Measured heatbed heat up times at 12V and 230V - how to speed it up?

Posted by mardy3d

|

Measured heatbed heat up times at 12V and 230V - how to speed it up? July 11, 2018 05:07PM |

Registered: 9 years ago Posts: 94 |

Dear RepRappers,

my setup: A modified MakerFarm i3v 10. I switched to a 230V 500W heatbed with ~5-8mm aluminium bed some time ago.

TL;DR: My heatbed is quite slow. What is your heatbed setup and how fast are they?

I have two heat beds: The stock one from Makerfarm for 12V (PCB heatbed) with a glass bed on top and one 230V mains 500W silicone heater glued to a CNC milled ~5-8mm aluminium heatbed.

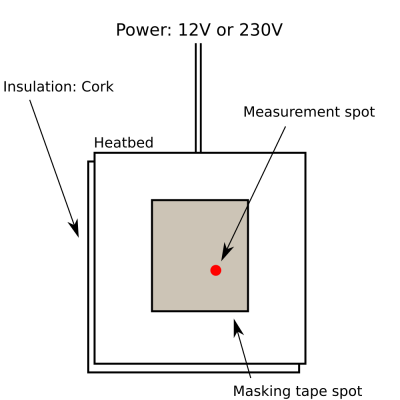

Thus, there are two setups: One using the 12V (PCB heater + glass) and another one using the 230V heatbed (silicon heater + thick aluminium plate). Each heatbed is covered with masking tape in the middle of the heatbed. Since an IR temperature measuring device is used to measure the temperature, the tape is required to really track the surface temperature and to avoid reflections. The heatbed setups are placed on two layers of cork to provide insulation from below.

I measure the temperature at some fixed spot every 15s and note it down. The setup is shown in the following figure ("experimental_setup.png" if not displayed).

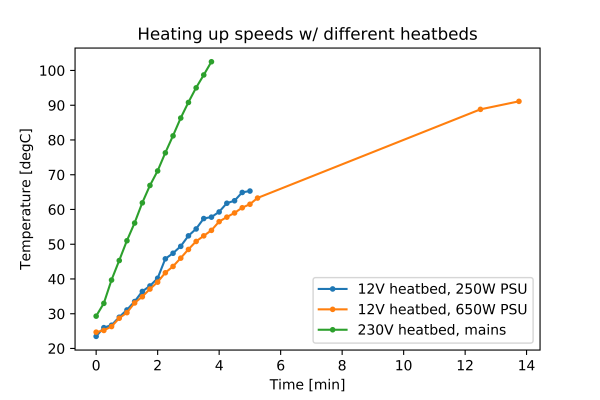

To evaluate the bare heating speed, there is no control connected to the power supply. That means the heating units should draw as much power as they can, which serves as an estimate for an lower bound of the heating times for production use. The 230V heater is plugged in the mains voltage and for the 12V heater, two different ATX PSUs are used with 250W and 650W (my production PSU), respectively.

The heating times are shown in the following section ("heatup_speeds.png" if not displayed).

One can see that for the 12V setups, both PSUs are approximately equally fast. The 230V setup is heating up much faster and, showing a linear relationship between temperature and time, doesn't run into stagnation. The 12V shows saturating behaviour for longer times. While the PLA temperature of about 50 degC is reached quickly, the ABS temperature of 100+ degC is not reached properly.

Problem: I would like to print ABS. The heater speed with 12V is too slow, if possible at all. However, I would prefer a 12V setup. The latter is because of the following aspects:

Question: How to speed the heatbed up? What are your heating times and what's your setup? I would be willing to continue to use the 230V but not at the current weight and lack of modularity. Some ideas that I had:

On the wattages of my heatbed setups

The resistances are 0.8 Ohms and approx 43.2 Ohms for the 12V and 230V heaters, respectively. That translates to 180W and 1200W, respectively. However, I am sure that my calculation for the 230V heater is not all correct as 1200W seems way too high.

my setup: A modified MakerFarm i3v 10. I switched to a 230V 500W heatbed with ~5-8mm aluminium bed some time ago.

