Enclosure for printer - what to look for

Posted by TillScout

|

Enclosure for printer - what to look for March 13, 2019 04:48PM |

Registered: 5 years ago Posts: 5 |

Hi everyone,

I own an Anet A8 printer and now I am planning/building an enclosure for it. I find online documentation of DIY enclosures sometimes a bit incomplete, so I decided to start this discussion as both a joint brainstorming session as well as a documentation of what I want to do.

I went the IKEA-way of building an enclosure and bought a Stuva cabinet.

What I want to achieve with the enclosure is

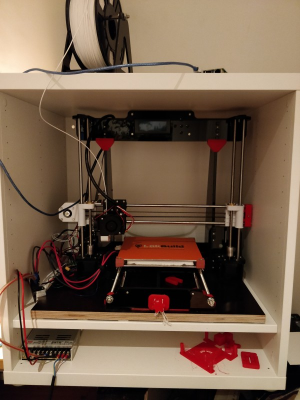

This is how it currently looks like (everything just cramped into a box):

It currently is a direct driven setup, but I will upgrade to a bowden setup soon, the bowden extruder will then sit on the top of the enclosure. There is a Stuva shelf board in there, where the printer stands on. For temperature reasons, I want the electronics down there in the smaller space.

My first priority is to build a filtration system. There is an example of a filter system built of a surgical mask and activated carbon, I would like to go down a similar road.

Now while planning this, I started thinking about temperature and airflow inside the enclosure.

I want to achieve an airtight ("airtight" as in "air only leaves it through the filter") system with a controllable temperature inside (by controlling the RPMs of the blower at the filter). At the same time, airflow inside the enclosure should not harm print quality. So I am wondering, where the air intakes should be to achieve an even airflow through the enclosure. The electronics should be cooled, so the air should enter the electronics room, cool the electronic components and then continue upwards into the printer room and then to the filter on the top.

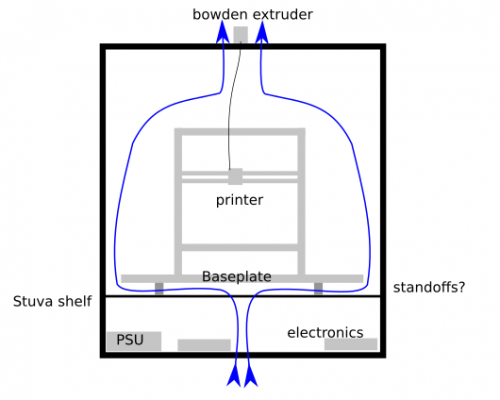

This is a drawing of it:

The printer is currently mounted on a wooden baseplate, which might be helpful or not (I did it to stiffen the frame). The baseplate has the same depth as the enclosure but is leaves open space on the sides. Would that be a beneficial airflow? Would standoffs between the shelf and the board make sense?

The PSU has its own cooling fan with a dedicated intake and outlet, I will probably reserve holes in the floor for these. Other than that there should be a hole in the floor or in the sides for fresh air intake. What would make most sense, the floor or the sides? I read somewhere that for fans there should be a clear path before the fan that has the same cross section as the fan itself. That would mean that with a 120mm fan I would need to make a similarly sized hole for fresh air intake. Is that correct?

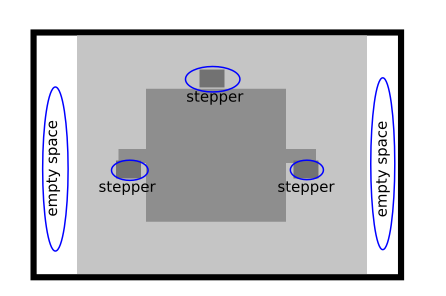

Looking at it from the top, the air could enter the printer space on several spots. Either on the sides (this is where the board on which the printer is currently mounted is narrower than the enclosure). But I thought it might also make sense to guide the airflow close to the steppers to cool them. But if the airflow is to uneven or to uncontrolled, it might cause unstable drafts around the printed object.

And finally (for tonight) I am wondering, what a good temperature inside would be and what limits the temperature. When the electronic components have their own space, it is probably the stepper motors that impose the temperature limit, right?

