Is it still worth it to build?

Posted by boredom.is.me

|

Is it still worth it to build? February 08, 2020 04:22PM |

Registered: 5 years ago Posts: 30 |

There is no better place to ask this than on the RepRap forums. For the most part, it all started here. As a builder, I don't mind spending a little extra if it means designing and building my own. Considering the progression (and copycats) over the years, is it still worth it to build a printer?

Ya, there's a lot of cheap crap out there, but some of what's available is pretty decent and, more importantly, ready to go.

Ya, there's a lot of cheap crap out there, but some of what's available is pretty decent and, more importantly, ready to go.

|

Re: Is it still worth it to build? February 08, 2020 04:51PM |

Registered: 5 years ago Posts: 30 |

In the time I spent thinking about this, someone else presented the same question.

[reprap.org]

EDIT:

That turned out to be a bumped 2 year old thread.

Edited 1 time(s). Last edit at 02/08/2020 04:55PM by boredom.is.me.

[reprap.org]

EDIT:

That turned out to be a bumped 2 year old thread.

Edited 1 time(s). Last edit at 02/08/2020 04:55PM by boredom.is.me.

|

Re: Is it still worth it to build? February 19, 2020 02:40AM |

Registered: 12 years ago Posts: 182 |

|

Re: Is it still worth it to build? February 19, 2020 02:48AM |

Admin Registered: 13 years ago Posts: 7,000 |

|

Re: Is it still worth it to build? February 20, 2020 05:04AM |

Registered: 8 years ago Posts: 622 |

I'd say that it's largely down to personal preference. Some of us like to tinker, others may be less so inclined. Then again, different people have different skills and abilities. Some people may be comfortable with the design process but less capable when it comes to the practical skills needed to turn that design into a reality. Others may be comfortable with the practical "hands on" aspects, but less comfortable with the design process. So it also depends on your definition of "build" because that could include starting with a cheap printer and improving it, rather that starting from scratch. Then again, what does "starting from scratch" actually mean? Few of us are likely to come up with a completely new design that nobody has thought about. So "starting from scratch" usually means making some sort of copy of a pre-existing design. So the question "Is it still worth it to build?" isn't the simple question that it may seem.

[somei3deas.wordpress.com]

[www.youtube.com]

[somei3deas.wordpress.com]

[www.youtube.com]

|

Re: Is it still worth it to build? February 20, 2020 10:35AM |

Registered: 12 years ago Posts: 182 |

From what I've seen, most of the cheaper printers need some tinkering anyways. Without the nessesary skill you may very likely run in a problem which isn't that easy to solve. Starting from scratich may give you those skills.

Or you buy a printer that does not need tinkering, an original Prusa or an Ultimaker, for example. But then you are far away from cheap.

Or you buy a printer that does not need tinkering, an original Prusa or an Ultimaker, for example. But then you are far away from cheap.

|

Re: Is it still worth it to build? February 20, 2020 10:59AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Is it still worth it to build? February 20, 2020 12:42PM |

Registered: 11 years ago Posts: 5,780 |

Cheap printers are cheap because the manufacturer selects the cheapest parts, not the best parts, they can find to do the job, and usually parts that are operating right at the limits of their performance. The result is usually a lot of tweaking and messing around to keep them running and a bunch of parts that won't be reusable to build a better printer once you have some experience printing and want something better. Don't even think about buying a cheapo printer and upgrading to make it into a good printer. It will cost more to do that then to just buy or build a good printer in the first place. Want a bed heater that will get the temperature high enough to print ABS? You'll replace the heater then discover that the power supply can't handle the current. So you'll replace the power supply and discover that the MOSFET on the controller board or the copper traces to the MOSFET can't handle the current and then you'll replace the controller board. Now you've spent as much as the original printer cost and you still have a crappy printer. A year from now you'll want to put a new extruder in the printer. You'll fire up the Arduino IDE so you can program the steps/mm for the new extruder and discover that the IDE can no longer compile the firmware for your controller board. Then you'll hunt for an obsolete version of the IDE only to discover you also need obsolete plugins for it and an obsolete USB driver. That's when you realize why that controller board cost only $25.

Prusa printers are good in the sense that they have tweaked the firmware and slicer to compensate for the relatively low build/parts quality. An assembled Prusa I3 costs about what I spent on parts to build UMMD. I also spent hundreds of hours working on the design and fabricating parts for it.

If I ever want another printer, I'll do that again over buying a ready-to-print machine, even if it's a machine with a small print envelope, because I like the challenge and have lots of tools and expert people available at the Milwaukee Makerspace.

If you really like building stuff and the budget is low, check local scrap yards for parts and materials. We have a couple makerspace-friendly scrap yards in the Milwaukee area that set aside things like t-slot for us because they know we'll buy it from them. I buy cut-off pieces of cast aluminum tooling plate from a local metals supplier for scrap price. Find and join your local makerspace, or start one. You'll find that in every group there are people with connections to get tools and materials on the cheap. At the Milwaukee Makerspace, most of the machine tools, wood shop tools etc. are owned by individual members and on indefinite loan to the makerspace for members to use. The space pays for and members provide the work to maintain and upgrade machines, buys blades/bits, etc..

