fast stepper motor

Posted by charlieRC

|

fast stepper motor October 22, 2018 07:27PM |

Registered: 11 years ago Posts: 157 |

I am on the downhill side of building a new printer that will be completely lead screw based. I know that it will be slower than a belt driven printer (about a forth of the distance per revolution) but I really want to see if I can make the best of this. I will probably go with a Rambo Mini or Rambo Einsy controller, but I am reasonably sure that the nema 17 steppers I have are not going to be my best bet. I would like to stay with the Nema 17 foot print, but was wondering if anybody knows of any relatively affordable but fast nema 17's. . I started to go with Nema 23's but I decided to try and stick with the 17's if I can. (most of the stuff I have around here are the cheapo Amazon 17s.)

Any suggestions?

Charlie

Any suggestions?

Charlie

|

Re: fast stepper motor October 22, 2018 11:36PM |

Registered: 10 years ago Posts: 564 |

If you want steppers to move faster, use as high a supply voltage as the driver chips and caps on your board will allow. (I think most ought to handle 24v at least.) Also, for a given size, try to choose a motor with the highest current rating your drivers can handle. These motors will have a correspondingly lower "rated" voltage, allowing them to be driven faster from, say, a 24v supply.

One other thing to be aware of with a lead screw is that the relatively rigid coupling between the motor and the load can make the motors much more prone to losing steps. I did an experiment a while back with a belt driven load and then a lead screw driven load, and then used both a conventional stepper driver (susceptible to losing steps) and a closed-loop driver (immune to step loss). I then generated a diabolically kinked motion profile that produced a lot of vibration. With the belt drive system, I could go just as fast with the conventional driver as with the closed-loop driver. However, with the lead screw system, I could only run the conventional driver at about half the speed of the closed-loop driver before I started losing steps. The insidious thing, though, is that when I ran the lead screw with a fairly smooth profile, I could go just as fast with either driver. The upshot is that with a very rigid drive system, vibrations can feed back into the motor causing it to lose steps. But you won't know if you've got a problem until you try executing a sufficiently torturous motion profile.

One other thing to be aware of with a lead screw is that the relatively rigid coupling between the motor and the load can make the motors much more prone to losing steps. I did an experiment a while back with a belt driven load and then a lead screw driven load, and then used both a conventional stepper driver (susceptible to losing steps) and a closed-loop driver (immune to step loss). I then generated a diabolically kinked motion profile that produced a lot of vibration. With the belt drive system, I could go just as fast with the conventional driver as with the closed-loop driver. However, with the lead screw system, I could only run the conventional driver at about half the speed of the closed-loop driver before I started losing steps. The insidious thing, though, is that when I ran the lead screw with a fairly smooth profile, I could go just as fast with either driver. The upshot is that with a very rigid drive system, vibrations can feed back into the motor causing it to lose steps. But you won't know if you've got a problem until you try executing a sufficiently torturous motion profile.

|

Re: fast stepper motor October 23, 2018 04:41AM |

Registered: 10 years ago Posts: 14,672 |

To run stepper motors fast, you need high driver supply voltage and/or low motor inductance. The higher the motor inductance, the higher the supply voltage you need. There is a calculator at [reprapfirmware.org] to help you work out the maximum speed you can achieve before you start to lose torque, for a given motor and supply voltage.

The drivers on the Einsy are not capable of high current, which means it should be used with low current motors - which also means high inductance. So the Einsy is probably not the best choice if you want high speed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The drivers on the Einsy are not capable of high current, which means it should be used with low current motors - which also means high inductance. So the Einsy is probably not the best choice if you want high speed.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: fast stepper motor October 23, 2018 08:24AM |

Registered: 11 years ago Posts: 157 |

Quote

dc42

The drivers on the Einsy are not capable of high current, which means it should be used with low current motors - which also means high inductance. So the Einsy is probably not the best choice if you want high speed.

Thank you. I will check out the link.

