New arm design? Would love feedback

Posted by DaGameFace

|

New arm design? Would love feedback September 18, 2018 01:15PM |

Registered: 8 years ago Posts: 318 |

So I was looking into whats available for open source robot arms and wasn't that impressed with the options. Anything that was decently cheap was small and weak, I think I came up with a novel way to allow a cheap yet accurate and strong arm to be built with readily available parts that have been made quite cheap by the boom in open source 3D printers. With two nema 17s and cheap lead screws I was able to get over 2 feet of reach and a max lift of 2.5 lbs and can even hold the weight with the steppers off (depending on where the nuts are located on the screw). The arm right now is only 3 axis but adding an end effector should be trivial.

I would love some feedback on my design, I plan on open sourcing the cad files and maybe even selling kits in the future. Also I'm not sure what exactly to call this layout of kinematics.

I have a forward kinematic model but not an inverse kinematic model yet, so I was just sending my ramps commands based on my excel dock.

PROS:

+Big build volume

+Great holding torque and lift capacity

+High precision

+Cheap to build

CONS:

-Calibration requires accurate measurements of the distances from pivots

Edited 3 time(s). Last edit at 09/18/2018 07:04PM by DaGameFace.

I would love some feedback on my design, I plan on open sourcing the cad files and maybe even selling kits in the future. Also I'm not sure what exactly to call this layout of kinematics.

I have a forward kinematic model but not an inverse kinematic model yet, so I was just sending my ramps commands based on my excel dock.

PROS:

+Big build volume

+Great holding torque and lift capacity

+High precision

+Cheap to build

CONS:

-Calibration requires accurate measurements of the distances from pivots

Edited 3 time(s). Last edit at 09/18/2018 07:04PM by DaGameFace.

|

Re: New arm design? September 18, 2018 04:28PM |

Registered: 5 years ago Posts: 61 |

|

Re: New arm design? September 18, 2018 05:51PM |

Registered: 8 years ago Posts: 318 |

Quote

Ed3D

Nice! Whats the speed / rigidity like? how about repeatability?

Speed and rigidity of the arm itself are quite good, still testing the speeds but it can move the end effector from max reach to near its base in around a second to give you a basic idea. Because of the mechanics the speed and torque change as the nut gets closer or farther from the pivot point of the two members on the arm. Unfortunately my v1 rotating base is pretty bad, due to the flexible petg and the mounting screws being too far from the center pivot it flexes the base and introduces considerable lash. Have updated my cad to fix the problem.

I dont have a dial gauge for a proper repeatability test but I am rigging up my digital caliper for a test.

EDIT: Mounted my digi caliper on the arm and am getting a repeatability of +/- .1 mm, the same repeatability of the caliper itself which makes sense because the steps/mm on the leadscrews is 400 with 1/16th microstepping (25 full steps/mm or .04mm per full step)

Edited 1 time(s). Last edit at 09/18/2018 06:57PM by DaGameFace.

|

Re: New arm design? Would love feedback September 19, 2018 12:24AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: New arm design? Would love feedback September 19, 2018 11:46AM |

Registered: 13 years ago Posts: 1,797 |

is there a way to make it use belts? this design seems rigid ,but how fast does it work. a good example would be to have it pick up and pace several items repeatably. is there a homing process that can make the device be ready and generally calibrated within minutes?

also it seems the only thing holding the motor arms in place is the rods that are connected to the motor shafts. is this good enough to hold the weights?

this is a cool design concepts, just wanted to have thought out there about how to have it in real world applications. 1 repeatability, reliability, ease of use.

belts would increase reliability and reduce wear and other issues.

reducing strain on motors from a bearing system than handles load and strain

homing system that can self calibrate in short time, and a math table for users to setup calibration for first time use.

these are just some of my opinions, it does look cool.

also it seems the only thing holding the motor arms in place is the rods that are connected to the motor shafts. is this good enough to hold the weights?

this is a cool design concepts, just wanted to have thought out there about how to have it in real world applications. 1 repeatability, reliability, ease of use.

belts would increase reliability and reduce wear and other issues.

reducing strain on motors from a bearing system than handles load and strain

homing system that can self calibrate in short time, and a math table for users to setup calibration for first time use.

these are just some of my opinions, it does look cool.

|

Re: New arm design? Would love feedback September 19, 2018 11:51AM |

Registered: 8 years ago Posts: 318 |

Quote

o_lampe

Interesting design!

On first glance, I see the weakest point in the leadscrew nuts. They are too short and any wear in the thread would lead to binding ( on the screw or the slides )

[www.amazon.com]

those are the leadscrews I used, dont think that wear should be a problem for a while as the nut is constrained to only move along the axis of the leadscrew and havent heard of 3d printer leadscrews binding.

