recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended)

Posted by ayozek

|

recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) June 29, 2021 05:56AM |

Registered: 2 years ago Posts: 22 |

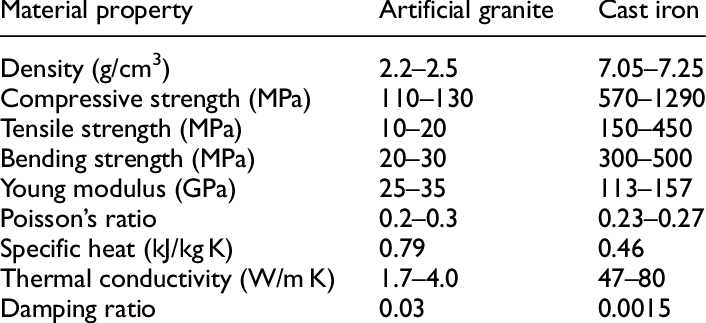

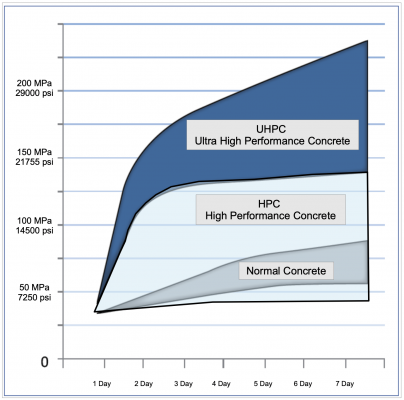

hi, to make green, cheap and accessible the construction of numerical rep-rap machines there can be used recycled plastics with different fillers or blends, ultra high performance geopolymer concrete UHPGC that uses recycled materials from industrial processes as slag or silica fume that can have 450Mpa of compressive strength, bio based epoxy conglomerate (called epoxy granite), milled stone as well as upcycled metal from doors, windows, etc that have aluminum profiles or recycled aluminum to create aluminum foam.

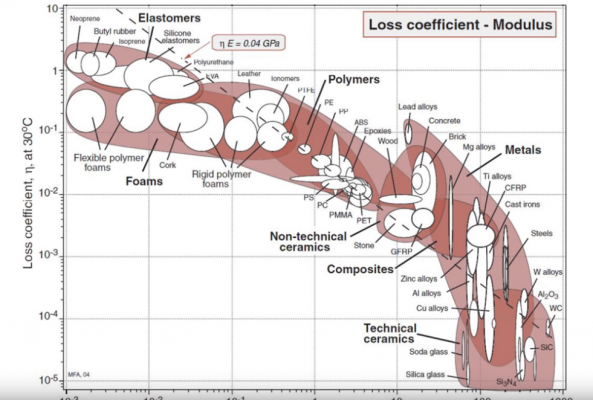

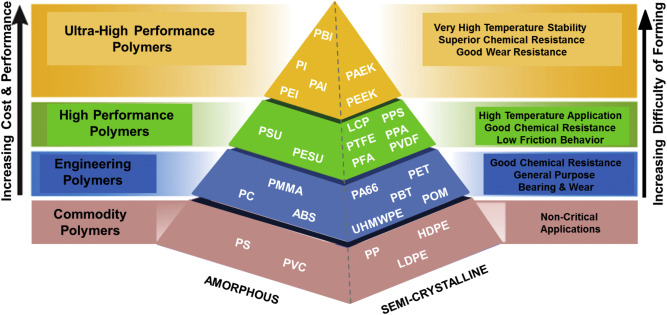

in the case of numerical machines structural materials, there are different factors to consider as dimensional stability and accuracy, creep (deformation), warping, shrinkage, stiffness, compressive and tensile strength and and the less talked, loss coefficient which means vibration damping measured in transmissibility and natural frequency that affects all numerical machines reducing accuracy, requiring more structural material to compensate the oscillation created by propagated vibration, and increasing stress to all the machine parts. so contrary to the established use of finite resources as metal in the numerical machine industry, reinforced recycled or biobased thermoplastics are more appropriate as structural materials for numerical machines rather than commonly used aluminum extrusion that only offers certain dimensional stability.

there are two approaches to make composite structures:

-reinforced thermoplastic structures with holes filled with continuous fiber reinforced UHPGC or biobased epoxy conglomerate, or assembled with recycled metal casting strings, upcycled metal beams or aluminum extrusion profiles or milled stone for compressive strength

-all those materials pointed above in sandwich structures using thermoplastic core that can be lattice, foam, honeycomb or corrugated as well as upcycled styrofoam and recycled metal foam or vesicular stone core that have good damping as well.

apart from the structural material damping there are other ways to reduce vibration:

-pneumatic steppers made with reinforced thermoplastic, they reduce weight and vibration in comparison to electric rotor

-by building a machine structure in a single or few pieces reduces incremental vibration created by loose parts.