I wonder if the regular Rambo or Mini Rambo would be better than the Einsy? Do you know?

|

Re: fast stepper motor October 23, 2018 08:47AM |

Registered: 11 years ago Posts: 157 |

Quote

LoboCNC

If you want steppers to move faster, use as high a supply voltage as the driver chips and caps on your board will allow. (I think most ought to handle 24v at least.) Also, for a given size, try to choose a motor with the highest current rating your drivers can handle. These motors will have a correspondingly lower "rated" voltage, allowing them to be driven faster from, say, a 24v supply..

Ok, I have some cheap amazon motors that are rated at about 2v per phase. I was looking at motors from another source (still not expensive) rated at 4v/phase. I was thinking the latter would be better, but your comment makes me think that the 2v/ph might be better... or am I over simplifying?

I will be using 24v ps. Do I really need to switch to nema 23s (assuming that the larger motor might provide more torque)

If you were in my shoes, can you think of a specific motor that you would use that has the best chance of over-coming the obstacles without breaking the bank?

|

Re: fast stepper motor October 23, 2018 11:31AM |

Registered: 9 years ago Posts: 465 |

The important factor is Amperage, not voltage.

In general, motors rated with lower voltage will be rated higher amperage, with the overall rated wattage about the same. Therefore doubling the rated voltage halves the rated amperage. Since you don't have the rated amperage specified, it's hard to say.

I think the nema 17 motors that I have are rated for 3.6V, but I don't remember anymore. I know they were rated for 1.5A, and I'm running them at 800mA. I don't actually know what my extruder motor is rated for, it came as a part of a kit. I'm running that at 1200mA, since it likes to stall when printing faster than about 50mm/s.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

In general, motors rated with lower voltage will be rated higher amperage, with the overall rated wattage about the same. Therefore doubling the rated voltage halves the rated amperage. Since you don't have the rated amperage specified, it's hard to say.

I think the nema 17 motors that I have are rated for 3.6V, but I don't remember anymore. I know they were rated for 1.5A, and I'm running them at 800mA. I don't actually know what my extruder motor is rated for, it came as a part of a kit. I'm running that at 1200mA, since it likes to stall when printing faster than about 50mm/s.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: fast stepper motor October 23, 2018 11:55AM |

Registered: 10 years ago Posts: 564 |

Quote

charlieRC

Quote

LoboCNC

If you want steppers to move faster, use as high a supply voltage as the driver chips and caps on your board will allow. (I think most ought to handle 24v at least.) Also, for a given size, try to choose a motor with the highest current rating your drivers can handle. These motors will have a correspondingly lower "rated" voltage, allowing them to be driven faster from, say, a 24v supply..

Ok, I have some cheap amazon motors that are rated at about 2v per phase. I was looking at motors from another source (still not expensive) rated at 4v/phase. I was thinking the latter would be better, but your comment makes me think that the 2v/ph might be better... or am I over simplifying?

I will be using 24v ps. Do I really need to switch to nema 23s (assuming that the larger motor might provide more torque)

If you were in my shoes, can you think of a specific motor that you would use that has the best chance of over-coming the obstacles without breaking the bank?

If your 2v motor and 4v motor were from the same motor series by the same manufacturer, I'd guess that the 2v motor would be better for driving faster. However, across manufacturers or even across different series by the same manufacturer, there's no good way to compare based on just the voltage alone. What you really need (and not often published for cheap motors) is the speed/torque curve, usually done for a 12 and/or 24v supply. Then you'd be able to see the actual rated torque at the speed you need to run.

|

Re: fast stepper motor October 23, 2018 12:33PM |

Registered: 11 years ago Posts: 157 |

Please forgive me if I still don't have my logic right, but....

What I have mounted right now is a nema 17 on the X and two more on the Z

I have a nema 23 on the Y

I was going to change out the nema 23 for a nema 17, but maybe not.

The nema 17's are 2a/ph with 83 oz in torque

The nema 23's are 2.8a/ph and 178 oz in

Since I am most worried about the X and Y does it make sense to swap out the nema 17 on X with a nema 23, leave the nema 23 on the Y and also leave the two nema 17's on the Z (my logic being that the Z is going to be the least demanding)?

What I have mounted right now is a nema 17 on the X and two more on the Z

I have a nema 23 on the Y

I was going to change out the nema 23 for a nema 17, but maybe not.

