What's the secret of belts running inside aluminum extrusions

Posted by Archiclem

|

What's the secret of belts running inside aluminum extrusions October 03, 2018 04:58PM |

Registered: 8 years ago Posts: 49 |

Hi everyone !

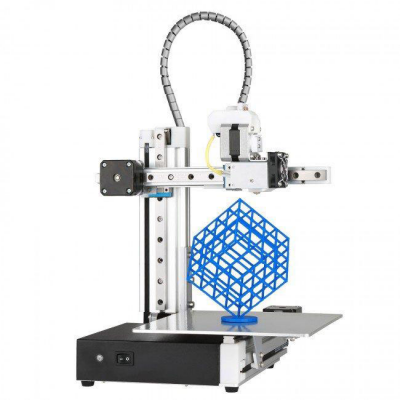

I'm currently building a crane style printer (a cetus ripoff to be completly honest)...

I know this is a flawed design (I mean cantilever... come on !) but I really like the compactness and minimalism of the overall machine...

Anyway... I find quite amazing the fact that They are able to run the belt inside the extrusion and yet, connecting it to an MGN12 carriage... I've looked again, and again, and I can't quite find the way they do it... So if you have a drawing, a link to a commercial product that does it... or a picture of your Cetus i would love it !

(I was wondering if they use some kind of crimping connector like these one [openbuildspartstore.com] )

I'm currently building a crane style printer (a cetus ripoff to be completly honest)...

I know this is a flawed design (I mean cantilever... come on !) but I really like the compactness and minimalism of the overall machine...

Anyway... I find quite amazing the fact that They are able to run the belt inside the extrusion and yet, connecting it to an MGN12 carriage... I've looked again, and again, and I can't quite find the way they do it... So if you have a drawing, a link to a commercial product that does it... or a picture of your Cetus i would love it !

(I was wondering if they use some kind of crimping connector like these one [openbuildspartstore.com] )

|

Re: What's the secret of belts running inside aluminum extrusions October 03, 2018 05:25PM |

Registered: 11 years ago Posts: 5,780 |

You simply use one large (the drive pulley) and two small pulleys (the far end) at the ends of the extrusion so the belt runs inside the slots.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What's the secret of belts running inside aluminum extrusions October 03, 2018 05:57PM |

Registered: 8 years ago Posts: 49 |

I'm not sure to uderstand what you are saying, but i think their is a misunderstanding : I mean for me the problem is not the way you keep the belt inside the extrusion, it is how do you connect a belt in such a tiny space (inside the extrusion) to the mgn12 carriage... I cant believe this is achieved with a 3D printed piece...

I've tried many design and the "clamping the belt" part is always the problem, too big for being a 3D printed part inside an extrusion (especially if you use open belt, because you have to overcome the tensioning forces that tends to rip your connector apart !)...

I've spotted this design [www.thingiverse.com] but it does not fit into my aluminium extrusion... And I was wondering how a commercial printer did it !

I don't know if that's more clear...

I've tried many design and the "clamping the belt" part is always the problem, too big for being a 3D printed part inside an extrusion (especially if you use open belt, because you have to overcome the tensioning forces that tends to rip your connector apart !)...

I've spotted this design [www.thingiverse.com] but it does not fit into my aluminium extrusion... And I was wondering how a commercial printer did it !

I don't know if that's more clear...

|

Re: What's the secret of belts running inside aluminum extrusions October 03, 2018 06:48PM |

Registered: 10 years ago Posts: 564 |

|

Re: What's the secret of belts running inside aluminum extrusions October 03, 2018 07:09PM |

Registered: 9 years ago Posts: 483 |

Just make a sandwich of a printed part which has the same profile of the belt, the belt, and an extension of the linear slide carriage. Use machine screws to hold it all together. The printed part and the belt should fit inside the extrusion.

p.s. What extrusion are you using? Can you provide a 3d model of the extrusion?

Edited 1 time(s). Last edit at 10/03/2018 07:11PM by etfrench.

p.s. What extrusion are you using? Can you provide a 3d model of the extrusion?

Edited 1 time(s). Last edit at 10/03/2018 07:11PM by etfrench.

|

Re: What's the secret of belts running inside aluminum extrusions October 03, 2018 08:01PM |

Registered: 8 years ago Posts: 49 |

@LoboCNC I know that a cantilevered design can be done the good way, It's going to be all metal connector, the main post being fixed on 6mm aluminium plate with countersunk screws... This is rock solid. I will do a thread once this is finished.

