Heatsink pastes for hotends

Posted by leadinglights

|

Heatsink pastes for hotends September 17, 2020 11:21AM |

Registered: 12 years ago Posts: 1,450 |

Has anybody used pyrolytic graphite based heatsink compounds on their hot-end heaters? Arctic MX-4 is an example of such a compound but they offer no data on maximum temperatures.

The significance of this question is that I have used such a compound that I acquired when it was banned by a health and safety officer due to the lack of a material hazards datasheet. This compound had a thermal conductivity of 8.0 W/mK which is about twice as good as copper loaded compounds. In addition, its max working temperature was 500°C - much higher than most heatsink greases. My 1ml syringe is now empty and I need to find a replacement.

Mike

The significance of this question is that I have used such a compound that I acquired when it was banned by a health and safety officer due to the lack of a material hazards datasheet. This compound had a thermal conductivity of 8.0 W/mK which is about twice as good as copper loaded compounds. In addition, its max working temperature was 500°C - much higher than most heatsink greases. My 1ml syringe is now empty and I need to find a replacement.

Mike

|

Re: Heatsink pastes for hotends September 17, 2020 12:37PM |

Admin Registered: 11 years ago Posts: 3,096 |

I believethe throat of the hotend in a v6 is more important and besides that, when using for example a titanium throat, I do not believe the top part gets hotter than 50% of the nozzle temp. I would try to calculate how hot the contact surface really gets, I think a thermal compound with a max between 250° and 300° would be fine in most cases unless you are printing in excess of 300°.

What hotend do you use and what temperature do you print at?

http://www.marinusdebeer.nl/

What hotend do you use and what temperature do you print at?

http://www.marinusdebeer.nl/

|

Re: Heatsink pastes for hotends September 17, 2020 01:16PM |

Registered: 12 years ago Posts: 1,450 |

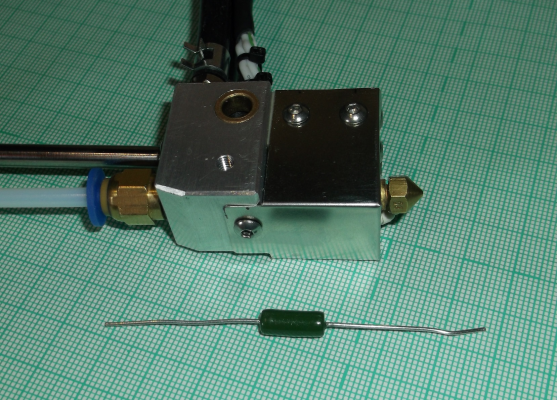

The hotend is my own design but uses a vitreous enamel wirewound resistor instead of a heater cartridge. The reason for this is that I was an early adopter of heater cartridges but they let me down badly - I have never had a WW resistor fail.

Part of the problem here is that this design uses a very small resistor which is over-run to the wazoo and beyond: The element wire temperature gets to 420°C with the block at 280°C. Although I ran resistors in dummy heater blocks at 280°C for over 1000 hours without failure to test them, the design of the resistors I use has been changed so that the outside diameter is nearly 0.4mm less than the ones I tested.

Combine the tiny resistor, the looser fit, and the lack of my miracle grease and I think you can guess why I am worried.

Mike

Part of the problem here is that this design uses a very small resistor which is over-run to the wazoo and beyond: The element wire temperature gets to 420°C with the block at 280°C. Although I ran resistors in dummy heater blocks at 280°C for over 1000 hours without failure to test them, the design of the resistors I use has been changed so that the outside diameter is nearly 0.4mm less than the ones I tested.

Combine the tiny resistor, the looser fit, and the lack of my miracle grease and I think you can guess why I am worried.

Mike

|

Re: Heatsink pastes for hotends September 17, 2020 01:46PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

leadinglights

The hotend is my own design but uses a vitreous enamel wirewound resistor instead of a heater cartridge. The reason for this is that I was an early adopter of heater cartridges but they let me down badly - I have never had a WW resistor fail.

