Design Review! Looking for comments / critiques and ideas for my new printer build.

Posted by Ed3D

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 02, 2018 10:13AM |

Registered: 5 years ago Posts: 61 |

Quote

MKSA

Is the acceleration in the Z direction ? Etc...

ah - I see the confusion, I've mixed up my axis as I typed up my response. Weight acts down in Z as does gravity, acceleration in Y. The CAE package I use uses Y as the vertical axis so when typing up I forgot to convert back to sensible axis.

Quote

MKSA

Anyway, at least you seem to give up on the cut wood/plastic sheet to reinforce the linear rail.

The plywood / plastic was never intended to reinforce the linear rail - I'm not really sure where you got this idea. It was simply a neat way of mounting one rail to the Y axis blocks - in terms of deflection there is no difference between the rail on plastic / wood and the rail on its own except the rail on a backing has the extra holes for mounting it a bit easier

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 03, 2018 04:59PM |

Registered: 5 years ago Posts: 61 |

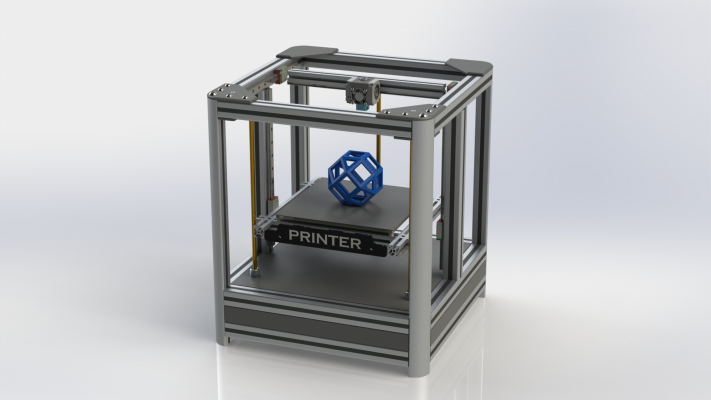

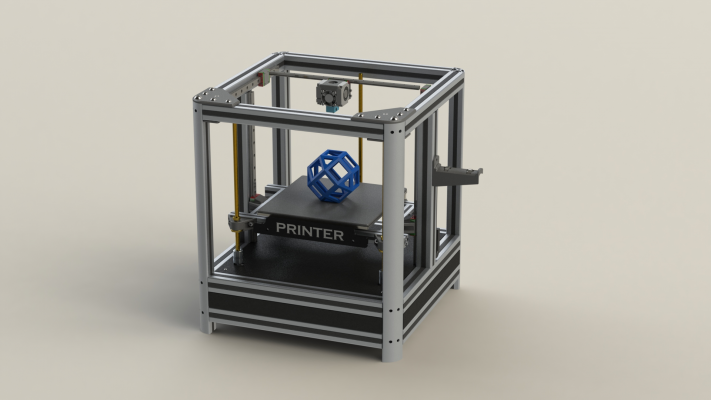

I've tried working in some of the suggestions people have made and have come to this new design:

The main changes are:

Things still to work out:

The main changes are:

- Removed frame brackets

- Changed to curved extrusion - because they look nice

- X Axis now uses a 2020 profile as a backing

- 2 Z Rails, 3 Leadscrews

- Considering using piezo instead of BLTouch (for packaging mainly)

- Considering switching to the threaded V6 instead of groove mount for easier mounting

- 3 Point bed levelling

Things still to work out:

- Belt tensioner

- Access to electronics

- A B Drives

- Most brackets

- Better belt solution in the basement

- ABL sensor integration

- Cable routing

- much much more

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 05, 2018 12:35PM |

Registered: 5 years ago Posts: 8 |

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 05, 2018 03:22PM |

Registered: 5 years ago Posts: 71 |

Looking good!

The 2 rail, 3 lead-screw Z axis is a popular arrangement that seams to work well (still over-constrained in multiple directions, but the Z should travel and build plate should always be perpendicular, so less of a concern).

I like the maglev 2020 X axis! When you do mount it to the rails, use plastic (3d printed or machined) to take up the slight possible Y axes out of parallel.

A note on the frame extrusions, 3030 is obviously stiffer than 2020, but compression or torsion is not the main concern here (for the cubic outer frame), racking is. 2020 extrusion with a diagonal brace on the face is orders magnitudes stiffer than 3030 with no brace. Think triangles instead of squares that can collapse.