@Etfrench (are you french ? cause I surely am...) It's the motedis I type extrusion from here [www.motedis.fr]

They give an STP file... For the moment I havn't been able to crack down this particular matter, for obvious reasons, the rail must be 90° from the running belt... Anyway the space inside the extrusion is verry small, and you have to solve the open loop problem here too.

@Etfrench (are you french ? cause I surely am...) It's the motedis I type extrusion from here [www.motedis.fr]

They give an STP file... For the moment I havn't been able to crack down this particular matter, for obvious reasons, the rail must be 90° from the running belt... Anyway the space inside the extrusion is verry small, and you have to solve the open loop problem here too.

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 12:28AM |

Registered: 8 years ago Posts: 5,232 |

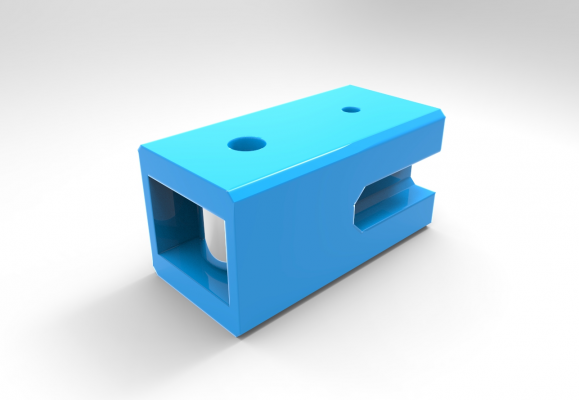

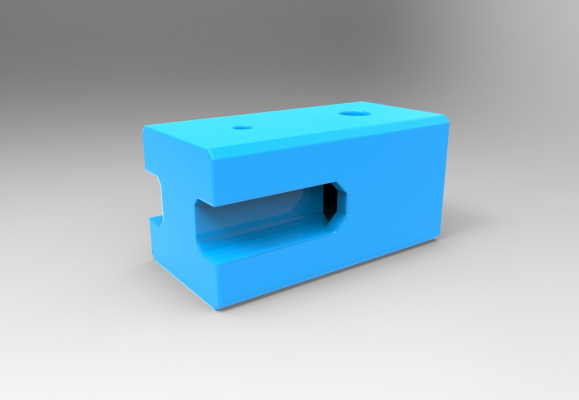

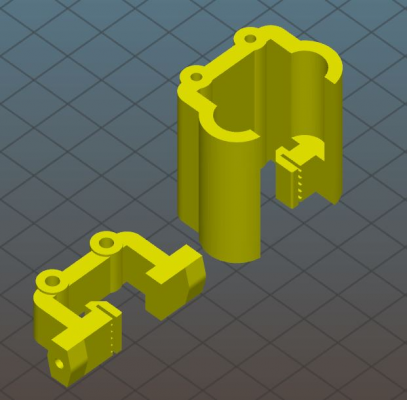

Maybe this design of my 'compact carrier' helps understanding? It is designed for 'Bosch slot5' extrusions and works surprisingly well on my Delta. They are made of PETG, which allows me to tighten the belt without breaking the clamping part.

To connect open belt together in a 'twisted' fashion, I simply CA-glued them. That's strong enough, but only works on straights. No bending allowed.

Edited 1 time(s). Last edit at 10/04/2018 12:37AM by o_lampe.

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 02:21AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 03:17AM |

Registered: 8 years ago Posts: 49 |

Quote

o_lampe

[attachment 107420 twisted-belt-M3.JPG]

Maybe this design of my 'compact carrier' helps understanding? It is designed for 'Bosch slot5' extrusions and works surprisingly well on my Delta. They are made of PETG, which allows me to tighten the belt without breaking the clamping part.

[attachment 107421 twistedbelt.jpg]

@o_lampe To connect open belt together in a 'twisted' fashion, I simply CA-glued them. That's strong enough, but only works on straights. No bending allowed.

this is very interesting indeed, but I have to questions, why would you need to twist the belt ? Is the friction not a problem ? What about the wear over time ? I never considered the fact that it could be a sliding part rather than a free "floating" connector.