Part of the problem here is that this design uses a very small resistor which is over-run to the wazoo and beyond: The element wire temperature gets to 420°C with the block at 280°C. Although I ran resistors in dummy heater blocks at 280°C for over 1000 hours without failure to test them, the design of the resistors I use has been changed so that the outside diameter is nearly 0.4mm less than the ones I tested.

[attachment 116760 DSCF0395B.jpg]

Combine the tiny resistor, the looser fit, and the lack of my miracle grease and I think you can guess why I am worried.

Mike

Ahhh, in that case... I used to use Holtz Firegum. It's meant to close exhaust valves I believe. My main use was to keep thermistors in place, and I'm not sure if it has any good thermal conductivity, but when it heats up it expands and then hardens even more so nothing moves around. I believe it might be more of an insulator though so that's definitely not what you're looking for. All the other thermal compounds I have used are definitely not suited for that application..

Interesting though, I also started way back with WW resistors! I even have a few hotends from back in the days

I'll see if I can dig them up.

I'll see if I can dig them up.http://www.marinusdebeer.nl/

|

Re: Heatsink pastes for hotends September 17, 2020 02:25PM |

Registered: 12 years ago Posts: 1,450 |

I have found 3 of the original 5 dummy hotend blocks that I used some years ago to do the failure test. I think I will try a repeat of the earlier test with different compounds - with and without copper shims to fill the gap. Machining new blocks to fit the resistors would be a pain - and wouldn't guarantee that the next batch would have the same diameter.

Mike

Mike

|

Re: Heatsink pastes for hotends September 17, 2020 05:02PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

leadinglights

I have found 3 of the original 5 dummy hotend blocks that I used some years ago to do the failure test. I think I will try a repeat of the earlier test with different compounds - with and without copper shims to fill the gap. Machining new blocks to fit the resistors would be a pain - and wouldn't guarantee that the next batch would have the same diameter.

Mike

Maybe I have some old replacement WW resistors laying around if you're interested?

http://www.marinusdebeer.nl/

|

Re: Heatsink pastes for hotends September 17, 2020 08:55PM |

Registered: 11 years ago Posts: 5,780 |

I use antiseize compound on everything that screws into the heater block and use plain old heatsink compound on the joint between the threaded tube and the heatsink. I can take things apart if I need to, and the extruder works fine. Is your extruder having some sort of problem?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heatsink pastes for hotends September 18, 2020 04:59AM |

Registered: 12 years ago Posts: 1,450 |

Quote

the_digital_dentist

.................. Is your extruder having some sort of problem?

I am not having any problems yet, but if I use a wirewound resistor rated at 3 Watts in air and ask it to dissipate up to 32 watts I have to be sure that the heat will get away - or I will have problems. Early trials showed that it will, but now the resistor body size has changed and most thermal compounds are likely to be inadequate for hotend use.

Mike

|

Re: Heatsink pastes for hotends December 10, 2020 11:56AM |

Registered: 12 years ago Posts: 1,450 |

I am returning to this as I have noticed several articles on Boron Nitride thermal paste. I will try Slice Engineering Mosquito Boron Nitride Paste as soon as I have got my hands on some.

Meanwhile, reporting back on a few brief trials with CPU Heatsink thermal compounds. Using my tiny 3W WW resistors and 0.05mm copper shim I did have my first ever burned out resistor when using no-name white compound although even this lasted for 80 hours. A second try with Halnziye HY610 is still happy after 200 hours when I had to shut it down as I needed the PSU. Despite it running O.K., the resistor looks distinctly charred and I am not as happy as I was with the Pyrolytic Graphite compound. Hopefully, Boron Nitride will be better.