I own an Anet A8 printer and now I am planning/building an enclosure for it. I find online documentation of DIY enclosures sometimes a bit incomplete, so I decided to start this discussion as both a joint brainstorming session as well as a documentation of what I want to do.

I went the IKEA-way of building an enclosure and bought a Stuva cabinet.

What I want to achieve with the enclosure is

- Air quality improvement (most important for me, since I have a child around and want to print ABS)

- Print quality improvement

- Noise reduction

This is how it currently looks like (everything just cramped into a box):

It currently is a direct driven setup, but I will upgrade to a bowden setup soon, the bowden extruder will then sit on the top of the enclosure. There is a Stuva shelf board in there, where the printer stands on. For temperature reasons, I want the electronics down there in the smaller space.

My first priority is to build a filtration system. There is an example of a filter system built of a surgical mask and activated carbon, I would like to go down a similar road.

Now while planning this, I started thinking about temperature and airflow inside the enclosure.

I want to achieve an airtight ("airtight" as in "air only leaves it through the filter") system with a controllable temperature inside (by controlling the RPMs of the blower at the filter). At the same time, airflow inside the enclosure should not harm print quality. So I am wondering, where the air intakes should be to achieve an even airflow through the enclosure. The electronics should be cooled, so the air should enter the electronics room, cool the electronic components and then continue upwards into the printer room and then to the filter on the top.

This is a drawing of it:

The printer is currently mounted on a wooden baseplate, which might be helpful or not (I did it to stiffen the frame). The baseplate has the same depth as the enclosure but is leaves open space on the sides. Would that be a beneficial airflow? Would standoffs between the shelf and the board make sense?

The PSU has its own cooling fan with a dedicated intake and outlet, I will probably reserve holes in the floor for these. Other than that there should be a hole in the floor or in the sides for fresh air intake. What would make most sense, the floor or the sides? I read somewhere that for fans there should be a clear path before the fan that has the same cross section as the fan itself. That would mean that with a 120mm fan I would need to make a similarly sized hole for fresh air intake. Is that correct?

Looking at it from the top, the air could enter the printer space on several spots. Either on the sides (this is where the board on which the printer is currently mounted is narrower than the enclosure). But I thought it might also make sense to guide the airflow close to the steppers to cool them. But if the airflow is to uneven or to uncontrolled, it might cause unstable drafts around the printed object.

And finally (for tonight) I am wondering, what a good temperature inside would be and what limits the temperature. When the electronic components have their own space, it is probably the stepper motors that impose the temperature limit, right?

|

Re: Enclosure for printer - what to look for March 13, 2019 09:16PM |

Registered: 11 years ago Posts: 5,780 |

If you want to print ABS, you don't want airflow. You want the enclosure to get up to 50C or so. Electronics should be outside the warm enclosure if you want them to last. You can turn on a fan and blow the crud out of the enclosure after the print has finished. I would be very suspicious of claims about the degree of filtration in any of the amateur made filters because measuring nanoparticles requires expensive equipment and training in its correct use. A false sense of security derived from a poorly operating filter may be worse than using no filter and behaving as if the printing process were dangerous.

If you want quiet, it may not be such a good idea to mount the extruder motor on a wood box resonator.

The motors should not require heat sinks or air flow to cool them. If they do, the current is set too high and/or the mechanism is not moving as smoothly as it should. The motor driver chips need cooling, especially if they are mounted on tiny plug-in circuit board modules. Buy a bunch of spares- you're going to need them.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you want quiet, it may not be such a good idea to mount the extruder motor on a wood box resonator.

The motors should not require heat sinks or air flow to cool them. If they do, the current is set too high and/or the mechanism is not moving as smoothly as it should. The motor driver chips need cooling, especially if they are mounted on tiny plug-in circuit board modules. Buy a bunch of spares- you're going to need them.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Enclosure for printer - what to look for March 13, 2019 09:36PM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Enclosure for printer - what to look for March 14, 2019 06:51AM |

Registered: 5 years ago Posts: 5 |

Thank you for the comments so far!

Fireprotection is indeed something that I am also thinking about. For the beginning I was planning to install a smoke detector, later an automated CO2 extinguisher.

Good point regarding the filter quality. As an alternative there are prepared bundles of HEPA filters with activated coal available, I might probably be going with this.

Do you think that anti vibration mats or so could help with the resonating extruder motor? I was planning to install it there because of ease of usage and to keep the filament cool.

