Reviving a Makerbot Replicator 2X

Posted by Ohmarinus

|

Re: Reviving a Makerbot Replicator 2X January 15, 2021 04:15PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

guru_florida

Hey Ohmarinus! How is the machine running now?

I am considering moving to single extruder and bowden-pusher instead of my extruder on the carriage. I just find dual extrusion such a pain to tune and 95% of the time I just want single head. Also, my glass plate cracked a bit (my own fault) and although it still works fine for now I am thinking PEI sheet is in order. What are you using for build plate?

Heyyy, sorry I've been quite busy IRL... I have decided to leave the project at rest for a while because I need to design a solution to print PLA instead of ABS. This machine has reminder me of how much I loathe ABS!

I have now bought a magnetic sheet that I can place a metal plate on with kapton on top of it. It's the easiest, this way you can remove the plate and bend it to release the print. I've bought '3D lac plus' with which the prints stick to the bed with great success.

The machine is running great when I'm running it, but I also built a Prusa i3 clone that's smaller and fits on my desk. So I have postponed fixing the Replicator 2x a bit. Also really busy with making pen plots. Reviving some vintage plotters right now. very addictive!

How is your machine running meanwhile? Did you replace the glass plate? My machine originally has a cast iron plate and silicone heated element underneath.

http://www.marinusdebeer.nl/

|

Re: Reviving a Makerbot Replicator 2X February 07, 2021 10:52PM |

Registered: 3 years ago Posts: 16 |

On long prints, I'm finding it tough to manage the heat creap vs ABS warpage (and popping off the plate). It's like threading the eye of a needle temp wise. I'm strongly thinking of going in your direction with the bowden tube and external extruder. I added little tiny fans to steppers and no go. My other alternative is to convert some of my carriage to metal (I have the stock and CNC machine) and it will conduct the heat and radiate it better....or I can go back to water cooled which really solved this problem - like a fire hose! I really wanted to have dual extrusion and ninjaflex but right now I just want a reliable print. I just thought I could simplify by removing water cooling but with a heated chamber + buildplate keeping steppers cool is hard - even with fans.

Did you post the design for your carriage on thingiverse? I would like to give it a try if you don't mind.

Thanks,

Colin

Did you post the design for your carriage on thingiverse? I would like to give it a try if you don't mind.

Thanks,

Colin

|

Re: Reviving a Makerbot Replicator 2X February 10, 2021 10:06PM |

Registered: 3 years ago Posts: 16 |

Hi Chraeje, Welcome! Sorry I missed your posts in between all the reply-quote stuff I already read. You can download my zipped up Config files and platformio.ini file (for Visual Code IDE) from my Google Drive link. You may not have the same setup as me though! I have new hotend and temp sensors and a BL touch. I assume you are doing a Mightboard to SKR conversion like Ohmarinus and I did. I think everything else would still be the same but I may be forgetting something. Best to review the differences. My config files are also for Marlin 2.0.x branch so if you use a newer branch (which you should) then settings will need to be integrated manually anyway. Good luck! If you have any struggles let us know.

Quote

chraeje

would you like to share the firmware somehow?

|

Re: Reviving a Makerbot Replicator 2X February 14, 2021 04:14AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

guru_florida

On long prints, I'm finding it tough to manage the heat creap vs ABS warpage (and popping off the plate). It's like threading the eye of a needle temp wise. I'm strongly thinking of going in your direction with the bowden tube and external extruder. I added little tiny fans to steppers and no go. My other alternative is to convert some of my carriage to metal (I have the stock and CNC machine) and it will conduct the heat and radiate it better....or I can go back to water cooled which really solved this problem - like a fire hose! I really wanted to have dual extrusion and ninjaflex but right now I just want a reliable print. I just thought I could simplify by removing water cooling but with a heated chamber + buildplate keeping steppers cool is hard - even with fans.

Did you post the design for your carriage on thingiverse? I would like to give it a try if you don't mind.