@MKSA Yes that kind of what I have in mind, but I can't find a correct dimension piece of metal... I could try to fold one myself but that's another story...

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 04:31AM |

Registered: 9 years ago Posts: 483 |

Not french, US.

There's plenty of room in the channel for the belt and a locking piece. The channel is 5.1mm wide, so the belt will need to be smaller than that if you want it to ride at the top of channel. You could also mill or file the channel wider to take 6mm belt (Wood routers and tablesaws handle aluminum fine, just noisy and a little more dangerous. Aluminum needs to more securely held than wood). If the belt is at the top of the channel, the locking piece can be 4+mm thick. If the belt will ride entirely in the channel, the locking piece would be 2+mm thick. The locking piece can be as long as the carriage, and that should be enough to secure the ends of an open loop belt. Personally, I'd use a closed loop belt.

p.s. I'm pretty sure 20x20 extrusion isn't going to be rigid enough.

There's plenty of room in the channel for the belt and a locking piece. The channel is 5.1mm wide, so the belt will need to be smaller than that if you want it to ride at the top of channel. You could also mill or file the channel wider to take 6mm belt (Wood routers and tablesaws handle aluminum fine, just noisy and a little more dangerous. Aluminum needs to more securely held than wood). If the belt is at the top of the channel, the locking piece can be 4+mm thick. If the belt will ride entirely in the channel, the locking piece would be 2+mm thick. The locking piece can be as long as the carriage, and that should be enough to secure the ends of an open loop belt. Personally, I'd use a closed loop belt.

p.s. I'm pretty sure 20x20 extrusion isn't going to be rigid enough.

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 06:54AM |

Registered: 11 years ago Posts: 5,780 |

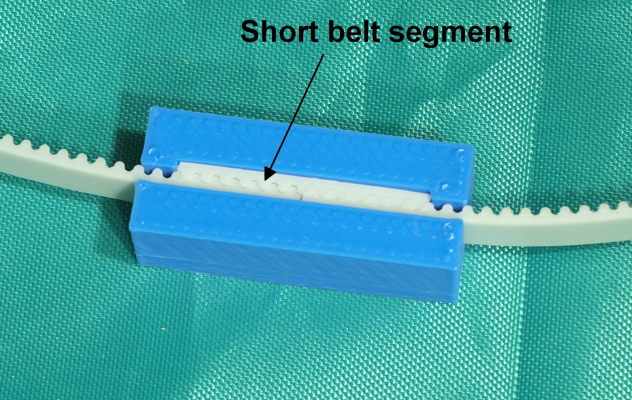

There's a twist in the belt so the teeth will interlock at the ends. If you don't mind the twist, just put the teeth together and fit them into a slot to keep them together. I would never trust CA glue to hold a belt.

I used this for the Z axis in UMMD and for the magnet carriage in a sand table:

No twisting needed. When you twist belts you may have problems with them riding on pulley flanges.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I used this for the Z axis in UMMD and for the magnet carriage in a sand table:

No twisting needed. When you twist belts you may have problems with them riding on pulley flanges.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 04:51PM |

Registered: 9 years ago Posts: 483 |

|

Re: What's the secret of belts running inside aluminum extrusions October 04, 2018 10:40PM |

Registered: 7 years ago Posts: 507 |

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 02:07AM |

Registered: 6 years ago Posts: 1,007 |

I made a closed loop GT2 belt using CA, the Loctite designed to make Orings and NO problem even going around pulleys after two years.

The trick is to properly prepare the end and of course for a belt you don't glue end to end like an Oring !

CA is really good on rubber. Of course not for PU belt !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

The trick is to properly prepare the end and of course for a belt you don't glue end to end like an Oring !

CA is really good on rubber. Of course not for PU belt !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 06:38AM |

Registered: 12 years ago Posts: 1,450 |

Although toothed belt materials may vary, the ones I have tested may be unsatisfactory glued tooth to tooth with cyanoacrylate. This was because the toothed part was made of a rubber (neoprene) in granular form fused with a white waxy lubricant. The lubricant made for poor adhesion even with CA. The back surface however did not contain any lubricant and glued well with "Black Witch" neoprene glue. In a pull test to failure the glued joint did start to peel but nonetheless it held until the belt broke.

