No-leadscrew, single-motor, precision Z-axis design

Posted by golfwolf

|

Re: No-leadscrew, single-motor, precision Z-axis design April 30, 2018 05:15PM |

Registered: 8 years ago Posts: 28 |

That is badddd asssss! With the fishing line tensioned with rubber bands it must let it have adjustable 'zeroes', avoiding the problem of overconstraint in the 4/17 post. Out of curiosity, without the rubber bands, are there hard 'zeroes', and does it fall down freely w/o the bands?

I'm definitely gonna build this mechanism now. It's climbing up the project roster, faster than an over-counterweighted carriage

I'm definitely gonna build this mechanism now. It's climbing up the project roster, faster than an over-counterweighted carriage

|

Re: No-leadscrew, single-motor, precision Z-axis design April 30, 2018 06:04PM |

Registered: 10 years ago Posts: 564 |

Quote

o_lampe

I made a short demo video about how the fishing line dual roller constrains the horizontal movement. The lines were tensioned by rubberband and as long as the tilting force is lower than the rubbers tension it stays horizontal.

I almost felt like David Copperfield, when I lifted the extrusion with two fingers

[attachment 104682 dual_roller_constraint.JPG]

Looks like a drafting parallel bar. I used one of them for years.

|

Re: No-leadscrew, single-motor, precision Z-axis design April 30, 2018 07:05PM |

Registered: 7 years ago Posts: 507 |

I believe drafting parallel bars have the spectra line fixed to the bar as shown here [corexy.com]

The arrangement in this thread has idlers rather than fixed ends on the bar. Not to say a parallel bar type mechanism would be a bad idea. My only problem with this mechanism seems like it could deflect fairly easily perpendicular to the axis of travel (translation, not twisting) since the only thing stopping this is tension, and everyone can attest to the fact you can noticeably pluck and deflect a cable no matter how much tension it's under. I can imagine it vibrating like a guitar string when the machine hits resonance.

The arrangement in this thread has idlers rather than fixed ends on the bar. Not to say a parallel bar type mechanism would be a bad idea. My only problem with this mechanism seems like it could deflect fairly easily perpendicular to the axis of travel (translation, not twisting) since the only thing stopping this is tension, and everyone can attest to the fact you can noticeably pluck and deflect a cable no matter how much tension it's under. I can imagine it vibrating like a guitar string when the machine hits resonance.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 01, 2018 01:30AM |

Registered: 8 years ago Posts: 5,232 |

Quote

LoboCNC

Quote

o_lampe

I made a short demo video about how the fishing line dual roller constrains the horizontal movement. The lines were tensioned by rubberband and as long as the tilting force is lower than the rubbers tension it stays horizontal.

I almost felt like David Copperfield, when I lifted the extrusion with two fingers

[attachment 104682 dual_roller_constraint.JPG]

Looks like a drafting parallel bar. I used one of them for years.

See the drawing on page 1. The author wants to use only one line per side. We discussed the common approach of using two lines and my vid was the demo of this arangement.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 01, 2018 01:45AM |

Registered: 8 years ago Posts: 5,232 |

Yes "zero" is adjustable now. I could've tried to make them without rubberbands, but wanted a quick result. One fixed length and one adjustable line would work, too. There are ways to adjust the line without any springiness.Quote

golfwolf

That is badddd asssss! With the fishing line tensioned with rubber bands it must let it have adjustable 'zeroes', avoiding the problem of overconstraint in the 4/17 post. Out of curiosity, without the rubber bands, are there hard 'zeroes', and does it fall down freely w/o the bands?

It wouldn't drop down, because the extrusion isn't in balance. I'd have to mount two rollers on each side of the extrusion. I could then lift it with one finger *mhuhahaha*

Edited 1 time(s). Last edit at 05/01/2018 01:52AM by o_lampe.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 01, 2018 01:50AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Trakyan

My only problem with this mechanism seems like it could deflect fairly easily perpendicular to the axis of travel (translation, not twisting) since the only thing stopping this is tension,

That's the whole idea behind the exact constraint method. The bar is only constraint in one DOF.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 01, 2018 03:08AM |

Registered: 7 years ago Posts: 507 |

|

Re: No-leadscrew, single-motor, precision Z-axis design May 01, 2018 06:29AM |

Registered: 8 years ago Posts: 5,232 |

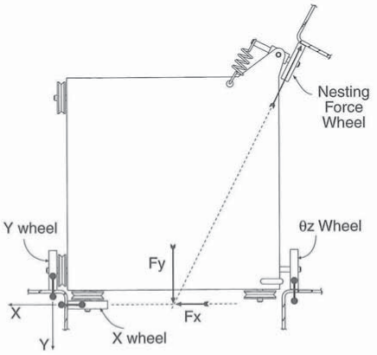

The whole installation with all the wheels and so on will constrain the bed to one DOF, but each part shouldn't add "involuntary" constraints to avoid binding and alignment problems.Quote