Thanks,

Colin

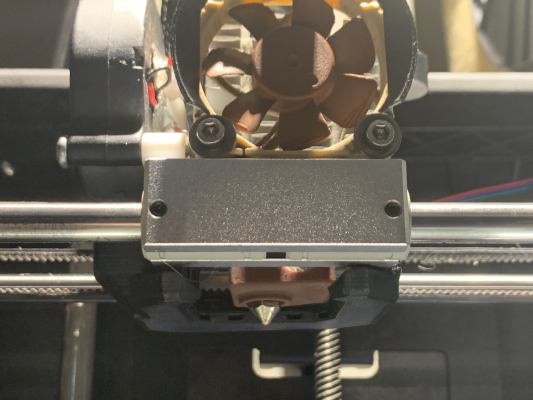

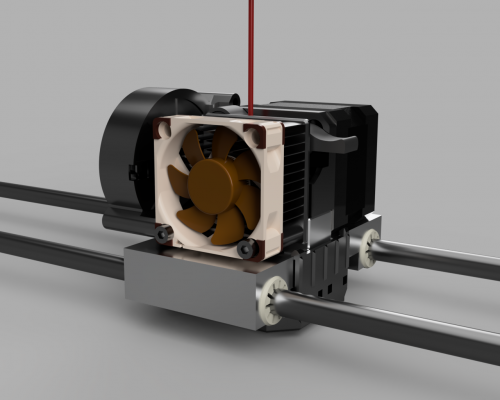

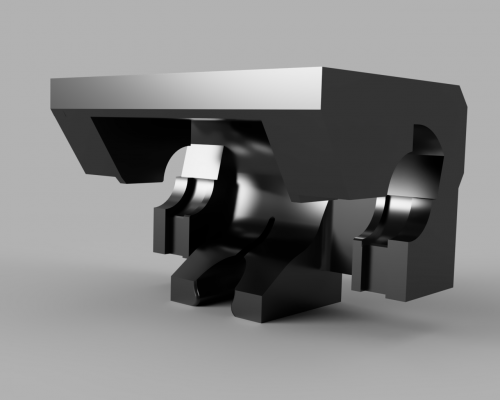

Heyhey, well I would like to share it when it's finished! I'm actually going to convert it to print with PLA. ABS is just too toxic. So I still have to design and print a print cooling fan, but the biggest challenge is fitting it in with the current carriage design... One other change I'm making is that I bought this magnetic flex plate because sometimes the prints stick so well to the bed thatI can't get them off. So, I have to 'yank' on the bed and I'm afraid this causes damage to the motion system.

Maybe I'll get to it next week. If I manage to add a print cooling fan I might have to make some changes to the carriage as well. I didn't add mounting holes.. Which was a mistake. So I'll probably drill and melt in some threaded inserts to accommodate an additional radial fan. Let's hope one radial fan is enough. I will update once it's finished. Also have to convert back the hotend to use a PTFE liner instead of the titanium one that I have in place right now, I think titanium doesn't like PLA.

http://www.marinusdebeer.nl/

|

Re: Reviving a Makerbot Replicator 2X February 15, 2021 11:49AM |

Registered: 3 years ago Posts: 16 |

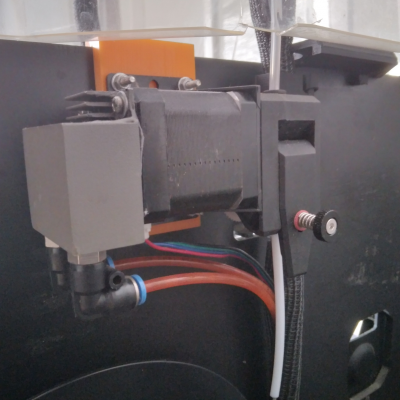

Interesting about the titanium insert. You and I are still putting the Experimental in "Rep 2X Experimental" aren't we! lol. I just went back to water cooled head, but this time minus the huge Koolance unit (for CPUs) and instead just a small 80mm radiator and what is basically a fish tank pump I think. All in all, cost me <50$. Motors sustain 10degC above room temp after hours so heat creep issue is definitely solved. I don't like the dual head anymore though, too heavy and a royal pain, I ordered an Orbiter V1.5 Extruder which will arrive this week. It's direct drive but lightweight. Hoping I can ramp up acceleration after.

