ULTIMAKER: Belts, Timing Pulleys & Bushing

Posted by 2robotguy

|

ULTIMAKER: Belts, Timing Pulleys & Bushing April 26, 2011 11:06PM |

Registered: 13 years ago Posts: 54 |

Does anybody know where I could order some of the Ultimaker parts from? I'm looking for:

Timing belt from the Nema 17 to the shaft (X&Y)

Open ended timing belt (600mm +)

Timing pulley they use for the motor

Timing pulley they use for the 8mm shaft

Bushing for all the bars.

Any help is better than no help :-) Extra question, does moving to T2.5 instead of T5 increase resolution in the print?

Cheers,

Mark

Timing belt from the Nema 17 to the shaft (X&Y)

Open ended timing belt (600mm +)

Timing pulley they use for the motor

Timing pulley they use for the 8mm shaft

Bushing for all the bars.

Any help is better than no help :-) Extra question, does moving to T2.5 instead of T5 increase resolution in the print?

Cheers,

Mark

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing April 26, 2011 11:24PM |

Registered: 13 years ago Posts: 486 |

T2.5 wont increase resolution unless you have a smaller pitch diameter on the pulley. You wont be printing T2.5 rez pullies, so the manufactured pullies may result in higher accuracy than T5 printed pullies, but there are a number of other factors that affect your accuracy. You know the diff between resolution and accuracy right?

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing April 26, 2011 11:55PM |

Registered: 13 years ago Posts: 581 |

sdp-si has all the pulleys you need, though you may need to drill and tap a set screw into certain pulleys. It looks like the ultimaker uses mxl sized belts and pulleys.

I couldn't find a good source for stock brass/graphite bushings, but using an O (as in Orange) drill bit makes a perfect slip fit on 8mm shaft, so you can make your bushings out of whatever you want. Plastic works almost as well as brass for this, as there is very little dynamic loading. If you go this route, be warned the bushings will bind occasionally until the belts are attached, so don't be too worried in testing before the belts are on.

I couldn't find a good source for stock brass/graphite bushings, but using an O (as in Orange) drill bit makes a perfect slip fit on 8mm shaft, so you can make your bushings out of whatever you want. Plastic works almost as well as brass for this, as there is very little dynamic loading. If you go this route, be warned the bushings will bind occasionally until the belts are attached, so don't be too worried in testing before the belts are on.

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing April 27, 2011 04:57PM |

Registered: 16 years ago Posts: 824 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 03, 2011 05:03PM |

Registered: 12 years ago Posts: 12 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 03, 2011 07:50PM |

Registered: 13 years ago Posts: 581 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 04, 2011 12:14AM |

Registered: 14 years ago Posts: 387 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 04, 2011 01:13PM |

Registered: 13 years ago Posts: 485 |

I went from printed T5 pulleys to metal GT2 pulleys (2mm pitch) from SDP/SI. I was able to find a GT2 pulley with a Ø5mm bore that had a smaller pitch diameter than the printed 8-tooth T5. As a result, I need more steps/mm which worked out to something like a 20% increase in resolution (and acceleration). The machined pulleys are also much more precise than the printed ones, so my prints are looking hugely better.

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 04, 2011 01:32PM |

Registered: 13 years ago Posts: 35 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 05, 2011 08:49AM |

Registered: 13 years ago Posts: 485 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 05, 2011 02:16PM |

Registered: 12 years ago Posts: 12 |

Is it possible for me to RepRap my own collar to take a set screw, and epoxy that to the side of a polycarbonate timing pulley?

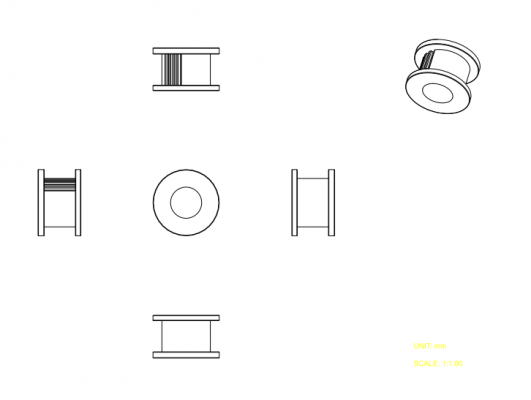

The part I have in mind (A 6M16M020DF60 at SDP/SI) is this one:

[sdp-si.com]

How about epoxying one of those to the side of a brass sleeve, which I drill and tap for set screws? I am also open to other suggestions.

The part I have in mind (A 6M16M020DF60 at SDP/SI) is this one:

[sdp-si.com]

How about epoxying one of those to the side of a brass sleeve, which I drill and tap for set screws? I am also open to other suggestions.

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 05, 2011 03:10PM |

Registered: 13 years ago Posts: 581 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 05, 2011 03:46PM |

Registered: 12 years ago Posts: 12 |

Andrew Diehl Wrote:

-------------------------------------------------------

> I drilled and tapped a very low profile 8-32 set

> screw right through the teeth of the pulley, so it

> did not interfere with the belt mesh. Not the

> ideal situation, but it did work.