TL;DR: My heatbed is quite slow. What is your heatbed setup and how fast are they?

I have two heat beds: The stock one from Makerfarm for 12V (PCB heatbed) with a glass bed on top and one 230V mains 500W silicone heater glued to a CNC milled ~5-8mm aluminium heatbed.

Thus, there are two setups: One using the 12V (PCB heater + glass) and another one using the 230V heatbed (silicon heater + thick aluminium plate). Each heatbed is covered with masking tape in the middle of the heatbed. Since an IR temperature measuring device is used to measure the temperature, the tape is required to really track the surface temperature and to avoid reflections. The heatbed setups are placed on two layers of cork to provide insulation from below.

I measure the temperature at some fixed spot every 15s and note it down. The setup is shown in the following figure ("experimental_setup.png" if not displayed).

To evaluate the bare heating speed, there is no control connected to the power supply. That means the heating units should draw as much power as they can, which serves as an estimate for an lower bound of the heating times for production use. The 230V heater is plugged in the mains voltage and for the 12V heater, two different ATX PSUs are used with 250W and 650W (my production PSU), respectively.

The heating times are shown in the following section ("heatup_speeds.png" if not displayed).

One can see that for the 12V setups, both PSUs are approximately equally fast. The 230V setup is heating up much faster and, showing a linear relationship between temperature and time, doesn't run into stagnation. The 12V shows saturating behaviour for longer times. While the PLA temperature of about 50 degC is reached quickly, the ABS temperature of 100+ degC is not reached properly.

Problem: I would like to print ABS. The heater speed with 12V is too slow, if possible at all. However, I would prefer a 12V setup. The latter is because of the following aspects:

- The aluminium plate that I already have is very heavy

- 12V is a little bit safer

- The actual print surface should be easily replacable and modular (e.g. glass)

- I use a capacitive sensor for ABL, so I wouldn't need aluminium necessarily

Question: How to speed the heatbed up? What are your heating times and what's your setup? I would be willing to continue to use the 230V but not at the current weight and lack of modularity. Some ideas that I had:

- Maybe I would need to stick to the 230V and use a thinner aluminium plate with a silicone heater at approximately the same wattage

- Build an enclosure, that could enable the 12V reach ABS temperature

- Get a more powerful 12V PCB heater but I don't know if that's available for my dimension of 254x254

- Switch to 24V

On the wattages of my heatbed setups

The resistances are 0.8 Ohms and approx 43.2 Ohms for the 12V and 230V heaters, respectively. That translates to 180W and 1200W, respectively. However, I am sure that my calculation for the 230V heater is not all correct as 1200W seems way too high.

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 11, 2018 05:32PM |

Registered: 11 years ago Posts: 5,780 |

You have discovered the truth about most 12V heaters. They are underpowered and only good for printing PLA and other low temperature filaments, unless the bed is very small.

You've also discovered that higher power translates into faster heat up (and actually reaching the target temperature).

If you want faster heat up, you need more power.

Don't waste time or money on a 12V/24V heater for a bed that size. The rule of thumb for heaters is 0.4-0.5W/cm^2 will get you reasonable heat up times. A 250 x250 mm bed is 625 cm^2, so you need at least 250W, but more is better (as you have demonstrated). A 12V 250W heater needs big thick cables to handle the 20 A it will require. A 230V 250W heater only needs 1A, so much smaller, more flexible wires will be fine. Heaters don't care if you give them regulated DC or AC, so why spend money on a regulated power supply to run a heater? If you use a line powered heater, you can use a smaller, cheaper, quieter power supply for the rest of the printer, and an SSR to switch power to the bed.

This site has a simulator that seems to pretty accurately calculate the heat up time based on the bed size, material, and heater power.

My printer has a line powered 750W heater to get the 300x300x8mm aluminum bed up to 100C in about 4.5 minutes. Here's details of the wiring.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You've also discovered that higher power translates into faster heat up (and actually reaching the target temperature).

If you want faster heat up, you need more power.

