Limitations and work arounds for Stratasys heated build chamber patent

Posted by amatta

|

Limitations and work arounds for Stratasys heated build chamber patent May 22, 2018 11:35PM |

Registered: 6 years ago Posts: 12 |

So at what point does a heated build chamber become in violation of Stratasys patents? This might be asked alot but I was only able to find a post from 2014 that didnt really give a conclusive answer.

I know that putting a printer in a box/enclosure seems to be allowed and if not everyone does it anyways. Also Raise3D printers are enclosed and there hasn't seemed to be any legal action against them.

Is it that the gantry has to be outside of the heated zone? What if the motors were just placed outside of the heated zone and the guide rails and everything else were left in? What if the gantry was inside the heated zone and the extruder was outside of it via a bowden setup?

Does the patent have to do with specific temps? like you aren't allowed to go above a specific temperature for your build chamber? I feel like this topic should be clarified since heated build chambers are becoming more and more common.

I know that putting a printer in a box/enclosure seems to be allowed and if not everyone does it anyways. Also Raise3D printers are enclosed and there hasn't seemed to be any legal action against them.

Is it that the gantry has to be outside of the heated zone? What if the motors were just placed outside of the heated zone and the guide rails and everything else were left in? What if the gantry was inside the heated zone and the extruder was outside of it via a bowden setup?

Does the patent have to do with specific temps? like you aren't allowed to go above a specific temperature for your build chamber? I feel like this topic should be clarified since heated build chambers are becoming more and more common.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 01:19AM |

Registered: 9 years ago Posts: 383 |

My understanding of patents is that unless you are planning to sell the maching it's not a problem? I'm not sure that would still stand if you also freely share your build files and machine Schematics/manuals.

What's the date on the pattent and due expiry? I'm guessing pre 2004ish as it's an intuative rather than novel concept that reorappers would likely be able to show prior art on after that date?

What's the date on the pattent and due expiry? I'm guessing pre 2004ish as it's an intuative rather than novel concept that reorappers would likely be able to show prior art on after that date?

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 01:33AM |

Registered: 9 years ago Posts: 383 |

Presume this is the thread you discuss?

[forums.reprap.org]

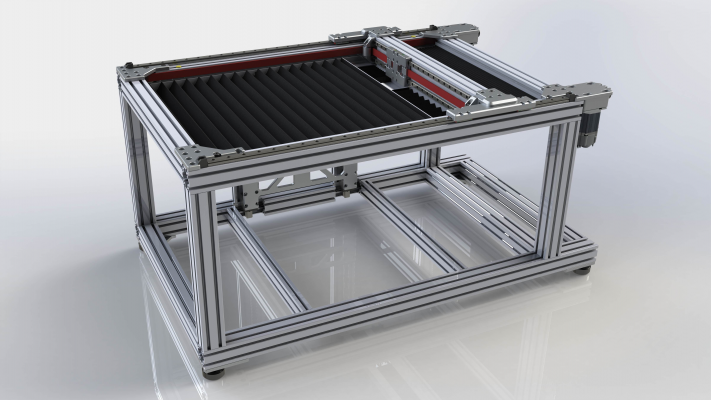

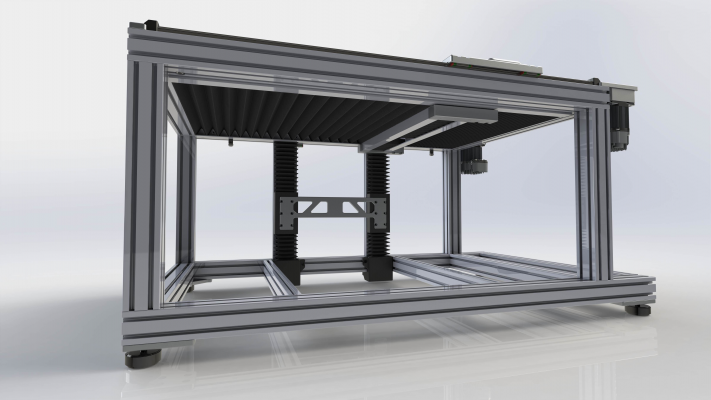

If so it is not pattenting a complete heated enclosure. Only pattents a system where the framework is outside and the bed/nozzle enclosed in some kind of flexible envelope. Going much above 80 or 100 and this is the easy way of doing it over trying to protect steppers, belts, wires, and bearings from the high temps, not to mention the difficulties around your frame growing and potentially distorting with the heat.