The nema 17's are 2a/ph with 83 oz in torque

The nema 23's are 2.8a/ph and 178 oz in

Since I am most worried about the X and Y does it make sense to swap out the nema 17 on X with a nema 23, leave the nema 23 on the Y and also leave the two nema 17's on the Z (my logic being that the Z is going to be the least demanding)?

|

Re: fast stepper motor October 23, 2018 01:46PM |

Registered: 11 years ago Posts: 157 |

Sorry LoboCNC, didn't see your response before I posted above.

At this point, I seem to be stuck with trial and error.

Any suggestions about a controller? I was planning on using the eincy Rambo until someone said they don't provide enough power. I am now thinking about the Rambo Mini or just the regular Rambo, but not sure if that's any better. I am no loner sure what's out there and being used. (that's the problem with having a printer that goes strong for five years.....I loose touch about other products).

At this point, I seem to be stuck with trial and error.

Any suggestions about a controller? I was planning on using the eincy Rambo until someone said they don't provide enough power. I am now thinking about the Rambo Mini or just the regular Rambo, but not sure if that's any better. I am no loner sure what's out there and being used. (that's the problem with having a printer that goes strong for five years.....I loose touch about other products).

|

Re: fast stepper motor October 23, 2018 03:24PM |

Registered: 10 years ago Posts: 564 |

Quote

charlieRC

Sorry LoboCNC, didn't see your response before I posted above.

At this point, I seem to be stuck with trial and error.

Any suggestions about a controller? I was planning on using the eincy Rambo until someone said they don't provide enough power. I am now thinking about the Rambo Mini or just the regular Rambo, but not sure if that's any better. I am no loner sure what's out there and being used. (that's the problem with having a printer that goes strong for five years.....I loose touch about other products).

Yeah, without a torque speed curve, you are somewhat stuck with trial and error. Regarding controllers, for a new printer, I'd definitely use either a smoothie board or a duet. No point in sticking with an 8-bit controller. I should be upgrading to one of those myself.

|

Re: fast stepper motor October 23, 2018 03:57PM |

Registered: 11 years ago Posts: 157 |

|

Re: fast stepper motor October 23, 2018 11:46PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: fast stepper motor October 24, 2018 08:22AM |

Registered: 11 years ago Posts: 157 |

Maybe someone else can answer that but this is my first attempt and not real sure what to expect.

Logically, I would think that speed is a big factor. My belt driven printers use gt2 16 tooth belt pulleys which would mean 32 mm per rotation. The lead screws I am using are T8 4 start screws with a 2 mm pitch, thus a revolution = 8mm (2 X 4), so right off the bat I am looking at 4 times the required stepper motor rotations to move the same distance. In my case, I plan to keep one belt driven printer for stuff that doesn't need as high of quality and the lead screw machine will be for things for which I don't mind waiting if it means better quality (assuming I do this right and actually get better quality)

Logically, I would think that speed is a big factor. My belt driven printers use gt2 16 tooth belt pulleys which would mean 32 mm per rotation. The lead screws I am using are T8 4 start screws with a 2 mm pitch, thus a revolution = 8mm (2 X 4), so right off the bat I am looking at 4 times the required stepper motor rotations to move the same distance. In my case, I plan to keep one belt driven printer for stuff that doesn't need as high of quality and the lead screw machine will be for things for which I don't mind waiting if it means better quality (assuming I do this right and actually get better quality)

|

Re: fast stepper motor October 24, 2018 09:21AM |

Admin Registered: 16 years ago Posts: 13,884 |

... there are "quick-lift spindles" available, which have much more pitch -- but they'll need more torque too, so mostly used with really "beefy" motors ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: fast stepper motor October 24, 2018 09:50AM |

Registered: 5 years ago Posts: 155 |

You can take fast steppers: normal size nema 17, low inductance like 1.8 mH. The calculated max speed is about 16 U/sec for a 2.5 A stepper (you need a controller capable of that), so for a Tr8x8(P2) spindle you get 128 mm/sec, which I think is enough.