Mike

Meanwhile, reporting back on a few brief trials with CPU Heatsink thermal compounds. Using my tiny 3W WW resistors and 0.05mm copper shim I did have my first ever burned out resistor when using no-name white compound although even this lasted for 80 hours. A second try with Halnziye HY610 is still happy after 200 hours when I had to shut it down as I needed the PSU. Despite it running O.K., the resistor looks distinctly charred and I am not as happy as I was with the Pyrolytic Graphite compound. Hopefully, Boron Nitride will be better.

Mike

|

Re: Heatsink pastes for hotends December 10, 2020 04:08PM |

Registered: 11 years ago Posts: 5,780 |

Actual heaters that are designed to transfer the heat to whatever they're mounted on cost about $5. You can even specify power and voltages. Why mess around with resistors that are not designed for the purpose?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heatsink pastes for hotends December 11, 2020 05:42AM |

Registered: 12 years ago Posts: 1,450 |

Quote

the_digital_dentist

................................................................................. Why mess around with resistors that are not designed for the purpose?

- Size. I would need a heater 5mm diameter by 12mm long and these are not generally available.

- The resistors do work reliably although this does require excellent thermal coupling.

- I tried heater cartridges in about 2012 when they first became common but I was very unimpressed by their quality.

- By avoiding the easy "just buy it" philosophy I come across potentially useful ideas - see the last two posts in [reprap.org]

- If I did fall for the "just buy it" philosophy I would probably just buy a Stratasys and be done with it.

Mike

|

Re: Heatsink pastes for hotends December 11, 2020 09:50AM |

Registered: 11 years ago Posts: 5,780 |

There's a huge difference between building a printer and buying a stratasys printer. You can get 99% of the stratasys function/performance for 5% of the cost with a DIY, and learn useful stuff along the way.

But a resistor vs a heater cartridge? You might save a few pennies after spending many hours screwing around with it, but will you be able to trust it to work for any length of time? There isn't much to be learned here besides the reason why every printer on the planet uses heater cartridges instead of resistors.

I would probably just order a heater cartridge and design and fabricate a new heater block to fit (or just enlarge the hole in the block you have). It'll cost $5 and an hour of effort and the end result will be far more reliable than a resistor slathered with some magic thermal compound.

Edited 1 time(s). Last edit at 12/13/2020 09:24AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

But a resistor vs a heater cartridge? You might save a few pennies after spending many hours screwing around with it, but will you be able to trust it to work for any length of time? There isn't much to be learned here besides the reason why every printer on the planet uses heater cartridges instead of resistors.

I would probably just order a heater cartridge and design and fabricate a new heater block to fit (or just enlarge the hole in the block you have). It'll cost $5 and an hour of effort and the end result will be far more reliable than a resistor slathered with some magic thermal compound.

Edited 1 time(s). Last edit at 12/13/2020 09:24AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heatsink pastes for hotends December 11, 2020 10:58AM |

Registered: 12 years ago Posts: 1,450 |

As I mentioned, I was an early adopter of heater cartridges back in 2012. I quickly became an early rejector of them after I purchased three batches of 5 cartridges, in both 12V and 24V ratings. Of these, a good number were rejected due to badly out of tolerance resistance or short circuits to the case. The point at which I would no longer tolerate them was when I had failures with heaters going open circuit during prints.

Heater cartridges sold for DIY 3D printers are almost certainly made on the same sort of production line that makes Christmas tree lights and outdoor solar lights and will have much the same quality control - little more than "does it work". By comparison, resistors from a reputable manufacturer will have robust quality control and little variability between resistors. If I test one and it gets more than 1000 hours of life then any variation between samples will depend on other factors - such as the thermal coupling to the heater block.

While I am not unconcerned about the possibility of failure, this is only because of the very small size of the resistors I am using, not because there is any problem with the materials or the construction of wirewound resistors which render them unsuitable for this purpose. I would also not expect a 3D printer manufacturer to use them, but this is because variables that do not affect their design intent of providing electrical resistance but would be less good in a heater. These differences, such as local enamel thickness changes, can be avoided by hand selection.