Orbiter is a much smaller stepper with planetary gears and dual-drive filament gears yet still capable of fast acceleration and velocity.

Orbiter is a much smaller stepper with planetary gears and dual-drive filament gears yet still capable of fast acceleration and velocity.

Quote

Ohmarinus

Hey hey, well I would like to share it when it's finished! I'm actually going to convert it to print with PLA. ABS is just too toxic. So I still have to design and print a print cooling fan, but the biggest challenge is fitting it in with the current carriage design... One other change I'm making is that I bought this magnetic flex plate because sometimes the prints stick so well to the bed thatI can't get them off. So, I have to 'yank' on the bed and I'm afraid this causes damage to the motion system.

Maybe I'll get to it next week. If I manage to add a print cooling fan I might have to make some changes to the carriage as well. I didn't add mounting holes.. Which was a mistake. So I'll probably drill and melt in some threaded inserts to accommodate an additional radial fan. Let's hope one radial fan is enough. I will update once it's finished. Also have to convert back the hotend to use a PTFE liner instead of the titanium one that I have in place right now, I think titanium doesn't like PLA.

|

Re: Reviving a Makerbot Replicator 2X February 16, 2021 08:34AM |

Registered: 3 years ago Posts: 4 |

Ohmarinus, thank you very much for sharing!

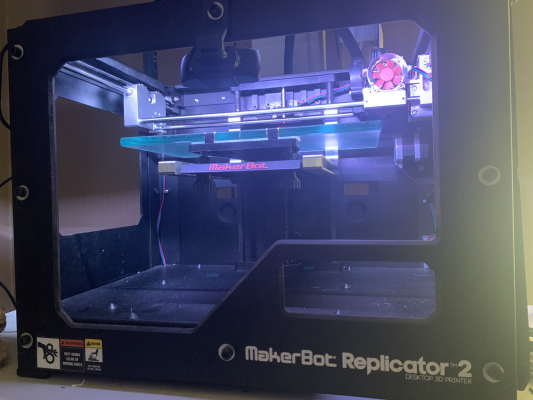

I have just started converting my Replicator 2 yesterday and already found some helpful hints from your thread.

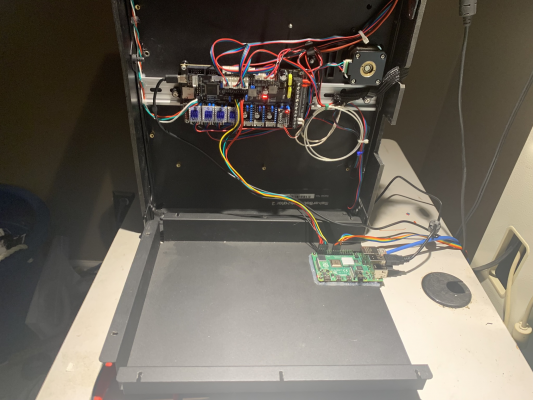

My setup is (or better will be) SKR3 v1.4 Turbo, TMC2208, TFT35 v3, BLTouch V3.0, ESP01S Wifi, DCDC MOD V1.0, BTMOS V2.0.

So far I replaced the connectors, integrated the TFT display and made all three axis + extruder move. Still a long way to go, but getting there step by step.

There are still some things which puzzle me with the Board and Marlin... But okay, nothing which cannot be solved :-)

PS: Always ground your electrostaticly active office assistant.

Cheers,

André

I have just started converting my Replicator 2 yesterday and already found some helpful hints from your thread.

My setup is (or better will be) SKR3 v1.4 Turbo, TMC2208, TFT35 v3, BLTouch V3.0, ESP01S Wifi, DCDC MOD V1.0, BTMOS V2.0.

So far I replaced the connectors, integrated the TFT display and made all three axis + extruder move. Still a long way to go, but getting there step by step.

