Help Needed - Custom Built 3d Printer - Finally Printing

Posted by BalajiS

Help Needed - Custom Built 3d Printer - Finally Printing  September 15, 2020 01:08AM |

Registered: 3 years ago Posts: 11 |

Hi There,

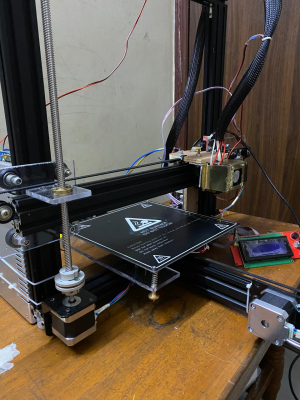

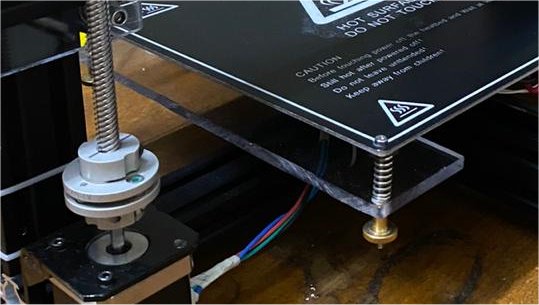

I am a big fan of DIY. I bought all parts one after the other and started building my own 3D printer. Mine is a 12v RAMPS 1.6 Marlin driven 3D printer. I have gone through many videos and forums for this build. I have attached the image of my printer that i build. Feels solid in terms of build. my X, Y and Z axis are moving fine without pully teeth missing..

After i was able to input my marlin firmware. I did count the no of steps for X, Y, Z axis along with Extruder settings. It is 80, 80, 1600, 94.54 are the steps. ( i calculated everything set by set for extruder marking 100mm in the filament and making it extruder and retract)

Things that worked fine..

1. Homing is fine

2. Endstop settings are fine

3. All heating are fine

Leveling Bed was fine initially. I did heat up the device to level the bed. I made it through MatterControl Slicer for leveling bed (but during print i see atleast 2 mm grap between nozzle and bed)

Things that did not work from the beginning

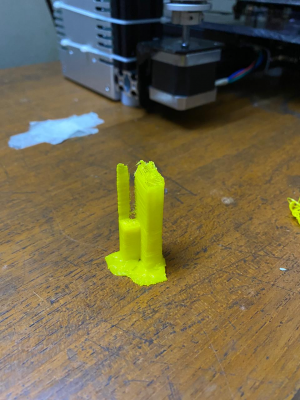

1. I wasn’t able to print anything with proper shapes. benchy Ship, does not look like ship at all. it looked like empire state building. (I am not sure if they are Layer shifting or may be worse than that)

2. I downloaded the STL file from thingiverse and slice it with either matter control or cura with almost all permutations and combination.. nothing worked!!!

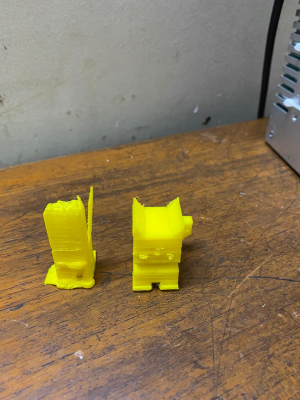

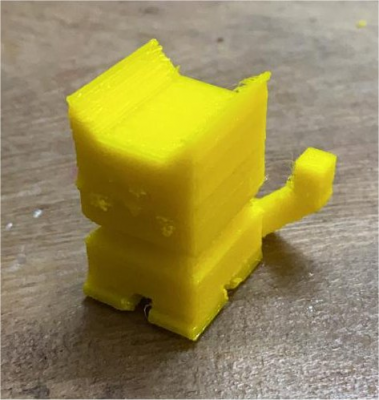

3. All my subjects are skewed taller!!! (Refer them below picture.. trust me i tried to print a Cali cat and it printed this!!! I have no idea where I did the mistake and

what settings I missed!!

4. Another issue is after about some time, the filament is not coming from extruder...

Pls help

My Printer

My print Subject Cali Cat

Please help

Edited 2 time(s). Last edit at 09/16/2020 05:24AM by BalajiS.

I am a big fan of DIY. I bought all parts one after the other and started building my own 3D printer. Mine is a 12v RAMPS 1.6 Marlin driven 3D printer. I have gone through many videos and forums for this build. I have attached the image of my printer that i build. Feels solid in terms of build. my X, Y and Z axis are moving fine without pully teeth missing..

After i was able to input my marlin firmware. I did count the no of steps for X, Y, Z axis along with Extruder settings. It is 80, 80, 1600, 94.54 are the steps. ( i calculated everything set by set for extruder marking 100mm in the filament and making it extruder and retract)

Things that worked fine..

