Wade vs Direct Extruders?

Posted by WesBrooks

|

Wade vs Direct Extruders? December 08, 2018 12:30PM |

Registered: 9 years ago Posts: 383 |

|

Re: Wade vs Direct Extruders? December 08, 2018 12:49PM |

Registered: 11 years ago Posts: 5,780 |

Wade's extruders are huge and reduce printable area compared to a direct extruder. Back in the days of 3mm filament, a Wade's extruder was a selling point. Now people look at them like they are some sort of antique, and care more about print envelope and speed, so they want small and light. If you want the extra torque of a geared extruder you can get an extruder with a motor that has a gearbox, or get something like a Titan that has gears in a much smaller, lighter package than a Wade's extruder.

Edited 1 time(s). Last edit at 12/08/2018 12:49PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 12/08/2018 12:49PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Wade vs Direct Extruders? December 08, 2018 12:52PM |

Registered: 9 years ago Posts: 383 |

|

Re: Wade vs Direct Extruders? December 08, 2018 01:24PM |

Registered: 11 years ago Posts: 5,780 |

I would say any geared extruder is going to be better than an ungeared extruder because you're going to get more push and better resolution (smoother plastic flow), so a Wade's extruder should still be OK. If you're bolting it to the printer's frame anyway the size won't affect performance of the printer. 1.75mm filament is easier to drive than 3 mm, and direct drive without gears was probably the main motivation to switch to 1.75mm filament.

I'm expecting that some time in the not too distant future filament is going to go to 1 mm, and the giant hot-end mount like the one on the E3D V6 will have to be done away with.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm expecting that some time in the not too distant future filament is going to go to 1 mm, and the giant hot-end mount like the one on the E3D V6 will have to be done away with.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Wade vs Direct Extruders? December 09, 2018 02:43AM |

Registered: 8 years ago Posts: 5,232 |

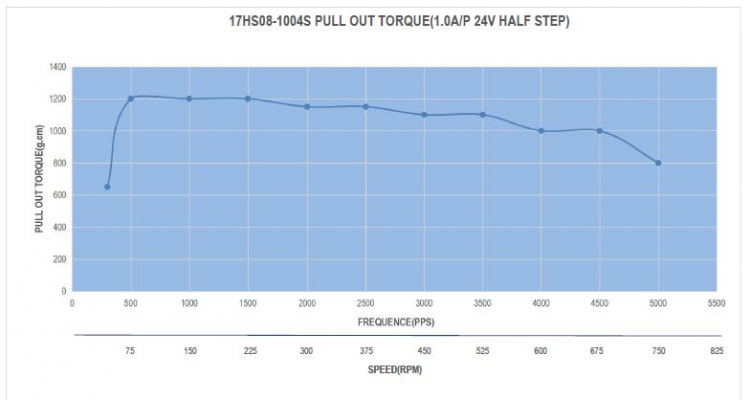

Common sense is: an e-machine has full torque from 0RPM on.

I once found a torque curve of a pancake-stepper that surprised me. It looks, like it needs a gear reduction and run above 75RPM.

Maybe it was only their test-setup or the driver, but it's worth keeping in mind.

|

Re: Wade vs Direct Extruders? December 09, 2018 03:33AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

Common sense is: an e-machine has full torque from 0RPM on.

I once found a torque curve of a pancake-stepper that surprised me. It looks, like it needs a gear reduction and run above 75RPM.

Maybe it was only their test-setup or the driver, but it's worth keeping in mind.

My guess is that the stepper driver he was using implemented standstill current reduction.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Wade vs Direct Extruders? December 09, 2018 02:44PM |

Registered: 12 years ago Posts: 2,470 |

I still have a wade running in my old machine (8 years now) and it does a very good job, even though its strength is wasted on the 1.75mm filament and the Merlin hotend.

With 1.75mm filament there is no real need for a geared extruder, yes, the theoretical resolution is better, but i can't say i have seen that this ever mattered to me. At Protoworx they use simple direct drive extruders with a Merlin and the print quality is basically perfect down to layerheights of less than 0.1mm.

I'm not sure about that switch to 1mm filament the dentist expects, it is already used by bigger commercial systems, where the extruder and nozzle are minimalistic and are thrown away with the filament cartridge, but i have yet to see an advantage for RepRap printers.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

With 1.75mm filament there is no real need for a geared extruder, yes, the theoretical resolution is better, but i can't say i have seen that this ever mattered to me. At Protoworx they use simple direct drive extruders with a Merlin and the print quality is basically perfect down to layerheights of less than 0.1mm.

