Stackable, printed extrusions that can be filled with resin

Posted by klcjr89

|

Re: Stackable, printed extrusions that can be filled with resin April 28, 2018 03:19AM |

Registered: 8 years ago Posts: 5,232 |

I'm concerned about the stackability of the printed parts. You'd have to cut the ends very precise, before stacking them.

Filling with Resin gets much cheaper by using 95% sand and 5% resin.

Filling with foam and also using 5% infill would improve things alot. The foam can bond with the infill, which makes it much stronger than bonding with the inner surface alone.

Filling with Resin gets much cheaper by using 95% sand and 5% resin.

Filling with foam and also using 5% infill would improve things alot. The foam can bond with the infill, which makes it much stronger than bonding with the inner surface alone.

|

Re: Stackable, printed extrusions that can be filled with resin April 28, 2018 05:31AM |

Registered: 8 years ago Posts: 312 |

If you use polyurethane liquids to make the foam, instead of using the builders foam, it will foam in nicer smaller cells and harden throughout.

It is also used to create sandwich constructions, so it has to harden in enclosed areas. I used it to fill my tubular chassis with foam, to make it a bit stiffer.

You can also pick out of a variety of cell sizes. Different liquids have different foam characteristics.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

It is also used to create sandwich constructions, so it has to harden in enclosed areas. I used it to fill my tubular chassis with foam, to make it a bit stiffer.

You can also pick out of a variety of cell sizes. Different liquids have different foam characteristics.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: Stackable, printed extrusions that can be filled with resin April 28, 2018 12:45PM |

Registered: 6 years ago Posts: 207 |

|

Re: Stackable, printed extrusions that can be filled with resin April 28, 2018 03:27PM |

Registered: 6 years ago Posts: 207 |

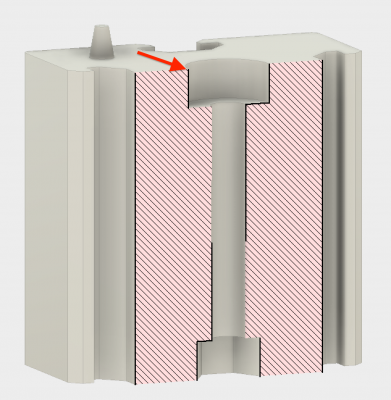

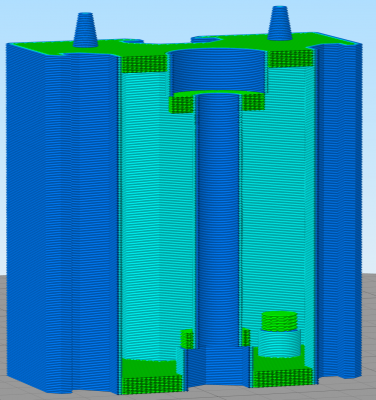

Originally, I had cutouts for a hex nyloc nut in the bottom, and a counterbore for a nut driver in the top to be able to tighten the top hex nut, negating the need for endcaps. The problem is, no matter how good the layer bonding is, the cutouts will migrate and separate away from the end faces of the extrusion; by having the hex nuts (with flat washers) resting on the top and bottom surfaces this problem was eliminated since it compresses everything. This was with no filling of foam or resin.

I think that the cutouts might actually work, provided you fill the cavity with resin and sand or other fillers. This would further simplify the design and I can make the extrusion size 50mm in height instead of the oddball 40mm + endcap requirements.

A cutaway view hopefully explains this better than my wording. Where the hex nut and counterbore cutout feature's perimeters bond to the top and bottom layers is one of the weak points, since these areas will be under tension when the internal tube's layers starts to compress from the threaded rod's clamping force.

Edited 9 time(s). Last edit at 04/28/2018 04:08PM by klcjr89.

I think that the cutouts might actually work, provided you fill the cavity with resin and sand or other fillers. This would further simplify the design and I can make the extrusion size 50mm in height instead of the oddball 40mm + endcap requirements.

A cutaway view hopefully explains this better than my wording. Where the hex nut and counterbore cutout feature's perimeters bond to the top and bottom layers is one of the weak points, since these areas will be under tension when the internal tube's layers starts to compress from the threaded rod's clamping force.