The pattents listed start around 2000 and they had published others (probably slight extensions) until 2007. There may be newer extensions about.

As a community it is well worth countering pattents that shouldn't be by openly publishing work that extends on existing pattents. This is not a violation, and is the original intent of the pattent system, share an idea in return for a period of commercial protection. It's a system that has been taken over by solicitors and clerks and now only really serves large companies or those with the resource in time/money to fight them.

Edited 1 time(s). Last edit at 05/23/2018 01:35AM by WesBrooks.

[forums.reprap.org]

If so it is not pattenting a complete heated enclosure. Only pattents a system where the framework is outside and the bed/nozzle enclosed in some kind of flexible envelope. Going much above 80 or 100 and this is the easy way of doing it over trying to protect steppers, belts, wires, and bearings from the high temps, not to mention the difficulties around your frame growing and potentially distorting with the heat.

The pattents listed start around 2000 and they had published others (probably slight extensions) until 2007. There may be newer extensions about.

As a community it is well worth countering pattents that shouldn't be by openly publishing work that extends on existing pattents. This is not a violation, and is the original intent of the pattent system, share an idea in return for a period of commercial protection. It's a system that has been taken over by solicitors and clerks and now only really serves large companies or those with the resource in time/money to fight them.

Edited 1 time(s). Last edit at 05/23/2018 01:35AM by WesBrooks.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 02:10AM |

Admin Registered: 13 years ago Posts: 7,000 |

"Stratasys’s (still active) patent describes an apparatus “That builds up three-dimensional objects in a heated build chamber” (…) “The motion control components of the apparatus are external to and thermally isolated from the build chamber.” That means if you put the stepper motors outside of an enclosure, you can’t sell the product, as it would violate the patent."

from [www.prusaprinters.org]

from [www.prusaprinters.org]

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 04:37AM |

Registered: 7 years ago Posts: 507 |

So simple solution: put your steppers inside the heated chamber. Actually, putting just the belts/leadscrews inside should be fine technically.

Another workaround is to set up operations in a country they haven't filed a patent in. Patents aren't global and there a lot of places they wouldn't have patents in.

That being said, none of these work arounds will prevent them from sending their lawyers to harass you and find some minor detail they can argue with in order to shut you down.

Another workaround is to set up operations in a country they haven't filed a patent in. Patents aren't global and there a lot of places they wouldn't have patents in.

That being said, none of these work arounds will prevent them from sending their lawyers to harass you and find some minor detail they can argue with in order to shut you down.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 08:27AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 10:44AM |

Registered: 6 years ago Posts: 12 |

I mean you cant patent the idea of a heated build chamber completely which is why people build enclosures with no problem. The question is some of the fine details. For really hot build chambers you would want to move the motors and possibly the belts/bearings outside the chamber, otherwise they can fry/break.The stratasys patents corresponding to this are below.

[patents.google.com]

[patents.google.com]

The real question is can the belts/screws and bearings and majority of the motion system could be kept in the chamber and move the steppers outside the chamber and not violate the patent.

[patents.google.com]

[patents.google.com]

The real question is can the belts/screws and bearings and majority of the motion system could be kept in the chamber and move the steppers outside the chamber and not violate the patent.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 06:49PM |

Registered: 7 years ago Posts: 507 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 10:04PM |

Registered: 11 years ago Posts: 5,780 |

As usual, it all boils down to your intentions. If you're planning to go into business making and selling 3D printers, you'd better lawyer up. If you're building one for your own use, while it's technically illegal to violate a patent, no one is going to harass you over it. They can, but they won't sue you for building a printer for personal use that violates a patent. They'd have to demonstrate that you've done harm to their business, and you haven't, and they know it. It would never get in front of a judge.