Anyone have an idea what end effector I should make first? Im considering putting a 3d printer head on it, would be a huge build volume to price ratio.

|

Re: New arm design? Would love feedback September 19, 2018 03:37PM |

Registered: 5 years ago Posts: 61 |

I would recommend switching out the lead screws for ball screws. You can get them cheap from china (link)

Second im not sure those couplers are good - switch them out for some of the more rigid style ones not the sprung ones.

Im really interested in this project - any plans to make it available to other people?

Edited 1 time(s). Last edit at 09/19/2018 03:38PM by Ed3D.

Second im not sure those couplers are good - switch them out for some of the more rigid style ones not the sprung ones.

Im really interested in this project - any plans to make it available to other people?

Edited 1 time(s). Last edit at 09/19/2018 03:38PM by Ed3D.

|

Re: New arm design? Would love feedback September 19, 2018 05:25PM |

Registered: 8 years ago Posts: 318 |

Quote

Ed3D

I would recommend switching out the lead screws for ball screws. You can get them cheap from china (link)

Second im not sure those couplers are good - switch them out for some of the more rigid style ones not the sprung ones.

Im really interested in this project - any plans to make it available to other people?

Yup im aware that ballscrews are far superior, but have had bad experiences with cheap ballscrews (and figured that the cheap leadscrews would be good enough for a proof of concept), because they are hardened steel if they are slightly bent then they would flex the aluminum bar. Im not worried about the sprung couplers though as the bearings on the leadscrew are well anchored to the frame and have set screws constraining the leadscrews from movement in any other direction than rotation. The spring couplers are quite good for purely rotational forces and only have issue with transverse forces, being pulled or pushed.

As mentioned in the first post I do plan on open sourcing this project. Anything specific you have in mind for the arm?

Edited 1 time(s). Last edit at 09/19/2018 05:27PM by DaGameFace.

|

Re: New arm design? Would love feedback September 19, 2018 06:44PM |

Registered: 10 years ago Posts: 564 |

What are you planning on doing for wrist joints, if anything? In designing robot arms, you typically start with the wrist joints and then move back towards the base, as each joint will have to deal with the mass of the more distal joints. The wrist joints are also typically more challenging to design in order to keep the mass and size to a minimum. One more consideration is that the speed of many motions is often limited by the speed of the wrist joints, which often have to go thru very large excursions to reorient parts or reorient to a new grasp orientation.

|

Re: New arm design? Would love feedback September 19, 2018 07:34PM |

Registered: 8 years ago Posts: 318 |

Quote

LoboCNC

What are you planning on doing for wrist joints, if anything? In designing robot arms, you typically start with the wrist joints and then move back towards the base, as each joint will have to deal with the mass of the more distal joints. The wrist joints are also typically more challenging to design in order to keep the mass and size to a minimum. One more consideration is that the speed of many motions is often limited by the speed of the wrist joints, which often have to go thru very large excursions to reorient parts or reorient to a new grasp orientation.

Im aware that I did the process a bit backward but I needed to test the new(?) idea of linear screws before i dumped time into designing more traditional joints. But luckily I am not constrained in weight much at all since 2.5 lbs of lift can go a long way in a wrist and still have a healthy amount left over for an object to be lifted. Right now im considering just adding a 4th axis to the end to be used a 3d printer platform but a 5 axis gripper could also be really neat. You happen to have any suggestions? Id love to hear them, I'm still in pretty early development.

Edited 1 time(s). Last edit at 09/19/2018 07:35PM by DaGameFace.

|

Re: New arm design? Would love feedback September 19, 2018 07:45PM |

Registered: 10 years ago Posts: 564 |

Quote

DaGameFace

Quote

LoboCNC

What are you planning on doing for wrist joints, if anything? In designing robot arms, you typically start with the wrist joints and then move back towards the base, as each joint will have to deal with the mass of the more distal joints. The wrist joints are also typically more challenging to design in order to keep the mass and size to a minimum. One more consideration is that the speed of many motions is often limited by the speed of the wrist joints, which often have to go thru very large excursions to reorient parts or reorient to a new grasp orientation.

Im aware that I did the process a bit backward but I needed to test the new(?) idea of linear screws before i dumped time into designing more traditional joints. But luckily I am not constrained in weight much at all since 2.5 lbs of lift can go a long way in a wrist and still have a healthy amount left over for an object to be lifted. Right now im considering just adding a 4th axis to the end to be used a 3d printer platform but a 5 axis gripper could also be really neat. You happen to have any suggestions? Id love to hear them, I'm still in pretty early development.

