Cartridge Heaters: Strain Relief Suggestions?

Posted by scndctr

|

Cartridge Heaters: Strain Relief Suggestions? June 04, 2018 10:57AM |

Registered: 7 years ago Posts: 15 |

Hello, I was wondering how people are implementing strain relief at the cable-to-cartridge interface on their printers, since it appears to be subject to a lot of mechanical as well as thermal stresses.

I was only using a zip tie for rudimentary strain relief in my setup, and not surprisingly, the cable broke one day in the middle of a print--the failure occurred right at the interface with the cartridge body. Ideally there would need to be a high-temperature sleeve made of silicone rubber or some other temperature resistant material, since my zip tie solution is likely to inevitably cause my new cartridge to fail, as well.

I'm not a thermal / mechanical expert so thank you for your recommendations.

I was only using a zip tie for rudimentary strain relief in my setup, and not surprisingly, the cable broke one day in the middle of a print--the failure occurred right at the interface with the cartridge body. Ideally there would need to be a high-temperature sleeve made of silicone rubber or some other temperature resistant material, since my zip tie solution is likely to inevitably cause my new cartridge to fail, as well.

I'm not a thermal / mechanical expert so thank you for your recommendations.

|

Re: Cartridge Heaters: Strain Relief Suggestions? June 04, 2018 11:54AM |

Registered: 11 years ago Posts: 5,780 |

I'd say extruder and hot-end designs have been ignoring this type of problem since forever. I suspect that the heater cartridges are designed and made for other purposes and not with 3D printers in mind, otherwise there'd be some provision for wire management. One of these days the hot-end makers will catch on and start making heater cartridges for the hot-ends and figure out how to manage the wires as an integral part of the design, or start designing the hot-ends with some provision for wire management.

I like the performance of the V6 hot-end, and I like the Titan extruder, but both have some design issues that have really been bugging me lately. The wires for the heater cartridge put mechanical force on the heater block and that either causes the entire hot-end to rotate in the weak grip of the Titan, often putting the heater block in contact with a print cooler nozzle, or causes the heat break to come unscrewed from the heatsink, which allows the nozzle to wobble and destroys print quality until you figure out what the problem is. The V6 has no good way to tighten the heat break into the heatsink- the heat break can't take much torque to tighten it in, and even if it could take a little more torque, there are no flat surfaces to hold with a wrench.

The volcano heater heater block is even worse than the standard block for wire management. There's very little room for the heater cartridge wires between the top of the block and the heatsink fins.

I usually bend the leads upward and use zip ties to lash them to either the hot-end or the extruder carriage. The heater cartridge wires can't take many flexes before they break, and bending them right at the cartridge is a bad idea- they will break after just a couple flexes there. It's best to grip the leads of a new cartridge maybe 5 mm away from the cartridge body and bend the leads in whatever direction they need to go.

I recently bought a cheap hot-end via Ali-express that addresses some of the issues, but still doesn't really offer much in the way of wire management.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I like the performance of the V6 hot-end, and I like the Titan extruder, but both have some design issues that have really been bugging me lately. The wires for the heater cartridge put mechanical force on the heater block and that either causes the entire hot-end to rotate in the weak grip of the Titan, often putting the heater block in contact with a print cooler nozzle, or causes the heat break to come unscrewed from the heatsink, which allows the nozzle to wobble and destroys print quality until you figure out what the problem is. The V6 has no good way to tighten the heat break into the heatsink- the heat break can't take much torque to tighten it in, and even if it could take a little more torque, there are no flat surfaces to hold with a wrench.

The volcano heater heater block is even worse than the standard block for wire management. There's very little room for the heater cartridge wires between the top of the block and the heatsink fins.

I usually bend the leads upward and use zip ties to lash them to either the hot-end or the extruder carriage. The heater cartridge wires can't take many flexes before they break, and bending them right at the cartridge is a bad idea- they will break after just a couple flexes there. It's best to grip the leads of a new cartridge maybe 5 mm away from the cartridge body and bend the leads in whatever direction they need to go.

I recently bought a cheap hot-end via Ali-express that addresses some of the issues, but still doesn't really offer much in the way of wire management.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Cartridge Heaters: Strain Relief Suggestions? June 04, 2018 12:16PM |

Registered: 9 years ago Posts: 465 |

Personally, I have always connected those wires to somewhere else on the print carriage, so that the wires do not move at the components. Strain relief can then happen at the connection point, away from the heat. Zip ties work fine then, but you have to have some provision to tie the wires to.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Cartridge Heaters: Strain Relief Suggestions? June 04, 2018 12:32PM |

Registered: 7 years ago Posts: 15 |

Thanks for the replies, folks. It doesn't surprise me that the ideal solution would be to rework the cartridge package for 3D printing applications at the component level itself--I sure hope there are manufactureres out there looking into more robust solutions.

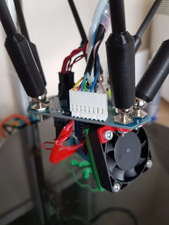

To clarify the details of my setup, I have a Kossel-style delta machine with an E3D V6 hot-end. Since the printer's arms need to be relatively free to move in every direction, my best option is to zip-tie the cable assembly a few centimetres behind the cartridge, to the arm nearest the side of the base where all my cables enter and connect to the electronics. However, due to the various end-effector positions while printing and the relatively fast arm motions of a delta, there is no way to prevent some flexing of the cable bundle, so failure of this cartridge cable is just about inevitable, it seems. :-/

Edited 2 time(s). Last edit at 06/04/2018 12:37PM by scndctr.

To clarify the details of my setup, I have a Kossel-style delta machine with an E3D V6 hot-end. Since the printer's arms need to be relatively free to move in every direction, my best option is to zip-tie the cable assembly a few centimetres behind the cartridge, to the arm nearest the side of the base where all my cables enter and connect to the electronics. However, due to the various end-effector positions while printing and the relatively fast arm motions of a delta, there is no way to prevent some flexing of the cable bundle, so failure of this cartridge cable is just about inevitable, it seems. :-/

Edited 2 time(s). Last edit at 06/04/2018 12:37PM by scndctr.

|

Re: Cartridge Heaters: Strain Relief Suggestions? June 05, 2018 02:42AM |

Registered: 10 years ago Posts: 14,672 |

Quote

scndctr

To clarify the details of my setup, I have a Kossel-style delta machine with an E3D V6 hot-end. Since the printer's arms need to be relatively free to move in every direction, my best option is to zip-tie the cable assembly a few centimetres behind the cartridge, to the arm nearest the side of the base where all my cables enter and connect to the electronics. However, due to the various end-effector positions while printing and the relatively fast arm motions of a delta, there is no way to prevent some flexing of the cable bundle, so failure of this cartridge cable is just about inevitable, it seems. :-/

Can't you zip tie the heater cables to the effector instead?

Another solution is to use a PCB effector. You can terminate the heater, thermistor and fan cables on the underside and have connectors on the top side. One example is the Duet3D Smart Effector, which also incorporates a nozzle contact Z probe, using the PCB itself as a strain gauge. Others have designed their own passive PCB effectors - I saw one for a Diamond hot and a few months ago. The cables can be twisted around the Bowden tube.

Edited 1 time(s). Last edit at 06/05/2018 02:43AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.