|

Thermal expansion June 10, 2019 12:22PM |

Registered: 9 years ago Posts: 752 |

I've been building on and off the last couple of months on my NFAN DIY corexy 3D printer build and run into some unexpected behavior.

I've now changed the bed (consisting of C250 EN AC 5083 Toolingplate Elox 6mm thick) mount from shims to kinematic as per the_digital_dentists design, with a few tweaks of my own for mounting it.

For now I haven't installed the springs to keep the bed down on the adjustment screws (which are now M5 bolds with rounded end nuts on them, sitting in milled slot and hole).

Before heating the bed (21 degrees C at room temperature) up I've taken measurements with a dial indicator mounted to the x carriage. This is the matrix with the first cell being to back left position and the numbers the dial indicator shows, which is in 10th of micro meters, so 10 is 0.1 mm:

-10 -2 8

-3 0 -5

10 4 -8

I know the measurement doesn't appear to read a flat bed, this is due to the frame not perfectly straight, a little bit twisted by a tenth of a millimeter. I thought this was enough in the ballpark to get started.

When I heat up the bed I noticed the values change. I did expect some change but not to the extent it has. These measurements are from the bed at 105 degrees C:

-6 4 11

2 9 0

15 11 -5

The difference 105 degrees compared to 21 degrees:

4 6 3

5 9 5

5 7 3

As you can see, the measurements are raised across the board with some deviations probably due to me not properly reading the exact value, with a deviation of about 1-2 I guess.

Especially in the center it raised 0.09, almost 0.1mm. Thermal expansion is mentioned in the tooling plate datasheet at 23.3 x 10^-6. According to an online calculator it should not expand more than 0.01mm.

The measurements are taken with a layer of buildtak. So I initially thought that might be the culprit. It was in part, it added about 0.04mm. Compared to the buildtak thickness (0.4mm) it's a huge expansion.

When I measured the thermal expansion next to the layer of buildtak , though the measurement was taken at a location where the silicone heater wasn't directly underneath (just 3mm from the original on the buildtak measurement, this time with 2 fans blowing over the heated bed to prevent the support structure from heating up). Still measured about 0.05mm, which is 5x more than expected.

Could it be that due to my heater pad being smaller (300x300mm) and my tooling plate bed larger (350x350mm) causing stresses in the plate and warp in the center?

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

I've now changed the bed (consisting of C250 EN AC 5083 Toolingplate Elox 6mm thick) mount from shims to kinematic as per the_digital_dentists design, with a few tweaks of my own for mounting it.

For now I haven't installed the springs to keep the bed down on the adjustment screws (which are now M5 bolds with rounded end nuts on them, sitting in milled slot and hole).

Before heating the bed (21 degrees C at room temperature) up I've taken measurements with a dial indicator mounted to the x carriage. This is the matrix with the first cell being to back left position and the numbers the dial indicator shows, which is in 10th of micro meters, so 10 is 0.1 mm:

-10 -2 8

-3 0 -5

10 4 -8

I know the measurement doesn't appear to read a flat bed, this is due to the frame not perfectly straight, a little bit twisted by a tenth of a millimeter. I thought this was enough in the ballpark to get started.

When I heat up the bed I noticed the values change. I did expect some change but not to the extent it has. These measurements are from the bed at 105 degrees C:

-6 4 11

2 9 0

15 11 -5

The difference 105 degrees compared to 21 degrees:

4 6 3

5 9 5

5 7 3

As you can see, the measurements are raised across the board with some deviations probably due to me not properly reading the exact value, with a deviation of about 1-2 I guess.

Especially in the center it raised 0.09, almost 0.1mm. Thermal expansion is mentioned in the tooling plate datasheet at 23.3 x 10^-6. According to an online calculator it should not expand more than 0.01mm.

The measurements are taken with a layer of buildtak. So I initially thought that might be the culprit. It was in part, it added about 0.04mm. Compared to the buildtak thickness (0.4mm) it's a huge expansion.

When I measured the thermal expansion next to the layer of buildtak , though the measurement was taken at a location where the silicone heater wasn't directly underneath (just 3mm from the original on the buildtak measurement, this time with 2 fans blowing over the heated bed to prevent the support structure from heating up). Still measured about 0.05mm, which is 5x more than expected.

Could it be that due to my heater pad being smaller (300x300mm) and my tooling plate bed larger (350x350mm) causing stresses in the plate and warp in the center?

