Strange banding on the sides

Posted by ArtemKuchin

|

Strange banding on the sides February 06, 2019 02:16AM |

Registered: 7 years ago Posts: 49 |

I think such question has been asked many times but i cannot find a definitive answer for my case.

Moving table (Y-axis) printer. TMC2100 drivers, 16 microsteps. MK8 direct extruder DRV8825 drivers with 32 microsteps

0.4 nozzle. 2GT belts, pulleys, etc.

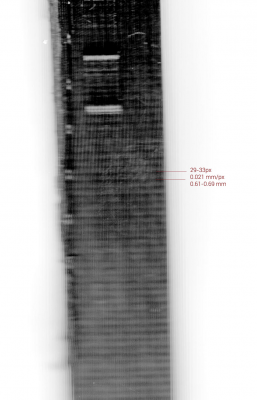

When i print a test cube on sides along Y axis (perpendicular to X axis) i see the ribs show in the attached image,

The period is about 0.6-0.7mm which does not relate to anything in mechanics.

I thought about extruder,

the toothed wheel of MK8 has a diameter of about 11mm and 26 teeth.

Perimeter is 34,54, that's 1,32mm per 1 tooth.

Devide by 2 and get close to what i see - 0,65

Usually only one or two teeth touch the filament, maybe that's why it is just half of 1,32.

Maybe not.

Maybe 8825 is bad for extruder?

Maybe it is not related to extruder, because i don't really see such lines along the X axis (perpendicular to Y). It has some banding,but close

to 2mm + some ringing. But that's different issue.

Please, help.

Moving table (Y-axis) printer. TMC2100 drivers, 16 microsteps. MK8 direct extruder DRV8825 drivers with 32 microsteps

0.4 nozzle. 2GT belts, pulleys, etc.

When i print a test cube on sides along Y axis (perpendicular to X axis) i see the ribs show in the attached image,

The period is about 0.6-0.7mm which does not relate to anything in mechanics.

I thought about extruder,

the toothed wheel of MK8 has a diameter of about 11mm and 26 teeth.

Perimeter is 34,54, that's 1,32mm per 1 tooth.

Devide by 2 and get close to what i see - 0,65

Usually only one or two teeth touch the filament, maybe that's why it is just half of 1,32.

Maybe not.

Maybe 8825 is bad for extruder?

Maybe it is not related to extruder, because i don't really see such lines along the X axis (perpendicular to Y). It has some banding,but close

to 2mm + some ringing. But that's different issue.

Please, help.

|

Re: Strange banding on the sides February 06, 2019 10:36AM |

Registered: 9 years ago Posts: 752 |

It looks a bit like what I got with the duet (which has a tmc2660). When the current was set too high the machine was loud and the steps were a bit jerky. When I lowered the current the smoothness improved. If 0.6mm is close to what a full step is, then it could be the problem.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Strange banding on the sides February 06, 2019 01:23PM |

Registered: 7 years ago Posts: 49 |

|

Re: Strange banding on the sides February 07, 2019 07:05AM |

Registered: 8 years ago Posts: 413 |

|

Re: Strange banding on the sides February 07, 2019 07:22AM |

Registered: 7 years ago Posts: 49 |

Quote

MCcarman

If it was the extruder i would have expected it to be in both directions.

Yes., i agree on that.

Quote

MCcarman

Does it change with print speed?

Yes it does, with HIGHER print speed it is greatly reduced and almost invisible.

Strange, huh?

The scanned model i posted is made on 20mm/s. If print at 40mm/s hard to see at all.

Even faster - non visible.

I estimated the amplitude of the wave and it is less than 0.01 mm, close to 0.005 mm.

Quote

MCcarman

Is the bed oscilating in the X direction while it moves in Y.

I don't see how it could happen. The bed on 4 v-wheel, all tight, no springs are used, nothing

pushes it in X direction from sides. Clean V-slots.

Edited 2 time(s). Last edit at 02/07/2019 07:24AM by ArtemKuchin.

|

Re: Strange banding on the sides February 07, 2019 07:24AM |

Registered: 11 years ago Posts: 5,780 |

Does the pattern angle tilt if you change the extruder motor current?

Edited 1 time(s). Last edit at 02/07/2019 07:24AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 02/07/2019 07:24AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Strange banding on the sides February 07, 2019 07:30AM |

Registered: 7 years ago Posts: 49 |

|

Re: Strange banding on the sides February 07, 2019 10:06AM |

Registered: 9 years ago Posts: 752 |

Sounds like the stepper motor driver has some issues with low speed. At some point at a certain speed changes mode and it's gone. Does it change with stealhmode on/off? Is the power supply stable? If you've got an oscilloscope try determining the voltage ripple.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Strange banding on the sides February 07, 2019 12:04PM |

Registered: 11 years ago Posts: 5,780 |

DRV8825 drivers are known to skip usteps at low speeds. Extruders operate at pretty low speeds. See: [cabristor.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Strange banding on the sides February 08, 2019 10:37AM |

Registered: 5 years ago Posts: 3 |

So it might relate to an electrical cycle then (4 full steps, i.e. 0.64mm). See discussion here: Fine Vertical Artifacts / Trinamic Chop Tuning, Any Effect?Quote

ArtemKuchin

No, does not seem to be relates to full step. The pulley is 16 teeth, 32mm perimeter, the motor is 200 steps (1.8 degree), so, 32/200=0.16mm

|

Re: Strange banding on the sides February 10, 2019 01:22PM |

Registered: 7 years ago Posts: 49 |

Hmm.. maybe it is related to a note in TMC2100 datasheet:

Which is far from truth in case of marlin.

Then

Which means if we go too slow on extrusion then standstill is detected.

And in case of stand still detected it says for one example:

So, that maybe the reason why gong FASTER (40mms/sec) make the lines disappear.

However, EN pin is connected to EN for driver on arduino and, i think, arguino, putout GND to the pin when enabled the motors. And ENN to GND disable stand still.

I don't know.

I will try to change extruder driver from DRV to another type and then try chnaging axis to other types and see.

Edited 1 time(s). Last edit at 02/10/2019 01:28PM by ArtemKuchin.

Attention microPlyer only works perfectly with a stable STEP frequency.

Which is far from truth in case of marlin.

Then

At 16 MHz system clock frequency, this results in a minimum step input frequency of 16 Hz for microPlyer operation. A lower step rate causes a standstill event to be detected.

Which means if we go too slow on extrusion then standstill is detected.

And in case of stand still detected it says for one example:

During the last cycle at the slower rate, microPlyer did not generate all 16 microsteps, so there is a small jump in motor angle between the first and second cycles at the higher rate.

So, that maybe the reason why gong FASTER (40mms/sec) make the lines disappear.

However, EN pin is connected to EN for driver on arduino and, i think, arguino, putout GND to the pin when enabled the motors. And ENN to GND disable stand still.

I don't know.

I will try to change extruder driver from DRV to another type and then try chnaging axis to other types and see.

Edited 1 time(s). Last edit at 02/10/2019 01:28PM by ArtemKuchin.

Sorry, only registered users may post in this forum.