Toward the Graal : Ultra-light extrusion

Posted by M_Xeno

|

Toward the Graal : Ultra-light extrusion June 12, 2018 10:41AM |

Registered: 10 years ago Posts: 150 |

Hi, everybody!

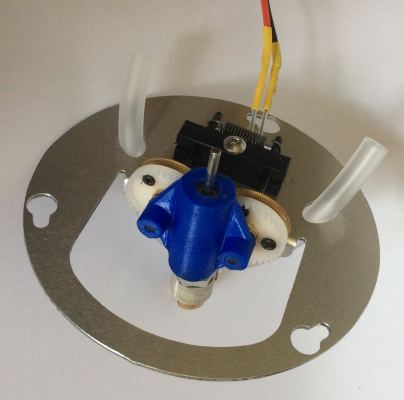

All printers have an interest in light extrusion heads, especially deltas.

And we all know that pushing the filament as close as possible to the fusion zone, i.e. Direct Drive, is better.

And if the extruder could be a Bondtech, with two symmetrical hobbed gears, that would be perfect!

And also with a water-cooled Hot-End, but simple, not a gas plant...

Would you like to have all this in a 32g set? Yes, 32g, not 320g!

More explanations on my recently added page on the HackaDay website:

[hackaday.io]

This is part of my project for the delta robot Zatsit, quoted here, but on another subforum (This might interest you too!)

[reprap.org]

All printers have an interest in light extrusion heads, especially deltas.

And we all know that pushing the filament as close as possible to the fusion zone, i.e. Direct Drive, is better.

And if the extruder could be a Bondtech, with two symmetrical hobbed gears, that would be perfect!

And also with a water-cooled Hot-End, but simple, not a gas plant...

Would you like to have all this in a 32g set? Yes, 32g, not 320g!

More explanations on my recently added page on the HackaDay website:

[hackaday.io]

This is part of my project for the delta robot Zatsit, quoted here, but on another subforum (This might interest you too!)

[reprap.org]

|

Re: Toward the Graal : Ultra-light extrusion June 12, 2018 12:45PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Toward the Graal : Ultra-light extrusion June 12, 2018 01:05PM |

Registered: 10 years ago Posts: 150 |

@o_lampe

The drive gears are big, as to limit stress and deformation of the filament. This has no effect on the e-steps/mm value: with a worm drive, hobbed gears advance by one pitch of the worm each turn, regardless of their diameter. Here, about 1,5mm/ revolution, a quite good resolution.

The drive gears are big, as to limit stress and deformation of the filament. This has no effect on the e-steps/mm value: with a worm drive, hobbed gears advance by one pitch of the worm each turn, regardless of their diameter. Here, about 1,5mm/ revolution, a quite good resolution.

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 01:16AM |

Registered: 7 years ago Posts: 507 |

I'm guessing you use a flex shaft ala flex3drive/zesty? Pretty cool design. Any idea what it would weigh if adapted to an air cooled system and how easy would it be to change hotend?

Also, great job on your delta, neat concept and execution. How well do the flexure hinges hold up over time?

Also, great job on your delta, neat concept and execution. How well do the flexure hinges hold up over time?

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 02:25AM |

Registered: 8 years ago Posts: 5,232 |

Quote

M_Xeno

@o_lampe

The drive gears are big, as to limit stress and deformation of the filament. This has no effect on the e-steps/mm value: with a worm drive, hobbed gears advance by one pitch of the worm each turn, regardless of their diameter. Here, about 1,5mm/ revolution, a quite good resolution.

The reason, why other worm driven extruders use a big gear ratio is: they can pick a thinner/lighter and more flexible flex-shaft.

In your case this isn't true and the stiffness of the cable has a bigger negative influence. Why not add a second gear stage and advance to a better suited drive cable?

Direct drive with a small pancake stepper would then work, too.

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 08:26AM |

Registered: 8 years ago Posts: 601 |

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 09:08AM |

Registered: 10 years ago Posts: 150 |

@o_lampe

Wrong : Flex3drive, Zesty Nimble and my setup use about the same ratio, for the same reasons (advance of the filament = worm pitch), and we all use a ~3mm flexible shaft, the smallest currently available.

I did try to use a second stage of gears, to be able to run a smaller motor, but then the problem is with pressure advance : the speed variations asked to the motor are way too high, and step losses occur, even without any back-pressure.

The gear ratio of the setup shown here is already quite high (1,5mm/turn is 4800 steps/mm with a 1.8° stepper, and x16 microstepping). Problems already occurs with not well suited steppers, i.e. too high impedance and inertia.

Edited 1 time(s). Last edit at 06/13/2018 09:37AM by M_Xeno.

