Power Supply Inductor Repair

Posted by heatvent

|

Power Supply Inductor Repair May 04, 2019 07:35PM |

Registered: 7 years ago Posts: 23 |

I have a 24V power supply that seems to have taken a hit in shipping and the inductor has come loose off the board. The legs have broken at the bottom in two spots. Is there an easy way to repair this possibly. I could possibly solder to the same holes in the board that still have part of the leg. I could desolder and maybe unwind a bit of wire and make longer legs which should be easier to resolder assuming I could figure out how it goes back in. I could also replace the inductor although I don't know the specs. Any thoughts / ideas would be apprecited.

|

Re: Power Supply Inductor Repair May 04, 2019 07:46PM |

Registered: 6 years ago Posts: 1,863 |

Show me a photo of what you have. I can take a look though.

It is highly possible that you could solder a lead onto what is still there and extend the wire to the same hole removing the broken lead

Solder a wire of the same size paint with almost anything even nail polish route the wire the the hole and re-solder.

After use something that will help relieve the stress to the Transformer / inductor "hot glue ", "Silicone calk", an you should be good.

Computer Programmer / Electronics Technician

It is highly possible that you could solder a lead onto what is still there and extend the wire to the same hole removing the broken lead

Solder a wire of the same size paint with almost anything even nail polish route the wire the the hole and re-solder.

After use something that will help relieve the stress to the Transformer / inductor "hot glue ", "Silicone calk", an you should be good.

Computer Programmer / Electronics Technician

|

Re: Power Supply Inductor Repair May 04, 2019 10:47PM |

Registered: 7 years ago Posts: 23 |

Here you go. The pictures are from both sides. You can see the broken wire and the hole it should go into. It's a bit tight of a fit so I may need to unsolder the whole inductor, extend the leads and then resolder? I have liquid electrical tape that I could use to seal when done and silicone caulk to hold in place.

Edited 1 time(s). Last edit at 05/04/2019 10:50PM by heatvent.

Edited 1 time(s). Last edit at 05/04/2019 10:50PM by heatvent.

|

Re: Power Supply Inductor Repair May 05, 2019 04:53AM |

Registered: 5 years ago Posts: 148 |

mmm that's totally fixable.

Looks like the wire has been cut too short for any solder to hold it in place.

I'd cut a short piece of solid core copper mains cable, solder that through the right hole and onto the wire on the inductor. Unless you have have solid copper wire laying around to use.

You might need to scrape a bit more insulation off that loose wire first to get a good soldered joint, difficult to tell.

Looks like the wire has been cut too short for any solder to hold it in place.

I'd cut a short piece of solid core copper mains cable, solder that through the right hole and onto the wire on the inductor. Unless you have have solid copper wire laying around to use.

You might need to scrape a bit more insulation off that loose wire first to get a good soldered joint, difficult to tell.

|

Re: Power Supply Inductor Repair May 05, 2019 09:31AM |

Registered: 6 years ago Posts: 1,863 |

This is very easy to fix.

Remove the solder from the mounting hole using any method, I use solder wick and a de-soldering solder sucker.

Both work very well in removing solder.

First I would Give it every effort I could to pull the wire as tight as possible to see if there is any chance you can place it back into the hole without extending the wires.

Then While pushing the wire into the hole with needle nose pliers solder generously.

If you do not succeed then try these options.

On the transformer / inductor loose wire remove some of the varnish to be able to get a overlap of the wires place another wire through the hole and align the two wires in parallel and solder.

If you think it is possible, It would be better if the two wires were twisted together then soldered. Though the transformer / inductor wire is fairly short and may be quite difficult to achieve...

Edited 5 time(s). Last edit at 05/05/2019 09:58AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Remove the solder from the mounting hole using any method, I use solder wick and a de-soldering solder sucker.

Both work very well in removing solder.

First I would Give it every effort I could to pull the wire as tight as possible to see if there is any chance you can place it back into the hole without extending the wires.

Then While pushing the wire into the hole with needle nose pliers solder generously.

If you do not succeed then try these options.

On the transformer / inductor loose wire remove some of the varnish to be able to get a overlap of the wires place another wire through the hole and align the two wires in parallel and solder.

If you think it is possible, It would be better if the two wires were twisted together then soldered. Though the transformer / inductor wire is fairly short and may be quite difficult to achieve...

