Another heated chamber

Posted by leadinglights

|

Another heated chamber December 27, 2018 11:44AM |

Registered: 12 years ago Posts: 1,450 |

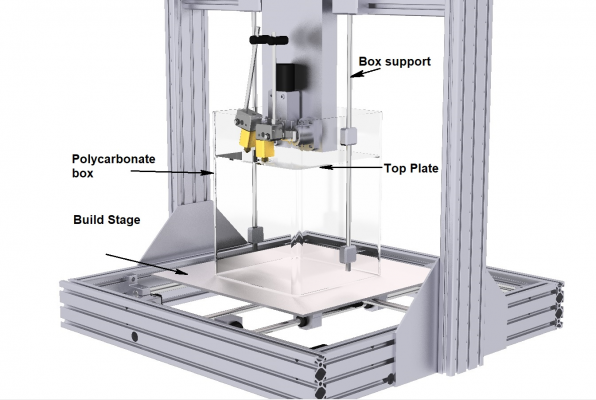

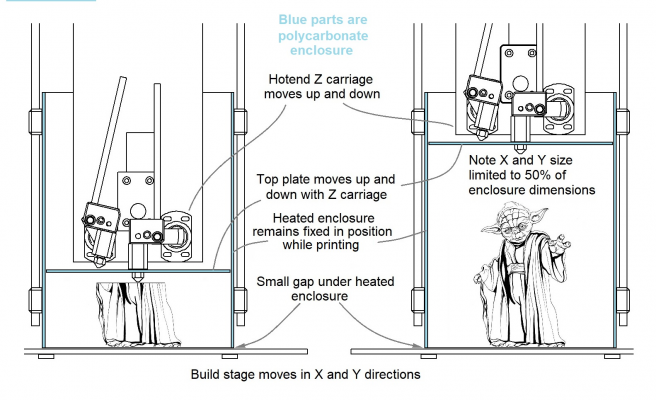

I was very intrigued by a posting by M_Xeno [reprap.org] (also BerryBot [diy3dprinting.blogspot.com] ) about a simple heated chamber. I have been playing about with the idea to see what can be done with cartesian printers. One of my printers has the table moving in both X and Y axes with the vertical part of the Z carriage having a quite small cross section and it has been quite easy to come up with an elegant design for a heated chamber. The general design is to have a box open at top and bottom and made of 0.5mm polycarbonate or similar material. This part is suspended from the printer frame with a small gap, maybe 0.5mm above the build stage. The top of the box is closed with a moving plate having only a small gap to the walls of the chamber box - this plate is fixed to the Z carriage and has a small hole through which the nozzle of the printer projects.

A little bit of doodling convinced me that the restriction in the XY plane of half of the movement need not apply if an oversize build stage is used. On the printer pictured the build volume looks to be about 150mm by 150mm by about 200mm - compared to 200mm x 200mm x 200mm without the chamber.

The CAD drawing above should hopefully convey the idea - Turbocad does not render transparent materials at all well.

As to how well the heat is contained and whether the build stage heated is sufficient or an auxilary heater is needed, only test will tell that.

As the originals by Zatsit and BerryBot are both on Delta printers, it would be interesting to see what can be done with more normal cartesian printers.

Mike

A little bit of doodling convinced me that the restriction in the XY plane of half of the movement need not apply if an oversize build stage is used. On the printer pictured the build volume looks to be about 150mm by 150mm by about 200mm - compared to 200mm x 200mm x 200mm without the chamber.

The CAD drawing above should hopefully convey the idea - Turbocad does not render transparent materials at all well.

As to how well the heat is contained and whether the build stage heated is sufficient or an auxilary heater is needed, only test will tell that.

As the originals by Zatsit and BerryBot are both on Delta printers, it would be interesting to see what can be done with more normal cartesian printers.

Mike

|

Re: Another heated chamber December 28, 2018 03:19AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Another heated chamber December 28, 2018 03:34AM |

Registered: 12 years ago Posts: 1,450 |

Quote

o_lampe

Wouldn't you create a chimney effect with the gaps at the bottom of the box and between box and upper plate?

What if the box deforms from the heat? You can't lower the hotend anymore, except the upper plate is very small.

The chimney effect may be a problem but it is the kind of problem that is easiest proven and fixed by building it.

I am not sure what you mean by "You can't lower the hotend anymore" as it can be lowered right down to the build stage and the top plate is carried with the hotend - one of the advantages of this printer geometry.

Edit: I guess you mean if the box deforms - again a try different materials and optimise the design.

Mike

Edited 1 time(s). Last edit at 12/28/2018 03:36AM by leadinglights.

|

Re: Another heated chamber April 04, 2019 07:50AM |

Registered: 12 years ago Posts: 1,450 |

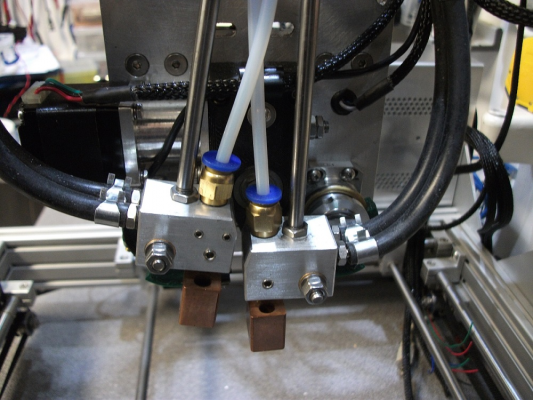

A recent discussion in the Reprappers sub-forum [reprap.org] had me thinking a little more about this heated chamber. Most heated chambers will have the filament along with the cooling for the print and the cold side of the hotend fed through the heated air. The - for lack of a better term, "mini oven" is able to keep these in the cooler air. The photo below shows the black silicone tubes feeding water to the hotend cooler and the white PTFE of the filament bowden tubes. The drawing shows that these will be outside the heated area.