Mike

Heater cartridges sold for DIY 3D printers are almost certainly made on the same sort of production line that makes Christmas tree lights and outdoor solar lights and will have much the same quality control - little more than "does it work". By comparison, resistors from a reputable manufacturer will have robust quality control and little variability between resistors. If I test one and it gets more than 1000 hours of life then any variation between samples will depend on other factors - such as the thermal coupling to the heater block.

While I am not unconcerned about the possibility of failure, this is only because of the very small size of the resistors I am using, not because there is any problem with the materials or the construction of wirewound resistors which render them unsuitable for this purpose. I would also not expect a 3D printer manufacturer to use them, but this is because variables that do not affect their design intent of providing electrical resistance but would be less good in a heater. These differences, such as local enamel thickness changes, can be avoided by hand selection.

Mike

|

Re: Heatsink pastes for hotends December 13, 2020 08:28AM |

Registered: 6 years ago Posts: 61 |

I'll set down my popcorn long enough to say that I'm sure that your experience in 2012 is definitive and that it demonstrates that the vast majority of us who have experienced long and reliable service with heater cartridges are suffering from a mass hallucination.

I'm going to persist in my hallucination, and go back to enjoying my popcorn.

I'm going to persist in my hallucination, and go back to enjoying my popcorn.

|

Re: Heatsink pastes for hotends December 13, 2020 09:53AM |

Registered: 12 years ago Posts: 1,450 |

I did not say that heater cartridges should not be used - other than to mention that my early experience of them was not good. I doubt that anybody would use them if the quality had not rapidly improved. What I did and do reject is the_digital_dentists insistence that resistors were not suitable for this purpose. My own experience is that resistors can give long and trouble-free service. In the case of my present hotend design, no suitable cartridge is available and I have shown that even a small resistor can give good service if it is well thermally coupled to the heater block. The purpose of this thread is to look at the thermal coupling alone.

If I took the attitude that I had to use an available heater cartridge then I would have to make the hotend bigger and substantial parts of the rest of the printer would have to be redesigned.

Mike

If I took the attitude that I had to use an available heater cartridge then I would have to make the hotend bigger and substantial parts of the rest of the printer would have to be redesigned.

Mike

|

Re: Heatsink pastes for hotends December 13, 2020 10:01AM |

Registered: 11 years ago Posts: 5,780 |

Quote

leadinglights

While I am not unconcerned about the possibility of failure, this is only because of the very small size of the resistors I am using, not because there is any problem with the materials or the construction of wirewound resistors which render them unsuitable for this purpose. I would also not expect a 3D printer manufacturer to use them, but this is because variables that do not affect their design intent of providing electrical resistance but would be less good in a heater. These differences, such as local enamel thickness changes, can be avoided by hand selection.

Let's consider the construction of wirewound resistors for a moment. Do you think a 3W resistor uses the same diameter nichrome wire that a 30W resistor (or a 30W heater cartridge) uses? A resistor designed to dissipate 3W uses a wire diameter chosen so that it doesn't get too hot when dissipating 3W. If you push 30W through it, it's going to get much too hot and the wire will certainly fail sooner than it would if it were dissipating 3W. Do you think a resistor designed to get to ~60C when dissipating its rated power is likely to be made from materials that won't burn or decompose at 250C? As you pointed out yourself, variations in enamel thickness make wirewound resistors less than ideal for use as heaters. So yeah, construction does matter.

The only and last time I saw a commercial product that attempted to use a resistor as a hot-end heater was the ridiculous budaschnozzle hot-end that deservedly disappeared about 6 or 7 years ago. It used a resistor (maybe a 5W part?) for a heater, had laser cut wood parts mounted very close to the heater block, and "heatsink" fins mounted on a PTFE tube. I think it was "designed" by chimpanzees.

When was the last time you ran anything at 10x it's ratings and got reliable operation from it?