I would take anti-backlash lead screws (screw with second short screw and spring between) to avoid errors with the many direction dchanges in the XY axes.

Edited 1 time(s). Last edit at 10/24/2018 09:51AM by JoergS5.

I would take anti-backlash lead screws (screw with second short screw and spring between) to avoid errors with the many direction dchanges in the XY axes.

Edited 1 time(s). Last edit at 10/24/2018 09:51AM by JoergS5.

|

Re: fast stepper motor October 24, 2018 10:02AM |

Registered: 6 years ago Posts: 1,007 |

Quote

JoergS5

You can take fast steppers: normal size nema 17, low inductance like 1.8 mH. The calculated max speed is about 16 U/sec for a 2.5 A stepper (you need a controller capable of that), so for a Tr8x8(P2) spindle you get 128 mm/sec, which I think is enough.

I would take anti-backlash lead screws (screw with second short screw and spring between) to avoid errors with the many direction dchanges in the XY axes.

That means extra friction in addition to extra complexity to get good ones.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: fast stepper motor October 24, 2018 10:29AM |

Admin Registered: 16 years ago Posts: 13,884 |

... here's a sampe of a cheaper high-pitch spindle with 25mm travel per rotation:

They have types with up to 100mm!!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

They have types with up to 100mm!!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: fast stepper motor October 24, 2018 11:25AM |

Registered: 11 years ago Posts: 157 |

My lead screws are all 350 and 450mm. Not sure what I would do with a 100mm lead screw. I am using all anti-backlash nuts, but I suspect I could get by with a bit less spring tension. I’m sure that’s adding some unneeded friction..

I have ordered a duet WiFi controller. (Thanks for the heads-up, LoboCNC) Hope that was a good move. The motors I have are all 2amps

Edited 1 time(s). Last edit at 10/24/2018 11:27AM by charlieRC.

I have ordered a duet WiFi controller. (Thanks for the heads-up, LoboCNC) Hope that was a good move. The motors I have are all 2amps

Edited 1 time(s). Last edit at 10/24/2018 11:27AM by charlieRC.

|

Re: fast stepper motor October 24, 2018 01:38PM |

Admin Registered: 16 years ago Posts: 13,884 |

... no, not a 100mm long lead screw -- but as long, as you order them, with a preselectable pitch of 2,5mm to 100mm per revolution!

The screw in the image is only a "free sample" (or give-away), I've got from IGUS when talking with the guys (got 6 of this screws and some more bearing stuff) -- it's 140mm long and has a pitch of 25mm ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The screw in the image is only a "free sample" (or give-away), I've got from IGUS when talking with the guys (got 6 of this screws and some more bearing stuff) -- it's 140mm long and has a pitch of 25mm ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: fast stepper motor October 24, 2018 04:42PM |

Registered: 6 years ago Posts: 134 |

|

Re: fast stepper motor October 24, 2018 06:13PM |

Registered: 9 years ago Posts: 465 |

@CharlieRC: I have a belt driven (MakerBot clone) and a leadscrew printer. I'm using very similar slicer settings in each as far as requested print speeds go, with printing pretty much topping out (bridging is set for 70mm/s) at about the same requested speeds.

In general, the leadscrew printer (2mm, 4 start 8mm rods) doesn't seem to be having trouble keeping up. I COULD probably bump up the speed on my MBot clone, but the ringing on the Y axis is about at my limits to tolerate. I still get some ringing on the Y axis of the leadscrew printer, after I made the bed mounts a little more rigid, but it's still much better than the other. I'm running ABS through he MBot, and PETG through the leadscrew printer. Despite having nearly identical heat beds, I was never able to get a successful print out of the MBot, even once. I'm having very good success with the leadscrew printer.

The leadscrew printer is usually quieter, but that probably has to do with completely different design rather than drive mechanism. I'm running the leadscrew printer on a Duet Wifi, and the MBot on a MKS Gen board. Both are run on 24V for motor drive supplies.

Thew motor RPM is definitely higher on the leadscrew printer. that may have other consequences, including long-term ones that I haven't run into yet, but in general, I'm using the leadscrew printer more and more and the MBot printer less and less.

