Dual hobbed extruder

Posted by herve robert

|

Re: Dual drive extruder December 11, 2018 04:21PM |

Registered: 10 years ago Posts: 14,672 |

Quote

MKSA

Most current extruders are non geared....

Really??? Have you any evidence for that assertion? I've come across more geared extruders than non-geared ones.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dual drive extruder December 12, 2018 01:15AM |

Registered: 6 years ago Posts: 1,007 |

Quote

dc42

Quote

MKSA

Most current extruders are non geared....

Really??? Have you any evidence for that assertion? I've come across more geared extruders than non-geared ones.

What I see being sold/ installed/copied are mainly the cheap MK8.

Anyway, the key point I wanted to raise is the small hobbed gear diam, required to get the push from these, that are used even with geared extruder.

OK, my assertion can be removed. May be wrong from a market perspective and is irrelevant to the technical discussion that follows.

I started with a MK8, poor hoobed gear, made my own, had to go for 8.5mm diam then designed a compact, light geared one using a NEMA14, a bigger hobbed gear (12mm, case hardened steel, bites like a shark) at the same time.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Dual hobbed extruder December 12, 2018 01:37PM |

Registered: 8 years ago Posts: 5,232 |

Just a wild thought:

One of these on each side: More bite/less pinch and better guidance...

One of these on each side: More bite/less pinch and better guidance...

|

Re: Dual hobbed extruder December 12, 2018 01:48PM |

Registered: 6 years ago Posts: 1,007 |

Quote

o_lampe

Just a wild thought:

One of these on each side: More bite/less pinch and better guidance...

Indeed, here the diam is infinite, all good then, too bad the movement is not continuous. Belts then ? Already done but too bulky, not worth it.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Dual hobbed extruder December 21, 2018 09:26AM |

Registered: 13 years ago Posts: 1,797 |

try out your design, more surface contact area would be best, having an extruder that is short and not to high will be best unless this is a Bowden design.

please post results fail or successful. it improves everyones understanding of what works or needs improvements.

if people say something doesn't work, look into why or what they did that failed and work from there. good luck!

also watch out for people just trying to keep you busy. decide in advance what you are willing and not willing to work on for this to work.

Edited 1 time(s). Last edit at 12/21/2018 09:28AM by jamesdanielv.

please post results fail or successful. it improves everyones understanding of what works or needs improvements.

if people say something doesn't work, look into why or what they did that failed and work from there. good luck!

also watch out for people just trying to keep you busy. decide in advance what you are willing and not willing to work on for this to work.

Edited 1 time(s). Last edit at 12/21/2018 09:28AM by jamesdanielv.

|

Re: Dual hobbed extruder December 26, 2018 05:13AM |

Registered: 5 years ago Posts: 26 |

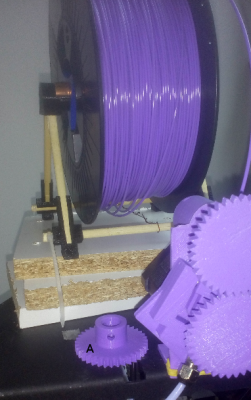

to start, I made this. a lot of mistakes and a lot to fix but I succeed to print the gear "A".

|

Re: Dual hobbed extruder December 26, 2018 07:16AM |

Registered: 5 years ago Posts: 26 |

|

Re: Dual hobbed extruder December 27, 2018 06:06PM |

Registered: 11 years ago Posts: 1,049 |

I've got a Vaeder V-struder feeding filament on DaVinci 1.0

[reprap.org]

The belt solution, which drives

filament using belts. This allows for great torque on your filament, without

slipping or damaging the filament. The geared solution gives enormous torque

from even a simple stepper motor.

[reprap.org]

The belt solution, which drives

filament using belts. This allows for great torque on your filament, without

slipping or damaging the filament. The geared solution gives enormous torque

from even a simple stepper motor.

|

Re: Dual hobbed extruder January 01, 2019 09:02AM |

Registered: 5 years ago Posts: 45 |

A Wade style extruder with a sharp enough hobbed bolt and tight enough idler should sufficiently overcome a 4kg roll's rotation without stressing the stepper. I cut my hobbed bolts wide with a sharp M8 tap and use stiff springs. I'm impressed with the force with which the filament is pulled, and I don't see the need for any more force (one time it was great enough that the extruder broke away from its mount when the hot end jammed and had to be repaired).

If one is looking for alternative/interesting solutions--I would consider running the second extruder before the PTFE--acting as a pre-feed. If a second driver (for example, E1 on RAMPS) with which to mirror the primary extruder is not available, wire the second extruder parallel to the primary. Or, one could design a powered spool holder, either synchronized with the extruder, or triggered by filament tension.

If one is looking for alternative/interesting solutions--I would consider running the second extruder before the PTFE--acting as a pre-feed. If a second driver (for example, E1 on RAMPS) with which to mirror the primary extruder is not available, wire the second extruder parallel to the primary. Or, one could design a powered spool holder, either synchronized with the extruder, or triggered by filament tension.

|

Re: Dual hobbed extruder February 09, 2019 08:00AM |

Registered: 5 years ago Posts: 26 |

hello,

I made an archive with stl and scad files and pictures..

[www.dropbox.com]

I'll try a dual extrusion with one nozzle with this new version.

I made an archive with stl and scad files and pictures..

[www.dropbox.com]

I'll try a dual extrusion with one nozzle with this new version.

|

Re: Dual hobbed extruder March 24, 2019 07:53AM |

Registered: 5 years ago Posts: 26 |

new release for the arm

extruder calibration, look here:

https://mattshub.com/2017/04/19/extruder-calibration/

the scad files:

https://www.dropbox.com/s/rb4mzyhejuzd62a/armMk2.tar.gz?dl=0

try dual extrusion with single nozzle, but doesn't really work:

https://reprap.org/forum/read.php?70,849907,849907#msg-849907

Edited 2 time(s). Last edit at 03/24/2019 08:12AM by herve robert.

extruder calibration, look here:

https://mattshub.com/2017/04/19/extruder-calibration/

the scad files:

https://www.dropbox.com/s/rb4mzyhejuzd62a/armMk2.tar.gz?dl=0

try dual extrusion with single nozzle, but doesn't really work:

https://reprap.org/forum/read.php?70,849907,849907#msg-849907

Edited 2 time(s). Last edit at 03/24/2019 08:12AM by herve robert.

Sorry, only registered users may post in this forum.