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heatsink pastes for hotends December 13, 2020 10:31AM |

Registered: 12 years ago Posts: 1,450 |

Quote

the_digital_dentist

...................................... Do you think a 3W resistor uses the same diameter nichrome wire that a 30W resistor (or a 30W heater cartridge) uses?............................................

Hmm, If I find that it does, will you stop being so negative? Or is that too much to hope for?

Mike

|

Re: Heatsink pastes for hotends December 13, 2020 10:49AM |

Registered: 11 years ago Posts: 5,780 |

Far too much. I will remain firmly rooted in reality.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heatsink pastes for hotends December 13, 2020 12:05PM |

Registered: 12 years ago Posts: 1,450 |

Alternative realities then? The Donald would be proud.

Incidentally, this is almost a reprise of a discussion we had back in 2016 [reprap.org] where you were concerned that a PTFE insulated wire could get as hot as 350°C In reality (that word again) the temperature rise above ambient was 53°C so the PTFE would never get above say 163°C with the plate at 110°C.

Mike

Incidentally, this is almost a reprise of a discussion we had back in 2016 [reprap.org] where you were concerned that a PTFE insulated wire could get as hot as 350°C In reality (that word again) the temperature rise above ambient was 53°C so the PTFE would never get above say 163°C with the plate at 110°C.

Mike

|

Re: Heatsink pastes for hotends December 14, 2020 09:30AM |

Registered: 11 years ago Posts: 5,780 |

More likely the Dunning-Kruger effect than politics...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heatsink pastes for hotends December 14, 2020 10:10AM |

Registered: 12 years ago Posts: 1,450 |

|

Re: Heatsink pastes for hotends December 14, 2020 11:01AM |

Registered: 12 years ago Posts: 1,450 |

Since even the best crafted insults can only offer so much entertainment, I will go back to my main pleasure, the making of new and challenging things.

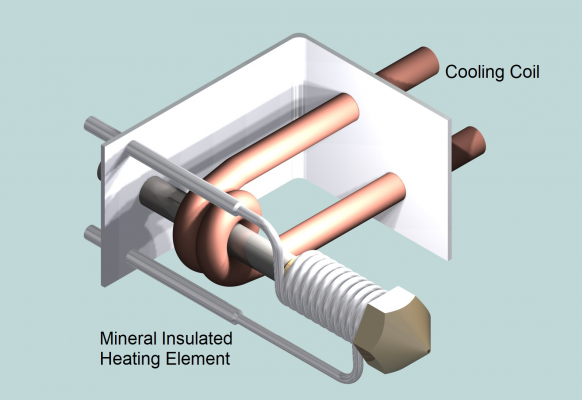

I have been looking at a simple, very lightweight hotend to be used in a small Delta printer with a heated enclosure. I made a prototype hotend pictured below which weighs in at only 7 grams but have not yet made a good heater for it. A promising avenue is mineral insulated heating elements and I have attached a CAD rendering of a hotend with one of these elements on it. In this case, the heating element is silver-soldered directly to the brass tubular body to which the nozzle mounts. This should neatly sidestep the issue of finding heatsink compounds.

Meanwhile, in the absence of any recommendations pro or anti, I will be using Boron Nitride heatsink compound on my existing printer - complete with its 3W wire-wound resistor elements. In the unlikely event of premature resistor failure, I will report that event on this forum. Incidentally, since the Tech Talk subforum appears on lt attract web indexing bots and the occasional misguided person who thinks "RepRap" is something salacious, I will keep to this subforum in the future.

Mike

I have been looking at a simple, very lightweight hotend to be used in a small Delta printer with a heated enclosure. I made a prototype hotend pictured below which weighs in at only 7 grams but have not yet made a good heater for it. A promising avenue is mineral insulated heating elements and I have attached a CAD rendering of a hotend with one of these elements on it. In this case, the heating element is silver-soldered directly to the brass tubular body to which the nozzle mounts. This should neatly sidestep the issue of finding heatsink compounds.