1. Homing is fine

2. Endstop settings are fine

3. All heating are fine

Leveling Bed was fine initially. I did heat up the device to level the bed. I made it through MatterControl Slicer for leveling bed (but during print i see atleast 2 mm grap between nozzle and bed)

Things that did not work from the beginning

1. I wasn’t able to print anything with proper shapes. benchy Ship, does not look like ship at all. it looked like empire state building. (I am not sure if they are Layer shifting or may be worse than that)

2. I downloaded the STL file from thingiverse and slice it with either matter control or cura with almost all permutations and combination.. nothing worked!!!

3. All my subjects are skewed taller!!! (Refer them below picture.. trust me i tried to print a Cali cat and it printed this!!! I have no idea where I did the mistake and

what settings I missed!!

4. Another issue is after about some time, the filament is not coming from extruder...

Pls help

My Printer

My print Subject Cali Cat

Please help

Edited 2 time(s). Last edit at 09/16/2020 05:24AM by BalajiS.

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 02:49AM |

Admin Registered: 11 years ago Posts: 3,096 |

Not bad for a first try!

First of all, what filament are you using? PLA? ABS? PETG?

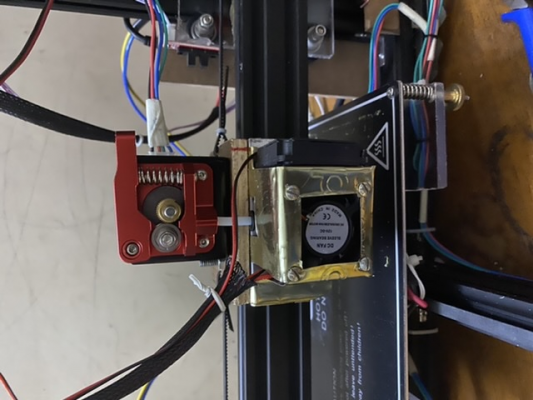

If it's PLA, you need a hotend that has PTFE tube in the throat or else the filament can get stuck if the surface isn't perfectly smooth inside of the hotends throat/transition zone. Also, if it's PLA, you need a part cooling fan. But the print seems to fail because the filament gets stuck as I can see the further up the print gets, the less is extruded.

Does the extruder maybe skip steps, or can it be that the gear is grinding on the filament?

Second, the cantilever on the Z-axis where the nuts are seated in looks like it could give issues with flexing, Z-height is very important. The flex might cause variances in Z-height and might add layer-artifacts.

Above all, I think it's a nice first try, the machine already looks like a good first try and once you get it to print, you can design and print better X-ends that hold the Z-nut.

http://www.marinusdebeer.nl/

First of all, what filament are you using? PLA? ABS? PETG?

If it's PLA, you need a hotend that has PTFE tube in the throat or else the filament can get stuck if the surface isn't perfectly smooth inside of the hotends throat/transition zone. Also, if it's PLA, you need a part cooling fan. But the print seems to fail because the filament gets stuck as I can see the further up the print gets, the less is extruded.

Does the extruder maybe skip steps, or can it be that the gear is grinding on the filament?

Second, the cantilever on the Z-axis where the nuts are seated in looks like it could give issues with flexing, Z-height is very important. The flex might cause variances in Z-height and might add layer-artifacts.

Above all, I think it's a nice first try, the machine already looks like a good first try and once you get it to print, you can design and print better X-ends that hold the Z-nut.

http://www.marinusdebeer.nl/

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 10:01AM |

Registered: 6 years ago Posts: 1,863 |

Looking at your attached photo I see your lead screws and you should change the configurations 80, 80, 1600, 94.54.

The 1600 was meant for a T8x2 not your T8x8 lead screw.

If you place a mark on the lead screw while the nozzle is on the bed. Then turn the lead screw 360 degrees (one full revolution)

You will see the the nozzle moves 8mm up the 1600 was designed for a lead screw that only moves 2mm up.

Your settings should start here 80, 80, 400, 94.54 or 80, 80, 398, 94.54 in some cases this 2mm makes a the model closer to the correct size.

This is only a suggestion as viewed from a photo.

Edited 6 time(s). Last edit at 09/15/2020 10:08AM by Roberts_Clif.

Computer Programmer / Electronics Technician

The 1600 was meant for a T8x2 not your T8x8 lead screw.

If you place a mark on the lead screw while the nozzle is on the bed. Then turn the lead screw 360 degrees (one full revolution)

You will see the the nozzle moves 8mm up the 1600 was designed for a lead screw that only moves 2mm up.

Your settings should start here 80, 80, 400, 94.54 or 80, 80, 398, 94.54 in some cases this 2mm makes a the model closer to the correct size.

This is only a suggestion as viewed from a photo.