Don't waste time or money on a 12V/24V heater for a bed that size. The rule of thumb for heaters is 0.4-0.5W/cm^2 will get you reasonable heat up times. A 250 x250 mm bed is 625 cm^2, so you need at least 250W, but more is better (as you have demonstrated). A 12V 250W heater needs big thick cables to handle the 20 A it will require. A 230V 250W heater only needs 1A, so much smaller, more flexible wires will be fine. Heaters don't care if you give them regulated DC or AC, so why spend money on a regulated power supply to run a heater? If you use a line powered heater, you can use a smaller, cheaper, quieter power supply for the rest of the printer, and an SSR to switch power to the bed.

This site has a simulator that seems to pretty accurately calculate the heat up time based on the bed size, material, and heater power.

My printer has a line powered 750W heater to get the 300x300x8mm aluminum bed up to 100C in about 4.5 minutes. Here's details of the wiring.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 12, 2018 03:42AM |

Registered: 10 years ago Posts: 14,672 |

I have 2 printers with heated beds. One has a 210mm x 210mm PCB heater with a thin aluminium heat spreader and 3mm glass attached to the top using Swiss clips. The other has a 330mm diameter x 5mm thick aluminium plate with a 230v 350W 300mm silicone heater attached to the underside, and 4mm glass attached to the top using foldback clips. Both are modular in that I can use different glass plates on top, with whatever additional surface (or none) that I want on top of the glass.

Two issues you facing are:

1. 12V power isn't really adequate for a bed size greater than 210mm square, because the current needed to heat the bed at a reasonable speed gets above the practical limit of around 15A.

2. PCB bed heaters vary a lot, probably because the copper thickness isn't controlled accurately, and are frequently under-powered. Also the heating power of PCB heaters reduces with increasing temperature.

Here are some options for you:

1. Build an enclosure (which you will need to print ABS anyway), insulate under the bed, and turn the power supply voltage up. Most 12V power supplies other than ATX ones have a voltage adjustment potentiometer, which usually goes up to at least 14V. Using 14V instead of 12V will increase the heating power by 36%. Caution: if you are using RAMPS electronics, you will need make additional changes to avoid overheating the 5V regulator on the Arduino; also replace the badly-chosen bed heater mosfet on the RAMPS by a better one. To avoid feeding too much voltage to the 12V fans, connect two IN4001 or similar silicon diodes in series with them. Make sure your PSU can handle the additional load.

This might just allow you to reach and maintain 100C, but the heating time will still be slow.

2. Follow digital_dentist's advice and use a 230V silicone heater, aluminium plate (preferably cast aluminium tooling plate), and SSR. You can still use glass on top if you want, as I do. Choose a silicone heater a little smaller than the bed plate to leave a margin of about 15mm all the way round, for fixings and bed clips.

3. As #2 but use a 24V heater and a PSU large enough to handle it. You will need to either convert the rest of your printer to 24V operation, or use two PSUs, or one PSU and a 12V regulator.

#2 and #3 require either that you choose the heating power carefully so that the heater doesn't reach dangerous temperatures if left on at full power, or a thermal cutout attached to the bed.

Edited 2 time(s). Last edit at 07/12/2018 03:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Two issues you facing are:

1. 12V power isn't really adequate for a bed size greater than 210mm square, because the current needed to heat the bed at a reasonable speed gets above the practical limit of around 15A.

2. PCB bed heaters vary a lot, probably because the copper thickness isn't controlled accurately, and are frequently under-powered. Also the heating power of PCB heaters reduces with increasing temperature.

Here are some options for you:

1. Build an enclosure (which you will need to print ABS anyway), insulate under the bed, and turn the power supply voltage up. Most 12V power supplies other than ATX ones have a voltage adjustment potentiometer, which usually goes up to at least 14V. Using 14V instead of 12V will increase the heating power by 36%. Caution: if you are using RAMPS electronics, you will need make additional changes to avoid overheating the 5V regulator on the Arduino; also replace the badly-chosen bed heater mosfet on the RAMPS by a better one. To avoid feeding too much voltage to the 12V fans, connect two IN4001 or similar silicon diodes in series with them. Make sure your PSU can handle the additional load.

This might just allow you to reach and maintain 100C, but the heating time will still be slow.

