows how many hours and how much mess you would create just for one.

So I then went off with him to see the Sherline Toys, what a setup, just a few miles away, I wanted to get stuck in, I wanted to leave with something....but he had talked me out of it, before we left my house...he know I'd be better building something, and has offered to help, time permitting, he offered the loan of one of his mills, also would like to buy a printer...but how can I, I must return the offer.

He will help with a firm alu plate base...and some parts, he showed me what I should do by plonking a handful of parts in front of me, Large linear rail, this thing was at least one inch thick/high...chinese 1605 kit, Sherline or Taig headstock, large nema 34...not servo, not hybrid...but i'm looking into those...but maybe not get sucked into that price bracket for starters.

My Mate bought a Lorch and wants me to turn it into a cnc lathe...I try to explain it might be better just to throw the money in another direction, there are so many choices of configs, pre made items to bolt together, where do you start & what parts I try...all on my head..

but first he already has 4x 16mm open bearing blocks, for supported rails, so need 2 of those 3 or 400mm for the travel from headstock to chuck, with the 1605 ballscrew, make a cross slide based on an 8mm leadscrew(thicker than in a taig or sherline) for about 100mm of travel. then power the Lorch with a new motor, or get a better headstock, and ditch the lorch or assign it specific tasks.

But this mate who has new found wealth doesnt like to part with it, would like me to build the machine, spend my time, suck my brain dry, use my catalytic properties, with zero reward discussed.., lets just say it gets very complicated very quick, and i'm better just building for myself, my choice, my budget, my risk, my problem.

I also never said I would build what they built for 2k(certainly not the tool changer), but feel its a much more realistic budget to create a useful machine, a base machine to build on.

But as you asked, I would like a Mill before a Lathe, but a friend needs a Lathe, and it is the logical first step(easier), with the Mill attachments to follow.

Last month I went to see a Sherline(lathes & mills) & Taig, which where for sale on ebay, I told my mate I had a feeling I wanted to leave with both a Mill & Lathe, and pass the lathe to my friend...but things never worked out that way. The guy came to my home first, and saw my developments...I talked him through a few things, my logic, the price of pieces, etc... he was blown away by the £1 heatsink.

Who knows how many hours and how much mess you would create just for one.

So I then went off with him to see the Sherline Toys, what a setup, just a few miles away, I wanted to get stuck in, I wanted to leave with something....but he had talked me out of it, before we left my house...he know I'd be better building something, and has offered to help, time permitting, he offered the loan of one of his mills, also would like to buy a printer...but how can I, I must return the offer.

He will help with a firm alu plate base...and some parts, he showed me what I should do by plonking a handful of parts in front of me, Large linear rail, this thing was at least one inch thick/high...chinese 1605 kit, Sherline or Taig headstock, large nema 34...not servo, not hybrid...but i'm looking into those...but maybe not get sucked into that price bracket for starters.

My Mate bought a Lorch and wants me to turn it into a cnc lathe...I try to explain it might be better just to throw the money in another direction, there are so many choices of configs, pre made items to bolt together, where do you start & what parts I try...all on my head..

but first he already has 4x 16mm open bearing blocks, for supported rails, so need 2 of those 3 or 400mm for the travel from headstock to chuck, with the 1605 ballscrew, make a cross slide based on an 8mm leadscrew(thicker than in a taig or sherline) for about 100mm of travel. then power the Lorch with a new motor, or get a better headstock, and ditch the lorch or assign it specific tasks.

But this mate who has new found wealth doesnt like to part with it, would like me to build the machine, spend my time, suck my brain dry, use my catalytic properties, with zero reward discussed.., lets just say it gets very complicated very quick, and i'm better just building for myself, my choice, my budget, my risk, my problem.

|

Re: Thoughts on a beginner CNC April 19, 2018 11:49AM |

Registered: 8 years ago Posts: 601 |

Buy a router and a guide rail for £100 and make the whole thing out of MDF. You could make grooves in the MDF that delrin rollers (or cheap DIY wheels of some sort) can roll in. The router can then be used on the machine afterwards.

Don't expect a large build area, and don't expect great things. But it should do well enough to get someone started. Aside from that, how else can you make a CNC for less then £300?

Don't expect a large build area, and don't expect great things. But it should do well enough to get someone started. Aside from that, how else can you make a CNC for less then £300?

|

Re: Thoughts on a beginner CNC April 19, 2018 01:25PM |

Registered: 11 years ago Posts: 335 |

The problem is that most useful CNC builds require access to a manual/cnc machine shop to begin with, plus years of experience and several months of free time. Hobbyists generally have to bootstrap though iterations of progressively more capable machines.

When machinists talk about machine accuracy its a shorthand way of describing the full system. A machine that holds +-0.001" has many properties:

When hobbyists talk about accuracy they invariably consider only point #1, which is useless because it is by far the easiest and cheapest property to achieve. Any $30 chinese ballscrew will achieve +-0.002" under no load and over short distances.