Edited 6 time(s). Last edit at 09/15/2020 10:08AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 10:11AM |

Registered: 6 years ago Posts: 1,863 |

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 12:05PM |

Registered: 8 years ago Posts: 1,671 |

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 11:28PM |

Registered: 3 years ago Posts: 11 |

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 11:41PM |

Registered: 3 years ago Posts: 11 |

You beauty!! You are spot on. I did your test and it’s exactly 8mm is the length travelled.. I have changed the settings in Marlin.Quote

Roberts_Clif

Looking at your attached photo I see your lead screws and you should change the configurations 80, 80, 1600, 94.54.

The 1600 was meant for a T8x2 not your T8x8 lead screw.

If you place a mark on the lead screw while the nozzle is on the bed. Then turn the lead screw 360 degrees (one full revolution)

You will see the the nozzle moves 8mm up the 1600 was designed for a lead screw that only moves 2mm up.

Your settings should start here 80, 80, 400, 94.54 or 80, 80, 398, 94.54 in some cases this 2mm makes a the model closer to the correct size.

This is only a suggestion as viewed from a photo.

Well that’s sums for a taller skewed.. but any idea why Cali cat or any object that I slic not printing the same?

Re: Help Needed - Custom Built 3d Printer  September 15, 2020 11:47PM |

Registered: 3 years ago Posts: 11 |

Quote

Ohmarinus

Not bad for a first try!

First of all, what filament are you using? PLA? ABS? PETG?

If it's PLA, you need a hotend that has PTFE tube in the throat or else the filament can get stuck if the surface isn't perfectly smooth inside of the hotends throat/transition zone. Also, if it's PLA, you need a part cooling fan. But the print seems to fail because the filament gets stuck as I can see the further up the print gets, the less is extruded.

Does the extruder maybe skip steps, or can it be that the gear is grinding on the filament?

Second, the cantilever on the Z-axis where the nuts are seated in looks like it could give issues with flexing, Z-height is very important. The flex might cause variances in Z-height and might add layer-artifacts.

Above all, I think it's a nice first try, the machine already looks like a good first try and once you get it to print, you can design and print better X-ends that hold the Z-nut.

Apologies I should have included it.. I use PLA+ and the Hotend is CR-10 model

Yesterday I changed it to be somewhat direct drive with less PTFE tube. Yes I have part cooling fan as well..

Pls refer the pic

Re: Help Needed - Custom Built 3d Printer  September 16, 2020 01:41AM |

Registered: 3 years ago Posts: 11 |

Update:

After the Z axis steps turned to 400. I see a great improvement.

What is better now?

1. I can see the object takes its shape.

2. Printing is smooth now

3. Perfect or near good first Layer

Whats still skewed.

1. Looks like i have a series layer shift (right from the second Layer itself)

2. I hear a horrible motor sound. Not sure if there is something wrong with motor or some voltage change needs to happen.. it see its getting hot sometimes. i meassured the voltage and ist 0.5 to .60 on all stepper

Observations:

1. After slicing it in Mattercontrol. I see the Y Axis during completion of the first Layer moves diagonally to the start point. The movement is very slow or slightly jitters (attached the video). This happens for on the end of 2nd Layer also so its obvious shift after every layer. But other Y axis movement is fine. Something is not correct really. This did happened before also and the printer halted saying hardware error!!

What i checked after the observation?

1. I removed the Y axis motor wires, checked if the Y axis moves freely, fine tuned the eccentric nut also (but thats the max i can loose the eccentric nut). The belts looks fine, Y axis moves freely than X axis actually

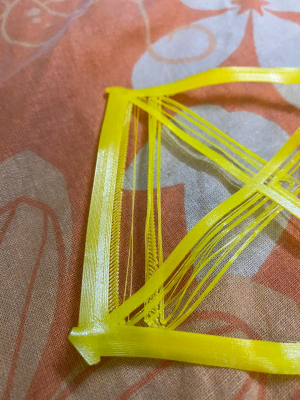

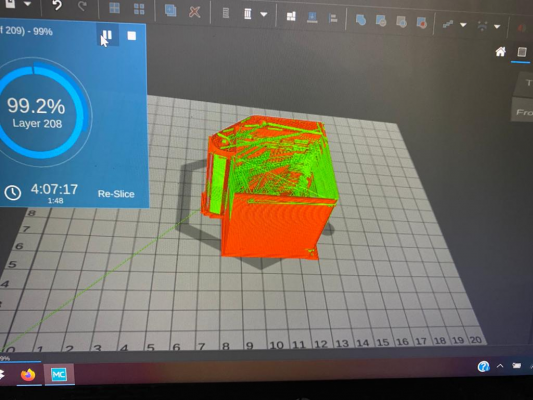

Images: First Layer

Good First Layer

Y axis jitter during Last diagonal movement.