Trakyan

From what I understand is it is supposed to be constrain TO one degree of travel, not IN one degree of travel.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 01, 2018 10:13PM |

Registered: 7 years ago Posts: 507 |

I understand that, I was just expressing my concerns. No matter how much you tension that string the bar can wobble and deflect the same way a string would when plucked. I'm totally a fan of using only strings to constrain something but I think there's a reason we use linear rods in XY mechanisms even though they aren't strictly necessary if you assume the tensioned belts don't deflect from a straight line.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 02, 2018 02:28PM |

Registered: 8 years ago Posts: 28 |

There are applications where this mechanism would not be appropriate, such as milling machines. The (single) strings work as constraints because the carriage, reliably, has got stable forces. Bed weight and nesting force. Small forces from pulling plastic off the nozzle. Vibration from the X/Y gantry. So a plucked constraint string would raise and rotate the bed, it's true, but there's not much in this particular system to do the plucking.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 02, 2018 09:36PM |

Registered: 7 years ago Posts: 507 |

I dunno, I just imagined the vibration from the XY movement could be enough to get it rocking side to side. If you look at some cantilevered beds, the XY motion of a printer can get them to shake pretty bad, so I imagine it would have some effect on this as well. To simulate this, you could grab near the top/bottom of the string and give it a shake (the same way it would if the print head was accelerating or decelerating) and see what happens. I would love to be proven wrong here, I'm a big fan of strings and cheap designs, and you can't get much cheaper than string and some bearings.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 03, 2018 01:30AM |

Registered: 8 years ago Posts: 5,232 |

@Trakyan

The wheels are responsible to deal with these forces. Not the fishing line.

The wheels are responsible to deal with these forces. Not the fishing line.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 03, 2018 06:17AM |

Registered: 7 years ago Posts: 507 |

|

Re: No-leadscrew, single-motor, precision Z-axis design May 04, 2018 05:56AM |

Registered: 12 years ago Posts: 1,450 |

Looking through several websites and available PDF papers (not being willing to spend £70 on the Exact Constraint book by Douglass L. Blanding) it appears to me that this design method should reduce the effect of vibration as long as the forces that generate the vibration are again constrained in the same manner as the more static forces.

I also like it as it supports my contention that using cable ties to hold LM8UU type linear bearings in 3D printers is better than using heavy bearing blocks: The constraints in two directions and two rotations is the mounting groove for the bearing and the nesting force is the tension of the cable ties. Anything more than sufficient constraint adds weight with no gain in operational rigidity.

Mike

I also like it as it supports my contention that using cable ties to hold LM8UU type linear bearings in 3D printers is better than using heavy bearing blocks: The constraints in two directions and two rotations is the mounting groove for the bearing and the nesting force is the tension of the cable ties. Anything more than sufficient constraint adds weight with no gain in operational rigidity.

Mike

|

Re: No-leadscrew, single-motor, precision Z-axis design May 04, 2018 06:13AM |

Registered: 8 years ago Posts: 28 |

the book is available on your local internet technical library [gen.lib.rus.ec]

|

Re: No-leadscrew, single-motor, precision Z-axis design May 04, 2018 07:10AM |

Registered: 12 years ago Posts: 1,450 |

Any attempt to download any of the books on this are met wit the message:-

ACCESS TO THE WEBSITES LISTED ON THIS PAGE HAS BEEN BLOCKED PURSUANT TO ORDERS OF THE HIGH COURT

I am not sure that I would like to steal a copy of the book but equally I am disappointed that the author does not make the book available freely for non-commercial use. If I get some time I may visit a university library to read it.

Mike

ACCESS TO THE WEBSITES LISTED ON THIS PAGE HAS BEEN BLOCKED PURSUANT TO ORDERS OF THE HIGH COURT

I am not sure that I would like to steal a copy of the book but equally I am disappointed that the author does not make the book available freely for non-commercial use. If I get some time I may visit a university library to read it.

Mike

|

Re: No-leadscrew, single-motor, precision Z-axis design May 04, 2018 10:49AM |

Registered: 6 years ago Posts: 1,007 |

Quote

leadinglights

Any attempt to download any of the books on this are met wit the message:-

ACCESS TO THE WEBSITES LISTED ON THIS PAGE HAS BEEN BLOCKED PURSUANT TO ORDERS OF THE HIGH COURT

I am not sure that I would like to steal a copy of the book but equally I am disappointed that the author does not make the book available freely for non-commercial use. If I get some time I may visit a university library to read it.

Mike

And how can you guarantee the knowledge gained from this book won't be used for commercial purpose ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: No-leadscrew, single-motor, precision Z-axis design May 04, 2018 12:11PM |

Registered: 11 years ago Posts: 335 |

Exact Constraint formalizes a lot of intuitive ideas, but also takes it a step further by meticulously avoiding overconstraints. This is a very application-specific way to design.

The preface talks about how Exact Constraint was refined at Kodak for handling high-speed feeding of paper. An overconstrained paper web might fold or bend, causing disastrous misfeeds. Optical designs are another proposed application, since eliminating overconstraint reduces the number of close-tolerance parts required.