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Thermal expansion June 10, 2019 12:47PM |

Registered: 11 years ago Posts: 5,780 |

Are the measurements being made at the same coordinates each time, or just approximate? What are the accuracy and precision specs of the gauge? Why are fans blowing on the bed? If you're using a kinematic mount, expansion of the support structure won't matter. If there's any air trapped under the printing surface it will expand and push it up. One advantage of PEI's transparency is that you can see if there is air trapped under it.

There may be some warp due the the edges being cooler than the heated center portion of the bed plate. The 25mm wide circumferential border is acting like a heatsink. That's why I used ears for the support/leveling screws instead of just using a larger plate and sized the plate to match the heater. You might be able to mitigate it by putting some thermal insulation under the plate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

There may be some warp due the the edges being cooler than the heated center portion of the bed plate. The 25mm wide circumferential border is acting like a heatsink. That's why I used ears for the support/leveling screws instead of just using a larger plate and sized the plate to match the heater. You might be able to mitigate it by putting some thermal insulation under the plate.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Thermal expansion June 10, 2019 04:19PM |

Registered: 9 years ago Posts: 752 |

Thanks for your comments digital_dentist, much appreciated!

There were made at the exact same coordinates.

The certificate of inspection can be found here. TLDR: well within 0.01mm as I read it:

[www.makercentral.net]

The fans were to test if the warp was due to the support structure or the heated bed itself.

I've seen no bubbles under the buildtak surface, though it's opaque black, no bulging can be seen nor does the dial indicator show any irregularities other than the matte surface finish.

Thanks for confirming my suspicions. I can still machine away the parts that are now redundant. I didn't remove them as I didn't know what type of mount I ended up with but the kinematic mount is the way to go.

Here are a few pictures of the tooling plate slot and hole:

[www.makercentral.net]

[www.makercentral.net]

[www.makercentral.net]

And the dial indicator mounted to the x carriage:

[www.makercentral.net]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

There were made at the exact same coordinates.

The certificate of inspection can be found here. TLDR: well within 0.01mm as I read it:

[www.makercentral.net]

The fans were to test if the warp was due to the support structure or the heated bed itself.

I've seen no bubbles under the buildtak surface, though it's opaque black, no bulging can be seen nor does the dial indicator show any irregularities other than the matte surface finish.

Thanks for confirming my suspicions. I can still machine away the parts that are now redundant. I didn't remove them as I didn't know what type of mount I ended up with but the kinematic mount is the way to go.

Here are a few pictures of the tooling plate slot and hole:

[www.makercentral.net]

[www.makercentral.net]

[www.makercentral.net]

And the dial indicator mounted to the x carriage:

[www.makercentral.net]

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Thermal expansion June 10, 2019 05:43PM |

Registered: 11 years ago Posts: 5,780 |

If that heater used 468MP adhesive, you might want to look at this link:

[keenovo.store]

They recommend sealing the edge of the heater with high temperature silicone. I have found that without sealing it, the 468MP starts letting go of the bed plate after about 2 years. I don't know if sealing it will prevent that, but I can't think of any other reason to seal it...

If you're going to seal it with silicone, I'd probably leave about a 3 mm wide perimeter to give the silicone some bottom surface to stick to instead of the sides (entirely for cosmetic reasons).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[keenovo.store]

They recommend sealing the edge of the heater with high temperature silicone. I have found that without sealing it, the 468MP starts letting go of the bed plate after about 2 years. I don't know if sealing it will prevent that, but I can't think of any other reason to seal it...

If you're going to seal it with silicone, I'd probably leave about a 3 mm wide perimeter to give the silicone some bottom surface to stick to instead of the sides (entirely for cosmetic reasons).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Thermal expansion June 11, 2019 07:29AM |

Registered: 9 years ago Posts: 752 |

I don't remember what adhesive was on, I know it was 3M. I've followed the included instruction except the sealing silicone. I'm not sure yet what silicone is suitable and it wasn't clear as to the reason behind sealing it. I noticed that the smell was still very strong of the adhesives of the silicone heater, it's now off gassed I guess, the smell is less. I can imagine that some of that off gassing will be trapped if it's sealed in. Not sure if that has any influence on the longevity of the heater sticking to the tooling plate.