I glue my belts in this manner to run the back side of the belt over the idler pulley. I have gone away from using the twisted belt method, prefering to have one glued joint with the other ends held in a toothed tension adjuster - also back to back

Mike

I glue my belts in this manner to run the back side of the belt over the idler pulley. I have gone away from using the twisted belt method, prefering to have one glued joint with the other ends held in a toothed tension adjuster - also back to back

Mike

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 08:05AM |

Registered: 6 years ago Posts: 1,007 |

Your problems come from improper preparation. You have to use a grinding wheel to remove the rubber on the back a bit more than 1cm on each end, till you reach the fibers. Then prepare a 2cm long piece by removing the tooth side till the fiber and glue this piece to join the belt. You need a jig to keep the pitch correct. The belt is jut a few tens thicker but it is OK as the fibers are on the same plane.

There are other techniques but requiring accurate jigs to cut interlocking profiles.

Edited 2 time(s). Last edit at 10/05/2018 08:09AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

There are other techniques but requiring accurate jigs to cut interlocking profiles.

Edited 2 time(s). Last edit at 10/05/2018 08:09AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 08:21AM |

Registered: 12 years ago Posts: 1,450 |

No problems, I have had no failures in the belts on three printers. As I said though, toothed belt materials vary and rubber impregnated with a solid lubricant is is likely to have different adhesion to plain rubber. I would add to your comment though about jigs: It is useful not only to have a good cutting jig, but also a good assembly jig, especially with CA as the parts should be presented without any sliding movement and maintained under pressure until the bond has formed.

Mike

Mike

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 08:30AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 08:50AM |

Registered: 6 years ago Posts: 1,007 |

Quote

leadinglights

No problems, I have had no failures in the belts on three printers. As I said though, toothed belt materials vary and rubber impregnated with a solid lubricant is is likely to have different adhesion to plain rubber. I would add to your comment though about jigs: It is useful not only to have a good cutting jig, but also a good assembly jig, especially with CA as the parts should be presented without any sliding movement and maintained under pressure until the bond has formed.

Mike

Of course, I made these jigs to cut and assemble.

Now, here here he doesn't need all this as it is for closed loop belts. Someone just suggested to use this kind of belt when in fact it is not necessary.

Edited 1 time(s). Last edit at 10/05/2018 08:53AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 09:11AM |

Registered: 12 years ago Posts: 1,450 |

Although I don't know the design intended, I would find it unusual to find anything (e.g. a carriage) clamped onto a closed loop belt. I mentioned this only as a comment on DDs assertion that CA adhesive was unsuitable - my attitude being that the appropriate adhesive will work well but depends on the material.

MechaBits, I am assuming you are commenting on my photo in a posting above so perhaps I should clarify. The two plates form part of the tensioning mechanism and have grooves machined into the surface to grip the belt teeth as shown in the photo below. One of the plates is slotted to allow it to be moved before locking in place.

Mike

MechaBits, I am assuming you are commenting on my photo in a posting above so perhaps I should clarify. The two plates form part of the tensioning mechanism and have grooves machined into the surface to grip the belt teeth as shown in the photo below. One of the plates is slotted to allow it to be moved before locking in place.

Mike

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 10:20AM |

Registered: 11 years ago Posts: 5,780 |

I never "asserted that CA adhesive was unsuitable". I said I wouldn't trust it. I also don't trust zip ties to hold bearings in accurate alignment. YMMV.

Clamps are so simple and reliable, I can't imagine a situation in which I would use anything else, but who knows, maybe some day I'll have to glue a belt...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Clamps are so simple and reliable, I can't imagine a situation in which I would use anything else, but who knows, maybe some day I'll have to glue a belt...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 11:39AM |

Registered: 8 years ago Posts: 1,671 |

@leadinglight, yeah was your mechanism I was talking about, a lot of work gone into making that tooth profile, so the slide bit only looks good for a few teeth, whereas if there where no teeth it could be more adjustable, especially if there was a horizontal slit(2.5mm x6mm wide-ish) in middle between adjustment slots. (though i'm sure you've probably done it like that elsewhere & chose to do it the way you did for a reason)

Edited 1 time(s). Last edit at 10/05/2018 11:43AM by MechaBits.

Edited 1 time(s). Last edit at 10/05/2018 11:43AM by MechaBits.