Poor quality machines don't just cut slower or less accurately; they make horrendous screeching noises, destroy tools, wreck surface finishes, and finally disassemble themselves with vibration. You are forced to reduce cutting forces by going to smaller diameter tools, but small tools are more sensitive to vibration/runout/stickout and remove material at anemic rates.

There is a floor on machine quality, and if you want to cut aluminum you pretty much need to be at Sherline level or you won't create anything but hearing damage and broken tools.

When machinists talk about machine accuracy its a shorthand way of describing the full system. A machine that holds +-0.001" has many properties:

- A motion system that can position at that tolerance

- Enough rigidity to hold position under load

- A toolholder and cutter combination that meets the rigidity and runout requirements

- A workpiece that is sufficiently rigid and supported so that it does not deflect during the cut.

When hobbyists talk about accuracy they invariably consider only point #1, which is useless because it is by far the easiest and cheapest property to achieve. Any $30 chinese ballscrew will achieve +-0.002" under no load and over short distances.

Poor quality machines don't just cut slower or less accurately; they make horrendous screeching noises, destroy tools, wreck surface finishes, and finally disassemble themselves with vibration. You are forced to reduce cutting forces by going to smaller diameter tools, but small tools are more sensitive to vibration/runout/stickout and remove material at anemic rates.

There is a floor on machine quality, and if you want to cut aluminum you pretty much need to be at Sherline level or you won't create anything but hearing damage and broken tools.

|

Re: Thoughts on a beginner CNC April 21, 2018 05:18AM |

Registered: 7 years ago Posts: 507 |

I'm not expecting (or claiming) great things. This isn't supposed to be a super machine, just a machine for someone who wants to use one but can't afford the expensive offerings out there. Early RepRaps produced appalling prints, but people still made, wanted and bought them because spending $10,000 dollars on a "proper" tool is out of the question for most people. I'm planning to take an approach like the MPCNC and use steel tubing. I've thought about MDF but don't like how temperature/humidity sensitive it is. I've considered using plastic sheet like acetal instead of MDF but for the moment steel tubing seems like the better approach.Quote

Origamib

Buy a router and a guide rail for £100 and make the whole thing out of MDF. You could make grooves in the MDF that delrin rollers (or cheap DIY wheels of some sort) can roll in. The router can then be used on the machine afterwards.

Don't expect a large build area, and don't expect great things. But it should do well enough to get someone started. Aside from that, how else can you make a CNC for less then £300?

My logic is that even if the machine isn't accurate, as long as its repeatable I can work around the issues. MDF being prone to humidity and temperature messes with the idea of repeat ability.

Way ahead of you. Using braided fishing line for the drive, by delrin sliders I'm assuming the v wheels used by openbuilds? I'm going a step more budget (possibly more rigid) with plain radial bearings.Quote

o_lampe

If you want to keep the cost low, why not try to adapt the Delrin slider idea and use heavy duty fishing line for the drive?

Both are cheap to get and the pulleys and brackets are printable.

I want to state again, there is no way I'll be able to make a "proper" cnc router for the budget I'm looking at. It wont impress any machinists, most wouldn't even be caught dead in the same room as it. But it will be cheap. I see this as the approach early repraps took. The print quality was far from spectacular but it also didn't cost a small fortune. I'm also not forcing anyone to build my design once it's done. If you can afford better, by all means go for better, I definitely would if I could. I'm just trying to say if you've got a budget of $300 bucks, a $1000 dollar machine is good for absolutely nothing, no matter what specs, bells and whistles its got. My question when I started this thread was basically if you're on a budget, what would you want the money spent on? Even setting aside the cost of the hardware, things like instruction manuals, pre configured software toolchains, customer support... etc...

This question wasn't aimed at professional machinists, or people with a deep wallet. I think MKSA and MechaBits are missing the point.

|

Re: Thoughts on a beginner CNC April 21, 2018 07:53AM |

Registered: 8 years ago Posts: 601 |

How do you cut steel tube for £300? The rate of expansion of MDF seems to be about 0.2% to 0.5%. Will this really be an issue at the tolerances you expect?

If you make a template, you can easily make panels of MDF and glue them together for extra strength, with most of the work done by hand with the router. Once the machine is made they can be redone with the CNC. You can even seal the MDF with a decent varnish and ensure you keep room humidity at a minimum.

If you make a template, you can easily make panels of MDF and glue them together for extra strength, with most of the work done by hand with the router. Once the machine is made they can be redone with the CNC. You can even seal the MDF with a decent varnish and ensure you keep room humidity at a minimum.

|

Re: Thoughts on a beginner CNC April 21, 2018 09:27AM |

Registered: 8 years ago Posts: 1,671 |

If only you knew how shallow my pockets are, in fact one is never ending(tardis) well I say never ending there is a limit as to how far I can get my arm down there(passing the hairy sack of magic) "is that my bootstraps or a grey pube", and it's because of this I make good choices with money, the reason I want things to have more than one function/use (shall I presume you dont get that?),

But I cant complain & keep telling myself Prison UK is better than some places, so count my blessings...

