Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB

Posted by doublec4

|

Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB October 31, 2020 10:48PM |

Registered: 3 years ago Posts: 2 |

Hi all, new to this forum, I wanted to share my latest project. Hopefully some people here might find the resources I've provided useful if you wish to modify your similar printer

[youtu.be]

So I converted a Dremel 3D20 printer (similar to Makerbot Replicator, Wanhao Duplicator, Flashforge Inventor) to Duet 2 Wifi control, Panel Due 5" touch screen, kinematic mount bed levelling system, custom spool holder, all metal hot end, and a hot swap PCB hot end.

The original printer was getting hung up around the same layer and exhibiting some other strange behaviors. Some of the hot end wiring was also shorting out. It was destined for scrap but I found that the mechanical parts of the printer were overall pretty solid and it was a decent printer despite being old (2014?). I figured the control system was the first thing that needed to go and it sort of snow balled from there...

I made the design files available for people with similar printers:

Duet Wifi Mount, Due Panel 5" Mount, End Stop Modifiers, Power Supply Adapters:

► [www.thingiverse.com]

Kinematic Mount Bed Levelling System:

► [www.thingiverse.com]

Three point bed levelling system using kinematic mount principles.

I designed this for use with a Dremel 3D20 printer but should also work on flashforge inventor or Wanhao / Makerbot variants of the same printer, possibly with some modifications.

PVC Spool Holder:

► [www.thingiverse.com]

PVC spool holder to adapt 3/4" Schedule 40 PVC pipe to hold filament above your printer for the most direct and restriction free feed.

The feet can be screwed to your work table, printer enclosure, shelf, etc and two PVC pipe will be fitted upright. The elbows hold a horizontal piece of PVC in place. It can be easily lifted for quick removal of filament.

The bearing and collars adapt the PVC OD to the eSUN filament ID of the spool. The collars keep the spool centered on the PVC pipe. They are intended to be a light friction fit over the PVC pipe to stay in place. Screws can be added if more friction is desired to clamp the collars tightly around the pipe.

Hot End Parts and Schematic:

► [www.thingiverse.com]

The hot swap PCB accommodates 2 part cooling fans, 1 extruder fan, 1 aux connection, thermistor, heater cartridge (24V only, 40W max), and the extruded motor connections.

RJ45 jacks are required to accept the network cables (should be cat5e with 24AWG stranded wire, unshielded twisted pair). Any 2.54mm (0.1") connectors should fit the other connection locations. (I used JST connectors for my printer).

350W 24V Power Supply:

► [www.digitmakers.ca]

Heater Block:

► [www.digitmakers.ca]

MicroSwiss Hot End:

► [www.digitmakers.ca]

E3D Thermistor:

► [www.digitmakers.ca]

24V 40W Heater Cartridge:

► [www.digitmakers.ca]

RJ45 Jack for PCB:

► [www.digikey.com]

Let me know if you guys have any questions I would love to discuss my project if you guys have any input!

[youtu.be]

So I converted a Dremel 3D20 printer (similar to Makerbot Replicator, Wanhao Duplicator, Flashforge Inventor) to Duet 2 Wifi control, Panel Due 5" touch screen, kinematic mount bed levelling system, custom spool holder, all metal hot end, and a hot swap PCB hot end.

The original printer was getting hung up around the same layer and exhibiting some other strange behaviors. Some of the hot end wiring was also shorting out. It was destined for scrap but I found that the mechanical parts of the printer were overall pretty solid and it was a decent printer despite being old (2014?). I figured the control system was the first thing that needed to go and it sort of snow balled from there...

I made the design files available for people with similar printers:

Duet Wifi Mount, Due Panel 5" Mount, End Stop Modifiers, Power Supply Adapters:

► [www.thingiverse.com]

Kinematic Mount Bed Levelling System:

► [www.thingiverse.com]

Three point bed levelling system using kinematic mount principles.

I designed this for use with a Dremel 3D20 printer but should also work on flashforge inventor or Wanhao / Makerbot variants of the same printer, possibly with some modifications.

PVC Spool Holder:

► [www.thingiverse.com]

PVC spool holder to adapt 3/4" Schedule 40 PVC pipe to hold filament above your printer for the most direct and restriction free feed.