If you just can't wait to start printing you'll probably have to pay a high price for parts or a printer. If you're on a tight budget, patience pays big dividends. Acquiring parts as they become available for good prices may take a while before you can print but your cash outlay will be much lower. Also realize that you don't have to have many specific parts. For example, linear guides of many sizes will work fine in a printer. Ebay is full of good deals if you search enough and are willing to wait a little. Good deals on high quality 9mm linear guides are rare, but you can easily find a good deal on a high quality 12 or 15 mm linear guide. The guides can be cut to whatever length you need, so you don't have to find one that's exactly the length needed for your design as long as it's long enough. Ball bearings of many different sizes can be used to make pulleys. Learn to use the advanced search features on ebay so you can filter stuff you're not interested in out of search results.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Prusa printers are good in the sense that they have tweaked the firmware and slicer to compensate for the relatively low build/parts quality. An assembled Prusa I3 costs about what I spent on parts to build UMMD. I also spent hundreds of hours working on the design and fabricating parts for it.

If I ever want another printer, I'll do that again over buying a ready-to-print machine, even if it's a machine with a small print envelope, because I like the challenge and have lots of tools and expert people available at the Milwaukee Makerspace.

If you really like building stuff and the budget is low, check local scrap yards for parts and materials. We have a couple makerspace-friendly scrap yards in the Milwaukee area that set aside things like t-slot for us because they know we'll buy it from them. I buy cut-off pieces of cast aluminum tooling plate from a local metals supplier for scrap price. Find and join your local makerspace, or start one. You'll find that in every group there are people with connections to get tools and materials on the cheap. At the Milwaukee Makerspace, most of the machine tools, wood shop tools etc. are owned by individual members and on indefinite loan to the makerspace for members to use. The space pays for and members provide the work to maintain and upgrade machines, buys blades/bits, etc..

If you just can't wait to start printing you'll probably have to pay a high price for parts or a printer. If you're on a tight budget, patience pays big dividends. Acquiring parts as they become available for good prices may take a while before you can print but your cash outlay will be much lower. Also realize that you don't have to have many specific parts. For example, linear guides of many sizes will work fine in a printer. Ebay is full of good deals if you search enough and are willing to wait a little. Good deals on high quality 9mm linear guides are rare, but you can easily find a good deal on a high quality 12 or 15 mm linear guide. The guides can be cut to whatever length you need, so you don't have to find one that's exactly the length needed for your design as long as it's long enough. Ball bearings of many different sizes can be used to make pulleys. Learn to use the advanced search features on ebay so you can filter stuff you're not interested in out of search results.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Is it still worth it to build? February 22, 2020 03:06PM |

Registered: 12 years ago Posts: 1,450 |

With a handle like boredom.is.me it sounds like you are looking at more than a simple "monkey see monkey do" project. You could of course simply get the best existing components and bolt them together. This may get you a printer that is pretty O.K.: It will earn plaudits for building a good printer and maybe a temporary cure for boredom but it will probably cost you more of your hard-earned money than buying one.

You could, of course, buy a cheap printer. Most cheap printers are dross, built at the command of a market-droid who perceives a gap in the market. Some are really quite good as they were designed by miracle workers who could build up to a standard and down to a price at the same time (the miracle workers are also known as engineers). Sadly, most of them have disappeared, the good and the dross alike.

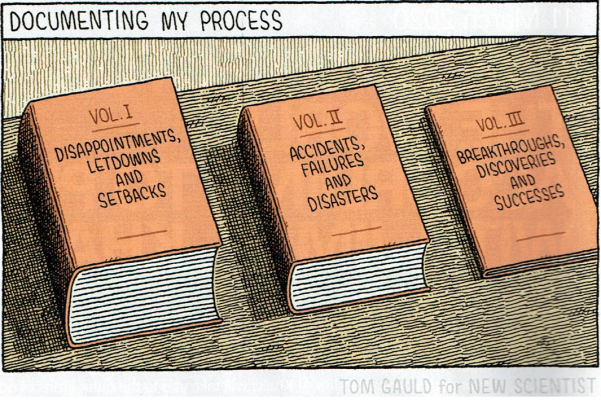

You could also design and build your own, seeking out the knowledge instead of copying the crowd wisdom; testing your new knowledge by experimentation to see if it really is so and then building iteration 1 of N attempts. I would simply point you at a cartoon I have shamelessly stolen from the pages of the latest New Scientist magazine that illustrates what your future will be like.

For this to work, your boredom must be the sort which can be allayed by the precious few Vol. III successes - but you won't get the praise and plaudits you would from throwing money at it.

Mike

You could, of course, buy a cheap printer. Most cheap printers are dross, built at the command of a market-droid who perceives a gap in the market. Some are really quite good as they were designed by miracle workers who could build up to a standard and down to a price at the same time (the miracle workers are also known as engineers). Sadly, most of them have disappeared, the good and the dross alike.