With your 2.5 lb payload, if you were only wanted a 1 or 2 axis wrist, you could simply use some NEMA (14 or 17) steppers with planetary gearheads. They are pretty cheap and the have big enough output bearings that you could just hang one off of another without any additional structure. A short NEMA 17 with a 5:1 gearhead is about 380g.

|

Re: New arm design? Would love feedback September 19, 2018 09:04PM |

Registered: 8 years ago Posts: 318 |

Quote

jamesdanielv

is there a way to make it use belts? this design seems rigid ,but how fast does it work. a good example would be to have it pick up and pace several items repeatably. is there a homing process that can make the device be ready and generally calibrated within minutes?

also it seems the only thing holding the motor arms in place is the rods that are connected to the motor shafts. is this good enough to hold the weights?

this is a cool design concepts, just wanted to have thought out there about how to have it in real world applications. 1 repeatability, reliability, ease of use.

belts would increase reliability and reduce wear and other issues.

reducing strain on motors from a bearing system than handles load and strain

homing system that can self calibrate in short time, and a math table for users to setup calibration for first time use.

these are just some of my opinions, it does look cool.

Sorry, I completely missed your comment, you must have made it while i was typing a response. As you can see in the attached photo not only are the motors secured to their plastic bracket (the bracket itself is secured to the aluminum with two bolts on either side as well as an m5 bolt threaded into the end of the aluminum) but the shaft itself is fully constrained so that there is no appreciable force pulling or pushing on the couplers. Belts were actually something I wanted to avoid due to the lash they introduce, especially with the weights involved you would need a gearbox to get the torque that a linear screw provides, the gearbox further increases lash. Ideally the design would be brushless motors on ballscrews. My proof of concept build has no endstops and is far from ready to use especially since I lack an inverse kinematic model.

Edited 1 time(s). Last edit at 09/19/2018 10:01PM by DaGameFace.

|

Re: New arm design? Would love feedback September 20, 2018 02:54AM |

Registered: 6 years ago Posts: 1,007 |

In fact, it is kinematic of a crane [autoline.info] just the leadscrews are arranged in a more complex way than the hydraulic actuators (that could be replaced by ball screws actuators BTW)

Can you give the equations of the X, Y, Z as functions of the three motors steps ?

Edited 1 time(s). Last edit at 09/20/2018 02:57AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Can you give the equations of the X, Y, Z as functions of the three motors steps ?

Edited 1 time(s). Last edit at 09/20/2018 02:57AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New arm design? Would love feedback September 20, 2018 03:43PM |

Registered: 5 years ago Posts: 61 |

|

Re: New arm design? Would love feedback September 20, 2018 04:15PM |

Registered: 8 years ago Posts: 318 |

Quote

MKSA

In fact, it is kinematic of a crane [autoline.info] just the leadscrews are arranged in a more complex way than the hydraulic actuators (that could be replaced by ball screws actuators BTW)

Can you give the equations of the X, Y, Z as functions of the three motors steps ?

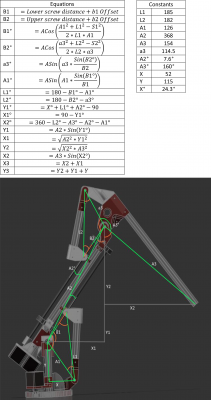

Here is the math for my forward kinematic model, my triginometry is a little rusty so i may have done a couple extra steps but Im pretty sure the math is correct.

Sorry for some weird labels, Green is constant in the image and orange is calculated, X3 and Y3 are the position of the end effector

EDIT: oh, I missed a negative on my Y2 calculation and forgot to include the b1 and b2 offsets in the constants table, but close enough, my excel doc is correct

Edited 2 time(s). Last edit at 09/20/2018 07:11PM by DaGameFace.

|

Re: New arm design? Would love feedback September 20, 2018 04:31PM |

Registered: 8 years ago Posts: 318 |

Quote

Ed3D

Quote

DaGameFace

Anything specific you have in mind for the arm?

Nope, just a really cool project. Im sure I can find some kind of use for it though! Perhaps an auto print remover? What are you planning to use it for?