There are still some things which puzzle me with the Board and Marlin... But okay, nothing which cannot be solved :-)

- Limited number of PWM FAN ports.

- Filament runout sensor in Marlin only works with an LCD screen. Or if you set EXTRUDE_MINTEMP 0 and risk cold extrusion

- TRP is not enabled by default

PS: Always ground your electrostaticly active office assistant.

Cheers,

André

|

Re: Reviving a Makerbot Replicator 2X February 16, 2021 09:57AM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

LordOfTheBatch

Ohmarinus, thank you very much for sharing!

I have just started converting my Replicator 2 yesterday and already found some helpful hints from your thread.

My setup is (or better will be) SKR3 v1.4 Turbo, TMC2208, TFT35 v3, BLTouch V3.0, ESP01S Wifi, DCDC MOD V1.0, BTMOS V2.0.

So far I replaced the connectors, integrated the TFT display and made all three axis + extruder move. Still a long way to go, but getting there step by step.

There are still some things which puzzle me with the Board and Marlin... But okay, nothing which cannot be solved :-)

- Limited number of PWM FAN ports.

- Filament runout sensor in Marlin only works with an LCD screen. Or if you set EXTRUDE_MINTEMP 0 and risk cold extrusion

- TRP is not enabled by default

PS: Always ground your electrostaticly active office assistant.

Cheers,

André

Very nice to hear! I think these machines are great platforms to upgrade to open source. Everything can be fit in the box underneath. I'm actually thinking of moving to RepRapFirmware and adding a Raspberry Pi with Duet web server. But first I'll have to get the new design running. meanwhile I'm also working on another machine that is getting a slight priority.

The PWM FAN controls can be expanded, I created a DIY expansion myself as posted on page 1. If you want to know more, this is the topic about the PWM controller that I built, and it works really well:

[reprap.org]

I kinda forgot how I ended up doing it. So I'll have to check out what I did to know for sure. Cute cat btw!!

Quote

guru_florida

Interesting about the titanium insert. You and I are still putting the Experimental in "Rep 2X Experimental" aren't we! lol. I just went back to water cooled head, but this time minus the huge Koolance unit (for CPUs) and instead just a small 80mm radiator and what is basically a fish tank pump I think. All in all, cost me <50$. Motors sustain 10degC above room temp after hours so heat creep issue is definitely solved. I don't like the dual head anymore though, too heavy and a royal pain, I ordered an Orbiter V1.5 Extruder which will arrive this week. It's direct drive but lightweight. Hoping I can ramp up acceleration after.

Orbiter is a much smaller stepper with planetary gears and dual-drive filament gears yet still capable of fast acceleration and velocity.

That's a great looking extruder! I think direct drive works better than bowden.. My diy prusa has direct drive and it performs really well, but better than my old printer. Is that orbiter extruder also available as a bowden extruder by any chance?

Edited 2 time(s). Last edit at 02/16/2021 10:00AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Reviving a Makerbot Replicator 2X February 16, 2021 01:27PM |

Registered: 3 years ago Posts: 16 |

Ohmarinus :

I wouldnt consider the Orbiter special for bowden use, I'm sure it could work but for bowden style weight isn't really a factor so normal stepper would work. The extruder gears are typical dual drive Bondtech-like ones. I just noticed in the pic the spring tensioner is underneath like the orbiter is resting on it, but it actually goes in the screw hole near the quick connect at the top...pic is misleading there but any other image you'd find shows it correct.

Doesn't the Duet have its own firmware and web server? And I hear it's pretty superior to our Marlin and RR firmware, but I am not an expert on this. There is also Klipper firmware that can work with Marlin and Duet and others that can offload kinematics calcs that I hear improves speed, performance and print quality.

LordOfTheBatch:

Any reason you didn't go with the TMC2209s? higher current ability (or less temp at lower currents) and serial setup (done from Marlin) is convenient.

Limited number of PWM is a big pain. They could have easily added a two more I'm sure.

Edited 1 time(s). Last edit at 02/16/2021 02:10PM by guru_florida.