You could also design and build your own, seeking out the knowledge instead of copying the crowd wisdom; testing your new knowledge by experimentation to see if it really is so and then building iteration 1 of N attempts. I would simply point you at a cartoon I have shamelessly stolen from the pages of the latest New Scientist magazine that illustrates what your future will be like.

For this to work, your boredom must be the sort which can be allayed by the precious few Vol. III successes - but you won't get the praise and plaudits you would from throwing money at it.

Mike

|

Re: Is it still worth it to build? February 24, 2020 10:16PM |

Registered: 5 years ago Posts: 30 |

Haha, like I said, I'm a builder and designer. Although nothing official beyond 60 credits, I do have an engineering background as well as hands on experience in manufacturing, materials, and pretty much anything to do with getting products from a screen to the physical realm. I just like prodding the community.  I've had three cnc machines, two of which I built, the last being completely my own.

I've had three cnc machines, two of which I built, the last being completely my own.

leadinglights:

Those book are the absolute truth, but there's no such thing as a failure. They are "let's not do that again"s.

I completely agree with what everyone has said. Pretty much all of these printers are garbage. There are three printers that I think are pretty decent. Two are the Prusas due to software. I don't like the mechanical side. The remaining is Anycubic's i3 for the price. You also have to consider the resin market booming now. The Elegoo Mars Pro is supposed to be $300 if it ever restocks. I've designed a few completed builds, but even the first models at my design infancy had better mechanics in my opinion.

This is my current design in both triple screw and cantilever variants. There are quite a few things that need to be addressed such as overall frame assembly and another extrusion across the front top. All plates would be machined from 3/16" 6061, 1/4" 6061, and 3mm carbon fiber. The only printed parts would be from SLS nylon, and those are the guide block mounts.

Edited 1 time(s). Last edit at 02/24/2020 10:17PM by boredom.is.me.

I've had three cnc machines, two of which I built, the last being completely my own.

I've had three cnc machines, two of which I built, the last being completely my own.leadinglights:

Those book are the absolute truth, but there's no such thing as a failure. They are "let's not do that again"s.

I completely agree with what everyone has said. Pretty much all of these printers are garbage. There are three printers that I think are pretty decent. Two are the Prusas due to software. I don't like the mechanical side. The remaining is Anycubic's i3 for the price. You also have to consider the resin market booming now. The Elegoo Mars Pro is supposed to be $300 if it ever restocks. I've designed a few completed builds, but even the first models at my design infancy had better mechanics in my opinion.

This is my current design in both triple screw and cantilever variants. There are quite a few things that need to be addressed such as overall frame assembly and another extrusion across the front top. All plates would be machined from 3/16" 6061, 1/4" 6061, and 3mm carbon fiber. The only printed parts would be from SLS nylon, and those are the guide block mounts.

Edited 1 time(s). Last edit at 02/24/2020 10:17PM by boredom.is.me.

|

Re: Is it still worth it to build? February 26, 2020 09:43AM |

Registered: 12 years ago Posts: 182 |

|

Re: Is it still worth it to build? February 27, 2020 08:46AM |

Registered: 7 years ago Posts: 270 |

|

Re: Is it still worth it to build? February 28, 2020 10:45AM |

Registered: 6 years ago Posts: 2 |

|

Re: Is it still worth it to build? March 02, 2020 01:44PM |

Registered: 9 years ago Posts: 175 |

|

Re: Is it still worth it to build? March 02, 2020 02:45PM |

Registered: 5 years ago Posts: 30 |

Simple bearing for radial support topped with a lock collar. For the triple screw, that should be more than fine. For the cantilever, it's a larger 10mm screw with a larger radial bearing topped with a thrust washer and lock collar.Quote

newbob

How is the roller shaft supported on the bottom end?

Thank you, but I don't put out incomplete and unbuilt designs.Quote

Alain60

Hello,

I like the design of your 3D printer as shown in the attachments. Is there any more documentation on it ?

That's the goal.Quote

chriske

Designed and built my own, never regretted it.

I make near perfect prints with it. Meanwhile a few friends copied my design and are very happy with it.

|

Re: Is it still worth it to build? March 17, 2020 05:15PM |

Registered: 4 years ago Posts: 19 |

use the $200 kit to print parts for the $1000 dream build. the $200 kit is just barely good enough to print PLA/PHA. not as good as PETG but much better than PLA. throw a garbage bag over the whole thing if you have a cold basement. the hermera is an amazing value for the money. the SKR mini for the ender 3 is a cheap drop in replacement on an ender 3. now that you have a 32bit hotend extruder and main board. so far $400 total budget. you can replace the kinematics platform and reuse the motors, bed, screen, spool holder, power supply. I see hypercube kits for $180. throw some linear rails on it and your done. total budget $700 to $800. another $200 to get the bed sorted and maybe some auto leveling. another $100 to make an eclosure for ABS. $1100 total.

Sorry, only registered users may post in this forum.