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 12:28PM |

Registered: 12 years ago Posts: 1,450 |

@DD. I apologize as your post was several back and I was too lazy to look up the wording that you used.

@MechaBits. The tooth profile was surprisingly easy, it was milled on a 3D printer with a Proxxon hand tool.With the hex screws about two turns loose the belt could be pulled up like a zip tie (click click instead of ziiip) and the few mm of movement used to fine trim so that the belt had a pleasant twang.

Mike

@MechaBits. The tooth profile was surprisingly easy, it was milled on a 3D printer with a Proxxon hand tool.With the hex screws about two turns loose the belt could be pulled up like a zip tie (click click instead of ziiip) and the few mm of movement used to fine trim so that the belt had a pleasant twang.

Mike

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 02:08PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 02:16PM |

Registered: 12 years ago Posts: 1,450 |

There is a video of it being used for another job on [www.youtube.com]

As long as the machining is light then 3D printers do a good job but not to be confused with for-real milling.

Mike

p.s., perhaps we have moved this thread a bit far from it's origin so maybe need to discuss the limits of 3D printer milling in a new thread.

As long as the machining is light then 3D printers do a good job but not to be confused with for-real milling.

Mike

p.s., perhaps we have moved this thread a bit far from it's origin so maybe need to discuss the limits of 3D printer milling in a new thread.

|

Re: What's the secret of belts running inside aluminum extrusions October 05, 2018 03:46PM |

Registered: 8 years ago Posts: 1,671 |

Ok Back on track...3030 has a wider slot than 2020 so a little more space for the belt, and probably better for the cantilever too.

I had the belt running in 3030 in this version, but have since changed the profile for something else.

So now I have to redo hotend part & idler as the clearance has changed.

Edited 1 time(s). Last edit at 10/05/2018 04:31PM by MechaBits.

I had the belt running in 3030 in this version, but have since changed the profile for something else.

So now I have to redo hotend part & idler as the clearance has changed.

Edited 1 time(s). Last edit at 10/05/2018 04:31PM by MechaBits.

|

Re: What's the secret of belts running inside aluminum extrusions October 06, 2018 06:47AM |

Registered: 8 years ago Posts: 49 |

|

Re: What's the secret of belts running inside aluminum extrusions October 06, 2018 09:13AM |

Registered: 8 years ago Posts: 1,671 |

It's easy enough to design an idler that fits within a 20x20x40(or less if you put your mind to it) envelope(especially with stronger filament) using say 5x5x14mm(flanged but wouldnt matter) bearings x2 = 10mm with a little clearance.(or just one & smaller)

with something 40mm long and gt2 idler pulley with 3mm hole you could use 2 holes on the rail one through the idler & plastic, and another 3mm screw in next rail hole. or with the 5mm example the block could be held with just one screw if it was butted up against the 2020 so it wouldnt rotate plus belt keeping it secure too.

Edited 3 time(s). Last edit at 10/06/2018 02:05PM by MechaBits.

with something 40mm long and gt2 idler pulley with 3mm hole you could use 2 holes on the rail one through the idler & plastic, and another 3mm screw in next rail hole. or with the 5mm example the block could be held with just one screw if it was butted up against the 2020 so it wouldnt rotate plus belt keeping it secure too.

Edited 3 time(s). Last edit at 10/06/2018 02:05PM by MechaBits.

|

Re: What's the secret of belts running inside aluminum extrusions October 14, 2018 08:21PM |

Registered: 8 years ago Posts: 120 |

|

Re: What's the secret of belts running inside aluminum extrusions October 15, 2018 03:11AM |

Registered: 8 years ago Posts: 49 |

Quote

MatthewHall

Archiclem... I built a printer in the design style of a Cetus. Here's the link to the respective forum thread. While I didn't put all the belts inside the extrusions, this might help. If you have any questions just ask.

Yes I know, I've built and printed some of the part you designed, but I really like the idea of belts running inside aluminum extrusions

And I nailed it this Weekend, I will post some pictures and design file soon... And i'm kind of going the "all metal way", using printed part only where I can't get metal to fit

And I nailed it this Weekend, I will post some pictures and design file soon... And i'm kind of going the "all metal way", using printed part only where I can't get metal to fit

Sorry, only registered users may post in this forum.

for using the printer as a CNC machine...gotta get me a dremel

for using the printer as a CNC machine...gotta get me a dremel