YaxisJitter.mp4

Normal Printing. The movement looks proper during diagonal and no jitters.

NormalPrinting.mp4

Edited 2 time(s). Last edit at 09/16/2020 02:00AM by BalajiS.

After the Z axis steps turned to 400. I see a great improvement.

What is better now?

1. I can see the object takes its shape.

2. Printing is smooth now

3. Perfect or near good first Layer

Whats still skewed.

1. Looks like i have a series layer shift (right from the second Layer itself)

2. I hear a horrible motor sound. Not sure if there is something wrong with motor or some voltage change needs to happen.. it see its getting hot sometimes. i meassured the voltage and ist 0.5 to .60 on all stepper

Observations:

1. After slicing it in Mattercontrol. I see the Y Axis during completion of the first Layer moves diagonally to the start point. The movement is very slow or slightly jitters (attached the video). This happens for on the end of 2nd Layer also so its obvious shift after every layer. But other Y axis movement is fine. Something is not correct really. This did happened before also and the printer halted saying hardware error!!

What i checked after the observation?

1. I removed the Y axis motor wires, checked if the Y axis moves freely, fine tuned the eccentric nut also (but thats the max i can loose the eccentric nut). The belts looks fine, Y axis moves freely than X axis actually

Images: First Layer

Good First Layer

Y axis jitter during Last diagonal movement.

YaxisJitter.mp4

Normal Printing. The movement looks proper during diagonal and no jitters.

NormalPrinting.mp4

Edited 2 time(s). Last edit at 09/16/2020 02:00AM by BalajiS.

Re: Help Needed - Custom Built 3d Printer  September 16, 2020 05:22AM |

Registered: 3 years ago Posts: 11 |

Update 2:

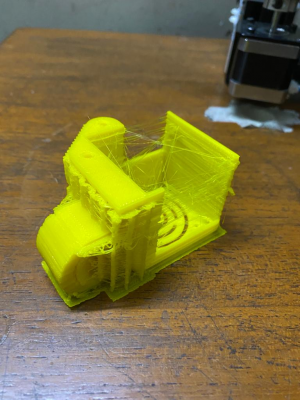

Good News. Finally was able to print the Cali Cat as cali cat!! Gave a print with full supports to know how the printer behaves. It was able to complete it all in 2 hours. Pretty good for a DIY custom Built printer.

Now before and after calibration and fixing the steps/mm

Outstanding issues:

1. Still Y Axis after few hours moves/Jitters slowly in diagonal..

2. Fine tune the subjets from slicers so that no stringing, over or under extrusions of filaments etc.

Edited 1 time(s). Last edit at 09/16/2020 05:25AM by BalajiS.

Good News. Finally was able to print the Cali Cat as cali cat!! Gave a print with full supports to know how the printer behaves. It was able to complete it all in 2 hours. Pretty good for a DIY custom Built printer.

Now before and after calibration and fixing the steps/mm

Outstanding issues:

1. Still Y Axis after few hours moves/Jitters slowly in diagonal..

2. Fine tune the subjets from slicers so that no stringing, over or under extrusions of filaments etc.

Edited 1 time(s). Last edit at 09/16/2020 05:25AM by BalajiS.

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 16, 2020 07:55AM |

Registered: 6 years ago Posts: 1,863 |

When you have a problem remember we are he to help, but not just for when you are in need of help.

Come back, read the posts see if your experiences can help others.

I would assume that after building a complete 3D Printer from scratch you have a lot experiences to give and to help others.

Computer Programmer / Electronics Technician

Come back, read the posts see if your experiences can help others.

I would assume that after building a complete 3D Printer from scratch you have a lot experiences to give and to help others.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 16, 2020 09:15AM |

Registered: 3 years ago Posts: 11 |

Quote

Roberts_Clif

When you have a problem remember we are he to help, but not just for when you are in need of help.

Come back, read the posts see if your experiences can help others.

I would assume that after building a complete 3D Printer from scratch you have a lot experiences to give and to help others.

yes mate for sure..

btw.. any idea on the other issues that i have Y axis jittering after some time.

Edited 1 time(s). Last edit at 09/16/2020 09:16AM by BalajiS.

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 16, 2020 09:37AM |

Admin Registered: 13 years ago Posts: 7,000 |

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 16, 2020 09:39AM |

Registered: 6 years ago Posts: 1,863 |

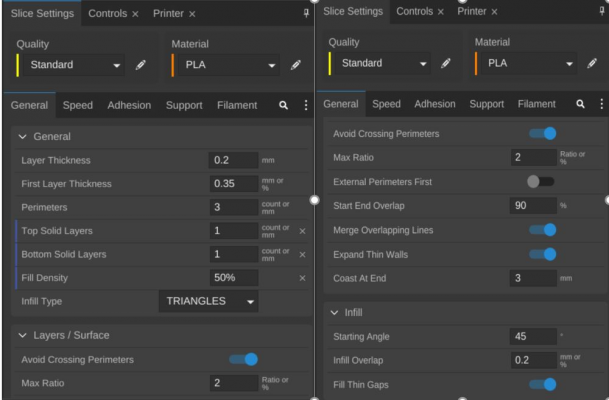

Looking at your CaliCat I see the edges are still a little ruff could you post your Mattercontrol slicer settings as I see no Mattercontrol thread continue here.