Wrong : Flex3drive, Zesty Nimble and my setup use about the same ratio, for the same reasons (advance of the filament = worm pitch), and we all use a ~3mm flexible shaft, the smallest currently available.

I did try to use a second stage of gears, to be able to run a smaller motor, but then the problem is with pressure advance : the speed variations asked to the motor are way too high, and step losses occur, even without any back-pressure.

The gear ratio of the setup shown here is already quite high (1,5mm/turn is 4800 steps/mm with a 1.8° stepper, and x16 microstepping). Problems already occurs with not well suited steppers, i.e. too high impedance and inertia.

Edited 1 time(s). Last edit at 06/13/2018 09:37AM by M_Xeno.

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 09:35AM |

Registered: 10 years ago Posts: 150 |

@Origamib

You're right, and that's a good question : available flexible shaft have a quite high linear mass.

For my prototype, I used only the core of the flexible shaft, and I replaced the sheath by another lighter one, of my manufacture.

But above all, I installed the stepper motor on a gimballed support, in a flystruder position (suspended between the three carriages), so that the length of the flexible shaft is only 12 cm. Under these conditions, the inertia, and parasitic forces, due to the flexible shaft are without appreciable consequence.

However, as when I use a flystruder with a bowden tube, I have to reduce the maximum speed along the Z axis to 500mm/s instead of the usual 600mm/s, because of the mass of the stepper. X and Y are still 600mm/s, so, no consequence either.

You're right, and that's a good question : available flexible shaft have a quite high linear mass.

For my prototype, I used only the core of the flexible shaft, and I replaced the sheath by another lighter one, of my manufacture.

But above all, I installed the stepper motor on a gimballed support, in a flystruder position (suspended between the three carriages), so that the length of the flexible shaft is only 12 cm. Under these conditions, the inertia, and parasitic forces, due to the flexible shaft are without appreciable consequence.

However, as when I use a flystruder with a bowden tube, I have to reduce the maximum speed along the Z axis to 500mm/s instead of the usual 600mm/s, because of the mass of the stepper. X and Y are still 600mm/s, so, no consequence either.

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 09:44AM |

Registered: 6 years ago Posts: 63 |

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 10:10AM |

Registered: 10 years ago Posts: 150 |

@Trakyan

Replacing this compact and lightweight water-cooled Hot-End with a classic and bulky 60g air-cooled solution would be a really weird idea! ;-)

The hot-End presented here really only has advantages, and remains compatible with all the standard stuff (nozzles, cartridges, etc...)

But if you really want that, it must be possible. You will need to make the adapter. The extrusion mechanism alone weighs 12g...

If you wanted to talk about cooling printed objects, Zatsit offers an excellent solution, very powerful, and here too ultra-light.

Give a look to these links

www.zatsit.fr

[hackaday.io]

You will have detailed responses to your questions, about durability, Hot-End exchange, etc.

Replacing this compact and lightweight water-cooled Hot-End with a classic and bulky 60g air-cooled solution would be a really weird idea! ;-)

The hot-End presented here really only has advantages, and remains compatible with all the standard stuff (nozzles, cartridges, etc...)

But if you really want that, it must be possible. You will need to make the adapter. The extrusion mechanism alone weighs 12g...

If you wanted to talk about cooling printed objects, Zatsit offers an excellent solution, very powerful, and here too ultra-light.

Give a look to these links

www.zatsit.fr

[hackaday.io]

You will have detailed responses to your questions, about durability, Hot-End exchange, etc.

|

Re: Toward the Graal : Ultra-light extrusion June 13, 2018 08:09PM |

Registered: 7 years ago Posts: 507 |

|

Re: Toward the Graal : Ultra-light extrusion June 14, 2018 02:46AM |

Registered: 10 years ago Posts: 150 |

@Trakyan

I don't quite understand what hassle you' re talking about.

I still have air-cooled Hot Ends, which I used at the beginning of the Zatsit project, before I developed the solution with water. I can replace them in a few seconds, if I feel like it, and this will not change any of the printer's other functions (cooling parts, extrusion, etc...). The design of Zatsit is such that all effectors are interchangeable, and are just attached with three screws.

The only hassle will be that it will be necessary to purge the water circuit, by blowing inside, before disconnecting it, just as when one wants to pass from a use as a 3D printer, to a use as a generic robot.

I'm guessing you haven't seen the videos where all this is explained. On the whole, it's very simple...

Edited 1 time(s). Last edit at 06/14/2018 02:56AM by M_Xeno.

I don't quite understand what hassle you' re talking about.

I still have air-cooled Hot Ends, which I used at the beginning of the Zatsit project, before I developed the solution with water. I can replace them in a few seconds, if I feel like it, and this will not change any of the printer's other functions (cooling parts, extrusion, etc...). The design of Zatsit is such that all effectors are interchangeable, and are just attached with three screws.