2. Follow digital_dentist's advice and use a 230V silicone heater, aluminium plate (preferably cast aluminium tooling plate), and SSR. You can still use glass on top if you want, as I do. Choose a silicone heater a little smaller than the bed plate to leave a margin of about 15mm all the way round, for fixings and bed clips.

3. As #2 but use a 24V heater and a PSU large enough to handle it. You will need to either convert the rest of your printer to 24V operation, or use two PSUs, or one PSU and a 12V regulator.

#2 and #3 require either that you choose the heating power carefully so that the heater doesn't reach dangerous temperatures if left on at full power, or a thermal cutout attached to the bed.

Edited 2 time(s). Last edit at 07/12/2018 03:45AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 12, 2018 04:20AM |

Registered: 8 years ago Posts: 5,232 |

Quote

The resistances are 0.8 Ohms and approx 43.2 Ohms for the 12V and 230V heaters, respectively. That translates to 180W and 1200W, respectively. However, I am sure that my calculation for the 230V heater is not all correct as 1200W seems way too high.

1200W is correct, when your resistance reading is truly 43.2Ohm. I'd be concerned about getting hotspots while heating up, because the alu-plate might not spread the heat fast enough. The heater could overheat here and there and silicone gets brittle...

You could add a single diode in the mains voltage line to reduce AC to 115V= 300W heating power. That would create a pulsing effect, like bang-bang mode.

A thick alu-plate won't care.

Another option is a 230V/110V transformator or AC/AC converter.

Edited 1 time(s). Last edit at 07/12/2018 04:20AM by o_lampe.

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 12, 2018 06:01AM |

Registered: 12 years ago Posts: 1,450 |

Exactly what the others said with a couple of additional notes:

Mike

- You did not mention what size your bed is. 200mm square should be workable to 100ºC with a 12V 250W supply but is better with a 24V 250W supply, 300mm square struggles with even a 24V and is better with 230V

- Connecting wire thickness and length is important at 12V. Commonly sold (Maplins before they went to the wall) speaker wire with many thin strands (for flexibility) of about 2.5mm2 works for me.

- Insulating the bed with a top cover usefully shortens warm up time. I use 6mm mdf with a covering of metalised bubble film. Thickness of the hot bed has only a minor effect.

Mike

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 12, 2018 01:31PM |

Registered: 9 years ago Posts: 465 |

Watts = heat. If you want more heat, it takes more power. It's easier to get more power from higher voltage (Fewer amps.)

Watt for watt, higher voltages are actually safer, because they would use less current. Current is what burns wires, so long as voltage is still below the point where the wire insulation starts to break down.

That said, there's a real difference in the amount of power between 180W and 1200W. Running that at half voltage and getting 300W is probably safer all round. It'll take longer to come to temperature, but the lower power dissipation is less risk.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

Watt for watt, higher voltages are actually safer, because they would use less current. Current is what burns wires, so long as voltage is still below the point where the wire insulation starts to break down.

That said, there's a real difference in the amount of power between 180W and 1200W. Running that at half voltage and getting 300W is probably safer all round. It'll take longer to come to temperature, but the lower power dissipation is less risk.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 12, 2018 02:18PM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

1200W is correct, when your resistance reading is truly 43.2Ohm. I'd be concerned about getting hotspots while heating up, because the alu-plate might not spread the heat fast enough. The heater could overheat here and there and silicone gets brittle...

You could add a single diode in the mains voltage line to reduce AC to 115V= 300W heating power. That would create a pulsing effect, like bang-bang mode.

A diode would reduce the RMS voltage by sqrt(2) and hence the heating power by 50% (to 600W), not 75%. But it's still a good option. The pulse frequency would be at 50Hz, high enough not to matter.

Edited 1 time(s). Last edit at 07/12/2018 02:19PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 12, 2018 02:36PM |

Registered: 6 years ago Posts: 93 |

Using an external mosfet for the heater, it's relatively easy to change just the bed to 24V, while leaving the rest of the system on 12V power. Then there's no need to change other heaters and fans to the higher voltage, and no need to play with voltage dividers and such for LED's or other gubbins you have attached.