It appears that the bed is a little high on the leveling springs this could cause some or all of the lines on your CaliCat, though some could be corrected by Mattercontrol settings.

Edited 2 time(s). Last edit at 09/16/2020 09:48AM by Roberts_Clif.

Computer Programmer / Electronics Technician

It appears that the bed is a little high on the leveling springs this could cause some or all of the lines on your CaliCat, though some could be corrected by Mattercontrol settings.

Edited 2 time(s). Last edit at 09/16/2020 09:48AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 16, 2020 11:10PM |

Registered: 3 years ago Posts: 11 |

Quote

Roberts_Clif

Looking at your CaliCat I see the edges are still a little ruff could you post your Mattercontrol slicer settings as I see no Mattercontrol thread continue here.

Quote

BalajiS

[attachment 116734 CaliCat.jpg]

It appears that the bed is a little high on the leveling springs this could cause some or all of the lines on your CaliCat, though some could be corrected by Mattercontrol settings.

[attachment 116737 Springs.jpg]

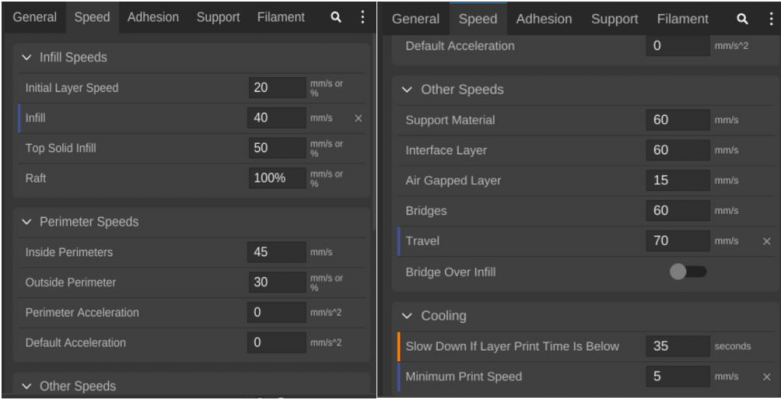

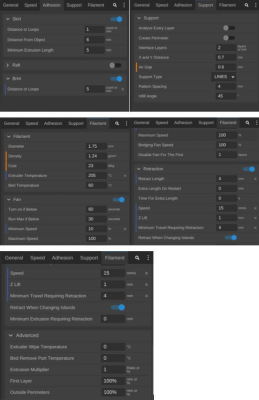

Here you go..

Reg the bed height. I have set it to the correct height. The pic was taken during cold conditions. things get little expanded during hot conditions and ideally the bed gets leveled. I use a 3 point plan leveling solution via matter control before printing so it gets leveled before printing

My worries are just that the motor gets nosier with time and getting slow or jittering Y axis on big prints. On a small prints there is no issues or differences

Edited 1 time(s). Last edit at 09/16/2020 11:12PM by BalajiS.

Re: Help Needed - Custom Built 3d Printer  September 17, 2020 08:28AM |

Registered: 6 years ago Posts: 1,863 |

Quote

Dust

Y stepper driver could be getting to hot, if so they shut down to cool off then continue.

Dust : : : Thank You

Quote

BalajiS

Whats still skewed.

1. Looks like i have a series layer shift (right from the second Layer itself)

2. I hear a horrible motor sound. Not sure if there is something wrong with motor or some voltage change needs to happen.. it see its getting hot sometimes. i meassured the voltage and ist 0.5 to .60 on all stepper

Observations:

1. After slicing it in Mattercontrol. I see the Y Axis during completion of the first Layer moves diagonally to the start point. The movement is very slow or slightly jitters (attached the video). This happens for on the end of 2nd Layer also so its obvious shift after every layer. But other Y axis movement is fine. Something is not correct really. This did happened before also and the printer halted saying hardware error!!

What i checked after the observation?

1. I removed the Y axis motor wires, checked if the Y axis moves freely, fine tuned the eccentric nut also (but thats the max i can loose the eccentric nut). The belts looks fine, Y axis moves freely than X axis actually

It sound like the Y-Axis May be the one complicating your 3D Printer experience, I would double the check the Y_Axis eccentric nuts this is quite a delicate adjustment.