The only hassle will be that it will be necessary to purge the water circuit, by blowing inside, before disconnecting it, just as when one wants to pass from a use as a 3D printer, to a use as a generic robot.

I'm guessing you haven't seen the videos where all this is explained. On the whole, it's very simple...

Edited 1 time(s). Last edit at 06/14/2018 02:56AM by M_Xeno.

|

Re: Toward the Graal : Ultra-light extrusion June 14, 2018 04:42AM |

Registered: 7 years ago Posts: 507 |

It's simple but it adds another step in the process. Plus you need to add a water reservoir which needs to be changed regularly and a pump which is usually noisier than a fan. I'm not saying a water cooled system is a bad idea, I just personally prefer an air cooled system for the slight advantage in simplicity and maintenance.

|

Re: Toward the Graal : Ultra-light extrusion June 14, 2018 06:24AM |

Registered: 10 years ago Posts: 150 |

I won't try to change your opinion, but my experience over two years contradicts your assertions: the submersible aquarium pump is incomparably quieter and also much more reliable over time than any DC fan (and I've tried many!). With a drop of hypochlorite in the water, there's no reason to change it. Seeing air cooling as simpler is, IMHO, simply the habit of seeing it everywhere as the standard solution.

Edited 1 time(s). Last edit at 06/14/2018 06:26AM by M_Xeno.

Edited 1 time(s). Last edit at 06/14/2018 06:26AM by M_Xeno.

|

Re: Toward the Graal : Ultra-light extrusion June 16, 2018 09:24PM |

Registered: 7 years ago Posts: 363 |

|

Re: Toward the Graal : Ultra-light extrusion June 17, 2018 05:40AM |

Registered: 10 years ago Posts: 150 |

@obelisk79

There will soon be a Kickstarter campaign for the Zatsit kit (see www.zatsit.fr), but I don't think I would have time to integrate this extruder, which still requires optimization studies, and especially, for mass production. The association of a POM pinion, and a metal hobbed gear, must be simplified, it is much too complicated to produce in series.

But it will be done, because I think there is a market for such an ultra-light extruder.

There will soon be a Kickstarter campaign for the Zatsit kit (see www.zatsit.fr), but I don't think I would have time to integrate this extruder, which still requires optimization studies, and especially, for mass production. The association of a POM pinion, and a metal hobbed gear, must be simplified, it is much too complicated to produce in series.

But it will be done, because I think there is a market for such an ultra-light extruder.

|

Re: Toward the Graal : Ultra-light extrusion May 06, 2019 09:14PM |

Registered: 10 years ago Posts: 39 |

|

Re: Toward the Graal : Ultra-light extrusion May 14, 2019 10:23AM |

Registered: 6 years ago Posts: 63 |

I never have time to test my work it seems but have you tried out this flex shaft? [www.mhz-powerboats.com]

It's 2.2mm instead of 3 something. Should be a little less weight & a bit more flexible.

It's 2.2mm instead of 3 something. Should be a little less weight & a bit more flexible.

|

Re: Toward the Graal : Ultra-light extrusion May 19, 2019 09:30PM |

Registered: 8 years ago Posts: 1,671 |

this could work as a flex shaft [www.ebay.co.uk]

|

Re: Toward the Graal : Ultra-light extrusion May 26, 2019 02:20PM |

Registered: 10 years ago Posts: 150 |

I'm working on it, but most of my time goes to completing the deliveries of the delta Zatsit printer for my Kickstarter Backers.Quote

Any news on bringing this promising extruder to market?

The first prototype I showed in this post evolved into a multi-material extruder concept (2, 4, 6...), with a single stepper motor, and a single electronic driver, for the 2xn channels. The basic idea is the same: a worm screw drives two pinch wheels simultaneously. In the multi-material version, the common drive shaft is horizontal, and the pinch wheel pairs come into contact with the drive by a simple pendulum movement. The switch from one material to another is therefore very fast.

The whole is miniaturized, and remains very light. The 2-way version weighs less than 40g (2 hot-end, water-cooled, 2 pinch wheels per track, common flexible drive shaft, support structure).

I hope to come up with a proposal that can be used on all types of 3D printers, and that will offer multi-material functionality, direct drive, lightweight and fast. It's very exciting. Stay tuned....

Edited 1 time(s). Last edit at 05/26/2019 02:21PM by M_Xeno.

|

Re: Toward the Graal : Ultra-light extrusion May 26, 2019 08:37PM |

Registered: 10 years ago Posts: 39 |

|

Re: Toward the Graal : Ultra-light extrusion May 26, 2019 11:19PM |

Registered: 9 years ago Posts: 978 |

Sorry, only registered users may post in this forum.