The feet can be screwed to your work table, printer enclosure, shelf, etc and two PVC pipe will be fitted upright. The elbows hold a horizontal piece of PVC in place. It can be easily lifted for quick removal of filament.

The bearing and collars adapt the PVC OD to the eSUN filament ID of the spool. The collars keep the spool centered on the PVC pipe. They are intended to be a light friction fit over the PVC pipe to stay in place. Screws can be added if more friction is desired to clamp the collars tightly around the pipe.

Hot End Parts and Schematic:

► [www.thingiverse.com]

The hot swap PCB accommodates 2 part cooling fans, 1 extruder fan, 1 aux connection, thermistor, heater cartridge (24V only, 40W max), and the extruded motor connections.

RJ45 jacks are required to accept the network cables (should be cat5e with 24AWG stranded wire, unshielded twisted pair). Any 2.54mm (0.1") connectors should fit the other connection locations. (I used JST connectors for my printer).

350W 24V Power Supply:

► [www.digitmakers.ca]

Heater Block:

► [www.digitmakers.ca]

MicroSwiss Hot End:

► [www.digitmakers.ca]

E3D Thermistor:

► [www.digitmakers.ca]

24V 40W Heater Cartridge:

► [www.digitmakers.ca]

RJ45 Jack for PCB:

► [www.digikey.com]

Let me know if you guys have any questions I would love to discuss my project if you guys have any input!

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 02, 2020 12:51AM |

Registered: 6 years ago Posts: 1,007 |

- A steel acorn nut against a plastic surface is not a very good choice for such mount.

- Looking at the bed, part 22 roll mount made out of plastic, the way it is attached to the glass/heater,composite plate can you explain how it is a "kinematic mount" ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

- Looking at the bed, part 22 roll mount made out of plastic, the way it is attached to the glass/heater,composite plate can you explain how it is a "kinematic mount" ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 02, 2020 11:15PM |

Registered: 3 years ago Posts: 2 |

Quote

MKSA

- A steel acorn nut against a plastic surface is not a very good choice for such mount.

- Looking at the bed, part 22 roll mount made out of plastic, the way it is attached to the glass/heater,composite plate can you explain how it is a "kinematic mount" ?

I printed those black mounting pieces from nylon carbon fiber. There *should be* no relative movement between the cap nut and the plastic parts... so far I haven't seen any wear on the plastic component.

Hopefully it is not false advertising, but I designed the 3 mounting points based on the kinematic mounting principles (of how I understand them at least):

[wp.optics.arizona.edu]

One of the screws (back left, part 22) is the reference adjustment (cone shape receptacle on the round cap nut), the second screw (back right, part 22) is the pitch adjustment (slotted cone shape receptacle on the round cap nut), the third screw (foremost, part 10) is the roll adjustment (flat plane on the round cap nut). For some reason on the BOM, the part number and description of those two parts is sort of at odds with one another. Not sure how they got reversed.

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 02, 2020 11:57PM |

Registered: 6 years ago Posts: 1,007 |

Quote

doublec4

Quote

MKSA

- A steel acorn nut against a plastic surface is not a very good choice for such mount.

- Looking at the bed, part 22 roll mount made out of plastic, the way it is attached to the glass/heater,composite plate can you explain how it is a "kinematic mount" ?

I printed those black mounting pieces from nylon carbon fiber. There *should be* no relative movement between the cap nut and the plastic parts... so far I haven't seen any wear on the plastic component.

Hopefully it is not false advertising, but I designed the 3 mounting points based on the kinematic mounting principles (of how I understand them at least):

[wp.optics.arizona.edu]

One of the screws (back left, part 22) is the reference adjustment (cone shape receptacle on the round cap nut), the second screw (back right, part 22) is the pitch adjustment (slotted cone shape receptacle on the round cap nut), the third screw (foremost, part 10) is the roll adjustment (flat plane on the round cap nut). For some reason on the BOM, the part number and description of those two parts is sort of at odds with one another. Not sure how they got reversed.

-THERE IS relative movement, it is why it works.