I wouldnt consider the Orbiter special for bowden use, I'm sure it could work but for bowden style weight isn't really a factor so normal stepper would work. The extruder gears are typical dual drive Bondtech-like ones. I just noticed in the pic the spring tensioner is underneath like the orbiter is resting on it, but it actually goes in the screw hole near the quick connect at the top...pic is misleading there but any other image you'd find shows it correct.

Doesn't the Duet have its own firmware and web server? And I hear it's pretty superior to our Marlin and RR firmware, but I am not an expert on this. There is also Klipper firmware that can work with Marlin and Duet and others that can offload kinematics calcs that I hear improves speed, performance and print quality.

LordOfTheBatch:

Any reason you didn't go with the TMC2209s? higher current ability (or less temp at lower currents) and serial setup (done from Marlin) is convenient.

Limited number of PWM is a big pain. They could have easily added a two more I'm sure.

Edited 1 time(s). Last edit at 02/16/2021 02:10PM by guru_florida.

|

Re: Reviving a Makerbot Replicator 2X February 16, 2021 02:09PM |

Registered: 3 years ago Posts: 16 |

I got switched back to water cooled head and latest print worked great. The hot-end is still fan cooled for now, but the issue was the extruder motor heat creeping into the gear and softening the filament until jam. Extruder motor was 40degC after 7 hour print - only 10deg above ambient. This was pretty cheap setup around $50 for the pump+resevoir and 80mm radiator. It'll be easy to mount right to the Makerbot frame.

80mm Radiator - Amazon

4w quiet pump + resevoir

Also needs some G 1/4 fittings and tubing (standard CPU cooling stuff) and some kind of cooling head. I have a CNC so I made my own, but probably you could find existing ones on amazon for 40mm motors/etc.

80mm Radiator - Amazon

4w quiet pump + resevoir

Also needs some G 1/4 fittings and tubing (standard CPU cooling stuff) and some kind of cooling head. I have a CNC so I made my own, but probably you could find existing ones on amazon for 40mm motors/etc.

|

Re: Reviving a Makerbot Replicator 2X February 17, 2021 02:39AM |

Registered: 3 years ago Posts: 4 |

Quote

guru_florida

LordOfTheBatch:

Any reason you didn't go with the TMC2209s? higher current ability (or less temp at lower currents) and serial setup (done from Marlin) is convenient.

Limited number of PWM is a big pain. They could have easily added a two more I'm sure.

I bought a set, it was coming with TMC2208s only. If I find any problems with the 2208s I will switch to 2209s - I saw they are like 20EUR for a set of 5.

Edited 1 time(s). Last edit at 02/17/2021 02:40AM by LordOfTheBatch.

|

Re: Reviving a Makerbot Replicator 2X February 17, 2021 02:47AM |

Registered: 3 years ago Posts: 4 |

Quote

Ohmarinus

Very nice to hear! I think these machines are great platforms to upgrade to open source. Everything can be fit in the box underneath.

Me too. It was just to nice to throw away completly. I like the stiff sheet metal box frame a lot - most cheap printers nowadays only consist of aluminum extrusion - I am surprised they work so well.

Quote

Ohmarinus

The PWM FAN controls can be expanded, I created a DIY expansion myself as posted on page 1. If you want to know more, this is the topic about the PWM controller that I built, and it works really well:

[reprap.org]

Thanks for the hint! I was looking at the I2C bus already, I created something similar for an ESP8226 some years ago.

Quote

Ohmarinus

That's a great looking extruder! I think direct drive works better than bowden.. My diy prusa has direct drive and it performs really well, but better than my old printer. Is that orbiter extruder also available as a bowden extruder by any chance?

I would always stay with direct extrusion, except for delta printers.

|

Re: Reviving a Makerbot Replicator 2X February 28, 2021 10:42AM |

Registered: 3 years ago Posts: 4 |

I am mostly done with my remodeling but still face two issues, maybe somebody can help / has some experience to share?!

- The original thermo sensors of the hotend and heated bed theme to be "thermocouples" (PT100 sensors), but I cannot get them to work with the BTT PT100 board. Did you replace the sensors or find a working solution to convert the values?