The 2 rail, 3 lead-screw Z axis is a popular arrangement that seams to work well (still over-constrained in multiple directions, but the Z should travel and build plate should always be perpendicular, so less of a concern).

I like the maglev 2020 X axis! When you do mount it to the rails, use plastic (3d printed or machined) to take up the slight possible Y axes out of parallel.

A note on the frame extrusions, 3030 is obviously stiffer than 2020, but compression or torsion is not the main concern here (for the cubic outer frame), racking is. 2020 extrusion with a diagonal brace on the face is orders magnitudes stiffer than 3030 with no brace. Think triangles instead of squares that can collapse.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 05, 2018 05:07PM |

Registered: 5 years ago Posts: 61 |

Quote

gmedlicott

I like the maglev 2020 X axis!

Me too - Design is so much easier when all the parts are maglev. The current plan is to print a bracket thing that holds the 2020 and the idlers.

Quote

gmedlicott

A note on the frame extrusions, 3030 is obviously stiffer than 2020, but compression or torsion is not the main concern here (for the cubic outer frame), racking is. 2020 extrusion with a diagonal brace on the face is orders magnitudes stiffer than 3030 with no brace. Think triangles instead of squares that can collapse.

Oh absolutely a triangle is miles better. I'm not sure how I'd get them in though because its a bit of a tolerance stack-up issue and its pretty hard to cut the V shape you would need on the end. Perhaps there's a way to make them work though - I'll have a think about it. Even If I can put one across the back it would help a load, the vertical pillars will get in the way of the sides.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 06, 2018 02:25AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 11, 2018 03:35PM |

Registered: 5 years ago Posts: 61 |

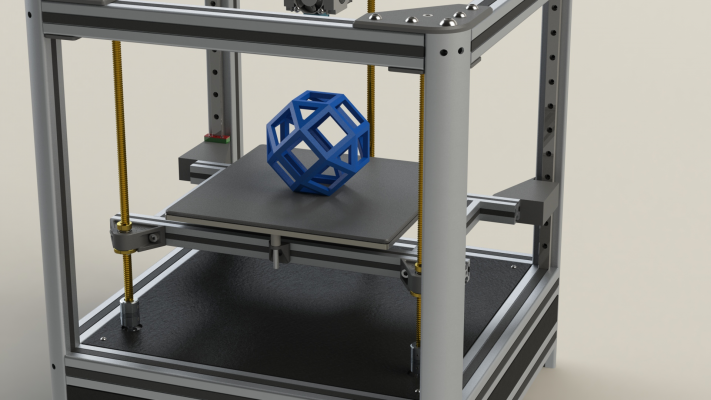

I've been working on the Z axis design, adding some brackets etc. It uses two central beams down the frame to hold the rails and then the three lead screws. I guess the extra extrusion will add a touch more rigidity to the frame but at this point its probably not going to have a huge effect. One of the compromises of the central beams is that the rails for the Y axis need to rotate 90 deg and face inwards (like on the Railcore). In its current form it looks like this:

I'm playing around with the idea of moving the two rails to the rear frame members to allow me to mount the Y rails on the underside of the extrusion. The benefit being I can run the belts under the extrusion which will drop the overall printer size and then use a system similar to the blackbox printer. The two rails at the back will prevent C rotation and XY translation the other degrees of freedom being handled by the 3 screws. Having the screws along one edge like that gives a need for a slightly more rigid bed frame but it should be ok. It's not quite cantilevered due to the two screws at the front. Idea like so: (excuse the terrible block brackets)

Thoughts?

I'd quite like to explore the carbon fibre square tube for the X axis that the blackbox uses.

Edited 1 time(s). Last edit at 12/11/2018 03:38PM by Ed3D.

I'm playing around with the idea of moving the two rails to the rear frame members to allow me to mount the Y rails on the underside of the extrusion. The benefit being I can run the belts under the extrusion which will drop the overall printer size and then use a system similar to the blackbox printer. The two rails at the back will prevent C rotation and XY translation the other degrees of freedom being handled by the 3 screws. Having the screws along one edge like that gives a need for a slightly more rigid bed frame but it should be ok. It's not quite cantilevered due to the two screws at the front. Idea like so: (excuse the terrible block brackets)

Thoughts?

I'd quite like to explore the carbon fibre square tube for the X axis that the blackbox uses.

Edited 1 time(s). Last edit at 12/11/2018 03:38PM by Ed3D.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 11, 2018 04:23PM |

Registered: 5 years ago Posts: 71 |

The Z-rails at the back look good, that's what I would do in this configuration as well. The outer Z bracket dimensions also look good, enough to compensate for slight rail miss-alignment but still stiff enough.

