Somebody Help ! Corner lift during print with a particular print

Posted by ulysse31

|

Somebody Help ! Corner lift during print with a particular print July 23, 2018 03:11PM |

Registered: 10 years ago Posts: 8 |

Hello all,

I usually don't post really often on the forums, and try to find the error by googling and by myself.

But this time, I really do not find the cause of the error : Corners lift, but during print but only in a particular print

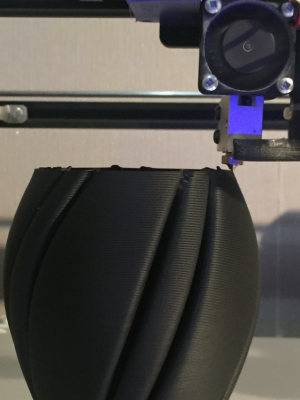

I'm trying to print a Spiral vase (quite common on the internet) in vase mode (so 1 perimeter), but for some reason the internal corners starts lifting up, not from the start, only about 75% of the print (when the body of the vase is "reducing" its size). Here are some pictures :

Here is some informations about the printer :

- e3dv6 hotend with volcano kit 0.6mm nozzle

- 2.85mm PLA filament

- direct drive with e3d titan extruder

the printer is a "custom" one (homemade build) with vslots.

about the printing parameters :

- printing at 0.5mm

- hotend at 204 C first layer, 200 C other layer

- PLA is quite good quality : Actifil 3D PLA 2.85mm (its a french brand)

- print cooling fan on (fan auto mode on the slicer).

- using last version of Slic3r PE

- extrusion is correct (a really tiny bit under extruding)

I'm really getting out of ideas, I've tried decreasing temperatures (first prints were at 212 and 208, same result).

tried with and without fan, (of course, without is worse ^^' )

I starting to think that there may be some particularity with this vase.

If someone knows the answer, or just have an idea, please share with me.

with all the different tests and combinations, I've now 6 "horror version" of this vase, I'm starting to get sick with this vase ^^'

Thanks a lot for you all.

Cheers,

--

Ulysse31

Edited 2 time(s). Last edit at 07/23/2018 03:23PM by ulysse31.

I usually don't post really often on the forums, and try to find the error by googling and by myself.

But this time, I really do not find the cause of the error : Corners lift, but during print but only in a particular print

I'm trying to print a Spiral vase (quite common on the internet) in vase mode (so 1 perimeter), but for some reason the internal corners starts lifting up, not from the start, only about 75% of the print (when the body of the vase is "reducing" its size). Here are some pictures :

Here is some informations about the printer :

- e3dv6 hotend with volcano kit 0.6mm nozzle

- 2.85mm PLA filament

- direct drive with e3d titan extruder

the printer is a "custom" one (homemade build) with vslots.

about the printing parameters :

- printing at 0.5mm

- hotend at 204 C first layer, 200 C other layer

- PLA is quite good quality : Actifil 3D PLA 2.85mm (its a french brand)

- print cooling fan on (fan auto mode on the slicer).

- using last version of Slic3r PE

- extrusion is correct (a really tiny bit under extruding)

I'm really getting out of ideas, I've tried decreasing temperatures (first prints were at 212 and 208, same result).

tried with and without fan, (of course, without is worse ^^' )

I starting to think that there may be some particularity with this vase.

If someone knows the answer, or just have an idea, please share with me.

with all the different tests and combinations, I've now 6 "horror version" of this vase, I'm starting to get sick with this vase ^^'

Thanks a lot for you all.

Cheers,

--

Ulysse31

Edited 2 time(s). Last edit at 07/23/2018 03:23PM by ulysse31.

|

Re: Somebody Help ! Corner lift during print with a particular print July 23, 2018 08:56PM |

Registered: 9 years ago Posts: 978 |

|

Re: Somebody Help ! Corner lift during print with a particular print July 24, 2018 12:22AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Somebody Help ! Corner lift during print with a particular print July 24, 2018 01:20AM |

Registered: 10 years ago Posts: 8 |

Quote

frankvdh

Print with a brim to improve adhesion.

Thanks but unfortunately, the bottom is already flat and really well stick to the bed. Forgot to mention : I use a flat aluminium plate with a heat pad under it (heated at 60 C), and use hairspray to fix the print. Might be overkill but it really sticks well to it and the bottom, as the 75% of the first layers, are flat.

|

Re: Somebody Help ! Corner lift during print with a particular print July 24, 2018 01:23AM |

Registered: 10 years ago Posts: 8 |

Quote

o_lampe

It seems you have to slow down the print when the diameter gets smaller.

I'd try to increase minimum layer time. Probably reduce temp a bit.

But one change at a time, so you know what made it work.

