Thoughts on a beginner CNC

Posted by Trakyan

|

Re: Thoughts on a beginner CNC April 25, 2018 04:17AM |

Registered: 7 years ago Posts: 507 |

II wouldn't dream of writing an entire toolpath myself, or asking anyone else to do the same. I was more asking if people thought it was important to provide a list of recommended CAD+CAM+Gcode sender programs and some pre configured profiles for them, or whether it's just left to the user to figure out. Similar to how some companies have pre-configured slicer profiles for 3D printers.

I think the VFD spindle with software control is a bit too specific. Not only are there a million and one configurations, but I suspect a lot of people would be running these machines with a router or similar which don't work with a VFD. Dunno, I guess it all depends on what price point I'll be building to I guess but right now it looks like that's out of the budget area.

Me? I'm after a fairly large format machine. I plan to use it for largish woodworking projects like longboard decks and furniture and stuff around the house. I also intend to use it for some small aluminium pieces. I know those two are at odds with each other but if I go with a steel tube construction like I'm currently planning it won't be hard to switch between the two if I need to for rigidity reasons. I personally don't need any more than +-0.1 mm, but I'd like to know what other are wanting. I'm fairly sure that these goals are achievable since I hear about similar results with the MPCNC, and I plan to make my design beefier and more rigid.

Edited 1 time(s). Last edit at 04/25/2018 04:36AM by Trakyan.

I think the VFD spindle with software control is a bit too specific. Not only are there a million and one configurations, but I suspect a lot of people would be running these machines with a router or similar which don't work with a VFD. Dunno, I guess it all depends on what price point I'll be building to I guess but right now it looks like that's out of the budget area.

I'm not sure whether that's a case of the questions being biased or I'm asking a specific audience. I've tried CNC-zone and got no response whatsoever, any suggestions for where else I could ask? I'm also fairly sure there are people here who are interested in CNC routers for reasons other than 3D printer upgrades, myself included. I doubt any of the people who chipped in here as owners of a CNC router built it for the purpose of upgrading their 3D printer.Quote

Origamib

Your questions are inherently biased. You're asking a 3D printing forum what they want... The answer is the ability to cut metal to 0.1mm or better and a build size of 300m2 or bigger. The main use will be for 3D printer upgrades.

The cost is obviously between £300 and £700. The higher end is approaching current machines on the market and the lower end may not even be possible. These answers are quite obvious...

Quote

Origamib

Now, ask a wider audience and you will get a better response. Perhaps most people are happy with +/- 1mm and only want to make furniture, household decorations and stuff they can sell on etsy.

What do you want? What do you think is possible at this price point? The lower price will require more thought on the design, and you are the designer.

Me? I'm after a fairly large format machine. I plan to use it for largish woodworking projects like longboard decks and furniture and stuff around the house. I also intend to use it for some small aluminium pieces. I know those two are at odds with each other but if I go with a steel tube construction like I'm currently planning it won't be hard to switch between the two if I need to for rigidity reasons. I personally don't need any more than +-0.1 mm, but I'd like to know what other are wanting. I'm fairly sure that these goals are achievable since I hear about similar results with the MPCNC, and I plan to make my design beefier and more rigid.

Edited 1 time(s). Last edit at 04/25/2018 04:36AM by Trakyan.

|

Re: Thoughts on a beginner CNC April 25, 2018 09:44AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Trakyan

...

Me? I'm after a fairly large format machine. I plan to use it for largish woodworking projects like longboard decks and furniture and stuff around the house. I also intend to use it for some small aluminium pieces. I know those two are at odds with each other but if I go with a steel tube construction like I'm currently planning it won't be hard to switch between the two if I need to for rigidity reasons. I personally don't need any more than +-0.1 mm, but I'd like to know what other are wanting. I'm fairly sure that these goals are achievable since I hear about similar results with the MPCNC, and I plan to make my design beefier and more rigid.

OK, so you answered your own initial question.

So based on what you want, just go ahead and "design" your machine. At least it will fulfill your requirements and may be others too.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Thoughts on a beginner CNC April 25, 2018 10:09AM |

Registered: 8 years ago Posts: 1,671 |

Havent you guy's figured it out yet, Trakyan is a Quantum Chat Bot designed by the Uni of NZ, it knows the answer before asking the question

Concrete Lathe [www.youtube.com]

Edited 1 time(s). Last edit at 04/25/2018 07:13PM by MechaBits.