-using a concrete base under the machine with foam pads

https://www.researchgate.net/publication/315075656_Vibration_Damping_Analysis_of_Lightweight_Structures_in_Machine_Tools

https://www.youtube.com/watch?v=pCU7H6Yyrmw

in the case of available recyclable plastics i would chose HDPE and PP for vibration damping, for structural applications PET has good stiffness and with proper fillings can be used as high performance structural material and also has good tribological properties for gears, bearings etc, that also can be improved with fillings. there can be used nylon from carpets for tribology and other thermoplastics and blends with other recycled plastics can be considered too to improve properties for those uses.

https://www.researchgate.net/publication/317209487_Effect_of_Material_Constituents_on_Mechanical_and_Fracture_Mechanics_Properties_of_Ultra-High-Performance_Concrete

structural materials for frames and connecting parts

+matrix materials

-recycled plastic

-UHPGP with recycled slag

-bio based epoxy

+fillings for longitudinal stiffness, tensile strength and less warping

-continuous fiber reinforcement, it can be pre-stressed to improve stiffness

--lignin based carbon fiber

--glass fiber

--basalt fiber

--clothing fabric

+fillings for compressive strength, hardness and dimensional stability

-aggregates

--micro aggregates

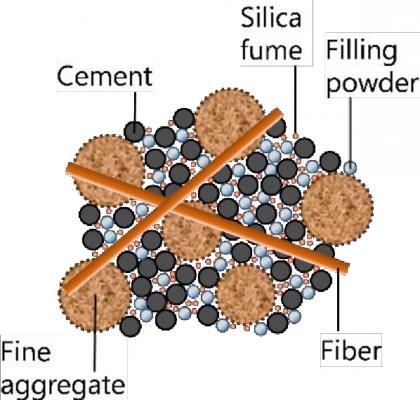

---silica fume, is the the basis for strength for UHPGC and bioepoxy or sand filled plastic

---silica fume replacement or combination

----glass powder

----rice husk ash

--sand filling, the round shape of cleaned sand granules from beaches or rivers give excellent results, there's no need for crushed granite. High-strength concrete with different fine aggregate

-short fibers with different length

--lignin based or recycled carbon fiber

--glass fiber

--basalt fiber

--steel fibers

+additives

-superplasticier polycarboxylate to reduce water content in UHPGC

materials for tribology

+uses

-rack and roller pinion, theres no need for precision metal rods and screws

-pneumatic steppers, reduce weight and vibration in comparison to electric rotor

-bearings

-gears

+recycled plastics

-PET

-nylon from carpets

+fillers

-short glass fiber

-silica fume

-cellulose

-wood dust

-additives for self-lubricant properties

processes to make the parts

+strengthen processes

-UHPGC

--vacuum mixing, reduces voids. Vacuum mixing technology to improve the mechanical properties of ultra-high performance concrete

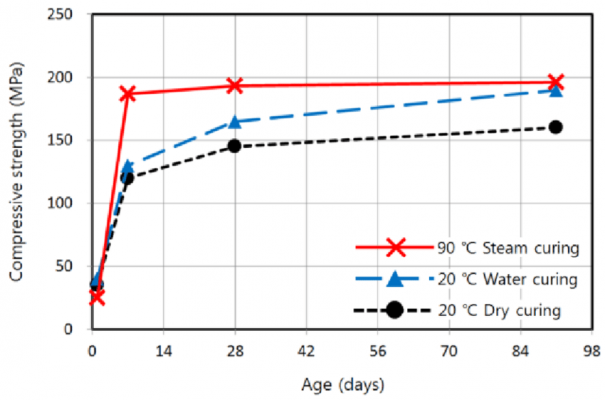

--heat treatment with 90ºc steam during the first 24-48 hours. with concentrated solar steam or molten salt steam during the night