Too loose the Bed wobbles, Too tight the Bed requires more torque to move. Are any of your stepper motors getting Hot this Axis is where you should be troubleshooting.

I have a Hictop 3DP11/12 and using Nema 17 Bipolar 1.5A 57oz.in or compatible stepper motors, I have set my Steppers according the the chart below.

Note:: Stock was running the steppers too hot, Red is a 24V and Blu is 12V 3D Printers

Stock | Red | Blu

X-Axis - 0.8 .695 .395

Y-Axis - 0.8 .695 .395

Z-Axis - 1.0 1.639 .710 --- one Pair Parallel Nema 17 Bipolar 1.5A 36.6oz

E0-E1 - 0.8 .695 .395

Edited 1 time(s). Last edit at 09/17/2020 08:30AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer  September 17, 2020 10:23PM |

Registered: 9 years ago Posts: 978 |

Quote

BalajiS

1. Still Y Axis after few hours moves/Jitters slowly in diagonal...

When things go wrong after a period of time, usually the problem is heating or cooling. If your Y axis motor or (more likely) stepper driver is overheating, it will skip steps and make the horrible graunching noise you describe, and of course the carriage won't move in that axis, or only move in one direction. Try heatsinks and a fan blowing on your stepper drivers. Or you could slow the print down, or pause it every few minutes, so that natural cooling can keep it cool. I think that if you have too much current going to your stepper, it causes overheating and the same thing happens. And if your stepper current is too low, it doesn't cause overheating, but it also causes steps to be skipped.

But do also check that there's no extra friction in the Y axis at that point in the movement. And that your wires and filament feed to the carriage are long enough and not catching on anything. Probably best would be to move the carriage to that position manually and try moving it around a bit.

Re: Help Needed - Custom Built 3d Printer  September 18, 2020 12:17AM |

Registered: 3 years ago Posts: 11 |

Quote

Roberts_Clif

I have a Hictop 3DP11/12 and using Nema 17 Bipolar 1.5A 57oz.in or compatible stepper motors, I have set my Steppers according the the chart below.

Note:: Stock was running the steppers too hot, Red is a 24V and Blu is 12V 3D Printers

Stock | Red | Blu X-Axis - 0.8 .695 .395 Y-Axis - 0.8 .695 .395 Z-Axis - 1.0 1.639 .710 --- one Pair Parallel Nema 17 Bipolar 1.5A 36.6oz E0-E1 - 0.8 .695 .395

Sounds like my stepper is running with high with .6 for a 12v. I will try to reduce it to .4 and see.

Yeah there could be problem of missing steps due to high voltage and stepper becoming hot as well. I suspect that. I cross checked the Y axis to see if the Y moves freely and if there are any play in the rollers etc.. it works fine.

Will keep you posted on this after tuning the voltage.

Coming back to slicer settings. @Roberts_Clif are you able to verify my slicer settings? i have provided what you asked. I tried to print the CR10 stock housing for hotend

Slicer from MatterControl Showing the stringing and all spider webs in green. (i need to adjust this stringing so that it prints fines any recomendations??? )

I have got the same in exact with strings after printing also

I find it too dificult to remove the supports from the object!! (looking like i am missing a correct settings in slicer)

Re: Help Needed - Custom Built 3d Printer  September 18, 2020 12:18AM |

Registered: 3 years ago Posts: 11 |

Quote

frankvdh

Quote

BalajiS

1. Still Y Axis after few hours moves/Jitters slowly in diagonal...

When things go wrong after a period of time, usually the problem is heating or cooling. If your Y axis motor or (more likely) stepper driver is overheating, it will skip steps and make the horrible graunching noise you describe, and of course the carriage won't move in that axis, or only move in one direction. Try heatsinks and a fan blowing on your stepper drivers. Or you could slow the print down, or pause it every few minutes, so that natural cooling can keep it cool. I think that if you have too much current going to your stepper, it causes overheating and the same thing happens. And if your stepper current is too low, it doesn't cause overheating, but it also causes steps to be skipped.

But do also check that there's no extra friction in the Y axis at that point in the movement. And that your wires and filament feed to the carriage are long enough and not catching on anything. Probably best would be to move the carriage to that position manually and try moving it around a bit.

Thanks Mate.. any recommendations on the slicer settings? u can refer my settings in the above posts..

Re: Help Needed - Custom Built 3d Printer  September 18, 2020 08:07AM |

Registered: 6 years ago Posts: 1,863 |

Sorry my 3D Printer Power Supplies voltages are backwards.

Posting My 3D Printer Cura Settings

Cura3.6.0.zip

Edited 1 time(s). Last edit at 09/18/2020 08:13AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Quote

Roberts_Clif

I have a Hictop 3DP11/12 and using Nema 17 Bipolar 1.5A 57oz.in or compatible stepper motors, I have set my Steppers according the the chart below.