Meanwhile, in the absence of any recommendations pro or anti, I will be using Boron Nitride heatsink compound on my existing printer - complete with its 3W wire-wound resistor elements. In the unlikely event of premature resistor failure, I will report that event on this forum. Incidentally, since the Tech Talk subforum appears on lt attract web indexing bots and the occasional misguided person who thinks "RepRap" is something salacious, I will keep to this subforum in the future.

Mike

|

Re: Heatsink pastes for hotends December 23, 2020 04:22AM |

Registered: 7 years ago Posts: 321 |

If it was me, I'd present this to the local health and safety killjoy and ask them what objections they had to it.

[www.arctic.de]

Not a joke, direct link from the manufacturer (scroll down to the bottom of the page). Perhaps Arctic have an English language version of a hazardous safety document on one of their pyrolitic jobbies?

[www.arctic.de]

It is RoHs compliant at least in English certified as non-hazardous material.

[www.arctic.de]

One other thing... I'd have thought you wanted heat resistant on a heatbreak connection screwing into a heatblock. You'd want heat conductive plugging the heatbreak into the cooler.

EDIT: I'm not particularly plugging that as an alternative, but I think it's a case of talk to the manufacturer about your requirements. The problem with any new heating solution is getting RoHs compliance.

Edited 2 time(s). Last edit at 12/23/2020 04:41AM by DragonFire.

[www.arctic.de]

Not a joke, direct link from the manufacturer (scroll down to the bottom of the page). Perhaps Arctic have an English language version of a hazardous safety document on one of their pyrolitic jobbies?

[www.arctic.de]

It is RoHs compliant at least in English certified as non-hazardous material.

[www.arctic.de]

One other thing... I'd have thought you wanted heat resistant on a heatbreak connection screwing into a heatblock. You'd want heat conductive plugging the heatbreak into the cooler.

EDIT: I'm not particularly plugging that as an alternative, but I think it's a case of talk to the manufacturer about your requirements. The problem with any new heating solution is getting RoHs compliance.

Edited 2 time(s). Last edit at 12/23/2020 04:41AM by DragonFire.

|

Re: Heatsink pastes for hotends December 23, 2020 05:58AM |

Registered: 12 years ago Posts: 1,450 |

Thanks DragonFire. I did look at selected parts of the datasheet using Google Translate. There doesn't seem to be any noteworthy acute or chronic toxicological effects.

I did find the spec sheet for MX2 interesting as the kind of temperature drops on load and at idle are pretty much in line with my tests although this is at a somewhat different temperature.

I have now got some Slice Engineering Boron Nitride paste and will be trying it in a couple of hotends using several new batches of tiny wire-wound resistors. The test method is to measure the resistance of each resistor at high temperature using 6.5 digit meters for voltage and current. Each one will then be run with different thermal compounds at high temperature until failure or for 1000 hours.

The acid test will be when they are tested under working conditions with heat being withdrawn through the plastic and also with repeated switching on and off - I think that exactly which "Magic Gloop" is used will be important.

I don't expect to be doing much on this until January at the earliest. I have too much on my plate with software and hardware problems with my toggling hotend, not to mention trying to get into the Christmas spirit and dodging vagrant viral particles.

Edit: I just found a materials safety datasheet [arctic-m.com] which shows that MX-4 contains 5-10% of mono-crystalline diamond but doesn't mention pyrolytic graphite. The paste I used before was > 66% pyrolytic graphite.

Mike

Edited 1 time(s). Last edit at 12/23/2020 07:10AM by leadinglights.

I did find the spec sheet for MX2 interesting as the kind of temperature drops on load and at idle are pretty much in line with my tests although this is at a somewhat different temperature.

I have now got some Slice Engineering Boron Nitride paste and will be trying it in a couple of hotends using several new batches of tiny wire-wound resistors. The test method is to measure the resistance of each resistor at high temperature using 6.5 digit meters for voltage and current. Each one will then be run with different thermal compounds at high temperature until failure or for 1000 hours.