-bioepoxy conglomerate

--vacuum mixing

-filled thermoplastics

--vacuum mixing

--long curing rate, maybe avoids annelation

--annelation with fine salt in oven

-IMPORTANT. vibration can be counterproductive because can reduce heterogeneity and reduce isotropy

+mold making for UHPGC, bioepoxy and plastic molding or casting

-male molds made with machined soy wax with wax recuperation female mold making process

-female molds

--two parts concrete molds with UHPGC for injection or compression molding

---for smaller parts rather than compression molding, the mold can be preheated and so the plastic can be poured instead of injected

--single use casting mold with plaster of paris recovered with recycling process

--3d printed mold

+post process for final dimensional accuracy after shrinkage

-table saw

-cnc milling

Edited 25 time(s). Last edit at 07/01/2021 05:46AM by ayozek.

in the case of numerical machines structural materials, there are different factors to consider as dimensional stability and accuracy, creep (deformation), warping, shrinkage, stiffness, compressive and tensile strength and and the less talked, loss coefficient which means vibration damping measured in transmissibility and natural frequency that affects all numerical machines reducing accuracy, requiring more structural material to compensate the oscillation created by propagated vibration, and increasing stress to all the machine parts. so contrary to the established use of finite resources as metal in the numerical machine industry, reinforced recycled or biobased thermoplastics are more appropriate as structural materials for numerical machines rather than commonly used aluminum extrusion that only offers certain dimensional stability.

there are two approaches to make composite structures:

-reinforced thermoplastic structures with holes filled with continuous fiber reinforced UHPGC or biobased epoxy conglomerate, or assembled with recycled metal casting strings, upcycled metal beams or aluminum extrusion profiles or milled stone for compressive strength

-all those materials pointed above in sandwich structures using thermoplastic core that can be lattice, foam, honeycomb or corrugated as well as upcycled styrofoam and recycled metal foam or vesicular stone core that have good damping as well.

apart from the structural material damping there are other ways to reduce vibration:

-pneumatic steppers made with reinforced thermoplastic, they reduce weight and vibration in comparison to electric rotor

-by building a machine structure in a single or few pieces reduces incremental vibration created by loose parts.

-using a concrete base under the machine with foam pads

https://www.researchgate.net/publication/315075656_Vibration_Damping_Analysis_of_Lightweight_Structures_in_Machine_Tools

https://www.youtube.com/watch?v=pCU7H6Yyrmw

in the case of available recyclable plastics i would chose HDPE and PP for vibration damping, for structural applications PET has good stiffness and with proper fillings can be used as high performance structural material and also has good tribological properties for gears, bearings etc, that also can be improved with fillings. there can be used nylon from carpets for tribology and other thermoplastics and blends with other recycled plastics can be considered too to improve properties for those uses.

https://www.researchgate.net/publication/317209487_Effect_of_Material_Constituents_on_Mechanical_and_Fracture_Mechanics_Properties_of_Ultra-High-Performance_Concrete

structural materials for frames and connecting parts

+matrix materials

-recycled plastic

-UHPGP with recycled slag

-bio based epoxy

+fillings for longitudinal stiffness, tensile strength and less warping

-continuous fiber reinforcement, it can be pre-stressed to improve stiffness

--lignin based carbon fiber

--glass fiber

--basalt fiber

--clothing fabric

+fillings for compressive strength, hardness and dimensional stability

-aggregates

--micro aggregates

---silica fume, is the the basis for strength for UHPGC and bioepoxy or sand filled plastic

---silica fume replacement or combination

----glass powder

----rice husk ash

--sand filling, the round shape of cleaned sand granules from beaches or rivers give excellent results, there's no need for crushed granite. High-strength concrete with different fine aggregate

-short fibers with different length

--lignin based or recycled carbon fiber

--glass fiber

--basalt fiber

--steel fibers

+additives

-superplasticier polycarboxylate to reduce water content in UHPGC

materials for tribology

+uses

-rack and roller pinion, theres no need for precision metal rods and screws

-pneumatic steppers, reduce weight and vibration in comparison to electric rotor

-bearings

-gears

+recycled plastics

-PET

-nylon from carpets

+fillers

-short glass fiber

-silica fume

-cellulose

-wood dust

-additives for self-lubricant properties

processes to make the parts

+strengthen processes

-UHPGC

--vacuum mixing, reduces voids. Vacuum mixing technology to improve the mechanical properties of ultra-high performance concrete