Concrete Lathe [www.youtube.com]

Edited 1 time(s). Last edit at 04/25/2018 07:13PM by MechaBits.

|

Re: Thoughts on a beginner CNC April 25, 2018 07:22PM |

Registered: 7 years ago Posts: 507 |

Except it's not about what I want. The course is about a business venture, that means the product has to adhere to what the market wants not what the creator wants. Origamib asked for my opinion on the subject, I answered.Quote

MKSA

OK, so you answered your own initial question.

So based on what you want, just go ahead and "design" your machine. At least it will fulfill your requirements and may be others too.

|

Re: Thoughts on a beginner CNC April 26, 2018 12:05PM |

Registered: 9 years ago Posts: 465 |

I would consider using whatever parts will get me acceptable results. Acceptable being as I defined earlier. For me, 3D printed parts are good as a prototype, but they're generally weak against mechanical stresses. For my 3D printer, one of the first things that I did was make a complete set of 3D printed parts to prepare for their eventual breaking. In my I3, before I retired it as being unusable, I think the only printed part that hadn't been replaced was the print head carriage.

What would I use a CNC for?

Well, I do a lot of DIY electronics projects, most of which need some sort of home. Currently many of these reside in 3D printed cases, but some are too large. (I have a DIY video projector which is quite bulky, the case for which was made on my table saw, but it's not really what you'd call "pretty" -- certainly not a show piece.) If I have a build area large enough, I'd like to make something nicer to house it in.

My home theatre PC is currently housed in a makeshift case to fit in Ikea Kallax shelving. I have done a 3D printing project to make something to hold the optical drive, power button, LEDs and USB ports which goes into a panel cut on the tablesaw. A CNC router would give me more flexibility in placing components without needing an ungainly sized 3D printed panel. (The front panel is 335mm by 335mm to fit in the shelving.) My DIY speakers use 8" drivers for the bass, plus 4" midrange drivers and a 1" tweeter. 3D printing a front panel for these is beyond the capabilities of my printer, and the material isn't really rigid enough for adequate power handling anyway. These are in hand-routed plates now. The DIY amplifier powering them has a very plain front face, which I built before choosing the current shelving solution, so it's 345mm long. It doesn't NEED to be that long, the heatsink on the back is 305mm in length, but as a result the amplifier has to sit beside the shelving. I would make a new case for the amplifier, and improve the front panel appearance. These are smaller projects that could be done with about a 13" square build area.

Of course I would also love to make parts for my 3D printer that are stronger and more rigid than what I currently have.

What sort of budget do I have for the machine?

Well, I'm Canadian, so figures are approximated Canadian dollars.

Well, currently not much, or else I'd have built it already. I've been looking at hobbycnc.com for prices on the motors and controllers for a CNC mill. A basic 3 axis kit is about $200 for the electronics. Maybe another $50 for a DC power supply. I'd budget about the same for the misc parts that I'd expect to come with the kit, motor holders, leadscrews, anti-backlash hardware, sliders. Probably another $100 or so for a couple sheets of MDF (12mm and 19mm) and probably a couple of lengths of gas pipe for rails. I already have a router, and a shop vac which I'll want to use for the project. A basic router is about $125, but just a spindle kit is probably about $75 for one that's not bad. All told, I'd expect that this would cost $600 or so. That should be about $450 USD or so, I guess. Allow another $100 or so for discretionary budget with "nice to have" items and a bit for "oops" factor with some room for design oversights.

What sort of extra features?

Well, I'm going to want some sort of hold-down. I'd love to build a vacuum table, but that's probably something that I will want to leave the ability to add later, rather than needing it in the initial design, as I expect this to be additional cost in materials, not to mention the power requirements for the vacuum itself. (I've seem some using shop vacs, but none of these seem really great) This is probably easier to build once the CNC itself is up and running. Initial build area is probably more important to me, so that I can use it to make its own improvements. I'd like to have some sort of homing for repeatable positioning. Simple microswitch homing should be fine. I already have the switches.

Other than the hardware?

Well, I think that on these forums, you're going to find a lot of people with a DIY mindset, so you're going to need to offer something to us. Look at the popular 3D printer designs. they can be assembled as-is, but are usually flexible, allowing the user to tinker with it, make alterations and adjustments the make it suitable for his or her specific purpose and materials. A baseline build with decent instructions to make a functional CNC router using likely available tools is the starting point. Then use the router to make certain upgraded parts with more complex shaping. Include files needed for the better parts, so that an inexperienced user can learn to use the machine and recommended software package.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

What would I use a CNC for?