But I cant complain & keep telling myself Prison UK is better than some places, so count my blessings...

|

Re: Thoughts on a beginner CNC April 21, 2018 04:05PM |

Registered: 9 years ago Posts: 483 |

|

Re: Thoughts on a beginner CNC April 21, 2018 04:06PM |

Registered: 12 years ago Posts: 1,450 |

You ask what would be wanted in a CNC router so I will do my best to answer in terms of what I have had to make recently either on my Proxxon MF70 milling machine (X Max=130mm, Y Max= 44mm, Z max = 80mm) or my 3D printer/router (X Max=180mm, Y Max=180mm, Z Max=120mm)

1) Batch of PCBs for investigation of MCU conditioner for piezo sensors. 0.15mm isolation routing with 30degree V bit, PCB outlines cut out with a 1.5mm end-mill bit. All done on the 3D printer/router.

2) Latching bars for a lathe speed and direction selector switch. Cut from 1.2mm steel plate with a needed accuracy of about 0.05mm on the Proxxon but could just about be cut on the 3D printer/Router - Accuracy would be the same but surface not as good.

3) Screw slots cut into 4mm aluminium bearing housing - 6mm long by 3.2mm wide cut with a 3mm end mill on the 3D Printer/Router.

Use small very sharp carbide cutters for everything

So it seems that I do know what I am talking about. My advice remains that it should be achievable at your price if you keep the volume to a 100mm cube. A 300mm cube is in the realm of fantasy unless you keep to the softest plastics (machinable wax) and allow a long time to make anything.

BTW, MDF is quite a good material and is pretty temperature stable and can be made humidity stable for most environments by varnishing it.

Mike

1) Batch of PCBs for investigation of MCU conditioner for piezo sensors. 0.15mm isolation routing with 30degree V bit, PCB outlines cut out with a 1.5mm end-mill bit. All done on the 3D printer/router.

2) Latching bars for a lathe speed and direction selector switch. Cut from 1.2mm steel plate with a needed accuracy of about 0.05mm on the Proxxon but could just about be cut on the 3D printer/Router - Accuracy would be the same but surface not as good.

3) Screw slots cut into 4mm aluminium bearing housing - 6mm long by 3.2mm wide cut with a 3mm end mill on the 3D Printer/Router.

Use small very sharp carbide cutters for everything

So it seems that I do know what I am talking about. My advice remains that it should be achievable at your price if you keep the volume to a 100mm cube. A 300mm cube is in the realm of fantasy unless you keep to the softest plastics (machinable wax) and allow a long time to make anything.

BTW, MDF is quite a good material and is pretty temperature stable and can be made humidity stable for most environments by varnishing it.

Mike

|

Re: Thoughts on a beginner CNC April 22, 2018 12:38AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Thoughts on a beginner CNC April 22, 2018 03:33PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Thoughts on a beginner CNC April 22, 2018 05:58PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Thoughts on a beginner CNC April 22, 2018 08:09PM |

Registered: 7 years ago Posts: 507 |

@Mechabits, Our definition of shallow pockets must be vastly different. Also I have seen the sien

@efrench, can you post some pictures? Also, is this using scavenged parts or parts you already had, or is it under $500 (USD?) including everything?

@leadinglights, I think you're overstating how small the machine should be. There are machines like the MPCNC, shapeoko, x-carve, Root 3 that can machine aluminium and are fairly large format. They don't machine it very quickly, but for me and many others it's good enough. The shapeoko/xcarve are somewhat more expensive but that's because of markups. The MPCNC and R3 are around the budget I'm aiming for.

@efrench, can you post some pictures? Also, is this using scavenged parts or parts you already had, or is it under $500 (USD?) including everything?

@leadinglights, I think you're overstating how small the machine should be. There are machines like the MPCNC, shapeoko, x-carve, Root 3 that can machine aluminium and are fairly large format. They don't machine it very quickly, but for me and many others it's good enough. The shapeoko/xcarve are somewhat more expensive but that's because of markups. The MPCNC and R3 are around the budget I'm aiming for.

|

Re: Thoughts on a beginner CNC April 22, 2018 09:04PM |

Registered: 9 years ago Posts: 483 |

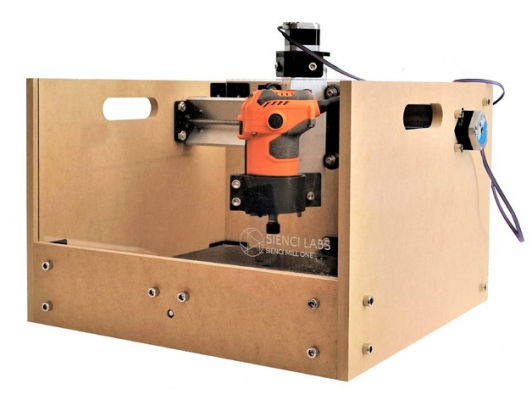

Here's the photobucket album. The machine is similar to Microcarve's BBox. The X and Y carriages are cast polyurethane. The rails are 25mm unsupported shafts from Misumi with Oilite bushings. Leadscrew nuts were formed from Acetal and there is no backlash.