Edited 5 time(s). Last edit at 05/05/2019 09:58AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Power Supply Inductor Repair May 05, 2019 09:36AM |

Registered: 7 years ago Posts: 23 |

Thanks for the info. I think I will try the desolder and get it to reach approach first. Maybe I will get lucky. Just checking on this but it's not a good idea to unwind one loop rather than extend the end. I am not too knowledgeable of electronics and I am sure this would weaken what the inductor does but I am thinking it may still function well enough ... or is this a no-no?

|

Re: Power Supply Inductor Repair May 05, 2019 10:11AM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Power Supply Inductor Repair May 05, 2019 10:17AM |

Registered: 7 years ago Posts: 23 |

|

Re: Power Supply Inductor Repair May 05, 2019 11:05AM |

Registered: 6 years ago Posts: 1,863 |

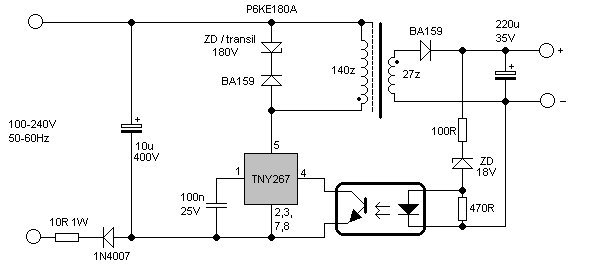

This style power supplies are not to complex as far as switching power supplies go.

An Input

A Switching circuit

An Output

Shown below in this super simple switching supply circuit

The Transformer you are working with steps down the house current 100-265 Vac rectified to our source voltage for our output supply voltage of 12-24Vdc.

The TNY267 being the heart of this super simply switching supply.

Most Users will tell you that these power supplies are so cheap it is simpler to just replace, however what is the fun in that.

I believe this is the fun in having hobbies it is to learn all that there is you want to learn about them. To gain that little extra knowledge.

So what did I do when my power supply went bad - Purchased a new one, then before it arrived could not stand it any longer and fixed the bad one...

Computer Programmer / Electronics Technician

An Input

A Switching circuit

An Output

Shown below in this super simple switching supply circuit

The Transformer you are working with steps down the house current 100-265 Vac rectified to our source voltage for our output supply voltage of 12-24Vdc.

The TNY267 being the heart of this super simply switching supply.

Most Users will tell you that these power supplies are so cheap it is simpler to just replace, however what is the fun in that.

I believe this is the fun in having hobbies it is to learn all that there is you want to learn about them. To gain that little extra knowledge.

So what did I do when my power supply went bad - Purchased a new one, then before it arrived could not stand it any longer and fixed the bad one...

Computer Programmer / Electronics Technician

|

Re: Power Supply Inductor Repair May 05, 2019 11:48AM |

Registered: 7 years ago Posts: 23 |

I agree, it's half the fun. I also couldn't see just throwing this in the trash. Although most of my 3D printing hobby seems to be working on the printer and printing stuff for it rather than anything else

Quote

Roberts_Clif

This style power supplies are not to complex as far as switching power supplies go.

An Input

A Switching circuit

An Output

Shown below in this super simple switching supply circuit

[attachment 111206 SimpleSwitchingsupply.jpg]

The Transformer you are working with steps down the house current 100-265 Vac rectified to our source voltage for our output supply voltage of 12-24Vdc.

The TNY267 being the heart of this super simply switching supply.

Most Users will tell you that these power supplies are so cheap it is simpler to just replace, however what is the fun in that.

I believe this is the fun in having hobbies it is to learn all that there is you want to learn about them. To gain that little extra knowledge.

So what did I do when my power supply went bad - Purchased a new one, then before it arrived could not stand it any longer and fixed the bad one...

|

Re: Power Supply Inductor Repair May 05, 2019 12:37PM |

Registered: 6 years ago Posts: 1,863 |

3D Printers are multiple hobbies all in one.

Computer Programming

Engineering / Design

Electronics Repair

3D Modeling

Its all good we learn what we deem necessary and I want to learn it all...

With My Next CNC project by V1 Engineering will be learning lots more.

Computer Programmer / Electronics Technician

Computer Programming

Engineering / Design

Electronics Repair

3D Modeling

Its all good we learn what we deem necessary and I want to learn it all...