I use a 24V 200W silicone heater pad stuck to a 230x230x3mm aluminum plate with garolite/g11FR5 on top instead of glass. My bed heats to 110C in 6:45. It is well insulated underneath, and printer is enclosed (and ventilated outside) for exotics.

I use bang-bang mode for control, +/- 2C.

This also allows you to turn up the voltage on just the bed to shorten times even more, with no side-effects on the rest of the system. Just make sure the mosfet you choose is rated for the voltage you wish to run, they are not all rated the same.

BTW, if it's not too much trouble, switching the whole system to 24V is totally worth it. The steppers move much more nicely (and faster too) and the system actually runs quieter. Just mind that fans and your hotend heater have to be swapped.

Edited 1 time(s). Last edit at 07/12/2018 02:57PM by Diggrr.

I use a 24V 200W silicone heater pad stuck to a 230x230x3mm aluminum plate with garolite/g11FR5 on top instead of glass. My bed heats to 110C in 6:45. It is well insulated underneath, and printer is enclosed (and ventilated outside) for exotics.

I use bang-bang mode for control, +/- 2C.

This also allows you to turn up the voltage on just the bed to shorten times even more, with no side-effects on the rest of the system. Just make sure the mosfet you choose is rated for the voltage you wish to run, they are not all rated the same.

BTW, if it's not too much trouble, switching the whole system to 24V is totally worth it. The steppers move much more nicely (and faster too) and the system actually runs quieter. Just mind that fans and your hotend heater have to be swapped.

Edited 1 time(s). Last edit at 07/12/2018 02:57PM by Diggrr.

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 15, 2018 01:07PM |

Registered: 9 years ago Posts: 94 |

Dear all,

thank you very much for the help of all of you, it really helped sorting my thoughts! I read everything thoroughly and am planning the next steps now. I would have the following questions and will summarise my whole stack of ideas in the end.

I would have the following few remaining questions. Maybe you can help me? :-)

My quite lengthy summary:

I am thanking you once more for helping me! I am looking forward to my finished perfect heatbed setup and will report back my findings as soon as possible :-).

thank you very much for the help of all of you, it really helped sorting my thoughts! I read everything thoroughly and am planning the next steps now. I would have the following questions and will summarise my whole stack of ideas in the end.

I would have the following few remaining questions. Maybe you can help me? :-)

- I don't know the advantages and disadvantages of using a transformator or AC/AC converter. So I wouldn't mind using either of the two. Which 230V/110V transformator or AC/AC converter would you recommend for my use case?

- Is there a thermal cutout that you would recommend or maybe use yourself? I have read about thermal fuses previously.

- At Diggrr:

Quote

Diggrr

is enclosed (and ventilated outside) for exotics

What do you mean with "and ventilated outside"? Do you mean exotic plastics? - Is your headbed moving? I am using a 254mm x 254mm x 8mm aluminium bed with the silicone heater. It has been my production setup for a while now and worked very well most of the time. However, I thought that it might be better to reduce the heatbed weight since with my Prusa i3 design, it is moving back and forth a lot. The additional weight of my heavy heatbed might reduce print quality, I don't know. I am currently thinking about getting another heatbed to address this issue: 3mm or 5mm with a new silicone heater.

- At dc42:

Quote

dc42

with a thin aluminium heat spreader

What do you mean with the thin aluminium spreader? How thick is it, is it one of these very flat aluminium plates?

My quite lengthy summary:

- Non-12V is what I will do. Since I already have my silicone heater, I will probably stick to that. The advantages over 12V are faster heating times, smaller amps and a smaller PSU for the rest of the printer. I will use my SSR to switch power of the bed, potentially with bang bang control instead of PID which is what I used before. Also, I need to tune my temperature readings to improve printing quality futher.

- I wanted to build an enclosure anyways. However, I will build it independently of the heatbed so that the powerful silicone heater is just fine for that plan as well.

- Just as before, I will use a proper insulation under my headbed (I used cork so far but will add some aluminium foil on top for heat radiation insulation). Additionally, also something to cover the bed while heating up.