No scavenging in the build. Total price was under $500.

Edited 1 time(s). Last edit at 04/22/2018 09:06PM by etfrench.

No scavenging in the build. Total price was under $500.

Edited 1 time(s). Last edit at 04/22/2018 09:06PM by etfrench.

|

Re: Thoughts on a beginner CNC April 22, 2018 09:08PM |

Registered: 8 years ago Posts: 1,671 |

I've already made my £300 cnc in a 3030 frame that cost £20 ....problem is I figured I needed another £500 to finish it, ie the more expensive parts router, motors, drivers, psu's, and now the requirement has changed, the choices of parts is changing, so now maybe I only spend a further £300.

Have you ever stated your country? Have you ever posted a picture here?

One of these machines looks like it can do what I wish I could do for starters

[www.youtube.com]

I'd just like to know for how long...MTBF

Edited 2 time(s). Last edit at 04/22/2018 09:44PM by MechaBits.

Have you ever stated your country? Have you ever posted a picture here?

One of these machines looks like it can do what I wish I could do for starters

[www.youtube.com]

I'd just like to know for how long...MTBF

Edited 2 time(s). Last edit at 04/22/2018 09:44PM by MechaBits.

|

Re: Thoughts on a beginner CNC April 22, 2018 10:14PM |

Registered: 7 years ago Posts: 507 |

@Mechabits I live in New Zealand, I thought I mentioned that somewhere with shipping costs. Though it's not just shipping that's expensive here, everything is expensive here. $20 for a 3030 frame sounds like a steal to me.

@etfrench, What are the blue plates made of? Looks like a cool build. Can I ask how much the rails cost and if you've had any binding/stiction issues with the bushings?

@etfrench, What are the blue plates made of? Looks like a cool build. Can I ask how much the rails cost and if you've had any binding/stiction issues with the bushings?

|

Re: Thoughts on a beginner CNC April 22, 2018 11:36PM |

Registered: 8 years ago Posts: 1,671 |

Paradise in Comparison( or just another captive audience to exploit with high tariffs?), you might have mentioned I must have missed it,

Here's me thinking people who lived there where all affluent. The frame was an old display case in a second hand shop, I couldn't believe it, finally a deal on some aluminium profile I thought only the Americans got.

Edited 1 time(s). Last edit at 04/22/2018 11:48PM by MechaBits.

Here's me thinking people who lived there where all affluent. The frame was an old display case in a second hand shop, I couldn't believe it, finally a deal on some aluminium profile I thought only the Americans got.

Edited 1 time(s). Last edit at 04/22/2018 11:48PM by MechaBits.

|

Re: Thoughts on a beginner CNC April 23, 2018 01:11AM |

Registered: 7 years ago Posts: 507 |

Ahh, that explains the price. Unfortunately for me I need to consider the cost of new rather than second hand materials and scavenged parts since this is for a business course. You can make a good one off machine for cheaper by buying used components and scavenging, but you can't do the same with a "production" machine which is what I'm supposed to look at. As for the affluence of people here I guess there are poor people in every part of the world, I live in a less expensive part of the country and towards the poorer side of town. That being said the northern half of the country has some of the highest house prices in the world, so that could be what gives of the money bags impression.

|

Re: Thoughts on a beginner CNC April 23, 2018 03:20AM |

Registered: 6 years ago Posts: 1,007 |

Trakyan, as I suggested earlier, how about taking a summer job in a machine shop to learn and earn ???

Came across this so beginners can see the difference between a mill and a router: [www.youtube.com]

So you learn "business" but what about technology ?

Edited 1 time(s). Last edit at 04/23/2018 03:22AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Came across this so beginners can see the difference between a mill and a router: [www.youtube.com]

So you learn "business" but what about technology ?

Edited 1 time(s). Last edit at 04/23/2018 03:22AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Thoughts on a beginner CNC April 23, 2018 04:26AM |

Registered: 7 years ago Posts: 507 |

@MKSA, You're completely missing the point. Finding a summer job at a machinist shop is also fairly irrelevant to the course I'm doing now considering the course is over in less than two months and my summer starts several months after that. I wasn't asking how to get access to big industrial machines and look at expensive, professional equipment. I'm looking at the complete other end of the spectrum, and I can't look to those big, expensive machines for inspiration or I'll end up with a big, expensive machine.

I'm learning about the technology the same way a lot of other people do, research, asking questions and messing around with the tools they have access to rather than dreaming about the ones they don't. I'm a hobbyist and doing what I can to learn about and experience CNC. For me that means bootstrapping a CNC router for as cheap as possible with the tools I have available. The technical aspect of it and the design part of this project is what interests me, the course I'm doing happens to be one on starting venture that lets me incorporate my own hobby.