Note:: Stock was running the steppers too hot, Red is a 12V and Blu is 24V 3D Printers

Stock | Red | Blu X-Axis - 0.8 .695 .395 Y-Axis - 0.8 .695 .395 Z-Axis - 1.0 1.639 .710 --- one Pair Parallel Nema 17 Bipolar 1.5A 36.6oz E0-E1 - 0.8 .695 .395

Posting My 3D Printer Cura Settings

Cura3.6.0.zip

Edited 1 time(s). Last edit at 09/18/2020 08:13AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer  September 18, 2020 11:25PM |

Registered: 3 years ago Posts: 11 |

Quote

Roberts_Clif

Sorry my 3D Printer Power Supplies voltages are backwards.

Quote

Roberts_Clif

I have a Hictop 3DP11/12 and using Nema 17 Bipolar 1.5A 57oz.in or compatible stepper motors, I have set my Steppers according the the chart below.

Note:: Stock was running the steppers too hot, Red is a 12V and Blu is 24V 3D Printers

Stock | Red | Blu X-Axis - 0.8 .695 .395 Y-Axis - 0.8 .695 .395 Z-Axis - 1.0 1.639 .710 --- one Pair Parallel Nema 17 Bipolar 1.5A 36.6oz E0-E1 - 0.8 .695 .395

Posting My 3D Printer Cura Settings

[attachment 116773 Cura3.6.0.zip]

Thanks for the settings and What you mean by power settings are backwards?

Edited 1 time(s). Last edit at 09/18/2020 11:26PM by BalajiS.

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 19, 2020 03:51AM |

Registered: 6 years ago Posts: 1,007 |

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 19, 2020 07:17AM |

Registered: 6 years ago Posts: 1,863 |

You may be correct though I have a starting point and an ending point. We start here then when we know the slicers and configurations are in at a good point.

Then we move on the the next step in this process of fine tuning of a well oiling innovative designed DIY 3D Printing solution..

I get better prints off my Two Chinese 3D Printers than I have seen from more expensive manufactured 3D Printers.

My 3D Printers are the start of this statement, many users from all over the world are getting the same results from their DIY machines some even better.

Want an example I can give you many. Starting with DIY Machines from V1 Engineering view there workings here You-Tube Video

Can not post all machines because the list is endless, and extends longer everyday, some have plans some are completely home brew.

Your design may one day be purchased my a multi-million dollar manufacture, so look forward to the fruits of your labor.

AS LOG AS YOU ARE REQUESTING HELP!

I WILL BE HERE TO HELP YOU TUNE YOUR 3D PRINTER TO THE BEST OF MY KNOWLEDGE!!!

Sorry!!!!! not yelling just being overzealous.....

One of the internet’s greatest assets is its ability for users to exchange ideas, provide each other with help

Edited 4 time(s). Last edit at 09/19/2020 07:51AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Then we move on the the next step in this process of fine tuning of a well oiling innovative designed DIY 3D Printing solution..

I get better prints off my Two Chinese 3D Printers than I have seen from more expensive manufactured 3D Printers.

My 3D Printers are the start of this statement, many users from all over the world are getting the same results from their DIY machines some even better.

Want an example I can give you many. Starting with DIY Machines from V1 Engineering view there workings here You-Tube Video

Can not post all machines because the list is endless, and extends longer everyday, some have plans some are completely home brew.

Your design may one day be purchased my a multi-million dollar manufacture, so look forward to the fruits of your labor.

AS LOG AS YOU ARE REQUESTING HELP!

I WILL BE HERE TO HELP YOU TUNE YOUR 3D PRINTER TO THE BEST OF MY KNOWLEDGE!!!

Sorry!!!!! not yelling just being overzealous.....

One of the internet’s greatest assets is its ability for users to exchange ideas, provide each other with help

Edited 4 time(s). Last edit at 09/19/2020 07:51AM by Roberts_Clif.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 21, 2020 08:49AM |

Registered: 6 years ago Posts: 1,007 |

@Roberts_Clif

I was referring to the OP machine !

The starting point is a sound design that has to be properly built, rigid and square.

The slicer config comes LAST ! It will not compensate for a flaky unreliable build.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

I was referring to the OP machine !

The starting point is a sound design that has to be properly built, rigid and square.

The slicer config comes LAST ! It will not compensate for a flaky unreliable build.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 21, 2020 01:00PM |

Registered: 6 years ago Posts: 1,863 |

@MKSA

Is there a reason why you are Insinuating most posts you respond too.

This is suppose to be RepRap 3D Printer forum, which gathers information from users worldwide that has the most informative posts.

Most users of RepRap forum have RepRap components attached to their 3D Printers of which is inquires to troubleshooting assistance.