For the high movement leadscrews, yes, they need more torque, but assuming that the transfer is even reasonably efficient, something that gets (As with the example above) 25mm/revolution probably needs less torque than the 16 tooth GT2 needs to get 32mm of movement. I would probably go for it if I could get my hands on a couple of rods with a 16mm lead, allowing me to go to 200 steps/mm.

Overall, I'm very satisfied with my leadscrew printer. it's not super fast, but it gets good results.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

In general, the leadscrew printer (2mm, 4 start 8mm rods) doesn't seem to be having trouble keeping up. I COULD probably bump up the speed on my MBot clone, but the ringing on the Y axis is about at my limits to tolerate. I still get some ringing on the Y axis of the leadscrew printer, after I made the bed mounts a little more rigid, but it's still much better than the other. I'm running ABS through he MBot, and PETG through the leadscrew printer. Despite having nearly identical heat beds, I was never able to get a successful print out of the MBot, even once. I'm having very good success with the leadscrew printer.

The leadscrew printer is usually quieter, but that probably has to do with completely different design rather than drive mechanism. I'm running the leadscrew printer on a Duet Wifi, and the MBot on a MKS Gen board. Both are run on 24V for motor drive supplies.

Thew motor RPM is definitely higher on the leadscrew printer. that may have other consequences, including long-term ones that I haven't run into yet, but in general, I'm using the leadscrew printer more and more and the MBot printer less and less.

For the high movement leadscrews, yes, they need more torque, but assuming that the transfer is even reasonably efficient, something that gets (As with the example above) 25mm/revolution probably needs less torque than the 16 tooth GT2 needs to get 32mm of movement. I would probably go for it if I could get my hands on a couple of rods with a 16mm lead, allowing me to go to 200 steps/mm.

Overall, I'm very satisfied with my leadscrew printer. it's not super fast, but it gets good results.

MBot3D Printer

MakerBot clone Kit from Amazon

Added heated bed.

Leadscrew self-built printer (in progress)

Duet Wifi, Precision Piezo parts

|

Re: fast stepper motor October 24, 2018 06:42PM |

Admin Registered: 16 years ago Posts: 13,884 |

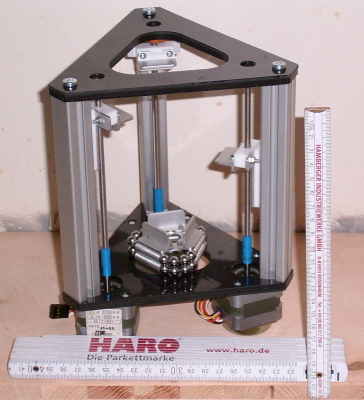

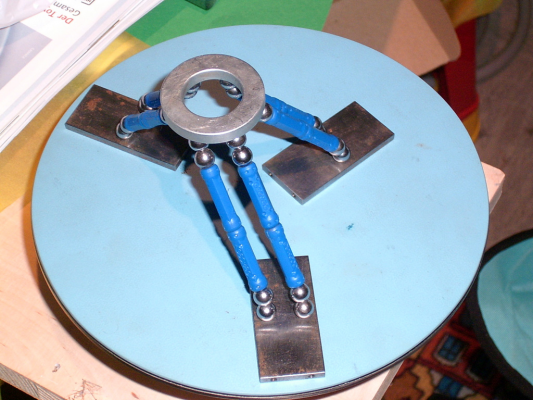

... and for the "short 140mm lead screws" - I'm thinking on rebuilding my first "mini-delta" (then called "tripod") with them ... it's a pity, that I've sold it to a friend and didn't take more pictures and backed them ... the old threads with the assembling images in the builders forum are all gone

But attached an image of the frame and another of the "magnetic ball joints" ... and here a video of the first "moving tests" 11 years ago - [vimeo.com]

Edited 2 time(s). Last edit at 10/24/2018 06:46PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But attached an image of the frame and another of the "magnetic ball joints" ... and here a video of the first "moving tests" 11 years ago - [vimeo.com]

Edited 2 time(s). Last edit at 10/24/2018 06:46PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.