Lastly, not to sound like a jackass, but not everyone has access to the seemingly vast array of options you do. There are very few machine shops here and all of the engineering students from the biggest engineering university in the the country competing for a placement. While I would love to spend time in a machine shop learning the tricks and tools of the trade, I can't afford to quit my jobs for the summer to do a (probably unpaid) internship for a couple of months. Even if it was paid I'd be taking a huge risk assuming I can find another job to pay bills right after it's over. I'd appreciate it if you stopped looking down your nose at me and what I am doing because I'm not doing CNC "properly" or up to your standard and price point.

Also, the distinction between mill and router is very ambiguous. Everyone picks their own definition, mine is that a router is less heavy duty than a mill. Where you draw the line is up to you. I believe I stated somewhere that this will be a router, to me that means it's a lighter duty machine.

Apologies for the rant.

I'm learning about the technology the same way a lot of other people do, research, asking questions and messing around with the tools they have access to rather than dreaming about the ones they don't. I'm a hobbyist and doing what I can to learn about and experience CNC. For me that means bootstrapping a CNC router for as cheap as possible with the tools I have available. The technical aspect of it and the design part of this project is what interests me, the course I'm doing happens to be one on starting venture that lets me incorporate my own hobby.

Lastly, not to sound like a jackass, but not everyone has access to the seemingly vast array of options you do. There are very few machine shops here and all of the engineering students from the biggest engineering university in the the country competing for a placement. While I would love to spend time in a machine shop learning the tricks and tools of the trade, I can't afford to quit my jobs for the summer to do a (probably unpaid) internship for a couple of months. Even if it was paid I'd be taking a huge risk assuming I can find another job to pay bills right after it's over. I'd appreciate it if you stopped looking down your nose at me and what I am doing because I'm not doing CNC "properly" or up to your standard and price point.

Also, the distinction between mill and router is very ambiguous. Everyone picks their own definition, mine is that a router is less heavy duty than a mill. Where you draw the line is up to you. I believe I stated somewhere that this will be a router, to me that means it's a lighter duty machine.

Apologies for the rant.

|

Re: Thoughts on a beginner CNC April 23, 2018 01:58PM |

Registered: 9 years ago Posts: 465 |

I've got pretty shallow pockets, and am looking to build something CNC like.

I have some tools. I have a table saw, and a lathe that I think works. I have a drill press, and a plunge router. The plunge router is almost certainly going to end up being my spindle, since I can't see myself buying another one at this juncture. Of course I also have my 3D printer for things that it can actually do in terms of a build like this.

I'm not looking for super precision, which I figure is probably out of reach with the tools at my disposal anyway. I am looking for "good enough" which I will define as able to machine a nice speaker box out of MDF or similar material. +- 0.05" is probably good enough tolerance for what I want. Of course I will want better, but I'll take what I can get, and hopefully once the machine is up and running I can use it to make better parts for it. For that matter, maybe I can make better parts for my 3D printer, too.

I'm probably going to start with something like this: [bootstrapcnc.com]

One of the biggest barriers to me is the cost of motors and electronics capable of handling the higher power requirements for moving the router around and through more solid material. My plan is to use this for MDF or similar material, maybe softwood like pine or spruce, but it would be nice to have the capability of dealing with hardwood like maple or oak and maybe even small aluminum projects. (I can think of a number of things in a 3D printer that I'd like to have custom made from aluminum.)

The motors and controllers will be the expensive parts, though I imagine that I won't come out unscathed from buying bearings and the nuts and bolts required by the project either. Probably buying in bulk for production will make unit prices lower. Additionally, if you are mass producing, some of the lightweight, but tricky parts being prepared beforehand making the customer's needs lower would hold some value for a simple machine, and can have a great effect on the quality of the end result. (For example, accurately making the rolling assemblies beforehand would be a huge added value.)

So if I were looking to buy, what I'd want is probably a selection of pre-manufactured parts. Motors and controllers, couplers, motor brackets, bearings and holders. I don't need the heavy and/or bulky parts if I can make them on my tablesaw and drill press. I want to be able to make most of the parts on my table saw.

For the materials that I have to buy, I want a small variety of material. Maybe 1/2" and 3/4" plywood or MDF. Or 1/2" plywood (for lighter weight parts) and 3/4" MDF for parts where dimensional rigidity is more important. Having to buy many different types of material to build my machine would be a negative, as it increases final cost as well as needing a more complicated cut list. Even better for many people is if the cut list could be handed to the dude at Home Depot for a couple of sheets of MDF and you could have them cut it for you. This is usually an additional cost, but if you don't have your own tablesaw, it's reasonable. They'll generally make a 1/8" tolerance guarantee, but if a 12" part is 12.065", then usually ALL of the 12" cuts will be 12.065", so if the cut list is done right, this can be made not to matter so much.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

I have some tools. I have a table saw, and a lathe that I think works. I have a drill press, and a plunge router. The plunge router is almost certainly going to end up being my spindle, since I can't see myself buying another one at this juncture. Of course I also have my 3D printer for things that it can actually do in terms of a build like this.

