How to make a stronger X car

Posted by drmaestro

|

How to make a stronger X car April 25, 2018 12:06PM |

Registered: 9 years ago Posts: 330 |

Hi,

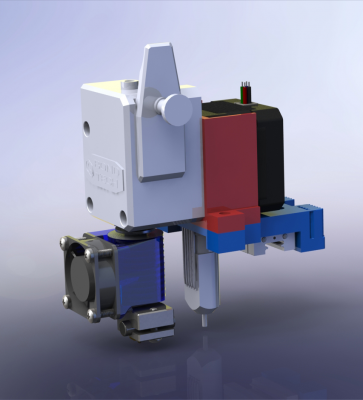

I am trying to make a design change to my cartesian printer. I wanted to try the Bondtech BMG extruder and while the form factor is close to Titan (my current extruder), it doesn't directly fit, so I wanted to make a new design. Here is the picture of what I did:

As you can see, it is a single rail system (MGN 9) and it integrates a BLTouch. The blue part is the car and the red part is the bracket. The car needs to have a recess for the BLTouch, as the length is too long for the BMG+E3DV6's combined length if it is directly attached underneath the car. The back side of the car has protrusions (with teeth like shapes) used to attach GT2 belts. I printed both parts but there is a problem: The car flexes too much, as it is only being held in place by a single carriage on the rail. How can I make this design more robust? Could it be CNCed from metal (the shape isn't complex but the GT2 attachments could be problematic)?

Thanks

I am trying to make a design change to my cartesian printer. I wanted to try the Bondtech BMG extruder and while the form factor is close to Titan (my current extruder), it doesn't directly fit, so I wanted to make a new design. Here is the picture of what I did:

As you can see, it is a single rail system (MGN 9) and it integrates a BLTouch. The blue part is the car and the red part is the bracket. The car needs to have a recess for the BLTouch, as the length is too long for the BMG+E3DV6's combined length if it is directly attached underneath the car. The back side of the car has protrusions (with teeth like shapes) used to attach GT2 belts. I printed both parts but there is a problem: The car flexes too much, as it is only being held in place by a single carriage on the rail. How can I make this design more robust? Could it be CNCed from metal (the shape isn't complex but the GT2 attachments could be problematic)?

Thanks

|

Re: How to make a stronger X car April 25, 2018 12:22PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: How to make a stronger X car April 25, 2018 12:51PM |

Registered: 11 years ago Posts: 5,780 |

Why not make the car out of metal and print the belt clamps to screw onto the metal car?

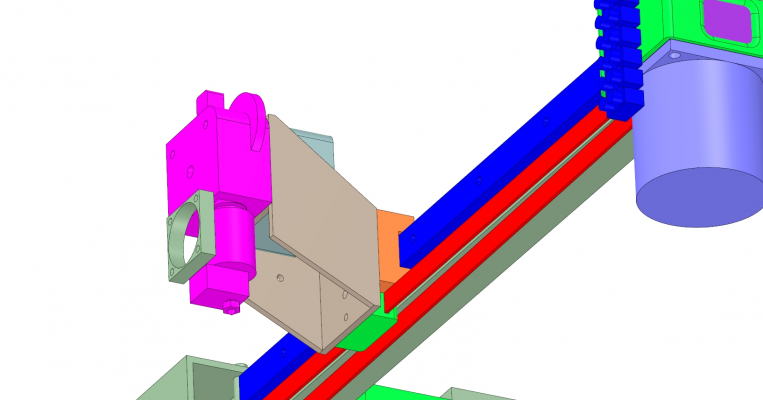

This is the mount (gray) I designed for Son of MegaMax when it was converted to the Titan. The mount itself is made from 2" square aluminum tubing that screws to the bearing block (orange). I kept the original belt clamp (bright green) which is a printed part and screws to the extruder mount with a single screw. The motor fits inside the tubing, and this makes a very rigid mount for the extruder.

The Titan and BMG mount in similar ways, which kind of sucks. You're stuck with either a flimsy plastic mount or you have to take the whole thing apart to do any work on the extruder. Fortunately, they're both relatively reliable and don't need a lot of attention. I wonder if anyone in China is making a metal bracket for the Titan...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

This is the mount (gray) I designed for Son of MegaMax when it was converted to the Titan. The mount itself is made from 2" square aluminum tubing that screws to the bearing block (orange). I kept the original belt clamp (bright green) which is a printed part and screws to the extruder mount with a single screw. The motor fits inside the tubing, and this makes a very rigid mount for the extruder.

The Titan and BMG mount in similar ways, which kind of sucks. You're stuck with either a flimsy plastic mount or you have to take the whole thing apart to do any work on the extruder. Fortunately, they're both relatively reliable and don't need a lot of attention. I wonder if anyone in China is making a metal bracket for the Titan...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: How to make a stronger X car April 26, 2018 02:05AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: How to make a stronger X car April 26, 2018 07:12AM |

Registered: 9 years ago Posts: 330 |

Thanks for the suggestions.

Doesn't using a single screw for the belt clamp create a possibility for the rotation of the clamp? When the belts are tensioned, they could apply a rotational force. Maybe using a larger belt clamp with 2 side holes could be a better solution?

About replacing BL touch, the Piezo solution has been on my mind for some time, however when using a Titan or a Bondtech, the hotend is directly placed inside the extruder, so the only way to add the Piezo is to replace the hotend with a plastic adapter and add the piezo and the hotend underneath the adapter. This could add some play in the assembly. Is there a good solution for this kind of extruder?

Quote

the_digital_dentist

I kept the original belt clamp (bright green) which is a printed part and screws to the extruder mount with a single screw.

Doesn't using a single screw for the belt clamp create a possibility for the rotation of the clamp? When the belts are tensioned, they could apply a rotational force. Maybe using a larger belt clamp with 2 side holes could be a better solution?

About replacing BL touch, the Piezo solution has been on my mind for some time, however when using a Titan or a Bondtech, the hotend is directly placed inside the extruder, so the only way to add the Piezo is to replace the hotend with a plastic adapter and add the piezo and the hotend underneath the adapter. This could add some play in the assembly. Is there a good solution for this kind of extruder?

|

Re: How to make a stronger X car April 26, 2018 07:32AM |

Registered: 11 years ago Posts: 5,780 |

The belt tension keeps the clamp lined up so there's no rotation. If the pulleys weren't aligned properly, I suppose there could be some tendency to rotate, but the pulleys are aligned with their axes parallel.

If you don't align the pulleys you're going to have bigger problems than the belt clamp rotating a little. The belt will try to climb on the pulley flanges and that can cause all sorts of issues.

You can always add a second screw...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you don't align the pulleys you're going to have bigger problems than the belt clamp rotating a little. The belt will try to climb on the pulley flanges and that can cause all sorts of issues.

You can always add a second screw...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.