The motor driver chips will be in the separate compartment for electronics, I have not yet measured temperature there, but it should be cool enough there.

In case of no airflow, I am concerned that there will be leakage of fumes through the enclosure, so I wanted to go for a system with underpressure, so some airflow would be unavoidable. Also if it gets over 50C (last night I measured up tp 41C, but that was a short print and it did not close properly yet.) there has to be some sort of intake. Would it be possible to guide the flow or make it as even as possible so that it does not do harm to the print?

Fireprotection is indeed something that I am also thinking about. For the beginning I was planning to install a smoke detector, later an automated CO2 extinguisher.

Good point regarding the filter quality. As an alternative there are prepared bundles of HEPA filters with activated coal available, I might probably be going with this.

Do you think that anti vibration mats or so could help with the resonating extruder motor? I was planning to install it there because of ease of usage and to keep the filament cool.

The motor driver chips will be in the separate compartment for electronics, I have not yet measured temperature there, but it should be cool enough there.

In case of no airflow, I am concerned that there will be leakage of fumes through the enclosure, so I wanted to go for a system with underpressure, so some airflow would be unavoidable. Also if it gets over 50C (last night I measured up tp 41C, but that was a short print and it did not close properly yet.) there has to be some sort of intake. Would it be possible to guide the flow or make it as even as possible so that it does not do harm to the print?

|

Re: Enclosure for printer - what to look for March 14, 2019 07:51AM |

Registered: 5 years ago Posts: 32 |

I second the fireproof building materials suggestion, you really don't want anything with multiple heat sources enclosed inside something that can burn.

If you're going to have a fan you're probably not going want to have it exhausting heat for the whole time the printer is running or it will never get hot enough. You might have to set the fan on a thermostat or set it for a warm up cycle where it only comes on once the chamber has been heated for a while. You'll will only need a very small fan to evacuate the contents of that enclosure in a very short time too.

If you're going to have a fan you're probably not going want to have it exhausting heat for the whole time the printer is running or it will never get hot enough. You might have to set the fan on a thermostat or set it for a warm up cycle where it only comes on once the chamber has been heated for a while. You'll will only need a very small fan to evacuate the contents of that enclosure in a very short time too.

|

Re: Enclosure for printer - what to look for March 15, 2019 01:26PM |

Registered: 5 years ago Posts: 5 |

|

Re: Enclosure for printer - what to look for March 15, 2019 02:42PM |

Registered: 11 years ago Posts: 5,780 |

Yes to all those things.

You can buy PIR foam insulation to line the inside of the enclosure for $15 for a 4'x8' sheet at Home Depot. PIR foam is, for all practical purposes, fireproof. It will help keep things warm in there, too.

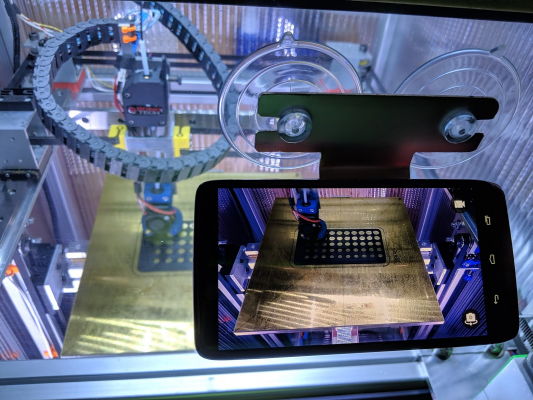

If you have a clear front door, you can use an old cell phone as a camera to monitor print progress:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You can buy PIR foam insulation to line the inside of the enclosure for $15 for a 4'x8' sheet at Home Depot. PIR foam is, for all practical purposes, fireproof. It will help keep things warm in there, too.

If you have a clear front door, you can use an old cell phone as a camera to monitor print progress:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Enclosure for printer - what to look for April 02, 2019 12:18PM |

Registered: 10 years ago Posts: 35 |

|

Re: Enclosure for printer - what to look for June 10, 2019 11:35AM |

Registered: 4 years ago Posts: 11 |

for the safe, there is a tiny wireless optical somke detector which can cut off the power automatically ,

[hackaday.io]

[hackaday.io]

Sorry, only registered users may post in this forum.