Most machine tools are highly overconstrained to achieve rigidity. Exact constraint principles are probably most applicable to the bed-leveling device (where it would essentially become a three-point design with springs and balls). I'm not as convinced by the linear axis designs.

The preface talks about how Exact Constraint was refined at Kodak for handling high-speed feeding of paper. An overconstrained paper web might fold or bend, causing disastrous misfeeds. Optical designs are another proposed application, since eliminating overconstraint reduces the number of close-tolerance parts required.

Most machine tools are highly overconstrained to achieve rigidity. Exact constraint principles are probably most applicable to the bed-leveling device (where it would essentially become a three-point design with springs and balls). I'm not as convinced by the linear axis designs.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 04, 2018 05:14PM |

Registered: 8 years ago Posts: 28 |

Quote

leadinglights

Any attempt to download any of the books on this are met wit the message:-

ACCESS TO THE WEBSITES LISTED ON THIS PAGE HAS BEEN BLOCKED PURSUANT TO ORDERS OF THE HIGH COURT

I am not sure that I would like to steal a copy of the book but equally I am disappointed that the author does not make the book available freely for non-commercial use. If I get some time I may visit a university library to read it.

Mike

That's crazy your government's censoring your internet from a library. Like, we all understand the why, it doesn't make the why any less insane. It's a book, do they not want their engineers educated? Not to get political about it. PM me and I can "lend" you a copy of the book I made with my computer.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 05, 2018 05:43AM |

Registered: 8 years ago Posts: 1,671 |

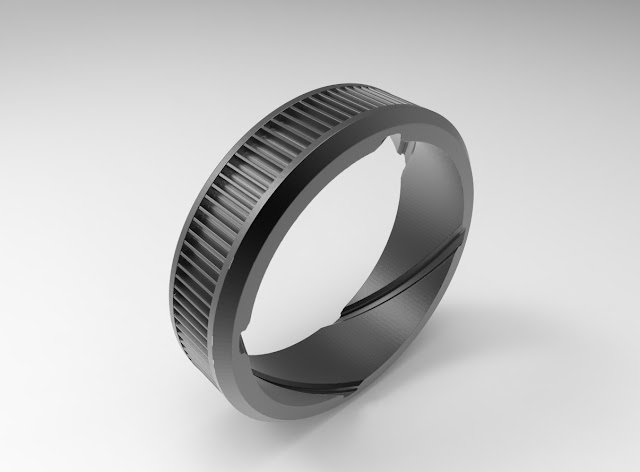

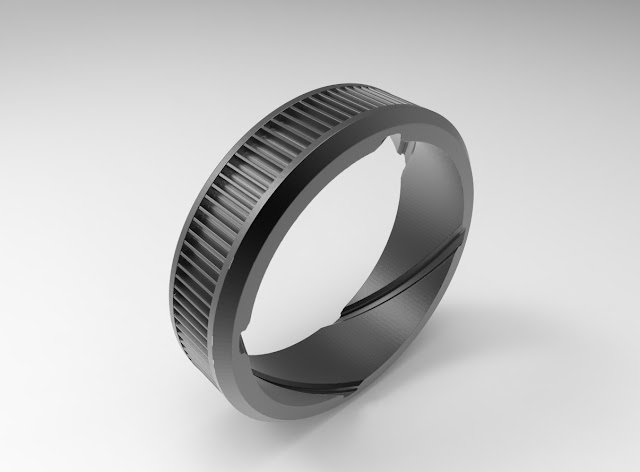

I think I may have an idea for Z without metal leadscrews

I've been making this for a lens assembly, but with a little modification maybe it could be used for Z elevators,

it sits on another tube with vertical slots, and another inside that that would rise or fall though which parts rise n fall depends on assembly, pins extending from the inner tube into the grooves, so when this ring spins...maybe an improved version with bearings, or a rise & fall platform with one central column base underneath....might need large hole in work surface or printer base, or maybe another orientation could solve that. Center piece could also be used to pull string.

Edited 2 time(s). Last edit at 05/05/2018 12:39PM by MechaBits.

I've been making this for a lens assembly, but with a little modification maybe it could be used for Z elevators,

it sits on another tube with vertical slots, and another inside that that would rise or fall though which parts rise n fall depends on assembly, pins extending from the inner tube into the grooves, so when this ring spins...maybe an improved version with bearings, or a rise & fall platform with one central column base underneath....might need large hole in work surface or printer base, or maybe another orientation could solve that. Center piece could also be used to pull string.

Edited 2 time(s). Last edit at 05/05/2018 12:39PM by MechaBits.

|

Re: No-leadscrew, single-motor, precision Z-axis design May 06, 2018 07:01AM |

Registered: 8 years ago Posts: 28 |

|

Re: No-leadscrew, single-motor, precision Z-axis design May 06, 2018 07:53AM |

Registered: 8 years ago Posts: 1,671 |

Sorry, only registered users may post in this forum.