Well, I do a lot of DIY electronics projects, most of which need some sort of home. Currently many of these reside in 3D printed cases, but some are too large. (I have a DIY video projector which is quite bulky, the case for which was made on my table saw, but it's not really what you'd call "pretty" -- certainly not a show piece.) If I have a build area large enough, I'd like to make something nicer to house it in.

My home theatre PC is currently housed in a makeshift case to fit in Ikea Kallax shelving. I have done a 3D printing project to make something to hold the optical drive, power button, LEDs and USB ports which goes into a panel cut on the tablesaw. A CNC router would give me more flexibility in placing components without needing an ungainly sized 3D printed panel. (The front panel is 335mm by 335mm to fit in the shelving.) My DIY speakers use 8" drivers for the bass, plus 4" midrange drivers and a 1" tweeter. 3D printing a front panel for these is beyond the capabilities of my printer, and the material isn't really rigid enough for adequate power handling anyway. These are in hand-routed plates now. The DIY amplifier powering them has a very plain front face, which I built before choosing the current shelving solution, so it's 345mm long. It doesn't NEED to be that long, the heatsink on the back is 305mm in length, but as a result the amplifier has to sit beside the shelving. I would make a new case for the amplifier, and improve the front panel appearance. These are smaller projects that could be done with about a 13" square build area.

Of course I would also love to make parts for my 3D printer that are stronger and more rigid than what I currently have.

What sort of budget do I have for the machine?

Well, I'm Canadian, so figures are approximated Canadian dollars.

Well, currently not much, or else I'd have built it already. I've been looking at hobbycnc.com for prices on the motors and controllers for a CNC mill. A basic 3 axis kit is about $200 for the electronics. Maybe another $50 for a DC power supply. I'd budget about the same for the misc parts that I'd expect to come with the kit, motor holders, leadscrews, anti-backlash hardware, sliders. Probably another $100 or so for a couple sheets of MDF (12mm and 19mm) and probably a couple of lengths of gas pipe for rails. I already have a router, and a shop vac which I'll want to use for the project. A basic router is about $125, but just a spindle kit is probably about $75 for one that's not bad. All told, I'd expect that this would cost $600 or so. That should be about $450 USD or so, I guess. Allow another $100 or so for discretionary budget with "nice to have" items and a bit for "oops" factor with some room for design oversights.

What sort of extra features?

Well, I'm going to want some sort of hold-down. I'd love to build a vacuum table, but that's probably something that I will want to leave the ability to add later, rather than needing it in the initial design, as I expect this to be additional cost in materials, not to mention the power requirements for the vacuum itself. (I've seem some using shop vacs, but none of these seem really great) This is probably easier to build once the CNC itself is up and running. Initial build area is probably more important to me, so that I can use it to make its own improvements. I'd like to have some sort of homing for repeatable positioning. Simple microswitch homing should be fine. I already have the switches.

Other than the hardware?

Well, I think that on these forums, you're going to find a lot of people with a DIY mindset, so you're going to need to offer something to us. Look at the popular 3D printer designs. they can be assembled as-is, but are usually flexible, allowing the user to tinker with it, make alterations and adjustments the make it suitable for his or her specific purpose and materials. A baseline build with decent instructions to make a functional CNC router using likely available tools is the starting point. Then use the router to make certain upgraded parts with more complex shaping. Include files needed for the better parts, so that an inexperienced user can learn to use the machine and recommended software package.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Thoughts on a beginner CNC April 26, 2018 08:27PM |

Registered: 7 years ago Posts: 507 |

Thanks for the thorough reply SupraGuy. My machine is going to use steel pipe/tubing and 3D printed parts, because that's what I have available. V2 will be a CNC milled CNC mill, naturally. It'll probably be a completely different design though since with my current design, it relies heavily on the geometric flexibility of 3D printing. I could create something similar to be CNC cut but it would have ohh so many parts and be a nightmare to assemble...

Right now the machine is looking to be around $200 USD (also not an american, but I figure that's what most people here will be familiar with) excluding the steel tubing (which depends on how big you build the machine and where you live) and a router or spindle. That's the rock bottom, minimum viable product. I'm probably going to end up upgrading some of the components (i.e. spectra like -> belts) if they don't perform well enough. The machine is designed to be hackable/expandable, and all of the source files will be published (not just STLs) when I'm done. The machine is designed in OpenSCAD which I know isn't everyone's favorite, but it makes it super easy for a beginner to customize a machine to fit their needs by just changing a couple of variables. That and I can't for the life of me make anything much more complex than a cylinder in graphical CAD programs.