I'm not sure about that switch to 1mm filament the dentist expects, it is already used by bigger commercial systems, where the extruder and nozzle are minimalistic and are thrown away with the filament cartridge, but i have yet to see an advantage for RepRap printers.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Wade vs Direct Extruders? December 09, 2018 03:48PM |

Registered: 6 years ago Posts: 1,007 |

Quote

Srek

I still have a wade running in my old machine (8 years now) and it does a very good job, even though its strength is wasted on the 1.75mm filament and the Merlin hotend.

With 1.75mm filament there is no real need for a geared extruder, yes, the theoretical resolution is better, but i can't say i have seen that this ever mattered to me. At Protoworx they use simple direct drive extruders with a Merlin and the print quality is basically perfect down to layerheights of less than 0.1mm.

I'm not sure about that switch to 1mm filament the dentist expects, it is already used by bigger commercial systems, where the extruder and nozzle are minimalistic and are thrown away with the filament cartridge, but i have yet to see an advantage for RepRap printers.

With gears, you can use a smaller motor like a NEMA14. My extruder weight 180 gr with hotend, is as good as my previous non geared one using a NEMA17. I thrown away the MK8 I had bought, just kept the motor.

Today, no excuse to make, use a Wade considering good gears are readily available.

Edited 1 time(s). Last edit at 12/09/2018 03:49PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Wade vs Direct Extruders? December 09, 2018 04:42PM |

Registered: 12 years ago Posts: 2,470 |

My direct drive extruder works fine with Nema 14 as well. I used them in the past but had problems. Later it turned out the problem was a design issue and that Nema 14 is sufficient. Maybe i switch back to it at some point, vut currently there is no need.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Wade vs Direct Extruders? December 09, 2018 04:57PM |

Registered: 9 years ago Posts: 383 |

I've a couple of Ormerods with the standard reprappro extruders that have no spring loading or adjustment. These are geard but tend to get back driven by the filament when I try to get data points for non-linear extrusion correction at the higher speed points. The system seems limited to about 10mm3/sec at 190C for PLA. Is this all down to the hot end design or due to lack of extruder torque? I'm guessing it's hard to tell but the extrusion rate didn't seem to tally to some of the head line figures you hear towted by some.

|

Re: Wade vs Direct Extruders? December 21, 2018 09:33AM |

Registered: 13 years ago Posts: 1,797 |

with todays 3d printer designs, direct drive is ok. systems voltages are higher to allow more motot torque today than years gone by. also 1.75mm feedstock is about 9 times (may need to fact check that) easier to squish thru the nozzle, because of less surface area.

the advantages of direct drive are faster extraction. my personal preference is to use geared extruders, but they are not necessarily needed these days if proper care is done in the system design (>12 v system, 70oz/in motors, for example)

the advantages of direct drive are faster extraction. my personal preference is to use geared extruders, but they are not necessarily needed these days if proper care is done in the system design (>12 v system, 70oz/in motors, for example)

|

Re: Wade vs Direct Extruders? December 21, 2018 10:36AM |

Registered: 9 years ago Posts: 383 |

|

Re: Wade vs Direct Extruders? December 22, 2018 02:16AM |

Registered: 10 years ago Posts: 14,672 |

Quote

WesBrooks

I tend to see missed steps on my 12V geared RepRapPro extruder/hotend at about 10mm3/sec through a 0.4mm nozzle. That's around 65-75mm/sec print speed with PLA @190C, 0.3mm layers and 0.5mm extrusion width. Not that greater speed.

It sounds to me that you need to use either higher extruder motor current, a more powerful motor, or a higher extrusion temperature when printing at high speeds.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Wade vs Direct Extruders? December 22, 2018 04:05AM |

Registered: 9 years ago Posts: 383 |

I'll check out the current setting again, but thought it was at the limits of the Ormerod motors. This was at 0.3mm layers. I'd recently considered dropping nozzle temp as the y-axis bearing mount with the tag was showing significant over melting on the tag. This was with 3 other tags building at the same time and a radial blower at 100%

|

Re: Wade vs Direct Extruders? December 24, 2018 01:39AM |

Registered: 6 years ago Posts: 134 |

|

Re: Wade vs Direct Extruders? December 24, 2018 02:26AM |

Registered: 6 years ago Posts: 1,007 |

Quote

piper3d

Last time (today) I checked Lulzbot printers at microcenter they have been equipped with Wade's extruders. I heard Lulzbot have been moving to bondtech, but most likely because it is too expensive to make Wades extruders considering the cost of the local workforce.

I think it is because they realized the Wade extruder is an antique and had to be retired, too heavy, bulky, noisy, printed gears ....

Having a machine fitted with one would entice the customer to look somewhere else.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.