|

Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 27, 2011 09:39PM |

Registered: 16 years ago Posts: 438 |

Various designs for heating the beds (be the actual bed made of whatever) have been used.

Some use uninsulated nichrome wire attached to the bottom of the bed with kapton tape.

Some use aluminum clad resistors.

Some use TO220 resistors.

Some use etched PCBs. ($50)

Some use "hot plates" normally used for cooking.

Some use cheap (in every sense of that word) clothes irons.

What else are people actually using?

What are the strengths/weaknesses of each approach?

What's the all-around best approach?

How do they fail when they fail (you lose points for catching fire)?

How often do they fail?

I note that the "heated bed" page doesn't even mention what sort of heater to use, so I'll be putting your comments up on the wiki.

Edit: Added link for utilimachine's PCB bed heater.

Edited 1 time(s). Last edit at 04/27/2011 11:08PM by jgilmore.

--

I'm building it with Baling Wire

Some use uninsulated nichrome wire attached to the bottom of the bed with kapton tape.

Some use aluminum clad resistors.

Some use TO220 resistors.

Some use etched PCBs. ($50)

Some use "hot plates" normally used for cooking.

Some use cheap (in every sense of that word) clothes irons.

What else are people actually using?

What are the strengths/weaknesses of each approach?

What's the all-around best approach?

How do they fail when they fail (you lose points for catching fire)?

How often do they fail?

I note that the "heated bed" page doesn't even mention what sort of heater to use, so I'll be putting your comments up on the wiki.

Edit: Added link for utilimachine's PCB bed heater.

Edited 1 time(s). Last edit at 04/27/2011 11:08PM by jgilmore.

--

I'm building it with Baling Wire

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 27, 2011 10:56PM |

Registered: 13 years ago Posts: 581 |

I use a poorly etched PCB epoxied to a .1875in AL sheet. Works beautifully. I usually run it at 110-120C. Only failed once, due to crappy etching. The circuit just opened. I'm sure professionally made PCB's work much better.

PROS:

Even Heat Distribution

Simple, clean implementation

Very little space required

Lightweight

CONS:

Relatively expensive (if you use a Professionally manufactured board)

PROS:

Even Heat Distribution

Simple, clean implementation

Very little space required

Lightweight

CONS:

Relatively expensive (if you use a Professionally manufactured board)

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 03:00AM |

Registered: 13 years ago Posts: 486 |

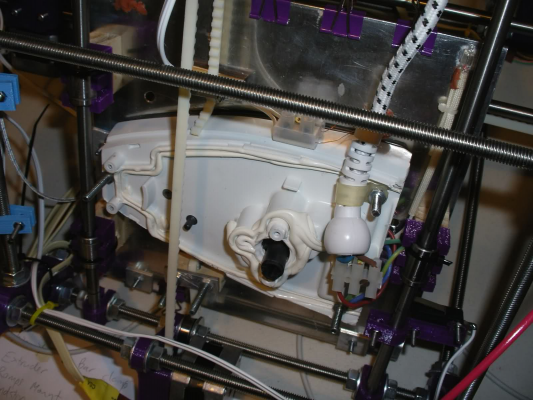

I use a 1600W clothes iron with the water tank and handle removed.

Attached to 3mm alu bed with countersunk screws.

Bed covered in 2mm glass.

I had to cut the tip off to get it to fit under the bed properly.

Pros:

Very inexpensive ($14 + fixings)

Very fast heat up (1600W)

Integrated thermostat (just turn the dial to select the temperature).

Mains voltage. No need for a power supply.

Most irons come with a little indicator light that shows when it is heating.

The knobs and buttons on the iron come with little springs that look like they will be good for extruder idler.

Glass can be removed and a spare one used for quick swapover between prints.

Cons:

Slightly on the heavier side.

Needs a bit of space under the bed.

Unless you also use a solid state relay, temperature is not regulated by the firmware and you need to manually turn it off (con for unattended printing).

Mains voltage. Danger if not installed safely.

Edited 1 time(s). Last edit at 04/28/2011 03:02AM by Greg Frost.

Attached to 3mm alu bed with countersunk screws.

Bed covered in 2mm glass.

I had to cut the tip off to get it to fit under the bed properly.