What print speeds are you aiming for? If it isn't super fast, the moving mass of the XY is more of a red hearing if your linear guides are stiff enough.

What print speeds are you aiming for? If it isn't super fast, the moving mass of the XY is more of a red hearing if your linear guides are stiff enough.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 11, 2018 05:13PM |

Registered: 5 years ago Posts: 71 |

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 12, 2018 12:30PM |

Registered: 5 years ago Posts: 61 |

I Think im going to go for the two rear rails - I cant see any major downside to them and the benefit of tucking the rails underneath the extrusion is worth it in my opinion. Shame because I liked the symmetry of the central rails.

The brackets are going to be designed to slide in and out to compensate for rail spacing and also potentially allow the carriage to rotate +/- 2 deg or so to allow for rail alignment. On the design with the central Z rails the whole aluminium extrusion of the bed frame would slide in and out being held in with corner brackets (not pictured). So either way the rail alignment was compensated for! My only concern is the massive amount of space those brackets fill but I think that's because it reminds me of cantilevered beds, which this wouldn't be.

In terms of print speeds I'm not looking for anything super fast but something reasonable would be good. Obviously its a bit of a sliding scale where increasing print speed typically decreases print quality but if I can get something good at around 75 - 80 mm/s that would be great.

For this project I'm using Solidworks for the CAD. The images are taken from the PhotoView 360 add in which I believe is being made obsolete this year in favour of their new rendering solution. I am by no means the best at rendering but the defaults seem to give semi decent results! I've never got on with Fusion 360 for modelling but use it semi regularly for CNC tool-paths (less so now that I no longer have my CNC though). I find fusion struggles with larger assemblies, especially when it comes to making changes, and the UI is quite slow compared to what I'm used to.

Edited 1 time(s). Last edit at 12/12/2018 02:16PM by Ed3D.

Quote

gmedlicott

The outer Z bracket dimensions also look good, enough to compensate for slight rail miss-alignment but still stiff enough.

The brackets are going to be designed to slide in and out to compensate for rail spacing and also potentially allow the carriage to rotate +/- 2 deg or so to allow for rail alignment. On the design with the central Z rails the whole aluminium extrusion of the bed frame would slide in and out being held in with corner brackets (not pictured). So either way the rail alignment was compensated for! My only concern is the massive amount of space those brackets fill but I think that's because it reminds me of cantilevered beds, which this wouldn't be.

In terms of print speeds I'm not looking for anything super fast but something reasonable would be good. Obviously its a bit of a sliding scale where increasing print speed typically decreases print quality but if I can get something good at around 75 - 80 mm/s that would be great.

For this project I'm using Solidworks for the CAD. The images are taken from the PhotoView 360 add in which I believe is being made obsolete this year in favour of their new rendering solution. I am by no means the best at rendering but the defaults seem to give semi decent results! I've never got on with Fusion 360 for modelling but use it semi regularly for CNC tool-paths (less so now that I no longer have my CNC though). I find fusion struggles with larger assemblies, especially when it comes to making changes, and the UI is quite slow compared to what I'm used to.

Edited 1 time(s). Last edit at 12/12/2018 02:16PM by Ed3D.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 12, 2018 03:50PM |

Registered: 5 years ago Posts: 71 |

Quote

Ed3D

In terms of print speeds I'm not looking for anything super fast but something reasonable would be good. Obviously its a bit of a sliding scale where increasing print speed typically decreases print quality but if I can get something good at around 75 - 80 mm/s that would be great.

That isn't that fast in relative terms, I would just stick with a 2020 aluminum extrusion for the X, as your carriage is likely to be quite sturdy (i.e. no round rods). Maybe others can chime in here.

Quote

Ed3D

I've never got on with Fusion 360 for modelling but use it semi regularly for CNC tool-paths (less so now that I no longer have my CNC though). I find fusion struggles with larger assemblies, especially when it comes to making changes, and the UI is quite slow compared to what I'm used to.

I find part modeling in Fusion 360 much better than Solidworks now (long time user of Solidworks too), mainly due to how the sketch just adds features to the face, that can then be independently selected for extrudes.

I agree on the assemblies though, changes aren't as easy to make, and it can go sideways quickly. If I deviate too far from the original intent, I just start a new clean assembly.