Thanks for the advice, will try out today lowering again temperature, and, if it still doesn’t work, try to set a minimum_layer_time (wasn’t aware of this type of parameter ^^’)

Thanks again, I’ll keep you in touch after trying out these.

|

Re: Somebody Help ! Corner lift during print with a particular print July 24, 2018 03:12AM |

Registered: 6 years ago Posts: 60 |

|

Re: Somebody Help ! Corner lift during print with a particular print July 24, 2018 04:23PM |

Registered: 10 years ago Posts: 8 |

Hi all,

Ok ... I've been printing tonight (I'm running the second print now), and here is what happened until now :

- I do not have find in the Slic3r PE where is minimum layer time, so started by printing at lower temp

- I. started to print and reduce temperature again (printing at 190C) : the result was that corner curling started even earlier (?!) at about 50% of the print , so up to the top it was even worse than at 200C

- then I remembered that at 212C, I do not had fan on, so I started again a print with fan on at 212 (don't ask me why)

- and now, it still curls (...) but clearly less than at 200C ...

I don't know what to think now, I suppose that I'll try printing even hotter and see what it does ... but I'm done for tonight, so will try again tomorrow.

Thanks all again for your help.

Cheers all,

--

Ulysse31

Edited 1 time(s). Last edit at 07/24/2018 04:36PM by ulysse31.

Ok ... I've been printing tonight (I'm running the second print now), and here is what happened until now :

- I do not have find in the Slic3r PE where is minimum layer time, so started by printing at lower temp

- I. started to print and reduce temperature again (printing at 190C) : the result was that corner curling started even earlier (?!) at about 50% of the print , so up to the top it was even worse than at 200C

- then I remembered that at 212C, I do not had fan on, so I started again a print with fan on at 212 (don't ask me why)

- and now, it still curls (...) but clearly less than at 200C ...

I don't know what to think now, I suppose that I'll try printing even hotter and see what it does ... but I'm done for tonight, so will try again tomorrow.

Thanks all again for your help.

Cheers all,

--

Ulysse31

Edited 1 time(s). Last edit at 07/24/2018 04:36PM by ulysse31.

|

Re: Somebody Help ! Corner lift during print with a particular print July 24, 2018 06:37PM |

Registered: 10 years ago Posts: 564 |

|

Re: Somebody Help ! Corner lift during print with a particular print July 25, 2018 12:21AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Somebody Help ! Corner lift during print with a particular print July 25, 2018 04:44PM |

Registered: 10 years ago Posts: 8 |

Quote

o_lampe

Quote

- I do not have find in the Slic3r PE where is minimum layer time, so started by printing at lower temp

It is called 'slow down if layer print time is below: ### seconds' and you find it in Filament Settings / cooling

Hi all,

So tonight, I read the post of o_lampe and had a try on that, so I firstly printed one vase at 206C with "standard" values, which gave, as expected, this :

Then, following o_lampe advice, I changed the default value of that field from 5 secs to 20 secs, and printed again (same other parameters), which gave me this :

And a BIG THANKS TO O_LAMPE !!

Of course, it still not perfect, because I left the minimum down-speed to 10mm/s, which gave a shiny effect in the really slow areas.

I think that I should change the minimum down-speed to something like 25mm/s (generally, it prints around 80mm/s) that will suppress those shiny zones, and will also improve print speed (since I "normally" printed the first horrors in 1h, and which this option set to 20s, I have printed it in 1h30, i suppose I would be between those 2 ^^' ).

EDIT : or maybe "play" a little with those 2 fields, like increasing minimum layer time to 40 secs or more, and set minimum down-speed to 30mm/s ... still hesitating on that one ^^'

Thanks again o_lampe for your help,

Thanks also to all of those who gave me advices.

Cheers all,

--

Ulysse31

Edited 1 time(s). Last edit at 07/25/2018 04:47PM by ulysse31.

|

Re: Somebody Help ! Corner lift during print with a particular print July 25, 2018 09:06PM |

Registered: 10 years ago Posts: 564 |

|

Re: Somebody Help ! Corner lift during print with a particular print July 26, 2018 02:35AM |

Registered: 10 years ago Posts: 8 |

Quote

LoboCNC

Note that if you just lower your acceleration, you will only slow down at the parts with tight curvature (which is where your curling is occurring) without slowing down the rest of the path.

Hi @LoboCNC,

Yes in fact, Im also looking into that, but still reading stuff on acceleration and junction_deviation (max_jerk) in smoothie.

Modifying it via printer values also means applied to all prints, therefore slowing down all prints, and for now I only had this particular print where I had this issue (well I suppose, it might be more relevant when doing vase mode since it only prints 1 layer thickness).

But yeah, I'm still thinking on modifying those directly on the printer, if other prints gives me similar issues, I'll write that down ^^.