- I will put some print surface on top of my bed. Either glass or the proposed "garolite/g11FR5". That's possible due to my capacitive ABL sensor. Initially, I only had an inductive ABL sensor which didn't allow me to use anything on top of the metal.

- I would like to limit the heating power.

- Even when the power is left on, the final temperature shouldn't be too high. That should prevent thermal runaways.

- I would like to attach a thermal cutout to the bed. I am planning some Arduino-based watchdog currently that will be capable of some other tasks as well (I will show it off, once it is finished). However, such an additional thermal cutout will let me sleep even better while the printer is running over night.

- Using the full 230V might result in hot spots that lead to uneven heat distribution and could make the silicone brittle.

- Thus, I'd like to reduce the voltage. Reducing to approx. 110V seems very reasonable to me, resulting in 300W.

- To follow an incremental update procedure, I will stick to my thick aluminium bed at first. It worked good initially even though it is quite heavy. A thinner aluminium bed with a slightly weaker silicone heater is easy to use as a replacement if it becomes necessary. It could become necessary as I have never used a glass plate on top of my heavy aluminium heat bed which could result in a way too heavy setup. I doubt the latter when using a 2mm thick glass, though.

I am thanking you once more for helping me! I am looking forward to my finished perfect heatbed setup and will report back my findings as soon as possible :-).

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 15, 2018 02:13PM |

Registered: 11 years ago Posts: 5,780 |

Your 230V heater is 1200W if the 43.2 Ohm resistance value is correct. It will take about 5.3A. If you reduce voltage by 1/2, you end up with 1/4 the rated power, so if you used a transformer to drop the voltage, you'll need a transformer that's good for at least 300W which is a pretty large, pretty heavy piece of iron and copper. But if you're going to power the bed from 110V, why not just use 110V line input for it and skip the transformer? OTOH, if you simply put a rectifier in series with the heater and run it from 230V, you reduce the power to about 600W, which will get the bed up to temperature quickly. A rectifier weighs and costs a lot less than a transformer, and takes only a tiny fraction of the space. The heater doesn't care if you give it AC, DC, or pulsed DC. Use a fuse, a TCO, and careful wiring and any of these should work fine.

Insulation under the bed is only needed if there's something under there that needs protection from heat or the heater is under powered and can't get the bed up to temperature without some help. In an i3 type printer, the airspace between the "frog-plate" and the bed, and frog plate itself provide all the shielding and insulation needed to protect anything under the bed. You don't have an under powered heater, so it won't be necessary to insulate the underside of the bed in order to get the bed to reach print temperature. You're going to be enclosing the printer to keep it warm so heat "lost" from the underside of the bed is going to help warm the enclosure. If you insulate the bottom of bed it will heat up faster, but it will also take longer to cool off. Not an issue if you use a removable print surface, but something to consider if you're worried about starting the next print as quickly as possible. Covering the top of the bed while heating up will speed heat-up a little, but really won't be necessary, unless you absolutely gotta have it heat up faster (but if you did, just powering the heater from 230V would get you the fastest heat up without any messing around with insulation or rectifiers, or transformers).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Insulation under the bed is only needed if there's something under there that needs protection from heat or the heater is under powered and can't get the bed up to temperature without some help. In an i3 type printer, the airspace between the "frog-plate" and the bed, and frog plate itself provide all the shielding and insulation needed to protect anything under the bed. You don't have an under powered heater, so it won't be necessary to insulate the underside of the bed in order to get the bed to reach print temperature. You're going to be enclosing the printer to keep it warm so heat "lost" from the underside of the bed is going to help warm the enclosure. If you insulate the bottom of bed it will heat up faster, but it will also take longer to cool off. Not an issue if you use a removable print surface, but something to consider if you're worried about starting the next print as quickly as possible. Covering the top of the bed while heating up will speed heat-up a little, but really won't be necessary, unless you absolutely gotta have it heat up faster (but if you did, just powering the heater from 230V would get you the fastest heat up without any messing around with insulation or rectifiers, or transformers).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 15, 2018 09:17PM |

Registered: 6 years ago Posts: 93 |

I print mostly with ABS, and though some brands have more fumes than others, I've had a few brands that make my eyes water and irritate my throat for days. Mine is ventilated to my unused chimney in my very old house, using just two little 2050 blowers...you don't need a ton of air for exhaust, just a little negative pressure.