I'm not looking for super precision, which I figure is probably out of reach with the tools at my disposal anyway. I am looking for "good enough" which I will define as able to machine a nice speaker box out of MDF or similar material. +- 0.05" is probably good enough tolerance for what I want. Of course I will want better, but I'll take what I can get, and hopefully once the machine is up and running I can use it to make better parts for it. For that matter, maybe I can make better parts for my 3D printer, too.

I'm probably going to start with something like this: [bootstrapcnc.com]

One of the biggest barriers to me is the cost of motors and electronics capable of handling the higher power requirements for moving the router around and through more solid material. My plan is to use this for MDF or similar material, maybe softwood like pine or spruce, but it would be nice to have the capability of dealing with hardwood like maple or oak and maybe even small aluminum projects. (I can think of a number of things in a 3D printer that I'd like to have custom made from aluminum.)

The motors and controllers will be the expensive parts, though I imagine that I won't come out unscathed from buying bearings and the nuts and bolts required by the project either. Probably buying in bulk for production will make unit prices lower. Additionally, if you are mass producing, some of the lightweight, but tricky parts being prepared beforehand making the customer's needs lower would hold some value for a simple machine, and can have a great effect on the quality of the end result. (For example, accurately making the rolling assemblies beforehand would be a huge added value.)

So if I were looking to buy, what I'd want is probably a selection of pre-manufactured parts. Motors and controllers, couplers, motor brackets, bearings and holders. I don't need the heavy and/or bulky parts if I can make them on my tablesaw and drill press. I want to be able to make most of the parts on my table saw.

For the materials that I have to buy, I want a small variety of material. Maybe 1/2" and 3/4" plywood or MDF. Or 1/2" plywood (for lighter weight parts) and 3/4" MDF for parts where dimensional rigidity is more important. Having to buy many different types of material to build my machine would be a negative, as it increases final cost as well as needing a more complicated cut list. Even better for many people is if the cut list could be handed to the dude at Home Depot for a couple of sheets of MDF and you could have them cut it for you. This is usually an additional cost, but if you don't have your own tablesaw, it's reasonable. They'll generally make a 1/8" tolerance guarantee, but if a 12" part is 12.065", then usually ALL of the 12" cuts will be 12.065", so if the cut list is done right, this can be made not to matter so much.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Thoughts on a beginner CNC April 23, 2018 05:10PM |

Registered: 7 years ago Posts: 507 |

Sweet, thanks for the feedback Supraguy. I completely agree with you about providing the smaller assemblies and parts. Things like spoilboards etc. it's cheaper and easier for everyone if the end user sources it locally. Same with the targeted (is this the right word?) BOM. It's so much easier and nicer having to buy a bulk lot of a single part rather than a million unique parts.

The machine I'm working on will use 3D printed parts, since that's what I have to build it with. The rest of my tools are limited to a drill, hacksaw and a hammer (plus screwdrivers, wrenches, allan keys etc...) so building the designs that are out there using sheets of MDF is out of the question for me. I do plan to make a router that's more suitable for making out of sheet material once I've built my CNC. It'll be made to be CNC routed, but wont be hard to build with a table saw/mitre saw and drill press.

Would you consider building a CNC with some printed parts? I'm hoping to release the STLs/CAD files for my machine in the next few weeks.

The machine I'm working on will use 3D printed parts, since that's what I have to build it with. The rest of my tools are limited to a drill, hacksaw and a hammer (plus screwdrivers, wrenches, allan keys etc...) so building the designs that are out there using sheets of MDF is out of the question for me. I do plan to make a router that's more suitable for making out of sheet material once I've built my CNC. It'll be made to be CNC routed, but wont be hard to build with a table saw/mitre saw and drill press.

Would you consider building a CNC with some printed parts? I'm hoping to release the STLs/CAD files for my machine in the next few weeks.

|

Re: Thoughts on a beginner CNC April 23, 2018 06:07PM |

Registered: 10 years ago Posts: 97 |

@Trakyan Good luck on your cnc if you need any help, we are also building a cnc machine with interchangeable heads, although it will not be a £200 machine. Its loosely based on a routing machine, using linear slides, lead screws and nema 23 motors. We are adding linear encoders to a smart drivers to each of the axis to give an accurate positioning system.

The cnc with be controlled via a smoothieboard interfacing with a touch screen. The interchangeable heads we designing initially will be routing head, 3d printing, laser engraving, waterjet cutting and uv piezoelectric resin printing. Bed size approximately 800 x 600.