- Apply the principles explained in the link to your "build" !. Why this kind of mount and how it works (or NOT) here ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 03, 2020 06:18AM |

Registered: 12 years ago Posts: 1,450 |

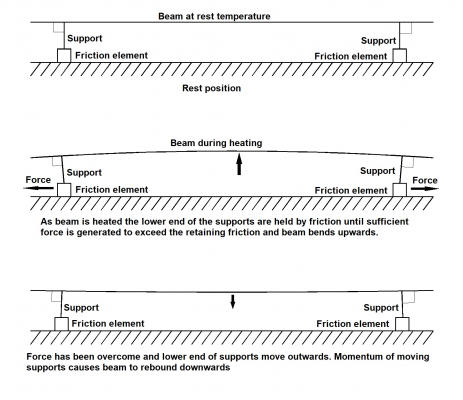

As far as I can see, your kinematic mount should work satisfactorily although you may find unwanted behavior with heating or cooling of the build stage. This is caused by slip-stick friction as the bed expands or contracts.

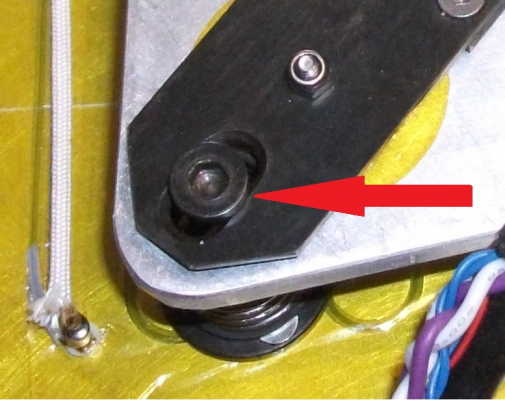

On my printer, I used Maxwell type kinematic mounts and found the middle of the bed could rise and fall by up to 50 microns. Picture below of one of the three mounts with an arrow pointing to a friction surface. I have also attached a diagram of stick-slip behavior.

The temporary answer seems to be to lubricate the sliding surfaces with extreme pressure grease which seems to keep this stick-slip to a few microns. If I were to redesign this I would shorten the adjusting screws to bring the plane of the build surface as close to the Maxwell mount as possible.

Mike

On my printer, I used Maxwell type kinematic mounts and found the middle of the bed could rise and fall by up to 50 microns. Picture below of one of the three mounts with an arrow pointing to a friction surface. I have also attached a diagram of stick-slip behavior.

The temporary answer seems to be to lubricate the sliding surfaces with extreme pressure grease which seems to keep this stick-slip to a few microns. If I were to redesign this I would shorten the adjusting screws to bring the plane of the build surface as close to the Maxwell mount as possible.

Mike

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 05, 2020 07:50PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 05, 2020 09:49PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 05, 2020 10:03PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Revived a Dremel 3D20... Duet 2 Wifi, PanelDue, kinematic bed, hot swap PCB November 06, 2020 04:57AM |

Registered: 12 years ago Posts: 1,450 |

Quote

MKSA

Quote

leadinglights

As far as I can see, your kinematic mount should work satisfactorily although you may find unwanted behavior with heating or cooling of the build stage....

Mike

No, it doesn't.

Hmmm, you may be right or you may be wrong. When I looked at the video from doublec4 I saw a Kelvin kinematic mount with tension springs to maintain a seating force. Within the constraints of RepRap engineering and of printed plastics, it should work satisfactorily. Although I was tempted to view this video again to see what you claim to see that I had missed, I won't do that without a clue as to what you saw - I am not here to waste my time on trolls. It is surely up to you to give details - that after all is what the o.p. asked for.

And two points in passing. The contradiction of "As far as I can see, your kinematic mount should work satisfactorily" is No it won't, not no it doesn't. Your English could do with some improvement.

The other point is that your tag line "A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t) is still stupid. Whether a comical prototype merely evinces a wry grin or pandemic-roll-on-floor-die-laughing is immaterial. The test is only if the comical prototype works in which case the idea is possible and hence, not dumb.

Edit: in the next post you say

Quote

MKSA

I saw that too plus other issues.

Anyway.

Also unhepful, which issues?

Mike

Edited 2 time(s). Last edit at 11/06/2020 09:49AM by leadinglights.

Sorry, only registered users may post in this forum.