Think about it this way. There are literally hundreds of thousands or even millions of current patents. Everyone who makes anything themselves may be violating someone's patent for something. Do you think that you're legally obligated to perform exhaustive patent searches before you embark on any personal project?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Think about it this way. There are literally hundreds of thousands or even millions of current patents. Everyone who makes anything themselves may be violating someone's patent for something. Do you think that you're legally obligated to perform exhaustive patent searches before you embark on any personal project?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 23, 2018 10:29PM |

Registered: 11 years ago Posts: 335 |

While the patent itself describes a very specific arrangement of parts, in practice they can apply quite broadly. For example, piping cold air to shrouds surrounding the extruder and motors could be a violation of their patent, as cold air has been separated from the build chamber using a flexible barrier. I suspect it would be virtually impossible to develop a practical commercial printer that can safely hold ~150c/300f in the build chamber without getting sued, since motion requires a flexible barrier between hot and cold air. Water cooling is a possible workaround I suppose.

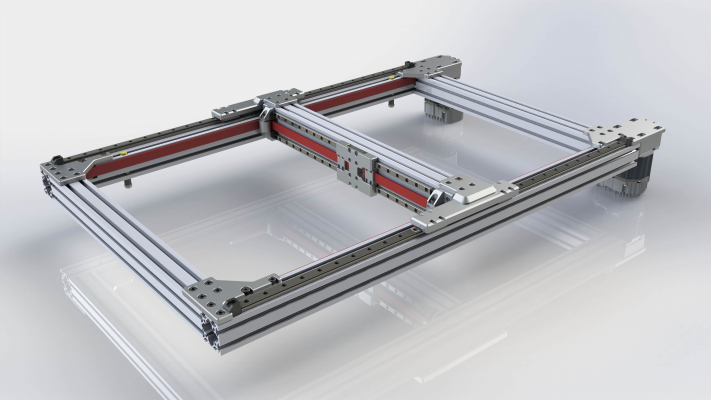

I'm currently designing a personal printer that is pretty much a straight ripoff of their patent. The original mechanism is actually fairly clever, although I suspect that it would have been discovered by hobbyists had it not been developed by Stratasys.

Edited 1 time(s). Last edit at 05/23/2018 10:30PM by 691175002.

I'm currently designing a personal printer that is pretty much a straight ripoff of their patent. The original mechanism is actually fairly clever, although I suspect that it would have been discovered by hobbyists had it not been developed by Stratasys.

Edited 1 time(s). Last edit at 05/23/2018 10:30PM by 691175002.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 02:45AM |

Registered: 9 years ago Posts: 383 |

Ok, so I don't understand the patent system as well as I thought.

So home use isn't excepted, rather it is not likely to be able to get through the court with them being able to show you'd cost the business money.

So what about a job shop running there own design of printer which may or may not infringe patents? I was hoping it would be possibke to set up a demonstration facility showing how this tech has reduced the requirement for large start up loans and investments that leave you subservient to the will of the lender!

Anyhow I digressed there. Back on track now. So we need to discuss ways that this patent can be avoided and perhaps other ways to achieve a similar goal. Open discussion can form part of the prior art argument to avoid future patent issues.

So route issue is printed polymer needs to be held at an elevated temperature in order to avoid warping issues. I'm not aware of any material that has to remain at the processing temperature, so the route challenge is controlling the rate of cooling of the part, rather than heating the part.

Seeing how critical part cooling fans are I'd be surprised if printing in a vacuum would be the answer. The degassing of the polymer melt would likely cause issues if the overhangs didn't. Perhaps a partial vacuum would help.

Microwave to warm the part slightly to limit rate of cooling? While going through university I heard one lecturer discuss an idea (not sure whose idea it was) of home heating systems that relied on microwave energy to keep people warm. Obviously fraught with tevhmical challenges, not least any metal objects caught within! But the base idea was only heating the people, rather than the whole building. So with our smller systems is that style of thinking more viable? Can the wavelength of microwave emitter be tuned to better target the poymer chains rather tham the hydrogen oxygen bond in water? Saftey precautions would need to be uber from microwave nd high voltage precautions.

Edited 1 time(s). Last edit at 05/24/2018 02:56AM by WesBrooks.

So home use isn't excepted, rather it is not likely to be able to get through the court with them being able to show you'd cost the business money.

So what about a job shop running there own design of printer which may or may not infringe patents? I was hoping it would be possibke to set up a demonstration facility showing how this tech has reduced the requirement for large start up loans and investments that leave you subservient to the will of the lender!

Anyhow I digressed there. Back on track now. So we need to discuss ways that this patent can be avoided and perhaps other ways to achieve a similar goal. Open discussion can form part of the prior art argument to avoid future patent issues.