Thanks again,

Cheers

--

Ulysse31

Edited 1 time(s). Last edit at 07/26/2018 02:36AM by ulysse31.

|

Re: Somebody Help ! Corner lift during print with a particular print July 26, 2018 04:53AM |

Registered: 10 years ago Posts: 8 |

A little question @LoboCNC about the acceleration parameter :

Following the smoothie documentation, it says that 3000mm/s/s is a "standard" value for a 3D printer, you spoke ealier to reduce it to less than 250mm/s/s, so I'm a little bit lost on this and would like to have your point about which values should be good for acceleration, and also what is your personal experience on its impact on the overall speed (following the smoothie doc, there is an impact) ?

If any good soul has some knowledge and/or experience on acceleration values (under smoothie or other), please share I'm really curious on that point.

As any 3D printer hobbyist, my goal is to print the fastest possible, but with the most reliable printing settings performing good prints results most of the time.

It does not annoy me that in some particular prints, I need to modify some slicer parameters because of an "exception" in printing. But if it becomes needed on different types of prints, then it would mean that those values should be re-evaluated on my printer, and if I need to re-evaluate them, I really would like to know what are the reasons (maybe I could also do some physical changes on the printer to "correct" it).

I might be trying to anticipate too much on this ^^' but I tend to be really curious on any aspects of my hobbies (and I generally like to learn stuffs ^^' ).

Thanks a lot for your help, knowledges and advices.

--

Ulysse31

Following the smoothie documentation, it says that 3000mm/s/s is a "standard" value for a 3D printer, you spoke ealier to reduce it to less than 250mm/s/s, so I'm a little bit lost on this and would like to have your point about which values should be good for acceleration, and also what is your personal experience on its impact on the overall speed (following the smoothie doc, there is an impact) ?

If any good soul has some knowledge and/or experience on acceleration values (under smoothie or other), please share I'm really curious on that point.

As any 3D printer hobbyist, my goal is to print the fastest possible, but with the most reliable printing settings performing good prints results most of the time.

It does not annoy me that in some particular prints, I need to modify some slicer parameters because of an "exception" in printing. But if it becomes needed on different types of prints, then it would mean that those values should be re-evaluated on my printer, and if I need to re-evaluate them, I really would like to know what are the reasons (maybe I could also do some physical changes on the printer to "correct" it).

I might be trying to anticipate too much on this ^^' but I tend to be really curious on any aspects of my hobbies (and I generally like to learn stuffs ^^' ).

Thanks a lot for your help, knowledges and advices.

--

Ulysse31

|

Re: Somebody Help ! Corner lift during print with a particular print July 26, 2018 12:22PM |

Registered: 10 years ago Posts: 564 |

Quote

ulysse31

A little question @LoboCNC about the acceleration parameter :

Following the smoothie documentation, it says that 3000mm/s/s is a "standard" value for a 3D printer, you spoke ealier to reduce it to less than 250mm/s/s, so I'm a little bit lost on this and would like to have your point about which values should be good for acceleration, and also what is your personal experience on its impact on the overall speed (following the smoothie doc, there is an impact) ?

If any good soul has some knowledge and/or experience on acceleration values (under smoothie or other), please share I'm really curious on that point.

As any 3D printer hobbyist, my goal is to print the fastest possible, but with the most reliable printing settings performing good prints results most of the time.

It does not annoy me that in some particular prints, I need to modify some slicer parameters because of an "exception" in printing. But if it becomes needed on different types of prints, then it would mean that those values should be re-evaluated on my printer, and if I need to re-evaluate them, I really would like to know what are the reasons (maybe I could also do some physical changes on the printer to "correct" it).

I might be trying to anticipate too much on this ^^' but I tend to be really curious on any aspects of my hobbies (and I generally like to learn stuffs ^^' ).

Thanks a lot for your help, knowledges and advices.

--

Ulysse31

Without changing your firmware, you can use the command "M204 S250" to lower your acceleration for normal moves. This should work for smoothieware, but I see that recent versions of Marlin would use "M204 P250". This line of code would need to be inserted into your slicer's start-up script.

An acceleration of 3000mm/s/s seems to be pretty common, but I suspect that is actually too high for all but the most rigid of printers. Setting this value too high can result in "ringing" patterns in the print. I have a Makergear M2 which is pretty rigid, and I use a value of 1000 - 1500 and still get a little visible ringing. Slowing the acceleration down too much, however, not only slows down your printing, but it also can result in more visible overextrusion at sharp corners (due to extruder hysteresis). For your vase, though, which doesn't have lots of (or any, even) stop and start moves, and with no sharp corners, lowering the acceleration way down to something like 250 will just cause the extruder to slow down significantly around tighter curves, which is where you you're getting your curling problem.

|

Re: Somebody Help ! Corner lift during print with a particular print July 26, 2018 02:12PM |

Registered: 10 years ago Posts: 8 |

Sorry, only registered users may post in this forum.