The acid test will be when they are tested under working conditions with heat being withdrawn through the plastic and also with repeated switching on and off - I think that exactly which "Magic Gloop" is used will be important.

I don't expect to be doing much on this until January at the earliest. I have too much on my plate with software and hardware problems with my toggling hotend, not to mention trying to get into the Christmas spirit and dodging vagrant viral particles.

Edit: I just found a materials safety datasheet [arctic-m.com] which shows that MX-4 contains 5-10% of mono-crystalline diamond but doesn't mention pyrolytic graphite. The paste I used before was > 66% pyrolytic graphite.

Mike

Edited 1 time(s). Last edit at 12/23/2020 07:10AM by leadinglights.

|

Re: Heatsink pastes for hotends December 23, 2020 10:54AM |

Registered: 7 years ago Posts: 321 |

From what I understand, most kinds of thermal paste just dry out. The boron formulation usually steams a bit on first heating, that's normal.

I don't think there are any permanent solutions, they all fall apart sooner or later.

Only reason I'm kind of interested is I'm mulling modding a v5 cold end with an M7 tap and seeing if a real e3D titanium heatbreak will fit well enough. The tricky part is getting the depth of cut just right. Even then I'm not convinced it would be a tight enough fit.

One of those Okazaki heating elements in a heating block could be awesome. I don't really know enough about them.

Edited 1 time(s). Last edit at 12/23/2020 11:09AM by DragonFire.

I don't think there are any permanent solutions, they all fall apart sooner or later.

Only reason I'm kind of interested is I'm mulling modding a v5 cold end with an M7 tap and seeing if a real e3D titanium heatbreak will fit well enough. The tricky part is getting the depth of cut just right. Even then I'm not convinced it would be a tight enough fit.

One of those Okazaki heating elements in a heating block could be awesome. I don't really know enough about them.

Edited 1 time(s). Last edit at 12/23/2020 11:09AM by DragonFire.

|

Re: Heatsink pastes for hotends December 23, 2020 02:01PM |

Registered: 12 years ago Posts: 1,450 |

I agree that most pastes will dry out at FFF printing nozzle temperatures; but if they maintain sufficient flexibility to give a few years of service over a few thousand heating/cooling cycles, that should be enough for a practical heater.

I can't give any input on V5 cold ends or e3D titanium heatbreaks as I know nothing about them. This is not because I find any fault with them, but what I am trying to do is find ways of building things, like 3D printers for example, with the minimum possible of purchased parts, but with whatever scientific and technological knowledge and skills is needed.

Thank you for the pointer to Okazaki heating elements - had not found them myself although I have found several others. So far nothing that would make for a small enough heater coil with enough resistance that a higher voltage/lower current could be used. An example of this is that Okazakis smallest micro heater has a resistance of 26.9Ω/m. The available space is sufficient for only about 3.3Ω, somewhat too low for a practical heater.

There is an interesting nozzle heater on [www.youtube.com] from Friedr. Freek GmbH. I think this example is only 4mm inside diameter.

Mike

I can't give any input on V5 cold ends or e3D titanium heatbreaks as I know nothing about them. This is not because I find any fault with them, but what I am trying to do is find ways of building things, like 3D printers for example, with the minimum possible of purchased parts, but with whatever scientific and technological knowledge and skills is needed.

Thank you for the pointer to Okazaki heating elements - had not found them myself although I have found several others. So far nothing that would make for a small enough heater coil with enough resistance that a higher voltage/lower current could be used. An example of this is that Okazakis smallest micro heater has a resistance of 26.9Ω/m. The available space is sufficient for only about 3.3Ω, somewhat too low for a practical heater.

There is an interesting nozzle heater on [www.youtube.com] from Friedr. Freek GmbH. I think this example is only 4mm inside diameter.

Mike

|

Re: Heatsink pastes for hotends February 21, 2021 07:12AM |

Registered: 12 years ago Posts: 1,450 |

Just a quick report back and a further question.