--heat treatment with 90ºc steam during the first 24-48 hours. with concentrated solar steam or molten salt steam during the night

-bioepoxy conglomerate

--vacuum mixing

-filled thermoplastics

--vacuum mixing

--long curing rate, maybe avoids annelation

--annelation with fine salt in oven

-IMPORTANT. vibration can be counterproductive because can reduce heterogeneity and reduce isotropy

+mold making for UHPGC, bioepoxy and plastic molding or casting

-male molds made with machined soy wax with wax recuperation female mold making process

-female molds

--two parts concrete molds with UHPGC for injection or compression molding

---for smaller parts rather than compression molding, the mold can be preheated and so the plastic can be poured instead of injected

--single use casting mold with plaster of paris recovered with recycling process

--3d printed mold

+post process for final dimensional accuracy after shrinkage

-table saw

-cnc milling

Edited 25 time(s). Last edit at 07/01/2021 05:46AM by ayozek.

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 11:06AM |

Registered: 2 years ago Posts: 22 |

update:

structural materials for frames and connecting parts

+fillings for vibration damping for parts without much horizontal deflection as towers

-plastic beads

-polystyrene beads

+composite materials assembly parts (useful for parts with horizontal deflection as beams), they can be screwed or glued, because fibers have poor adhesion with concrete and combining plates increases recyclability while making plates usable for other uses and combined create different specs as weight, vibration and structural strength properties.

-continuous fiber reinforced plastic - uhpgc concrete - plastic foam structure. ( the most recyclable and interchangeable or modular option )

--continuous fiber reinforced thermoplastic plate for tensile strength, there can be used recycled ABS

--ugpgc plate for dimensional stability and compressive strength

--3d printed thermoplastic with foam structure or other structure for vibration damping

-epoxy impregnated continuous fiber ugpgc - plastic foam structure. for dimensional stability

-epoxy impregnated fibers thermoplastic - uhpc - plastic foam structure. for tensile strength and low weight, this epoxy-plastic mix is used by anisotropy printers

Edited 2 time(s). Last edit at 08/14/2021 01:20PM by ayozek.

structural materials for frames and connecting parts

+fillings for vibration damping for parts without much horizontal deflection as towers

-plastic beads

-polystyrene beads

+composite materials assembly parts (useful for parts with horizontal deflection as beams), they can be screwed or glued, because fibers have poor adhesion with concrete and combining plates increases recyclability while making plates usable for other uses and combined create different specs as weight, vibration and structural strength properties.

-continuous fiber reinforced plastic - uhpgc concrete - plastic foam structure. ( the most recyclable and interchangeable or modular option )

--continuous fiber reinforced thermoplastic plate for tensile strength, there can be used recycled ABS

--ugpgc plate for dimensional stability and compressive strength

--3d printed thermoplastic with foam structure or other structure for vibration damping

-epoxy impregnated continuous fiber ugpgc - plastic foam structure. for dimensional stability

-epoxy impregnated fibers thermoplastic - uhpc - plastic foam structure. for tensile strength and low weight, this epoxy-plastic mix is used by anisotropy printers

Edited 2 time(s). Last edit at 08/14/2021 01:20PM by ayozek.

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 12:37PM |

Admin Registered: 16 years ago Posts: 13,884 |

... if you're intereted, how ressources can be badly dumped or wasted, then look for chinese "tofu-dreg" projects

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 01:14PM |

Registered: 2 years ago Posts: 22 |

reported for hate speech towards the asian community, please remove this disgraceful comment from this thread and i hope you make an apology or get expelled from this forum,

you are making prejudiced generalizations or smears based in xenophobia and cultural or racial supremacy, you aren't even talking about contamination showing any linked evidence but using this argument to attack the asian community without facts.

i do not reply nor play the game with racial supremacists, for them i only use exposing, shaming, rejection or violence if necessary.

there must be other forum administrators that can expel, ban you or remove your hate speech comments in the following days, if that's not the case i will erase my account and this thread content and post in other forum that doesn't allow racial supremacy

Edited 14 time(s). Last edit at 08/14/2021 04:39PM by ayozek.

you are making prejudiced generalizations or smears based in xenophobia and cultural or racial supremacy, you aren't even talking about contamination showing any linked evidence but using this argument to attack the asian community without facts.

i do not reply nor play the game with racial supremacists, for them i only use exposing, shaming, rejection or violence if necessary.

there must be other forum administrators that can expel, ban you or remove your hate speech comments in the following days, if that's not the case i will erase my account and this thread content and post in other forum that doesn't allow racial supremacy

Edited 14 time(s). Last edit at 08/14/2021 04:39PM by ayozek.