So route issue is printed polymer needs to be held at an elevated temperature in order to avoid warping issues. I'm not aware of any material that has to remain at the processing temperature, so the route challenge is controlling the rate of cooling of the part, rather than heating the part.

Seeing how critical part cooling fans are I'd be surprised if printing in a vacuum would be the answer. The degassing of the polymer melt would likely cause issues if the overhangs didn't. Perhaps a partial vacuum would help.

Microwave to warm the part slightly to limit rate of cooling? While going through university I heard one lecturer discuss an idea (not sure whose idea it was) of home heating systems that relied on microwave energy to keep people warm. Obviously fraught with tevhmical challenges, not least any metal objects caught within! But the base idea was only heating the people, rather than the whole building. So with our smller systems is that style of thinking more viable? Can the wavelength of microwave emitter be tuned to better target the poymer chains rather tham the hydrogen oxygen bond in water? Saftey precautions would need to be uber from microwave nd high voltage precautions.

Edited 1 time(s). Last edit at 05/24/2018 02:56AM by WesBrooks.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 04:34AM |

Registered: 10 years ago Posts: 14,672 |

Does the Stratasys patent cover the case of not having a separate chamber heater? Many users find that the bed heater generates sufficient heat to keep the chamber at a suitably elevated temperature for printing ABS, if double-skinned insulation is used.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 09:53AM |

Registered: 10 years ago Posts: 239 |

Quote

691175002

I'm currently designing a personal printer that is pretty much a straight ripoff of their patent. The original mechanism is actually fairly clever, although I suspect that it would have been discovered by hobbyists had it not been developed by Stratasys.

Have you given any thought to what type of material or a source for the accordion thermal barrier separating the motion system from the chamber? I'm designing a similar machine.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 11:09AM |

Registered: 11 years ago Posts: 335 |

Quote

Bill Clark

Have you given any thought to what type of material or a source for the accordion thermal barrier separating the motion system from the chamber? I'm designing a similar machine.

The first iteration will use regular fabric way covers from China. They are not particularly well suited for this application, but are reasonably cheap, look nice, and can be customized. I expect them to survive reasonable chamber temperatures since one side will always be exposed to cold air. Machine tools bellows that are better suited for this application (coated/alumized fiberglass/kevlar) are available but expensive.

I've also considered using insulating/cellular blinds, which are lighter and considerably more insulating. You would have to to talk a blind vendor into selling you just the fabric (or pay for a finished assembly and cut it apart) but this seems like a reasonable option. And of course one can always make flat bellows by hand.

The open question is whether the chamber will also need active heating (in addition to the bed) or active cooling. This will have to be determined through trial and error, since its too difficult to predict how the chamber will perform without actually building it.

A secondary question is how aggressively you need to circulate the chamber air. Heated bed systems generally rely on passive convection, but Stratasys (which uses only a chamber heater) uses powerful fans. Fans that can be relied upon at >60c ambient are very expensive.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 12:52PM |

Registered: 10 years ago Posts: 239 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 01:58PM |

Registered: 11 years ago Posts: 5,780 |

If you want to run fans hot, put the motors outside the enclosure. That's how they do it in convection ovens.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 02:43PM |

Registered: 11 years ago Posts: 335 |

Quote

Bill Clark

Fortunately I do have access to a 900MC to study and they do use a cellular type barrier but don't know the material. I plan to run chamber temps over 200c as they do to print Ultem 1010

The required chamber temperatures are much lower if you use a heated bed. IIRC Stratasys prints ABS at ~70c in the chamber, whereas hobby printers do a 100c table and 45c chamber.

I've seen reports of very good peek printing at 150c table 70c chamber, so if you have a heated bed you can probably hold the chamber 50-100c below the glass transition temperature.

I haven't seen anyone who manufactures the bellows that stratasys uses in their various printers, to be honest I'm not even sure if the style has a standardized name.

If I were building a printer that could hit very high temperatures inside the chamber I would probably two it in two stages. Have the build chamber at ~150c, then put the motion behind a bellow at ~60c (not controlled), and surround the entire thing with rigid foam to insulate it from ambient air. A gradual transition from 150c -> 60c -> 20c is much easier to engineer than a single step of 200c -> 20c.