I have used a new "magic gloop" called Mosquito Boron Nitride Paste [reprapworld.co.uk] which seems to be doing the job. I have now fed several meters of filament through a hotend at 230°C and the resistance of the element does not seem to change.

Down to the question. So far I have simply looked at the temperature chart from Repetier Host to see how much additional power is used to melt the filament, as compared to the heat that is simply lost to radiation and convection. As the charts have not really told me anything, has anybody got data on how many Watts of heating power is actually used in the melt process.

Mike

I have used a new "magic gloop" called Mosquito Boron Nitride Paste [reprapworld.co.uk] which seems to be doing the job. I have now fed several meters of filament through a hotend at 230°C and the resistance of the element does not seem to change.

Down to the question. So far I have simply looked at the temperature chart from Repetier Host to see how much additional power is used to melt the filament, as compared to the heat that is simply lost to radiation and convection. As the charts have not really told me anything, has anybody got data on how many Watts of heating power is actually used in the melt process.

Mike

|

Re: Heatsink pastes for hotends February 24, 2021 11:35AM |

Registered: 12 years ago Posts: 1,450 |

Hmm, so nobody can offer a real-world measurement of how much energy is used to melt the plastic filament. My best calculations, based on 100cm³ of ABS per hour is that this takes about 8W while observations show that about 11W is needed to counter losses to the environment. The hotend heats up from 20°C to 230°C in a little less than 2 minutes which seems to be a lot faster than with the no-name white heatsink compound or the Halnziye HY610 - foolishly, I didn't time how long it took to heat up with those compounds though.

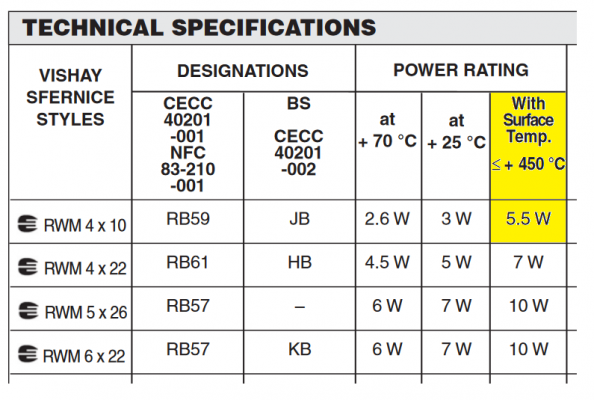

The resistor itself seems to be well able to tolerate working at these higher temperatures as it took quite a bit of abuse to get one to fail in 80 hours at 280°C. The picture below is an excerpt from the Vishay datasheet for these resistors [www.farnell.com] Note the highlighted bit showing operation at 450°C

One correspondent tells me that the most likely cause of failure is frequent cycling of the spot-welded joint between the resistor element wire and the resistor end caps.

Mike

The resistor itself seems to be well able to tolerate working at these higher temperatures as it took quite a bit of abuse to get one to fail in 80 hours at 280°C. The picture below is an excerpt from the Vishay datasheet for these resistors [www.farnell.com] Note the highlighted bit showing operation at 450°C

One correspondent tells me that the most likely cause of failure is frequent cycling of the spot-welded joint between the resistor element wire and the resistor end caps.

Mike

|

Re: Heatsink pastes for hotends February 24, 2021 04:41PM |

Registered: 4 years ago Posts: 285 |

|

Re: Heatsink pastes for hotends February 25, 2021 09:07AM |

Registered: 12 years ago Posts: 1,450 |

Thanks, rq3. That was exactly on topic. For the moment though, I will simply list the companies for future investigation as, with fingers crossed, I have a suitable material.

Coltronics, in particular, appears to have a wide range of potentially suitable thermally conductive fillers although none of these companies seem to have a visible presence in the U.K.

Mike

Coltronics, in particular, appears to have a wide range of potentially suitable thermally conductive fillers although none of these companies seem to have a visible presence in the U.K.

Mike

Sorry, only registered users may post in this forum.