Insinuating 3D Printer DIY builds and that they should immediately purchased a Kit is not helpful to them or to RepRap Forum.

Who knows one of his designs could very well be RepRap newest hottest sales items on the market over the next few years.

Diagnosing problems and passing information on to those reading the posts is what RepRap 3D Printer Forum was created.

@BalajiS

It was my moment of dyslexia the supply voltages from one 3D Printer to the Other were reversed.

I knew better just got by me during that post..

Computer Programmer / Electronics Technician

Is there a reason why you are Insinuating most posts you respond too.

This is suppose to be RepRap 3D Printer forum, which gathers information from users worldwide that has the most informative posts.

Most users of RepRap forum have RepRap components attached to their 3D Printers of which is inquires to troubleshooting assistance.

Insinuating 3D Printer DIY builds and that they should immediately purchased a Kit is not helpful to them or to RepRap Forum.

Who knows one of his designs could very well be RepRap newest hottest sales items on the market over the next few years.

Diagnosing problems and passing information on to those reading the posts is what RepRap 3D Printer Forum was created.

adjective: insinuating

hinting at something bad in an indirect and unpleasant way.

@BalajiS

It was my moment of dyslexia the supply voltages from one 3D Printer to the Other were reversed.

I knew better just got by me during that post..

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 21, 2020 01:37PM |

Registered: 8 years ago Posts: 1,671 |

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 21, 2020 07:04PM |

Registered: 7 years ago Posts: 619 |

Quote

Roberts_Clif

@MKSA

Is there a reason why you are Insinuating most posts you respond too.

This is suppose to be RepRap 3D Printer forum, which gathers information from users worldwide that has the most informative posts.

Most users of RepRap forum have RepRap components attached to their 3D Printers of which is inquires to troubleshooting assistance.

Insinuating 3D Printer DIY builds and that they should immediately purchased a Kit is not helpful to them or to RepRap Forum.

Who knows one of his designs could very well be RepRap newest hottest sales items on the market over the next few years.

Diagnosing problems and passing information on to those reading the posts is what RepRap 3D Printer Forum was created.

adjective: insinuating hinting at something bad in an indirect and unpleasant way.

@BalajiS

It was my moment of dyslexia the supply voltages from one 3D Printer to the Other were reversed.

I knew better just got by me during that post..

Totally with you man. I have learned a LOT from these forums. I have two completely scratch built printers that print extremely well, now. I have played with a few kits and upgraded all of them. If I had waited until I had the perfect machine before I tried to build a printer and print, I would never have started. Henry Ford didn't build the Shelby Cobra right out of the gate. Science and engineering iterate until things are good enough, and there is always someone for whom good enough, isn't. Then we iterate again.

The joy is in the journey, not the destination.

MKSA sometimes has good points, he isn't always up on the wrong side of the bed. He sometimes posts good links to the experts.

Fortunately, the experts on the lists have nearly endless patience with those of us who are re-discovering what others have often already perfected over time. Occasionally, someone comes up with something truly new and innovating - That is always worth waiting for.

It is said that science doesn't progress until the old guard dies off. Many of the "old guard" here are still interested in the ideas from the newcomers who don't know what isn't possible yet.

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 21, 2020 07:41PM |

Registered: 6 years ago Posts: 1,863 |

Quote

dlc60

MKSA sometimes has good points, he isn't always up on the wrong side of the bed. He sometimes posts good links to the experts.

Fortunately, the experts on the lists have nearly endless patience with those of us who are re-discovering what others have often already perfected over time.

Occasionally, someone comes up with something truly new and innovating - That is always worth waiting for.

It is said that science doesn't progress until the old guard dies off. Many of the "old guard" here are still interested in the ideas from the newcomers who don't know what isn't possible yet.

DLC

You make a really good point, I too am not exclusive in this, as all my ideals are still not perfected.

Wish I had more on hand knowledge of more 3D Printers. Bought a Delta though the seller did not have one to sell. Thanks for E-Bay Refunds.

@BalajiS

How is you 3D Printer troubleshooting going.

Edited 5 time(s). Last edit at 09/21/2020 08:08PM by Roberts_Clif.

Computer Programmer / Electronics Technician

Re: Help Needed - Custom Built 3d Printer - Finally Printing  September 22, 2020 07:51AM |

Registered: 8 years ago Posts: 1,671 |

Some people are just more adept at giving advice guidance(pause for thought) with fewer words, some like go through all the steps, some like to make the person think a bit harder, who here doesnt like Victor Meldrew, I've never watched that program wondering why he's in a mood or Rich Hall he's another grumpy funny guy(not sure this stuff works good in text form), I prefer direct / curt than sugar coating & waffle. A solution lies within all of the reply's.

Sorry, only registered users may post in this forum.