I think with a single bellow you risk leaking too much heat into the surrounding room.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 24, 2018 03:44PM |

Registered: 10 years ago Posts: 106 |

Quote

Bill Clark

Have you given any thought to what type of material or a source for the accordion thermal barrier separating the motion system from the chamber? I'm designing a similar machine.

Just thinking out load (without much thought into this), can you use insulation fabric on a roller, similar to a window spring roller blind

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 25, 2018 11:04AM |

Registered: 10 years ago Posts: 11 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 25, 2018 11:44AM |

Registered: 10 years ago Posts: 239 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent May 28, 2018 07:31PM |

Registered: 5 years ago Posts: 6 |

It's silicone coated fibreglass I think, it's what they say it is in one of the patents anyway - and the specification shows it is suitable to 260c

I am looking to build something similar at the moment, the only part I'm not sure about are the chamber fans. Can you tell if they are oven fans ? I.e. The fan is in the hot part and the motor is external to that ?

Anything else you have seen that is nice on the 900 that I won't have thought of yet ?

I am looking to build something similar at the moment, the only part I'm not sure about are the chamber fans. Can you tell if they are oven fans ? I.e. The fan is in the hot part and the motor is external to that ?

Anything else you have seen that is nice on the 900 that I won't have thought of yet ?

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 04, 2018 12:36PM |

Registered: 5 years ago Posts: 6 |

Both Vshaper with their 500 [vshaper.com]

and Roboze with the Argo 500 [www.roboze.com]

seem to be making machines ( or at least announced ) with a heated build chamber, and the Vshaper clearly has bellows to isolate the chamber.

and Roboze with the Argo 500 [www.roboze.com]

seem to be making machines ( or at least announced ) with a heated build chamber, and the Vshaper clearly has bellows to isolate the chamber.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 14, 2018 03:08AM |

Registered: 9 years ago Posts: 8 |

Some are now selling heated chamber printers, this one reaches 200ºC

[dynamicaltools.com]

Also 3NTR, Funmat intamsys, AON3D .....

¿There are limitations with so many building printers with heated chamber?

[dynamicaltools.com]

Also 3NTR, Funmat intamsys, AON3D .....

¿There are limitations with so many building printers with heated chamber?

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 14, 2018 09:46AM |

Registered: 5 years ago Posts: 6 |

I think the EU patent register shows the European patent was abandoned in various countries in 2009 :

[register.epo.org]

From my reading this is probably because the patent needs to be translated into the host countries language to be valid there.

I think this explains why some companies in some European countries are able to make what look like infringing machines, I assume they cannot sell them outside these countries though. I could understand if it was one or two very small countries but some of these places could clearly support quite a large company manufacturing 3d printers!

[register.epo.org]

From my reading this is probably because the patent needs to be translated into the host countries language to be valid there.

I think this explains why some companies in some European countries are able to make what look like infringing machines, I assume they cannot sell them outside these countries though. I could understand if it was one or two very small countries but some of these places could clearly support quite a large company manufacturing 3d printers!

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 14, 2018 08:57PM |

Registered: 7 years ago Posts: 507 |

They should be able to sell them outside of these countries, just not in countries where the patent is active, and I feel like that list of countries is smaller than you think. There are a lot of countries where companies never bother to file a patent, I hear there is no patent on the iPhone where I live.

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 28, 2018 11:46PM |

Registered: 10 years ago Posts: 239 |

Unless I'm missing something it looks like the Stratasys patent for high temperature modeling apparatus is going to expire in almost exactly 1 year from now

[patents.google.com]

[patents.google.com]

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 29, 2018 08:53AM |

Registered: 5 years ago Posts: 6 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 29, 2018 10:10AM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 29, 2018 12:12PM |

Registered: 10 years ago Posts: 239 |

|

Re: Limitations and work arounds for Stratasys heated build chamber patent June 29, 2018 12:21PM |

Registered: 10 years ago Posts: 239 |

Agreed but for us folks without a team of lawyers its nice to know that there's less chance (even it was already a remote chance) of them sending you a cease and disist after investing effort in to our machines wether we plan on marketing them or not. By the time I'm finished with this latest one I will have 1000's of dollars and at least a few hundred hours invested. Just helps put the mind at easeQuote

Roberts_Clif

If 3D Printers have been around sense. The first 3D printer ever created in 1983.

And heat chambers were then common knowledge before this patent, any heat chamber patent in itself violates the patent laws.

Sorry, only registered users may post in this forum.