- My Z axis motor gets pretty hot. I already turned down the amps on this axis, but they are still getting >45 degrees. When checking the motor specs I found out this stepper is a 12V version. Did you have the same issues or replaced the steppers?

Cheers

André

- The original thermo sensors of the hotend and heated bed theme to be "thermocouples" (PT100 sensors), but I cannot get them to work with the BTT PT100 board. Did you replace the sensors or find a working solution to convert the values?

- My Z axis motor gets pretty hot. I already turned down the amps on this axis, but they are still getting >45 degrees. When checking the motor specs I found out this stepper is a 12V version. Did you have the same issues or replaced the steppers?

Cheers

André

|

Re: Reviving a Makerbot Replicator 2X February 28, 2021 02:02PM |

Registered: 12 years ago Posts: 1,450 |

Thermocouples and PT100 are different kinds of sensors. Thermocouples produce a voltage output and the kind is important although it will almost always be type "K". PT100 and PT1000 are resistive types where the resistance depends on the temperature.

Stepper motors can get quite hot and 45°C is very acceptable. One of my motors runs at 80°C and is still well within working limits.

Mike

Stepper motors can get quite hot and 45°C is very acceptable. One of my motors runs at 80°C and is still well within working limits.

Mike

|

Re: Reviving a Makerbot Replicator 2X March 11, 2021 11:43PM |

Registered: 3 years ago Posts: 16 |

The original temp sensors were Type K thermocouples. leadinglights is right. I am using the PT100's now though since I switched to the Dragon hotends and SKR board. I didn't know the Z-axis was 12v...are you sure? All the motors get hot, and 70-80 degrees would be normal without cooling. There are better steppers out there than these makerbot originals for heat control. I found the heat from the extruder steppers often leaked into the hot-end and caused heat-creep-like problems which is why I went back to water cooling it. If you have the extruder steppers mounted to the thick aluminum bar (like on original Makerbot) this will help heatsink it, but it was always a fine line especially when printing fully enclosed.

|

Re: Reviving a Makerbot Replicator 2X May 01, 2021 12:35PM |

Registered: 8 years ago Posts: 18 |

Interesting thread to read through.

Do any of you who are converting machines have any left-over MakerBot electronics - dead or alive (or in between!) that you might be willing to donate to a project I'm running to create a drop-in Mightyboard replacement for the Rep2/2X?

I've just successfully restored several machines, but one was completely missing its motherboard and would be a good candidate for fix-upgrade - but I'm very keen to create something more plug and play and easy to... replicate...?

Cheers, Alex

Do any of you who are converting machines have any left-over MakerBot electronics - dead or alive (or in between!) that you might be willing to donate to a project I'm running to create a drop-in Mightyboard replacement for the Rep2/2X?

I've just successfully restored several machines, but one was completely missing its motherboard and would be a good candidate for fix-upgrade - but I'm very keen to create something more plug and play and easy to... replicate...?

Cheers, Alex

|

Re: Reviving a Makerbot Replicator 2X June 25, 2021 03:08PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

alexgibson3d

Interesting thread to read through.

Do any of you who are converting machines have any left-over MakerBot electronics - dead or alive (or in between!) that you might be willing to donate to a project I'm running to create a drop-in Mightyboard replacement for the Rep2/2X?

I've just successfully restored several machines, but one was completely missing its motherboard and would be a good candidate for fix-upgrade - but I'm very keen to create something more plug and play and easy to... replicate...?

Cheers, Alex

Hi Alex, sorry for the late reply. I was actually looking for a way to make some money on the old electronics to finance the upgrade of the Replicator, and some other quite expensive projects... I hope you find someone who is willing to donate some electronics though, I think the Makerbots Replicators can also be very good machines if you manage to fix some of the odd quirks it has.

