Is silicone heater going to warp aluminum extrusions?

Posted by jjfawkes

|

Is silicone heater going to warp aluminum extrusions? May 17, 2019 02:22AM |

Registered: 5 years ago Posts: 14 |

Hi,

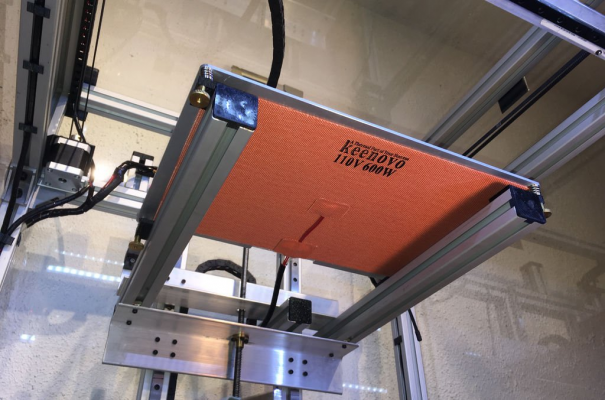

I will use a silicone heater which will be attached to the bottom of aluminum plate (6mm thick). The whole plate will sit on adjustments screws, which will be connected to aluminum extrusions.

Is the heat going to affect the extrusions and warp them over time? Do I need to add another aluminum plate under the heater, so it is sandwiched between two plates?

Something like this:

Or do I have to use two plates, something like this:

Edited 1 time(s). Last edit at 05/17/2019 02:23AM by jjfawkes.

I will use a silicone heater which will be attached to the bottom of aluminum plate (6mm thick). The whole plate will sit on adjustments screws, which will be connected to aluminum extrusions.

Is the heat going to affect the extrusions and warp them over time? Do I need to add another aluminum plate under the heater, so it is sandwiched between two plates?

Something like this:

Or do I have to use two plates, something like this:

Edited 1 time(s). Last edit at 05/17/2019 02:23AM by jjfawkes.

|

Re: Is silicone heater going to warp aluminum extrusions? May 17, 2019 02:30AM |

Registered: 10 years ago Posts: 14,672 |

I suggest you put some thermal insulation between the bottom of the heater and the top surface of the extrusions, so that the extrusions don't receive radiant heat from the heater. There won't be a lot of heat conduction through the levelling screws.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is silicone heater going to warp aluminum extrusions? May 17, 2019 05:31AM |

Registered: 5 years ago Posts: 14 |

|

Re: Is silicone heater going to warp aluminum extrusions? May 17, 2019 06:55AM |

Registered: 10 years ago Posts: 14,672 |

I use cork.Glass fibre is another possibility, but more difficult to work with and the fibres tend to get everywhere. I've also used triple-skin corrugated cardboard in the past.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Is silicone heater going to warp aluminum extrusions? May 17, 2019 09:58AM |

Registered: 5 years ago Posts: 148 |

I have some of this under my bed (a bit over kill no doubt) ..

[www.amazon.co.uk]

Cut a couple of strips to fit on top of the extrusions maybe?

Edited 1 time(s). Last edit at 05/17/2019 09:59AM by Pippy.

[www.amazon.co.uk]

Cut a couple of strips to fit on top of the extrusions maybe?

Edited 1 time(s). Last edit at 05/17/2019 09:59AM by Pippy.

|

Re: Is silicone heater going to warp aluminum extrusions? May 17, 2019 01:09PM |

Registered: 11 years ago Posts: 5,780 |

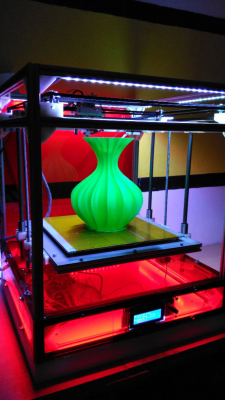

The heat will not warp the t-slot extrusions over time, though they will expand slightly when heated, just like the bed plate, though not nearly as much because they won't be getting nearly as hot as the bed plate.

The only circumstances in which you really need to insulate the underside of the heater is if there's something below it that needs protection from heat or the heater is underpowered and won't get the bed up to print temperature without it.

Insulating the underside of the heater will lead to faster warm up time to print temperature and longer cool-down time.

I don't use any insulation on the underside of my printer's heaters, but I mostly print ABS so any heat "lost" to the air under the heater contributes to warming the enclosure.

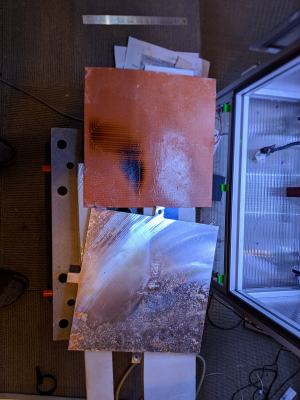

Keenovo recommends sealing the edges of the heater with a bead of silicone once it is stuck to the bed plate. This will presumably prevent the heater from letting go of the bed, which I have found to occur in about 2 years without using silicone. Mount a TCO on the heater using high temperature silicone so that if the heater lets go of the bed plate, the TCO will still do its job. Here's what happens when the heater let's go of the bed plate:

Edited 1 time(s). Last edit at 05/17/2019 02:04PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The only circumstances in which you really need to insulate the underside of the heater is if there's something below it that needs protection from heat or the heater is underpowered and won't get the bed up to print temperature without it.

Insulating the underside of the heater will lead to faster warm up time to print temperature and longer cool-down time.

I don't use any insulation on the underside of my printer's heaters, but I mostly print ABS so any heat "lost" to the air under the heater contributes to warming the enclosure.

Keenovo recommends sealing the edges of the heater with a bead of silicone once it is stuck to the bed plate. This will presumably prevent the heater from letting go of the bed, which I have found to occur in about 2 years without using silicone. Mount a TCO on the heater using high temperature silicone so that if the heater lets go of the bed plate, the TCO will still do its job. Here's what happens when the heater let's go of the bed plate:

Edited 1 time(s). Last edit at 05/17/2019 02:04PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.