The cnc with be controlled via a smoothieboard interfacing with a touch screen. The interchangeable heads we designing initially will be routing head, 3d printing, laser engraving, waterjet cutting and uv piezoelectric resin printing. Bed size approximately 800 x 600.

|

Re: Thoughts on a beginner CNC April 23, 2018 06:20PM |

Registered: 7 years ago Posts: 507 |

Sounds like an awesome machine. I imagine a machine like that would be fairly costly with all those bells and whistles. Is it open source? There aren't many waterjet cutters out there and I wish those were more accessible. Also by UC piezoelectric resin printing, I assume you mean sort of like the objet systems? If so, also really cool. Any links to the machine?

|

Re: Thoughts on a beginner CNC April 24, 2018 03:04AM |

Registered: 8 years ago Posts: 5,232 |

Quote

andornot

...we are also building a cnc machine with interchangeable heads, although it will not be a £200 machine. Its loosely based on a routing machine, using linear slides, lead screws and nema 23 motors. We are adding linear encoders to a smart drivers to each of the axis to give an accurate positioning system.

The cnc with be controlled via a smoothieboard interfacing with a touch screen. The interchangeable heads we designing initially will be routing head, 3d printing, laser engraving, waterjet cutting and uv piezoelectric resin printing. Bed size approximately 800 x 600.

Quote

Trakyan

Any links to the machine?

Why do you fall for this selfpromoting BS? Keep the thread close to your subject...The other machine is nowhere near your specs.

|

Re: Thoughts on a beginner CNC April 24, 2018 04:05AM |

Registered: 8 years ago Posts: 114 |

To be honest I don't get whats the purpose of this thread either. Conversation jumps back and forth. First question I read was: "how much would you pay for a budget machine" (for buying a kit, over sourcing all parts yourself). Although it looks like you just want to hear how much people would buy a CNC kit for so you can put the right pricetag on your (soon finished?) CNC. But then you said its not marketting here so idk. Lets stick to the initial question...

Its 500$. My MPCNC (link: [www.youtube.com] & [www.v1engineering.com]) costs <400$ to make, 2 weeks of non-stop printing and a couple more hours to assemble.

About the "shit is too expensive in my country" problem: most parts you can order in China (Router, Electronics, even the screws and filament - not recommended though!). The only thing I actually bought NOT in China was the rails (shipped from Austria to my country), those were wardrobe rails, super cheap, suprisingly good quality in terms of finish and straightness.

Thats it, cant give more input on this topic since its not clear what your asking for (other then pricetag opinions). If its just for chit-chat: I'm fine with it, I'm also interested in new machines, too.

Edited 1 time(s). Last edit at 04/24/2018 04:11AM by SQLException.

Laser: 50w Co2 SH-G350

Drucker: bq Prusa i3 Hephestos - Print Bed Expansion Kit - Igus RJZM-02-08 - TMC2100 - Alu-DDP + Silikonheizmatte 300w (300 x 200mm) - Netzteil Dell DA-2

Its 500$. My MPCNC (link: [www.youtube.com] & [www.v1engineering.com]) costs <400$ to make, 2 weeks of non-stop printing and a couple more hours to assemble.

About the "shit is too expensive in my country" problem: most parts you can order in China (Router, Electronics, even the screws and filament - not recommended though!). The only thing I actually bought NOT in China was the rails (shipped from Austria to my country), those were wardrobe rails, super cheap, suprisingly good quality in terms of finish and straightness.

Thats it, cant give more input on this topic since its not clear what your asking for (other then pricetag opinions). If its just for chit-chat: I'm fine with it, I'm also interested in new machines, too.

Edited 1 time(s). Last edit at 04/24/2018 04:11AM by SQLException.

Laser: 50w Co2 SH-G350

Drucker: bq Prusa i3 Hephestos - Print Bed Expansion Kit - Igus RJZM-02-08 - TMC2100 - Alu-DDP + Silikonheizmatte 300w (300 x 200mm) - Netzteil Dell DA-2

|

Re: Thoughts on a beginner CNC April 24, 2018 05:23AM |

Registered: 10 years ago Posts: 97 |

Quote

Trakyan

Sounds like an awesome machine. I imagine a machine like that would be fairly costly with all those bells and whistles. Is it open source? There aren't many waterjet cutters out there and I wish those were more accessible. Also by UC piezoelectric resin printing, I assume you mean sort of like the objet systems? If so, also really cool. Any links to the machine?

The machine is being designed and built by Preston Hackspace, this evening we will be setting up and testing the touch screen interface with a smoothieboard delta printer so some of the members can get on with designing the interface. The physical design of the machine is still work in progress and as there is something to show i will post it.

The machine will be opensource when it is finished.

|

Re: Thoughts on a beginner CNC April 24, 2018 11:09PM |

Registered: 7 years ago Posts: 507 |

I'm just interested in machines that do cool stuff, then I try and find a way to do it for cheap. Sort of figured it was self promotion but I was hoping it might be open source as well.Quote

o_lampe

Why do you fall for this selfpromoting BS? Keep the thread close to your subject...The other machine is nowhere near your specs.