Auto print remover could be a good use for all the torque, Personally I would like to eventually have a printer that can print some sort of expanded extrusion (like foam or aerated plastic) but it also seems like a good platform to develop a few other things on, maybe a camera gimble?

|

Re: New arm design? Would love feedback September 20, 2018 06:59PM |

Registered: 8 years ago Posts: 1,671 |

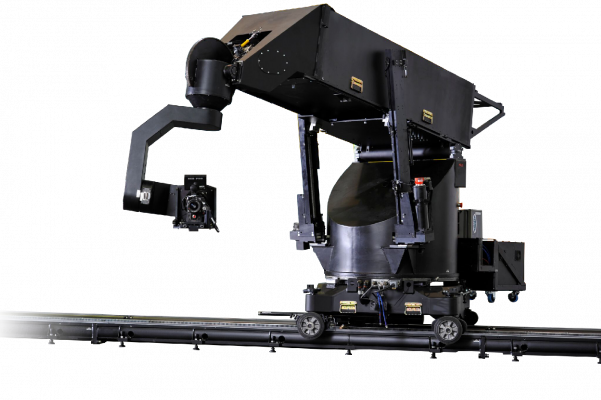

you might like this one [www.facebook.com]

|

Re: New arm design? Would love feedback September 20, 2018 07:49PM |

Registered: 8 years ago Posts: 318 |

WOW, that is an awesome overbuilt overhead camera crane,

Anyone know of a good open source robot forum? i went looking around and found a couple that seem to have no active users and a few others that are the forums for companies that sell closed source stuff. I suppose Hackaday could be a good place but think Id like to wait till its a bit more complete

Edited 1 time(s). Last edit at 09/20/2018 07:57PM by DaGameFace.

|

Re: New arm design? Would love feedback September 20, 2018 10:34PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: New arm design? Would love feedback September 21, 2018 03:47AM |

Registered: 6 years ago Posts: 1,007 |

Quote

MechaBits

Yeah I thought it was way over built too...maybe he's planning on relocating it, thought the camera was overkill for in a shop too.

More money, skill & time than sense or something for the real pro market?

Yet, it is similar to the "arm" proposed but the "actuators" are simpler, better mounted, just like the Cat crane !

(Seeing the guy level of expertise, pretty sure he knows why he made this camera jig that "complex")

(Seeing the guy level of expertise, pretty sure he knows why he made this camera jig that "complex")Edited 1 time(s). Last edit at 09/21/2018 03:48AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New arm design? Would love feedback September 21, 2018 04:28AM |

Registered: 6 years ago Posts: 1,007 |

I fail to see the advantages of the way the lead screws are mounted considering the extra complexity (although the math is done by the microcontroller luckily current 32bits can do). Each joints mean play and there are plenty.

As for rigidity, repeatability, accuracy I wonder even for a FFM 3D printer.

Edited 1 time(s). Last edit at 09/21/2018 04:30AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

As for rigidity, repeatability, accuracy I wonder even for a FFM 3D printer.

Edited 1 time(s). Last edit at 09/21/2018 04:30AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New arm design? Would love feedback September 21, 2018 02:17PM |

Registered: 8 years ago Posts: 1,671 |

Yeah I'm pretty sure he knows why he did what he did, and I know what I would do to make it smaller, less parts, the slider part of the rig is massive (I can see it being used inside a O/B Van or something & more functionality...I didnt see any motors as I thought at first it would be like a MILO motion control rig

...mine would be based on the arm that I already have done the CAD work for...the gimbal i bought & some tracks on the floor.

...mine would be based on the arm that I already have done the CAD work for...the gimbal i bought & some tracks on the floor.

|

Re: New arm design? Would love feedback September 21, 2018 04:03PM |

Registered: 8 years ago Posts: 318 |

Quote

MKSA

I fail to see the advantages of the way the lead screws are mounted considering the extra complexity (although the math is done by the microcontroller luckily current 32bits can do). Each joints mean play and there are plenty.

As for rigidity, repeatability, accuracy I wonder even for a FFM 3D printer.

The layout of the leadscrews was chosen because it was easy to design and cheap to build. The whole build was under $200. I couldnt find linear actuators for a decent price anywhere and I have been exploring other layouts of the linear screws where the first screw would be stationary and moves a beam that holds the second screw but I liked the idea of the nema 17s being used as a counter weight. The complexity of the math or the number of joints wouldnt change much with other layouts of actuators or screws though. I wish the maker muscle actuators had better build quality, they are just a lead screw and 3d printed nut. Anyone happen to have a specific suggestion for a better layout?

I am not worried about rigidity, repeatability, accuracy for FFF. The worst part of it is I measured about 5mm of deflection with 2.5lbs of weight at max reach (which is a lot but so is that load compared to a more realistic use case) and the majority of that deflection is caused by the base. I took some really promising measurements of repeatability with a dial gauge though, uploading a video to youtube, will add it to this comment when its uploaded

[youtu.be]

Edited 2 time(s). Last edit at 09/21/2018 04:12PM by DaGameFace.

|

Re: New arm design? Would love feedback September 22, 2018 02:11AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: New arm design? Would love feedback September 22, 2018 03:40AM |

Registered: 6 years ago Posts: 1,007 |

Quote

DaGameFace

....