I've printed some crazy plastics, with no MSDS available, like Fluorocarbon fishing leader for example. (and no, it's not a great printing material. )

)

My bed does move in Y, like a Prusa. Since my carrier plate is also 3mm aluminum, and my Openbuilds Poly-carbonate wheels and belts bolt directly to it, I wish to stop temperature transfer to those items. It is also a consideration that the heating power is moving mostly upward, and I've noticed that the heater comes on less than without insulation...I pay the electric bill, so..

I got rid of heavy bed artifacts by switching to dual 9mm wide GT2 belts. I'd suspected all along that a single 6mm wide belt is as much rubber band as belt when it's moving weighty items in a warm enclosure, and that seems to be the case.

I've printed some crazy plastics, with no MSDS available, like Fluorocarbon fishing leader for example. (and no, it's not a great printing material.

)

)My bed does move in Y, like a Prusa. Since my carrier plate is also 3mm aluminum, and my Openbuilds Poly-carbonate wheels and belts bolt directly to it, I wish to stop temperature transfer to those items. It is also a consideration that the heating power is moving mostly upward, and I've noticed that the heater comes on less than without insulation...I pay the electric bill, so..

I got rid of heavy bed artifacts by switching to dual 9mm wide GT2 belts. I'd suspected all along that a single 6mm wide belt is as much rubber band as belt when it's moving weighty items in a warm enclosure, and that seems to be the case.

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 21, 2018 05:36AM |

Registered: 9 years ago Posts: 94 |

Thank you very much for your replies! Again, it helped me a lot!

Avoiding such a large transformator is a good idea.

What do you mean by the 110V line? In the country I live in (Germany), there is no 110V line according to my best knowledge.

Do you might know of a good rectifier that serves my desired purpose? I looked it up on eBay but I am not sure if I found the device you mean.

My Prusa design uses a wooden frog-plate with belts and wheels for linear motion being somewhat close to the bed. Thus, I feel that insulation is a good idea. If it even reduces the energy consumption: Great!

That's a great idea! I will put that aspect on my todo list for printer modifications :-). It sounds like you modified your printer from a 1x 6mm GT2 belt to 2x 9mm GT2 belts. How did you modify your y setup to do so? Do you use some additional lengthened axis attached to the y motor to mount two belts? Or did you use something like that: [de.aliexpress.com]? The latter seems to be called "GT2 pulley double head".

Cheeerio!

Edited 2 time(s). Last edit at 07/21/2018 05:43AM by mardy3d.

Avoiding such a large transformator is a good idea.

Quote

the_digital_dentist

why not just use 110V line input for it and skip the transformator

What do you mean by the 110V line? In the country I live in (Germany), there is no 110V line according to my best knowledge.

Quote

the_digital_dentist

put a rectifier in series with the heater and run it from 230V

Do you might know of a good rectifier that serves my desired purpose? I looked it up on eBay but I am not sure if I found the device you mean.

My Prusa design uses a wooden frog-plate with belts and wheels for linear motion being somewhat close to the bed. Thus, I feel that insulation is a good idea. If it even reduces the energy consumption: Great!

Quote

Diggrr

I got rid of heavy bed artifacts by switching to dual 9mm wide GT2 belts.

That's a great idea! I will put that aspect on my todo list for printer modifications :-). It sounds like you modified your printer from a 1x 6mm GT2 belt to 2x 9mm GT2 belts. How did you modify your y setup to do so? Do you use some additional lengthened axis attached to the y motor to mount two belts? Or did you use something like that: [de.aliexpress.com]? The latter seems to be called "GT2 pulley double head".

Cheeerio!

Edited 2 time(s). Last edit at 07/21/2018 05:43AM by mardy3d.

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 21, 2018 06:31AM |

Registered: 10 years ago Posts: 14,672 |

Quote

mardy3d

What do you mean by the 110V line? In the country I live in (Germany), there is no 110V line according to my best knowledge.