Edited 1 time(s). Last edit at 12/12/2018 03:51PM by gmedlicott.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. December 12, 2018 05:13PM |

Registered: 5 years ago Posts: 61 |

2020 is my first thought but the carbon fibre will likely be stiffer and lighter. I dont think it matters too much at that kind of speed though but it would be nice to go faster. (CF also looks good!) They're actually very cheap (about £4 a meter!).

Im not sure I follow what you mean about fusions sketching. My experience is mostly in Solidworks but I use NX a lot as well. I dont think part modelling is actually too bad in fusion but I make a lot of use of the gestures in Solidworks and the ribbon toolbar is excellent for quick access to tools.

Im not sure I follow what you mean about fusions sketching. My experience is mostly in Solidworks but I use NX a lot as well. I dont think part modelling is actually too bad in fusion but I make a lot of use of the gestures in Solidworks and the ribbon toolbar is excellent for quick access to tools.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. February 26, 2019 02:32AM |

Registered: 6 years ago Posts: 1,007 |

@Ed3D Any news ?

Just curious. Indeed I would have liked you back up your claim about the benefits of belt spring tensionners on it.

ref: [reprap.org]

This thread should be moved to the Corexy section for easy follow up.

Edited 1 time(s). Last edit at 02/26/2019 05:56AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Just curious. Indeed I would have liked you back up your claim about the benefits of belt spring tensionners on it.

ref: [reprap.org]

This thread should be moved to the Corexy section for easy follow up.

Edited 1 time(s). Last edit at 02/26/2019 05:56AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. February 26, 2019 02:04PM |

Registered: 5 years ago Posts: 61 |

@MKSA

I have been working on this slowly but due to some personal things its had to take a back burner for a short while.

Its had some major (and some minor) changes and is what I would say is nearly ready to build with the potential to be a very nice printer. A specific 'system' has been taking up a lot of my time (more than expected) but results are extremely promising from the test machines Ive had it run on so that is relatively exciting.

Im not sure how you want me to prove the benefits of spring based tensioners - the evidence is already out there and we discussed it before, even in that post you linked. I'm not really interested in taking this discussion further (here or elsewhere) because I see no benefit to it - I have already outlined the key points which you seem to fail to acknowledge, find some pedantic argument around, or completely dismiss for your superior knowledge.

And yes I agree it should be moved to the CoreXY Section but like I said before I dont know how to do that so repeating yourself doesn't really help.

It is unlikely I will be posting any further updates to this project on this site - It seems that unfortunately the userbase interested in constructive discussion is very small and outnumbered by those intent on derailing and discouraging. (I am of course not referring to this thread exclusively)

Edited 1 time(s). Last edit at 02/26/2019 02:13PM by Ed3D.

I have been working on this slowly but due to some personal things its had to take a back burner for a short while.

Its had some major (and some minor) changes and is what I would say is nearly ready to build with the potential to be a very nice printer. A specific 'system' has been taking up a lot of my time (more than expected) but results are extremely promising from the test machines Ive had it run on so that is relatively exciting.

Im not sure how you want me to prove the benefits of spring based tensioners - the evidence is already out there and we discussed it before, even in that post you linked. I'm not really interested in taking this discussion further (here or elsewhere) because I see no benefit to it - I have already outlined the key points which you seem to fail to acknowledge, find some pedantic argument around, or completely dismiss for your superior knowledge.

And yes I agree it should be moved to the CoreXY Section but like I said before I dont know how to do that so repeating yourself doesn't really help.

It is unlikely I will be posting any further updates to this project on this site - It seems that unfortunately the userbase interested in constructive discussion is very small and outnumbered by those intent on derailing and discouraging. (I am of course not referring to this thread exclusively)

Edited 1 time(s). Last edit at 02/26/2019 02:13PM by Ed3D.

|

Re: Design Review! Looking for comments / critiques and ideas for my new printer build. February 27, 2019 05:40AM |

Registered: 6 years ago Posts: 1,007 |

To move to the Corexy, easy, just ask an admin, for ex. VDX.

The evidences you provided are everything but evident and challenged by a few here, not just me.

To demonstrate it on your machine, that would be an evidence. The rest is just opinions.

Strange but all great designs that just start as a computer rendering never complete ???? Reality is such a bitch !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

The evidences you provided are everything but evident and challenged by a few here, not just me.

To demonstrate it on your machine, that would be an evidence. The rest is just opinions.

Strange but all great designs that just start as a computer rendering never complete ???? Reality is such a bitch !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.