I will regularly check if the adhesive is still good. I don't think this 3D printer will see nearly as much use as yours has, I occasionally print say once a week as time and project allows or requires.

Thanks for the 3mm recommendation, I'm also not very comfortable with the end mill getting too close to the heater pad since it's hard to remove. Do you have any experience with removing it? And is the heater pad still usable after removal? I was thinking if the tooling plate got bend by using shims I may have to transfer the heater over to a new tooling plate, but I think I'll probably ending up buying a new one. We live, we learn

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

I will regularly check if the adhesive is still good. I don't think this 3D printer will see nearly as much use as yours has, I occasionally print say once a week as time and project allows or requires.

Thanks for the 3mm recommendation, I'm also not very comfortable with the end mill getting too close to the heater pad since it's hard to remove. Do you have any experience with removing it? And is the heater pad still usable after removal? I was thinking if the tooling plate got bend by using shims I may have to transfer the heater over to a new tooling plate, but I think I'll probably ending up buying a new one. We live, we learn

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Thermal expansion June 11, 2019 10:24AM |

Registered: 11 years ago Posts: 5,780 |

Your plate should be fine. You didn't bend it unless you drove a truck over it.

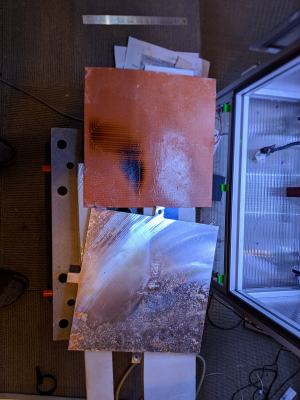

I recently removed a heater from UMMD's bed plate- it was starting to let go of the plate so I was going to take it off, clean off the adhesive, and remount it with silicone, but as you can see, that wasn't a good way to go:

This is why you don't want to let it come off the plate. The plate is a heatsink for the heater, when it detaches, the heater gets super hot in the places that have detached. Seal the edges with silicone!

I think it is safer to mill the plate with the heater mounted than to try to remove it and then reattach it. When I removed the heater from UMMD I heated it up to 110C, disconnected power, and used a scraper with a sharp edge to lift it off the plate. You have to work at every mm of it, and you're bound to nick/gouge the heater in the process, possibly ruining it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I recently removed a heater from UMMD's bed plate- it was starting to let go of the plate so I was going to take it off, clean off the adhesive, and remount it with silicone, but as you can see, that wasn't a good way to go:

This is why you don't want to let it come off the plate. The plate is a heatsink for the heater, when it detaches, the heater gets super hot in the places that have detached. Seal the edges with silicone!

I think it is safer to mill the plate with the heater mounted than to try to remove it and then reattach it. When I removed the heater from UMMD I heated it up to 110C, disconnected power, and used a scraper with a sharp edge to lift it off the plate. You have to work at every mm of it, and you're bound to nick/gouge the heater in the process, possibly ruining it.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Thermal expansion June 12, 2019 11:44AM |

Registered: 9 years ago Posts: 752 |

You're right,the bed is fine. I've adjusted the frame to be more square, it's now within + or - 0.03mm flat according to the dial indicator.

Wow, that's a serious burn mark there. Did the adhesive burn away too and released it from the heater pad?

Maybe clamping it with another insulating material would help?

Will do, I've found silicone kit that's capable of handling 1300 degrees C, that should be good enough.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

Wow, that's a serious burn mark there. Did the adhesive burn away too and released it from the heater pad?

Maybe clamping it with another insulating material would help?

Will do, I've found silicone kit that's capable of handling 1300 degrees C, that should be good enough.

--

Kind regards

Imqqmi

NFAN CoreXY printer:

[reprap.org]

|

Re: Thermal expansion June 12, 2019 02:10PM |

Registered: 11 years ago Posts: 5,780 |

I noticed that the heater had come detached at the dark areas because it was at the front edge of the bed plate, right where I could see it. I put a piece of silicone foam between the heat and the bed support to keep the heater pressed up against the plate for a while, but I'm sure the damage was probably done in the first few minutes that the heater was detached. The adhesive stayed on the heater, and came off the plate in those locations. Once I removed it from the plate I could see what had happened to the heater.

Auto parts store sell small tubes of high temperature silicone made by Permatex and others for $5-8.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Auto parts store sell small tubes of high temperature silicone made by Permatex and others for $5-8.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.