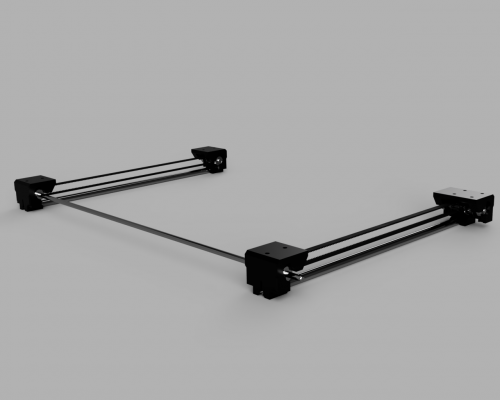

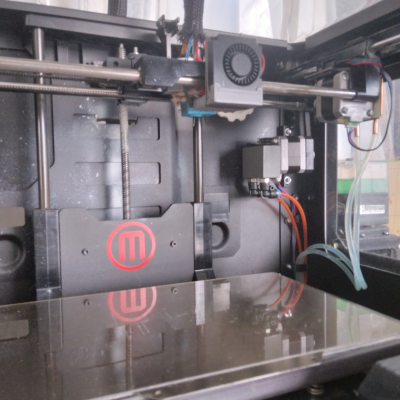

Some update on the Replicator 2x, I haven't forgotten this sweet vintage machine

Meanwhile I've started working on the Replicator 2x again, adding a part cooling fan and adding a filament drybox and some tweaks to the firmware. It now prints PETG quite successfully! I think this is due to the insulated heater block, helping to block heat radiation. I almost never use the part cooling fan and it prints really well.

See this video for some more info:

[www.youtube.com]

Most things to do now are just slicer optimization. And I'm thinking of upgrading the firmware, it's now running on Marlin 2.0.5.4 or something and since Marlin 2.0.9 is out I'm thinking it's a good choice to upgrade now. Oh and I really need to add a cooling fan to the Z-motor as it tends to run extremely hot, nothing compared to how hot the other motors run. And it's only being fed 300mA so I'm kind of lost on what else it could be.

The next project will probably be to remove the TFT screen and add in a Raspberry Pi with Octoprint to further improve the machine. I decided I really don't like SD card switching anymore. My laptop also doesn't has an integrated SD card reader, and it's just a hassle, especially considering that the alternative is already within easy reach.

But first I'm going to work on my pen plotter. So I fixed the Replicator 2x, which is now one of the best printing printers that I own, with which I can print parts for my pen plotter. It's just a long chain of machines that keep improving each other and I really like it.

In the video you can see the part cooling fan, it's very slimline, it mounts around one of the bearings with a tie-rap and uses a small 4010 radial fan. This fan is connected to my DIY additional PWM fan controller breakout board that I mentioned earlier. It works like a charm.

Edited 1 time(s). Last edit at 06/25/2021 03:12PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Reviving a Makerbot Replicator 2X November 10, 2021 08:30PM |

Registered: 2 years ago Posts: 1 |

|

Re: Reviving a Makerbot Replicator 2X December 27, 2021 12:02PM |

Registered: 2 years ago Posts: 1 |

I'm really glad I saw this post. It gave me the motovation to start upgrading mine. I had done a bit already, upgrading much of it to aluminum. The lure of klipper was too great so I ditched the mightyboard for a Fysetc Spider w/ TMC2209's and a Pi. So quiet now and much faster. The back right gantry bracket had become loose so I had to reverse engineer the gantry mounting system and print some replacements out of ASA. The ultimate goal is to be able to print hi temp plastics but I need a heated build plate. Keenovo still sells silicone pads for the Rep2/2x so I have one on the way I just don't know how I'm gonna jigger it in. Any advice would be great, as of now I've done some rough design for it but I keep coming back to a custom milled aluminum plate and I don't know how far down the financial rabbit hole I want to go. My son told me to name it Theseus.

|

Re: Reviving a Makerbot Replicator 2X August 09, 2023 08:27PM |

Registered: 9 years ago Posts: 60 |

Sorry to bump the thread. This is my mods for 2X

- Watercooling

- Chimera hotend

- Duet 2 WiFi

- Heated Chamber

- Nextion Display

Sorry, only registered users may post in this forum.