Edited 9 time(s). Last edit at 04/28/2018 04:08PM by klcjr89.

|

Re: Stackable, printed extrusions that can be filled with resin April 29, 2018 01:58AM |

Registered: 8 years ago Posts: 5,232 |

Why did you choose 50mm height? Is that your printers max. height? I think, making them as long as possible will reduce the number of contact areas ( read: chances of misalignment )

I've made airfoils for a vertical windmill 270mm high on my CoreXY. Others will report much taller parts ( tall vases and such )

For my Delta I'm currently inventing a new print mode, I call Tower mode. It didn't work out yet, but I'm close. ( The magnets of the rods are too close to the fans )

It prints the first half of a very tall part in normal mode, then I revers the effector/rod/carrier orientation ( carriers are now below the effector ) and print the upper half of the part. One day I can print parts taller than the Delta frame

Edited 1 time(s). Last edit at 04/29/2018 02:01AM by o_lampe.

I've made airfoils for a vertical windmill 270mm high on my CoreXY. Others will report much taller parts ( tall vases and such )

For my Delta I'm currently inventing a new print mode, I call Tower mode. It didn't work out yet, but I'm close. ( The magnets of the rods are too close to the fans )

It prints the first half of a very tall part in normal mode, then I revers the effector/rod/carrier orientation ( carriers are now below the effector ) and print the upper half of the part. One day I can print parts taller than the Delta frame

Edited 1 time(s). Last edit at 04/29/2018 02:01AM by o_lampe.

|

Re: Stackable, printed extrusions that can be filled with resin April 29, 2018 02:00AM |

Registered: 6 years ago Posts: 207 |

Quote

o_lampe

Why did you choose 50mm height? Is that your printers max. height? I think, making them as long as possible will reduce the number of contact areas ( read: chances of misalignment )

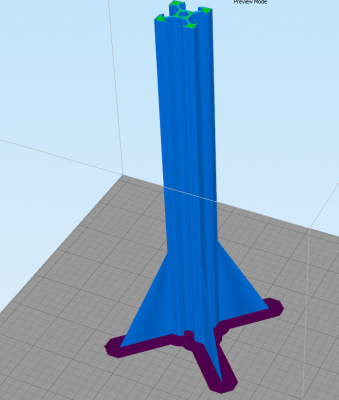

It was done to keep possible print failures at a lower point instead of printing a 300mm tall extrusion and have it fail and waste plastic.

Edited 1 time(s). Last edit at 04/29/2018 02:01AM by klcjr89.

|

Re: Stackable, printed extrusions that can be filled with resin April 29, 2018 02:05AM |

Registered: 8 years ago Posts: 5,232 |

Quote

klcjr89

This hasn't been an issue at all. Ready to go straight off a well-tuned delta printer.Quote

o_lampe

You'd have to cut the ends very precise, before stacking them.

Quote

It was done to keep possible print failures at a lower point instead of printing a 300mm tall extrusion and have it fail and waste plastic.

What now? Do you have a well tuned Delta or not?

You'd need gooood bed adhesion too.

You'd need gooood bed adhesion too.

|

Re: Stackable, printed extrusions that can be filled with resin April 29, 2018 08:19AM |

Registered: 8 years ago Posts: 601 |

Quote

klcjr89

Quote

o_lampe

Why did you choose 50mm height? Is that your printers max. height? I think, making them as long as possible will reduce the number of contact areas ( read: chances of misalignment )

It was done to keep possible print failures at a lower point instead of printing a 300mm tall extrusion and have it fail and waste plastic.

I'f you're worried about adhesion... get creative. Add some ribs to the design that are a single extrusion thick (0.48mm in my case) and then cut them off with a sharp blade. Add a brim for extra strength.

|

Re: Stackable, printed extrusions that can be filled with resin April 29, 2018 09:47AM |

Registered: 6 years ago Posts: 207 |

Quote

Origamib

Quote

klcjr89

Quote

o_lampe

Why did you choose 50mm height? Is that your printers max. height? I think, making them as long as possible will reduce the number of contact areas ( read: chances of misalignment )

It was done to keep possible print failures at a lower point instead of printing a 300mm tall extrusion and have it fail and waste plastic.

I'f you're worried about adhesion... get creative. Add some ribs to the design that are a single extrusion thick (0.48mm in my case) and then cut them off with a sharp blade. Add a brim for extra strength.

I think I'll stick to the original plan since the printer can clear its own bed of parts for automation. This will be detailed in another thread sometime in the future after more testing

Edited 2 time(s). Last edit at 04/29/2018 01:26PM by klcjr89.

Sorry, only registered users may post in this forum.