I should have the design done and start printing the parts in the next week or two, so I'll post on that when I get to that stage. After that it's assembly and testing. Anyone keen to do a build along?

Right now the machine is looking to be around $200 USD (also not an american, but I figure that's what most people here will be familiar with) excluding the steel tubing (which depends on how big you build the machine and where you live) and a router or spindle. That's the rock bottom, minimum viable product. I'm probably going to end up upgrading some of the components (i.e. spectra like -> belts) if they don't perform well enough. The machine is designed to be hackable/expandable, and all of the source files will be published (not just STLs) when I'm done. The machine is designed in OpenSCAD which I know isn't everyone's favorite, but it makes it super easy for a beginner to customize a machine to fit their needs by just changing a couple of variables. That and I can't for the life of me make anything much more complex than a cylinder in graphical CAD programs.

I should have the design done and start printing the parts in the next week or two, so I'll post on that when I get to that stage. After that it's assembly and testing. Anyone keen to do a build along?

|

Re: Thoughts on a beginner CNC May 07, 2018 01:54AM |

Registered: 8 years ago Posts: 1,671 |

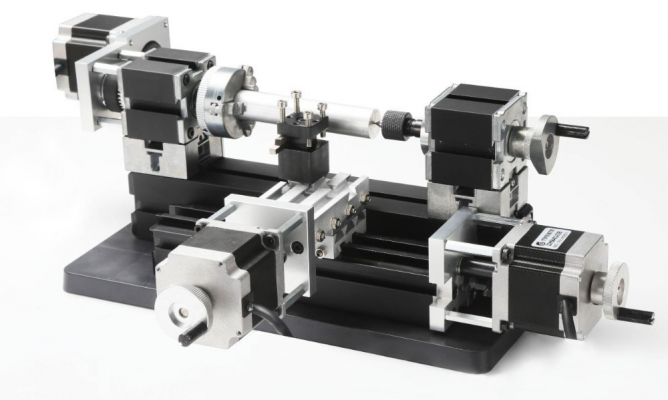

If the CNC was for a Teaching Tool, then these are cheap( & Nasty)

Hoping my micro machine performs a little better but I won't know until I try.

Still waiting for Collet, need some tooling, work on live center, and think about how I would arrange it with custom metal parts.

Edited 2 time(s). Last edit at 05/07/2018 02:06AM by MechaBits.

Hoping my micro machine performs a little better but I won't know until I try.

Still waiting for Collet, need some tooling, work on live center, and think about how I would arrange it with custom metal parts.

Edited 2 time(s). Last edit at 05/07/2018 02:06AM by MechaBits.

|

Re: Thoughts on a beginner CNC May 07, 2018 05:28AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Thoughts on a beginner CNC May 07, 2018 08:44AM |

Registered: 8 years ago Posts: 1,671 |

Funny you should say that, it was a skip find....it's 2 inch thick,

but just wood chips & melamine...I got 3 pieces.

If I want a granite slab its Home Bargains for 4.99

but the other week at a party, I met the local stonemason,

we talked marbles, and how I needed some accurate holes drilling,

he said to call up to the local cemetery some time and pick up some of his pieces he's been saving

and the lads will put some holes in it....

As soon as I figure out where I want them holes i'll be up there,

problem is the guy was really old & if I dont figure things out soon...

I might miss my chance

I assume the granite slab was the only thing you liked

Edited 2 time(s). Last edit at 05/07/2018 01:20PM by MechaBits.

but just wood chips & melamine...I got 3 pieces.

If I want a granite slab its Home Bargains for 4.99

but the other week at a party, I met the local stonemason,

we talked marbles, and how I needed some accurate holes drilling,

he said to call up to the local cemetery some time and pick up some of his pieces he's been saving

and the lads will put some holes in it....

As soon as I figure out where I want them holes i'll be up there,

problem is the guy was really old & if I dont figure things out soon...

I might miss my chance

I assume the granite slab was the only thing you liked

Edited 2 time(s). Last edit at 05/07/2018 01:20PM by MechaBits.

|

Re: Thoughts on a beginner CNC May 07, 2018 02:54PM |

Registered: 6 years ago Posts: 1,007 |

Quote

MechaBits

Funny you should say that, it was a skip find....it's 2 inch thick,

but just wood chips & melamine...I got 3 pieces.