PROS:

+Big build volume

+Great holding torque and lift capacity

+High precision

+Cheap to build

CONS:

-Calibration requires accurate measurements of the distances from pivots

Frankly, to achieve the 3 first PROS goals, quality materials, tools even a machine shop and the expertise to run them are required. This is beyond the capacity of the vast majority of 3D printer hobbyists who have difficulties computing steps/mm, use a tap and a caliper. Of course forget the cheap.

Regarding the calibration aspect, it is even more than what you wrote, you have to consider that the step/mm of the head displacements varies as they depends on the arm position. The arm actuators zero must be determined accurately and can't change.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New arm design? Would love feedback September 22, 2018 12:01PM |

Registered: 8 years ago Posts: 318 |

Quote

MKSA

Quote

DaGameFace

....

PROS:

+Big build volume

+Great holding torque and lift capacity

+High precision

+Cheap to build

CONS:

-Calibration requires accurate measurements of the distances from pivots

Frankly, to achieve the 3 first PROS goals, quality materials, tools even a machine shop and the expertise to run them are required. This is beyond the capacity of the vast majority of 3D printer hobbyists who have difficulties computing steps/mm, use a tap and a caliper. Of course forget the cheap.

Regarding the calibration aspect, it is even more than what you wrote, you have to consider that the step/mm of the head displacements varies as they depends on the arm position. The arm actuators zero must be determined accurately and can't change.

Um, no. I already have a big build volume, the holding torque, lift capacity and high precision are all guaranteed side effects of using screws, even better with ball screws, (I didnt promise high accuracy, which is different) And as for cheap, you let me know when you find an arm that can lift more than 1kg for a reasonable price.

Obviously calibration needs a zero position, endstops are an easy addition, but I also intended on adding encoders on the main joints of the arm.

|

Re: New arm design? Would love feedback September 23, 2018 03:15AM |

Registered: 6 years ago Posts: 1,007 |

Quote

DaGameFace

Um, no. I already have a big build volume, the holding torque, lift capacity and high precision are all guaranteed side effects of using screws, even better with ball screws, (I didnt promise high accuracy, which is different) And as for cheap, you let me know when you find an arm that can lift more than 1kg for a reasonable price.

Obviously calibration needs a zero position, endstops are an easy addition, but I also intended on adding encoders on the main joints of the arm.

5mm flex for 1kg, I don't call that rigid. Worse it depends on the arm position. What about flex and oscillation when moving a print head ?

And the rotating base is an other challenge !

Calibration here is more complex than a Delta.

Encoders will help greatly, ball screws too but then where is the "cheap" ? Cheap chinese ones ? Better plan to buy a few more than needed and sort them out.

Anyway good luck.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New arm design? Would love feedback September 24, 2018 12:37AM |

Registered: 7 years ago Posts: 507 |

Quote

MKSA

5mm flex for 1kg, I don't call that rigid.

Don't used a 1kg print head? The flex should be fairly repeatable so it could be calibrated out with bed leveling (look at scara arms). Of course it isnt as constant in the z axis like with scara but for reasonable z axis ranges it should be "constant enough". At this scale you're likely working with big nozzles, layer heights and extrusion widths. +-1mm may not be too bad.

|

Re: New arm design? Would love feedback September 24, 2018 03:51AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Trakyan

Quote

MKSA

5mm flex for 1kg, I don't call that rigid.

Don't used a 1kg print head? The flex should be fairly repeatable so it could be calibrated out with bed leveling (look at scara arms). Of course it isnt as constant in the z axis like with scara but for reasonable z axis ranges it should be "constant enough". At this scale you're likely working with big nozzles, layer heights and extrusion widths. +-1mm may not be too bad.

You do realize that this deflection is not constant and depends on the arm position which makes it fairly complicated to "compensate".

Fact, this set up is more complex than a SCARA and so far, the only decent ones are using quality parts, bearings, machined Al etc...

I have yet to see a cheap, high precision, big machine even more when based on a complex kinematic.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: New arm design? Would love feedback September 24, 2018 04:08PM |

Registered: 5 years ago Posts: 61 |

I can appreciate both sides of what you two are saying. No the deflection isn’t great, neither is repeatability and it could easily be much much better using machined Al but then its no longer this cheap to build. I think this poises itself in a certain price to quality level that many might find appealing / fun.

Sorry, only registered users may post in this forum.