Which format has the most robust and accurate bed design?

Posted by luckyflyer

|

Which format has the most robust and accurate bed design? December 12, 2019 12:41AM |

Registered: 6 years ago Posts: 33 |

I've owned a Monoprice maker select for several years now and have modified it extensively. I've come to find that among other things the bed is a weak link in these printers. I've upgraded to a better carriage and an anycubic glass bed with piezo underbed sensors but even with unified bed leveling I have trouble with the pla prints sticking at the corners. The bed is leveled mechanically pretty well with a max deviation of -.248 at the worst corner. I get to a certain point in the mechanical leveling and I'm just chasing the errors. So which format has the best bed design? Because the flatness/trueness of the bed is a requirement for layer adhesion I will be placing a high priority on this in the selection of my next printer. Your thought on this?

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 01:54AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 02:04AM |

Registered: 6 years ago Posts: 33 |

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 02:53AM |

Registered: 9 years ago Posts: 483 |

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 03:25AM |

Registered: 12 years ago Posts: 2,470 |

.25 mm is a rather large gap that will mess up your prints. If you can't get a more even printbead you should use automatic bed levelling to compensate.

The number of mounting points is not realy an important factor in this. As long as the plate is not planar 3 or 4 mount points make no difference. If the plate is planar it is easier to adjust the level with 3 mount points, but it is perfectly possible and not much more difficult with 4.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

The number of mounting points is not realy an important factor in this. As long as the plate is not planar 3 or 4 mount points make no difference. If the plate is planar it is easier to adjust the level with 3 mount points, but it is perfectly possible and not much more difficult with 4.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 05:27AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 11:08AM |

Registered: 11 years ago Posts: 5,780 |

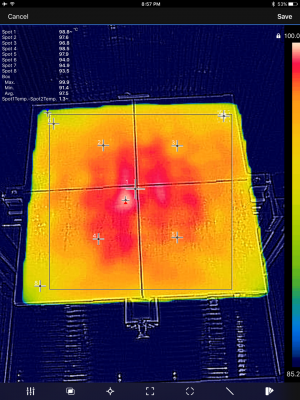

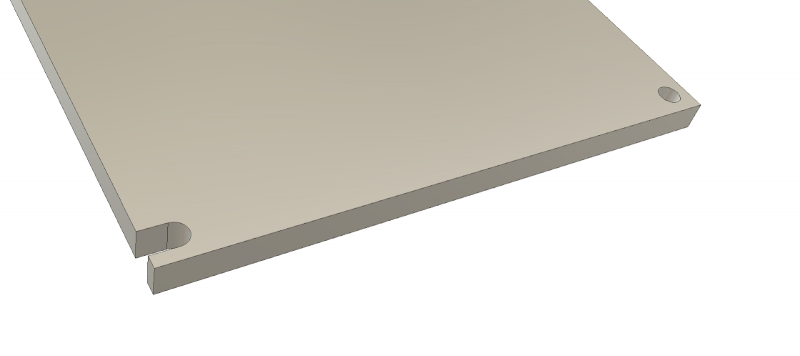

I favor cast aluminum tooling plate beds with same-size, line powered heater on the bottom and a thin layer of PEI on top. I put the plate on a 3 screw kinematic mount so it is stable and does not require releveling. The bed is flat, heats evenly and quickly, and prints stick from edge to edge.

For bed moving in Z, here's what I did.

For bed moving in Y, here's what I did.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

For bed moving in Z, here's what I did.

For bed moving in Y, here's what I did.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which format has the most robust and accurate bed design? December 12, 2019 03:13PM |

Registered: 6 years ago Posts: 33 |

|

Re: Which format has the most robust and accurate bed design? December 13, 2019 10:15AM |

Registered: 11 years ago Posts: 5,780 |

When you're trying to make things really good, you have to try to think about what needs to happen without thinking about the tools you have available. Once you've found something that works really well, then start thinking about how to make it happen with the tools you have access to. For example, it isn't necessary to use machine tools to make a kinematic mount for the bed plate. You can do it with a drill, a saw, and a couple taps. The reference hole doesn't have to be chamfered- you can simply drill a hole in the plate that is too small for the leveling screw to fit through. You don't have to use a spherical head screw- put an acorn nut on a the end of a screw instead. The slot is only slightly trickier. You can make it by screwing down two pieces of metal spaced apart to create the equivalent of the slot I milled. Alternatively, you can just cut a slot in the plate with a saw. I milled the teflon blocks with antirotation tangs that allows them to be held in place with a single screw and t-nut each. If you can't do that just use rectangular blocks and two screws and t-nuts each to hold them in place and keep them from rotating. It isn't as neat as using machine tools, but it will work just as well.

Machine tools are nice, but aluminum can be drilled with any drill, and can be cut with a hacksaw.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Machine tools are nice, but aluminum can be drilled with any drill, and can be cut with a hacksaw.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.