If I want a granite slab its Home Bargains for 4.99

but the other week at a party, I met the local stonemason,

we talked marbles, and how I needed some accurate holes drilling,

he said to call up to the local cemetery some time and pick up some of his pieces he's been saving

and the lads will put some holes in it....

...

In fact I was half joking as indeed, I looked at the same places, stone for kitchen top, headstone... , not just for the base but for a bed too.

Edited 1 time(s). Last edit at 05/07/2018 02:59PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Thoughts on a beginner CNC May 07, 2018 05:02PM |

Registered: 7 years ago Posts: 507 |

It's a machine for personal/hobby use. Or at least I intend to use it as such, I have nothing against someone wanting to use it as a teaching tool. That and the machine you linked to isn't a CNC. It also isn't really too much cheaper, especially compared to the size and performance difference I'll be getting from my machine.

|

Re: Thoughts on a beginner CNC May 12, 2018 04:02PM |

Registered: 8 years ago Posts: 28 |

Definitely do a CNC lathe... the lathe can make nearly everything a mill can, plus items like your leadscrews, bearings, and smooth rods. A lathe with a boring bar, chucked along the XY plane, can also manufacture flat planes for your build surface. For other things, access to a mill might be more convenient. I think there is more overlap in usefulness between a mill and a 3D printer, than perhaps there is between a lathe and a printer.

|

Re: Thoughts on a beginner CNC May 13, 2018 07:28AM |

Registered: 7 years ago Posts: 507 |

I wouldn't say a lathe can do nearly anything a mill can. With live tooling then maybe, but at that point it's a mill with an A axis if you ask me. The reason I'm going for CNC is that the spindle for a CNC can often be much smaller, lighter and cheaper than the spindle setup on a lathe which has to be bigger, heavier and I'd argue more precise. That and using a lathe for a large format cutting like sheets of MDF and plywood (which is what most hobbyist seem to use their CNC routers for) would require very long axis on the lathe, with large cantilevers for the tooling.

|

Re: Thoughts on a beginner CNC May 23, 2018 09:55PM |

Registered: 8 years ago Posts: 1,671 |

This is the Pic I should have posted,

I just found the first one on ebay as example, the metal ones look better but still kinda cheap looking, this seems a lot better.

I just found the first one on ebay as example, the metal ones look better but still kinda cheap looking, this seems a lot better.

|

Re: Thoughts on a beginner CNC May 23, 2018 11:17PM |

Registered: 7 years ago Posts: 507 |

What sort of price are those things going for? I might be interested for making some round parts. That being said, it doesn't fit the goals I (and I'm pretty sure many other hobbyists) are after and that's to work with large, flat sheet materials like plywood, MDF and the occasional bit of sheet metal.

|

Re: Thoughts on a beginner CNC May 24, 2018 11:09AM |

Registered: 8 years ago Posts: 1,671 |

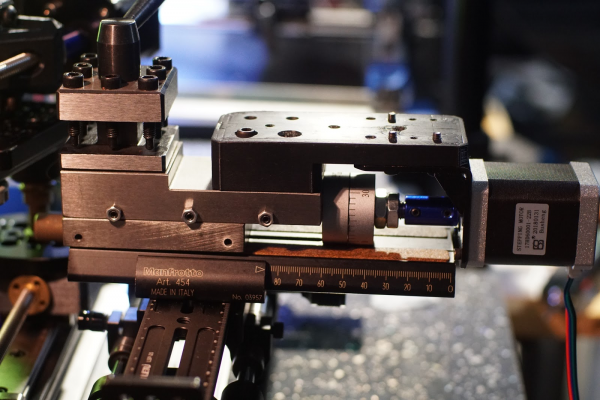

or mod the cheap one with 3D printing,

This tool holder was £40 and converted for next to nothing. Could easily be reconfigured as a short Z for router head, I'm tempted to get another for that use.

Edited 1 time(s). Last edit at 05/25/2018 11:26AM by MechaBits.

This tool holder was £40 and converted for next to nothing. Could easily be reconfigured as a short Z for router head, I'm tempted to get another for that use.

Edited 1 time(s). Last edit at 05/25/2018 11:26AM by MechaBits.

Sorry, only registered users may post in this forum.