With My Next CNC project by V1 Engineering will be learning lots more.

Computer Programmer / Electronics Technician

|

Re: Power Supply Inductor Repair May 05, 2019 12:39PM |

Registered: 5 years ago Posts: 148 |

|

Re: Power Supply Inductor Repair May 05, 2019 01:12PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

heatvent

Although most of my 3D printing hobby seems to be working on the printer and printing stuff for it rather than anything else

Hahaha, this is so me. More than half the time I'm busy reworking my printer and trying out new stuff either in firmware or hardware.

Right now I'm thinking about ditching my classic MendelMax 1.5 design and rebuilding it in a self-designed V-slot 2040 beam frame. Much sturdier. I was having some severe issues with frame squaring and I found out that there is something wrong with the beams that I originally received 6 years ago when I started building this printer back in early 2013.

It never ends. But luckily now I have time to design and print the parts for a new designed printer and I see it as learning more about engineering and think that all these extracurricular work is always good to show in a curriculum vitae.

http://www.marinusdebeer.nl/

|

Re: Power Supply Inductor Repair May 05, 2019 02:28PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Power Supply Inductor Repair May 05, 2019 08:25PM |

Registered: 7 years ago Posts: 23 |

Good news, I was able to get the wires extended just enough to solder back in the holes after removing the solder with a solder sucker. I have the supply back together and tested it out. No white smoke and 24.18V coming out the other end!

Only step left is to secure the inductor back down to the board. I have some 100% Silicone Caulk (like this [www.lowes.com]). Just want to double check to make sure this is good to use. I know somewhere hot glue was mentioned but this is going to run a 3D printer and can generate some heat so I wouldn't want to glue melting.

Thanks again for all the help!

Only step left is to secure the inductor back down to the board. I have some 100% Silicone Caulk (like this [www.lowes.com]). Just want to double check to make sure this is good to use. I know somewhere hot glue was mentioned but this is going to run a 3D printer and can generate some heat so I wouldn't want to glue melting.

Thanks again for all the help!

|

Re: Power Supply Inductor Repair May 05, 2019 10:01PM |

Registered: 6 years ago Posts: 1,863 |

|

Re: Power Supply Inductor Repair May 05, 2019 10:55PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: Power Supply Inductor Repair May 06, 2019 01:58PM |

Registered: 6 years ago Posts: 265 |

Watch out with silicone caulk - plain caulk releases acetic acid as it cures which can cause corrosion. There are silicone caulks that do not release acetic acid but they are more expensive. Look at Electronics Grade Silicone.

|

Re: Power Supply Inductor Repair May 06, 2019 02:01PM |

Registered: 7 years ago Posts: 23 |

Oops ... caulked it up last night. I will keep that in mind for the future. The link for the silicone product that you posted was about 1/2 the price of the power supply, so I would probably just have used the stuff I had on hand anyway. Thanks though, good information to know.

Edited 1 time(s). Last edit at 05/06/2019 02:13PM by heatvent.

Edited 1 time(s). Last edit at 05/06/2019 02:13PM by heatvent.

|

Re: Power Supply Inductor Repair May 08, 2019 04:56AM |

Registered: 5 years ago Posts: 148 |

|

Re: Power Supply Inductor Repair May 08, 2019 08:41AM |

Registered: 7 years ago Posts: 23 |

|

Re: Power Supply Inductor Repair May 08, 2019 08:59AM |

Registered: 6 years ago Posts: 1,863 |

I designed a Case for this power supply. with a knob for an LED dimmer for case lights.

I used a LM317 voltage regulator adjustable for 0-12 volt supply.

Hictop24VpowersupplyCase.stl

Feel Free to modify for you own design, I used ThinkerCad

Edited 2 time(s). Last edit at 05/08/2019 09:12AM by Roberts_Clif.

Computer Programmer / Electronics Technician

I used a LM317 voltage regulator adjustable for 0-12 volt supply.

Hictop24VpowersupplyCase.stl

Feel Free to modify for you own design, I used ThinkerCad

Edited 2 time(s). Last edit at 05/08/2019 09:12AM by Roberts_Clif.

Computer Programmer / Electronics Technician

|

Re: Power Supply Inductor Repair May 08, 2019 09:17PM |

Registered: 7 years ago Posts: 23 |

Sorry, only registered users may post in this forum.