Why shouldn't i use extrusion width less than nozzle size? Or should i?

Posted by ArtemKuchin

|

Why shouldn't i use extrusion width less than nozzle size? Or should i? February 05, 2019 03:21PM |

Registered: 7 years ago Posts: 49 |

I always thought that extrusion width should be more than nozzle size, optimally like 1.2*nozzle size, but actually a little different for each material.

I also thought that i can extrude wider, until the width more than nozzle end width (hole+walls), so, the filament is still ironed by the nozzle.

I was sure that extruding less than nozzle width for normal shells will result in some kind of problems.

I have read that extrusion width less than nozzle size results in poor adhesion to the previous layer because the filament is not pushed to it strong enought due to less contact.

But now, i had an argument with a person show uses this technique constantly and has not problems. I use it one sometime and only for decorative prints, not loaded onces.

I thought about adhesion problem and i think it might not hold true, if you keep width to height proportions correct.

Example. 0.6nozzle, 0.3 extrusion width, 0.1 layer. We extrude 0.3. Filament might not even fill the full nozzle diameter, but it is pulled but adhered portion. It is still more than 0.1mm in diamter, so, the nozzle, which is 0.1mm above, will squash it. Not different if it was 0.6 or 0.7 extrusion width. Only the height matters.

I've read tons of post on that matter and found no reports that people actually had problems with width less than nozzle size.

However, i did not find any tests. Only theoritical explanation why it is bad and people saying that the explanation has no confirmation in reality.

Now, if it really works well why should we use nozzles of different diameter? Why not print anything with just one 1mm nozzle???

I am lost.

I also thought that i can extrude wider, until the width more than nozzle end width (hole+walls), so, the filament is still ironed by the nozzle.

I was sure that extruding less than nozzle width for normal shells will result in some kind of problems.

I have read that extrusion width less than nozzle size results in poor adhesion to the previous layer because the filament is not pushed to it strong enought due to less contact.

But now, i had an argument with a person show uses this technique constantly and has not problems. I use it one sometime and only for decorative prints, not loaded onces.

I thought about adhesion problem and i think it might not hold true, if you keep width to height proportions correct.

Example. 0.6nozzle, 0.3 extrusion width, 0.1 layer. We extrude 0.3. Filament might not even fill the full nozzle diameter, but it is pulled but adhered portion. It is still more than 0.1mm in diamter, so, the nozzle, which is 0.1mm above, will squash it. Not different if it was 0.6 or 0.7 extrusion width. Only the height matters.

I've read tons of post on that matter and found no reports that people actually had problems with width less than nozzle size.

However, i did not find any tests. Only theoritical explanation why it is bad and people saying that the explanation has no confirmation in reality.

Now, if it really works well why should we use nozzles of different diameter? Why not print anything with just one 1mm nozzle???

I am lost.

|

Re: Why shouldn't i use extrusion width less than nozzle size? Or should i? February 06, 2019 06:12AM |

Registered: 8 years ago Posts: 34 |

|

Re: Why shouldn't i use extrusion width less than nozzle size? Or should i? February 06, 2019 06:56AM |

Registered: 7 years ago Posts: 49 |

|

Re: Why shouldn't i use extrusion width less than nozzle size? Or should i? February 06, 2019 07:06AM |

Admin Registered: 13 years ago Posts: 7,001 |

the size limits the smallest line you can print in the X or Y direction and the maximum Z height per layer.

Say for arguments sake you wanted to print a hair comb, your printed teeth would be > 1mm thick.

Nothing could be less that the extrusion width thick in X or Y

Extruding less just results in blobs as it has to fill up the extuder orifice before the extruion exits the extuder hotend

If filament should (magically) leave the orifice it will have positional errors, as it wobbles about in free space inside the diameter of the nozzle.

Edited 1 time(s). Last edit at 02/06/2019 07:09AM by Dust.

Say for arguments sake you wanted to print a hair comb, your printed teeth would be > 1mm thick.

Nothing could be less that the extrusion width thick in X or Y

Extruding less just results in blobs as it has to fill up the extuder orifice before the extruion exits the extuder hotend

If filament should (magically) leave the orifice it will have positional errors, as it wobbles about in free space inside the diameter of the nozzle.

Edited 1 time(s). Last edit at 02/06/2019 07:09AM by Dust.

|

Re: Why shouldn't i use extrusion width less than nozzle size? Or should i? February 06, 2019 08:23AM |

Registered: 11 years ago Posts: 5,780 |

I suggest you try printing with the line width narrower than the nozzle. You'll quickly find out if it works. In Slic3r, go to the print setting>advanced page and manually set the line widths to values narrower than the nozzle diameter.

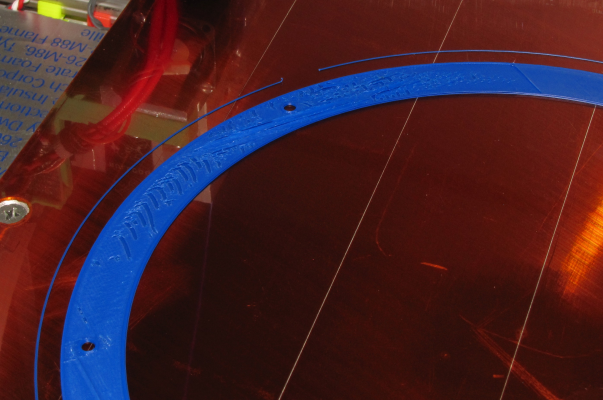

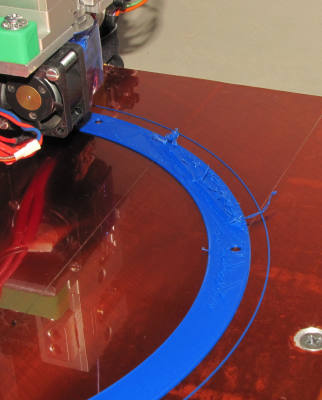

My experience has been that print quality and strength quickly become awful if you try to print narrow lines. I always set the line widths manually because in the past, when I let Slicer set the widths, it tried to use narrow lines and the result was a disaster that took me a while to figure out what was going on- it has set the infill line width to less than the nozzle diameter and the result was bad interlayer bonding. Here's are the first few layers of the print, still printing solid infill. I let it run and it did the same narrow lines in the sparse infill (no photos) and it was just a mess. The problem disappeared when I set the line width manually to match the nozzle diameter.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

My experience has been that print quality and strength quickly become awful if you try to print narrow lines. I always set the line widths manually because in the past, when I let Slicer set the widths, it tried to use narrow lines and the result was a disaster that took me a while to figure out what was going on- it has set the infill line width to less than the nozzle diameter and the result was bad interlayer bonding. Here's are the first few layers of the print, still printing solid infill. I let it run and it did the same narrow lines in the sparse infill (no photos) and it was just a mess. The problem disappeared when I set the line width manually to match the nozzle diameter.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Why shouldn't i use extrusion width less than nozzle size? Or should i? February 06, 2019 09:12AM |

Registered: 6 years ago Posts: 1,007 |

Sorry, only registered users may post in this forum.