Wow. That's *very* low profile. How much thread do you have in there, like 2mm? A colleague has suggested that I get 6mm bore aluminum timing screws and that he could use the edge detectors on the CNC router to automatically find the exact center of the piece and rebore the holes to 8mm. I'm not entirely convinced yet, though.

I suppose I could also have the laser cut holes made larger, get larger bearings, and just epoxy the pulleys in place with the bushings already in between. If the bearing holes are large enough to pass the pulleys through, then we should be fine.

-------------------------------------------------------

> I drilled and tapped a very low profile 8-32 set

> screw right through the teeth of the pulley, so it

> did not interfere with the belt mesh. Not the

> ideal situation, but it did work.

Wow. That's *very* low profile. How much thread do you have in there, like 2mm? A colleague has suggested that I get 6mm bore aluminum timing screws and that he could use the edge detectors on the CNC router to automatically find the exact center of the piece and rebore the holes to 8mm. I'm not entirely convinced yet, though.

I suppose I could also have the laser cut holes made larger, get larger bearings, and just epoxy the pulleys in place with the bushings already in between. If the bearing holes are large enough to pass the pulleys through, then we should be fine.

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 05, 2011 04:01PM |

Registered: 13 years ago Posts: 581 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 05, 2011 05:03PM |

Registered: 12 years ago Posts: 12 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 06, 2011 01:53PM |

Hi, I would like to know if the Ultimaker uses 1,75mm or 3mm filament, or if it could use both. Also, I would like to know if the material thickness would have any impact on the parts detail. Could you get smaller and more detailes parts using 1,75 plastic?

I would use the machine to make prototypes of injection molded parts, so I need at least 0,015mm max tolerance

I would appreciate any info

Thanks

Adrian

I would use the machine to make prototypes of injection molded parts, so I need at least 0,015mm max tolerance

I would appreciate any info

Thanks

Adrian

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 06, 2011 02:23PM |

Registered: 12 years ago Posts: 90 |

AEC Wrote:

-------------------------------------------------------

> Hi, I would like to know if the Ultimaker uses

> 1,75mm or 3mm filament, or if it could use both.

They ship a 3mm rig but I think it should be able to make it work (with parts) with 1.75mm, as long as the Bowden setup is ok with it.

I continue to be unconvinced that 3mm vs 1.75mm makes any real difference for +99% of us..

> I would use the machine to make prototypes of

> injection molded parts, so I need at least 0,015mm

> max tolerance

That's a reeeeally small number. I'm not sure any FDM-type machine, home or commercial, can promise doing that on a regular & repeatable basis.

-------------------------------------------------------

> Hi, I would like to know if the Ultimaker uses

> 1,75mm or 3mm filament, or if it could use both.

They ship a 3mm rig but I think it should be able to make it work (with parts) with 1.75mm, as long as the Bowden setup is ok with it.

I continue to be unconvinced that 3mm vs 1.75mm makes any real difference for +99% of us..

> I would use the machine to make prototypes of

> injection molded parts, so I need at least 0,015mm

> max tolerance

That's a reeeeally small number. I'm not sure any FDM-type machine, home or commercial, can promise doing that on a regular & repeatable basis.

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 06, 2011 05:01PM |

Registered: 13 years ago Posts: 581 |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 06, 2011 08:36PM |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 06, 2011 10:54PM |

Registered: 12 years ago Posts: 90 |

> Anyone has actual experience on both sizes?

I don't.

In theory, 1.75mm is more consistantly sized while a spool of 3mm can vary in diameter more.. Maybe it's 2.85mm in some parts and 2.90 or 2.82 in others while 1.75 sticks pretty close to 1.75. I don't know that anybody's actually tested this but I believe it.

Also, since you get less volume per extruder step with 1.75, you should be able to do finer extruder control. If you do one step (or microstep.. whatever) with 3mm, you'll get like 3x as much volume as with one step of 1.75. This sounds great but I don't think anybody in this crowd actually has a machine that can benefit from such added resolution on the extruder; we're talking tiny, tiny numbers here - numbers smaller than the tolerances of the rest of the machine.

> why is makerbot and others offering this now?

I haven't seen them mention why it's better but haven't really looked either...

I don't.

In theory, 1.75mm is more consistantly sized while a spool of 3mm can vary in diameter more.. Maybe it's 2.85mm in some parts and 2.90 or 2.82 in others while 1.75 sticks pretty close to 1.75. I don't know that anybody's actually tested this but I believe it.

Also, since you get less volume per extruder step with 1.75, you should be able to do finer extruder control. If you do one step (or microstep.. whatever) with 3mm, you'll get like 3x as much volume as with one step of 1.75. This sounds great but I don't think anybody in this crowd actually has a machine that can benefit from such added resolution on the extruder; we're talking tiny, tiny numbers here - numbers smaller than the tolerances of the rest of the machine.

> why is makerbot and others offering this now?

I haven't seen them mention why it's better but haven't really looked either...

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing October 06, 2011 10:59PM |

Admin Registered: 15 years ago Posts: 1,470 |

MakerBot is offering it because it allows for smaller extruders driven by smaller motors. It makes multi-extruder setups easier.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: ULTIMAKER: Belts, Timing Pulleys & Bushing November 11, 2011 12:13PM |

Sorry, only registered users may post in this forum.