Quote

SQLException

To be honest I don't get whats the purpose of this thread either. Conversation jumps back and forth. First question I read was: "how much would you pay for a budget machine" (for buying a kit, over sourcing all parts yourself). Although it looks like you just want to hear how much people would buy a CNC kit for so you can put the right pricetag on your (soon finished?) CNC. But then you said its not marketting here so idk. Lets stick to the initial question...

Its 500$. My MPCNC (link: [www.youtube.com] & [www.v1engineering.com]) costs <400$ to make, 2 weeks of non-stop printing and a couple more hours to assemble.

About the "shit is too expensive in my country" problem: most parts you can order in China (Router, Electronics, even the screws and filament - not recommended though!). The only thing I actually bought NOT in China was the rails (shipped from Austria to my country), those were wardrobe rails, super cheap, suprisingly good quality in terms of finish and straightness.

Thats it, cant give more input on this topic since its not clear what your asking for (other then pricetag opinions). If its just for chit-chat: I'm fine with it, I'm also interested in new machines, too.

I had a bunch of questions in my initial post, I'm really just wanting as many opinions on the subject as possible. Any information is good information, whether it's about cost, features and so on. I'm not asking for a cost so I can slap that price tag on the final machine, I'm asking about cost so I can figure out what features I can add or what features I need to remove to hit that price point. If I do end up selling the machine, I don't plan to add a mark up for the sake of a mark up, if I was planning to do that I wouldn't be focusing on making it easy to bootstrap.

Yes, I know you can buy most things from china, I've already bought some parts from aliexpress and plan to buy the rest of the parts for my personal machine from there. Unfortunately, you still have to ship things from china, and if I do sell the machine, I'll need to ship the machine out. Shipping from a small country in the pacific to just about anywhere is expensive. Like I said earlier it's not so much the cost of the items themselves, it's the cost of getting them here.

Here are my main questions:

What would you use a CNC for? If you can mention the sort of size and or tolerances you think you'll need, go ahead and mention that.

What sort of budget do you have for this machine? I'm not here hoping to hear $10000 so I can throw in a markup, I'm here expecting to hear $300-400 dollars so I can figure out what price point I need to build down to. What do I have to get rid of to hit that price point, or (with any luck), what extra features can I add in before it gets too expensive? Stuff like homing, touch plates, clamps, upgraded components and so on.

What, other than the hardware of the machine itself, do you think is important? Providing software tool chains, assembly instructions, getting started guides, customer support... etc...

If people say they're looking for a $700, small and high precision machine, then I'll drop my current bootstrap focused approach and start thinking about linear rails and lead screws. I'm not going to sell a $300 dollar machine for $700. Chit chat is welcome, too, it's how discussions happen and information gets out there. If people say they'd rather pay extra for a controller with digipots than fiddle with a tiny screwdriver, I'll take that into account. Even simple stuff like having a way to manually drive an axis. I heard with the x carve something people liked was a little knob on the z axis leadscrew which let them easily set z heights manually. This is easy and cheap to implement, but I might not think of it on my own.

|

Re: Thoughts on a beginner CNC April 25, 2018 02:15AM |

Registered: 8 years ago Posts: 5,232 |

Actually the whole toolchain is important. You need a CAD program that generates toolpath-code for your controller. And a spindle/VFC that also works with this code. It's OK, if you have to edit the code here and there ( adjust speed or origin coordinates ), but writing the whole toolpath is a drag.

|

Re: Thoughts on a beginner CNC April 25, 2018 03:57AM |

Registered: 8 years ago Posts: 601 |

Quote

Trakyan

Here are my main questions:

What would you use a CNC for? If you can mention the sort of size and or tolerances you think you'll need, go ahead and mention that.

What sort of budget do you have for this machine? I'm not here hoping to hear $10000 so I can throw in a markup, I'm here expecting to hear $300-400 dollars so I can figure out what price point I need to build down to. What do I have to get rid of to hit that price point, or (with any luck), what extra features can I add in before it gets too expensive? Stuff like homing, touch plates, clamps, upgraded components and so on.

What, other than the hardware of the machine itself, do you think is important? Providing software tool chains, assembly instructions, getting started guides, customer support... etc...

Your questions are inherently biased. You're asking a 3D printing forum what they want... The answer is the ability to cut metal to 0.1mm or better and a build size of 300m2 or bigger. The main use will be for 3D printer upgrades.

The cost is obviously between £300 and £700. The higher end is approaching current machines on the market and the lower end may not even be possible. These answers are quite obvious...

Now, ask a wider audience and you will get a better response. Perhaps most people are happy with +/- 1mm and only want to make furniture, household decorations and stuff they can sell on etsy.

What do you want? What do you think is possible at this price point? The lower price will require more thought on the design, and you are the designer.

Sorry, only registered users may post in this forum.