Hopefully the heated bed will be able to keep the enclosure up to temperature but if not I will fit some sort of hot air supply.

Mike

Hopefully the heated bed will be able to keep the enclosure up to temperature but if not I will fit some sort of hot air supply.

Mike

|

Re: Another heated chamber April 06, 2019 12:13PM |

Registered: 8 years ago Posts: 601 |

What chamber temps are you planning on achieving with this?

Is a miniature heated chamber very useful? I can print ABS parts about that size without issue. Perhaps useful for high temp materials like peek or ultem, but then you really will need to change the design heavily (high tg plastic and heaters)

Is a miniature heated chamber very useful? I can print ABS parts about that size without issue. Perhaps useful for high temp materials like peek or ultem, but then you really will need to change the design heavily (high tg plastic and heaters)

|

Re: Another heated chamber April 06, 2019 04:32PM |

Registered: 12 years ago Posts: 1,450 |

From reports by Berrybot and Zatsit (quoted at the begining of this thread) I hope for around 10°C less than the build stage. A brief test shows that this sort of figure should be achievable but that was without any gaps around the top plate or at the bottom of the side walls - additional heating can be added if needed.

As to whether it will work or be useful, who knows? Reports on ABS printed in enclosures at 80°C show a very good improvement in dimensional accuracy, a reduction in de-lamination and some improvement in strength.

A miniature heated chamber such as this is a simple add-on, far less complicated than my dual head setup, engraving head, 3D printer lathe or the vacuum hold down build stage.

Mike

As to whether it will work or be useful, who knows? Reports on ABS printed in enclosures at 80°C show a very good improvement in dimensional accuracy, a reduction in de-lamination and some improvement in strength.

A miniature heated chamber such as this is a simple add-on, far less complicated than my dual head setup, engraving head, 3D printer lathe or the vacuum hold down build stage.

Mike

|

Re: Another heated chamber April 17, 2019 05:50AM |

Registered: 10 years ago Posts: 150 |

Nice implementation of this idea, which I am very happy to see taken up again!

Be careful, however, to increase the surface area of exchange with the outside. In my example for Zatsit, the hot chamber was very flat, disc-shaped, and moreover, relatively well insulated upwards, by foam cardboard. Geometrically, the area through which losses occur was minimal. In addition, in a flat chamber a few centimetres high, convection cells have difficulty establishing themselves. For all these reasons, the internal temperature cannot be very different from that of the bed.

On the other hand, with a higher parallelepipedic chamber, all these favourable factors disappear, and it is likely that the mean temperature will be significantly lower than that of the bed.

Nevertheless, I am sure it will be very useful! With a larger volume, it may be useful to install a small additional DC 200W air heater in the chamber, blown by a small fan, such as this one:

[www.aliexpress.com]

Be careful, however, to increase the surface area of exchange with the outside. In my example for Zatsit, the hot chamber was very flat, disc-shaped, and moreover, relatively well insulated upwards, by foam cardboard. Geometrically, the area through which losses occur was minimal. In addition, in a flat chamber a few centimetres high, convection cells have difficulty establishing themselves. For all these reasons, the internal temperature cannot be very different from that of the bed.

On the other hand, with a higher parallelepipedic chamber, all these favourable factors disappear, and it is likely that the mean temperature will be significantly lower than that of the bed.

Nevertheless, I am sure it will be very useful! With a larger volume, it may be useful to install a small additional DC 200W air heater in the chamber, blown by a small fan, such as this one:

[www.aliexpress.com]

|

Re: Another heated chamber April 17, 2019 10:21AM |

Registered: 12 years ago Posts: 1,450 |

Hi M_Xeno,

I am not too sure yet what the thermal behaviour will be but for each lost factor there is often a gained one. For example: the top plate will have walls around it most of the time restricting the free flow of air currents. The most likely loss of heat will probably be by air rising on the outside wall having been preheated by the bed but the heated area of the wall remains short in the early part of the print.

That fan is interesting but I will trying a small fabricated external fan to pull air from the chamber and then pump it back in to economise on heat with extra heat added by a small finned resistor - power needed yet to be determined.

Mike

I am not too sure yet what the thermal behaviour will be but for each lost factor there is often a gained one. For example: the top plate will have walls around it most of the time restricting the free flow of air currents. The most likely loss of heat will probably be by air rising on the outside wall having been preheated by the bed but the heated area of the wall remains short in the early part of the print.

That fan is interesting but I will trying a small fabricated external fan to pull air from the chamber and then pump it back in to economise on heat with extra heat added by a small finned resistor - power needed yet to be determined.

Mike

Sorry, only registered users may post in this forum.