Pros:

Very inexpensive ($14 + fixings)

Very fast heat up (1600W)

Integrated thermostat (just turn the dial to select the temperature).

Mains voltage. No need for a power supply.

Most irons come with a little indicator light that shows when it is heating.

The knobs and buttons on the iron come with little springs that look like they will be good for extruder idler.

Glass can be removed and a spare one used for quick swapover between prints.

Cons:

Slightly on the heavier side.

Needs a bit of space under the bed.

Unless you also use a solid state relay, temperature is not regulated by the firmware and you need to manually turn it off (con for unattended printing).

Mains voltage. Danger if not installed safely.

Edited 1 time(s). Last edit at 04/28/2011 03:02AM by Greg Frost.

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 03:28AM |

Registered: 14 years ago Posts: 3,742 |

220 v silicon heating mat, thermistor and solid state relay to control bed temperature from the firmware.

Using MakerBot Gen3 electronics.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Using MakerBot Gen3 electronics.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 03:51AM |

Registered: 13 years ago Posts: 16 |

I use power resistors in aluminum JB-Welded to a 1.5mm aluminum sheet. The sheet has Kapton tape on top for when I want to print ABS, and I lay a sheet of single strength glass on top of it for when I want to use PLA.

The resistors are powered by 120V AC and are turned on or off by a relay that is switched by a MOSFET on the RAMPS board.

I have a writeup with pictures.

It's nice in that it was very cheap, it can handle ABS and PLA easily, and it's AC powered so I don't need a power supply and it is also very efficient.

The downside is that the aluminum sheet I used was probably a little too thin, as it has a slight curve to it. Also, the whole setup with glass on top has a decent amount of weight to it.

Edited 1 time(s). Last edit at 04/28/2011 03:55AM by nrp.

The resistors are powered by 120V AC and are turned on or off by a relay that is switched by a MOSFET on the RAMPS board.

I have a writeup with pictures.

It's nice in that it was very cheap, it can handle ABS and PLA easily, and it's AC powered so I don't need a power supply and it is also very efficient.

The downside is that the aluminum sheet I used was probably a little too thin, as it has a slight curve to it. Also, the whole setup with glass on top has a decent amount of weight to it.

Edited 1 time(s). Last edit at 04/28/2011 03:55AM by nrp.

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 04:08AM |

Admin Registered: 17 years ago Posts: 7,879 |

Don't use TO220 resistors. All mine failed eventually so I use AL clad now, which have never failed.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 09:25AM |

Registered: 16 years ago Posts: 438 |

Greg, I see a brief discussion about your design here:

[forums.reprap.org]

Do you know if either you or pdf417 ever wrote more about it?

If not, could you take a few pictures?

rhmorrison, what are the pros/cons? How much did it cost? How hard was it to get to work?

--

I'm building it with Baling Wire

[forums.reprap.org]

Do you know if either you or pdf417 ever wrote more about it?

If not, could you take a few pictures?

rhmorrison, what are the pros/cons? How much did it cost? How hard was it to get to work?

--

I'm building it with Baling Wire

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 10:37AM |

Registered: 14 years ago Posts: 3,742 |

CONS:

Expensive - silicon mat (50€) plus solid state relay (16€).

220v (or maybe 110v in your case) BUT can be purchased for 12v. Need GROUND line to aluminum bed for safety.

Relatively high temperatures possible (safety problem if thermistor dies/falls off).

PROS:

Fast

Reliable

220v (DOESN'T require any amps from the 12 volt supply).

Very low height

Easy to install (adhesive backed) - see WolfBed in the RepRap wiki.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Expensive - silicon mat (50€) plus solid state relay (16€).

220v (or maybe 110v in your case) BUT can be purchased for 12v. Need GROUND line to aluminum bed for safety.

Relatively high temperatures possible (safety problem if thermistor dies/falls off).

PROS:

Fast

Reliable

220v (DOESN'T require any amps from the 12 volt supply).

Very low height

Easy to install (adhesive backed) - see WolfBed in the RepRap wiki.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Nichome vs. aluminum clad vs. tip120 vs PCB vs ?? heated bed feedback? April 28, 2011 10:38PM |

Registered: 13 years ago Posts: 486 |

Sorry, only registered users may post in this forum.