That would be 230V in your country.

Quote

mardy3d

Do you might know of a good rectifier that serves my desired purpose? I looked it up on eBay but I am not sure if I found the device you mean.

Something like [www.ebay.de] or [www.ebay.de]. It will get quite hot, so make sure that air can circulate around it.

Edited 3 time(s). Last edit at 07/21/2018 06:34AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 21, 2018 08:30AM |

Registered: 11 years ago Posts: 5,780 |

I would not count on a wood frog plate to stay flat when exposed to heat, either from the bed or from a warm enclosure. Plywood warps and delaminates when exposed to heating and cooling cycles. You might want to think about replacing it with metal...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 28, 2018 02:31AM |

Registered: 9 years ago Posts: 94 |

Quote

dc42

Something like [www.ebay.de] or [www.ebay.de]. It will get quite hot, so make sure that air can circulate around it.

That's interesting as it's not what I expected it to be. I searched for some tutorials of how to build my own rectifier unit from these diodes. I found a few videos, such as: [www.youtube.com], [www.youtube.com], [www.youtube.com] and [www.youtube.com] that describe how to assemble the 4 diodes to obtain a rectifier unit. Is that what you had in mind as well? I would do it the same way, with proper wiring, of course, and potentially some heatsinks or cooling.

Quote

the_digital_dentist

You might want to think about replacing it with metal

That's a great idea! I have a Makerfarm i3 which is completely made from plywood and my frog-plate is already warping actually ... that started when I switched to the 230V silicone heater, I believe. What would be a good place to source a metal frog-plate from? My printer is not the typical 200x200 size so the standard parts typically don't fit, I fear. I was dreaming of a metal frog-plate for quite some time already.

About the enclosure: I found resources that have the same wooden printer as I do and put it in an enclosure even thought the printer is made from wood, see [moczys.com]. I have to re-read the article but it seems that putting a printer made from plywood into an enclosure seems to work fine here.

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 28, 2018 10:53AM |

Registered: 11 years ago Posts: 5,780 |

The point of using a single diode is to reduce the power input to the heater by blocking current for 1/2 of each cycle of the power line voltage. If you make a bridge rectifier using 4 diodes, you allow both halves of the voltage waveform to hit the heater. You may as well not use the rectifier in that case because the heater will deliver full power (minus a bit burned up in the diodes) in the form of heat.

Plywood printers are fine for a little while, but heat and humidity will eventually warp and even delaminate the wood layers. Have you noticed that almost no companies are selling printer kits made from plywood any more? There's a reason, and it isn't just cost... We had a plywood makerbot machine at the makerspace for a while, several years ago. After about 2 years all the frame panels were warped, and the screws that held the whole thing together had to be retightened every couple months because the wood compressed under them and the screws kept loosening.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Plywood printers are fine for a little while, but heat and humidity will eventually warp and even delaminate the wood layers. Have you noticed that almost no companies are selling printer kits made from plywood any more? There's a reason, and it isn't just cost... We had a plywood makerbot machine at the makerspace for a while, several years ago. After about 2 years all the frame panels were warped, and the screws that held the whole thing together had to be retightened every couple months because the wood compressed under them and the screws kept loosening.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Measured heatbed heat up times at 12V and 230V - how to speed it up? July 31, 2018 09:07AM |

Registered: 9 years ago Posts: 94 |

Thanks for the explanation. That makes the whole set-up even easier by just hooking one diode in the power line.

Yeah, I have noticed that there are no wood printers anymore. However, I got mine quite some years ago so that I am confined to using my wooden printer for now :-/. I was considering re-building it by using aluminium extrusions. But that needs to wait until it is delivering a good print quality again with its wooden frame as it did when I bought it.

Yeah, I have noticed that there are no wood printers anymore. However, I got mine quite some years ago so that I am confined to using my wooden printer for now :-/. I was considering re-building it by using aluminium extrusions. But that needs to wait until it is delivering a good print quality again with its wooden frame as it did when I bought it.

Sorry, only registered users may post in this forum.