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 01:46PM |

Admin Registered: 16 years ago Posts: 13,884 |

... "hate speech towards the asian community"?

Nope -- it's simply the sad truth

[en.wikipedia.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Nope -- it's simply the sad truth

[en.wikipedia.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 03:53PM |

Admin Registered: 15 years ago Posts: 1,470 |

I’m sorry, but I don’t see how VDX’s comments can be construed as “hate speech”.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 04:16PM |

Registered: 2 years ago Posts: 22 |

hate speech not only encompass violent acts or insults but also normalized hate as smears, "jokes" or systemic racism or "microracism"

to report his smears i have to brand them as hate speech, his smears are based in xenophobia, which is hate, fear, dislike of or prejudice against people from other countries

Edited 1 time(s). Last edit at 08/14/2021 04:17PM by ayozek.

to report his smears i have to brand them as hate speech, his smears are based in xenophobia, which is hate, fear, dislike of or prejudice against people from other countries

Edited 1 time(s). Last edit at 08/14/2021 04:17PM by ayozek.

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 04:49PM |

Registered: 12 years ago Posts: 1,450 |

I find it hard to find anything in the posting by VDX that appears to be what ayozek is complaining about - perhaps not capitalizing the word Chinese??

Finding the conduct of a nation reprehensible does not equate with insulting the peoples of that nation as that conduct is primarily a result of government policies. "Tofu-Dreg" appears to be an appelation given by the Chinese people themselves to these projects and the blame for these will exist in some part of the government without blame attaching to the people or even to any other part of the government.

Mike

Quote

VDX

... if you're intereted, how ressources can be badly dumped or wasted, then look for chinese "tofu-dreg" projects

Finding the conduct of a nation reprehensible does not equate with insulting the peoples of that nation as that conduct is primarily a result of government policies. "Tofu-Dreg" appears to be an appelation given by the Chinese people themselves to these projects and the blame for these will exist in some part of the government without blame attaching to the people or even to any other part of the government.

Mike

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 05:07PM |

Registered: 2 years ago Posts: 22 |

i am not questioning resource waste by manufacturing process but scapegoating an entire community, country, race as if they are the only resource wasters

it's only a xenophobic remark that only fuels prejudice and hate toward the asians and chinese and also a classist smear because those things are consumed by the lower classes

however there's the paradox while talking about tech class because by buying a low end reprap machine (anet a8 for example) and making appropriate tuning with diy solutions through experimentation or application of scientific papers anyone can reach similar or more specs than available industrial grade machines constrained by future market sales projection with drip upgrading, piled up costs, patents, market size, marketing, etc

Edited 6 time(s). Last edit at 08/14/2021 05:25PM by ayozek.

it's only a xenophobic remark that only fuels prejudice and hate toward the asians and chinese and also a classist smear because those things are consumed by the lower classes

however there's the paradox while talking about tech class because by buying a low end reprap machine (anet a8 for example) and making appropriate tuning with diy solutions through experimentation or application of scientific papers anyone can reach similar or more specs than available industrial grade machines constrained by future market sales projection with drip upgrading, piled up costs, patents, market size, marketing, etc

Edited 6 time(s). Last edit at 08/14/2021 05:25PM by ayozek.

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 05:33PM |

Registered: 12 years ago Posts: 1,450 |

Quoting from your earlier posting

Do you realize that threatening violence is actually illegal in most countries. Another point, quoting again from your last post, you use a term which could be construed as being intended to insult a large number of people and characterizes anybody disagreing with your world view as being "lower classes"

While I could report you for the implied threat of violence, I won't because I believe that high emotions and even strong opinions have no place in this forum. Finishing with yet another quote

Mike

Quote

ayozek

...............i do not reply nor play the game with racial supremacists, for them i only use exposing, shaming, rejection or violence if necessary. .............

Do you realize that threatening violence is actually illegal in most countries. Another point, quoting again from your last post, you use a term which could be construed as being intended to insult a large number of people and characterizes anybody disagreing with your world view as being "lower classes"

Quote

ayozek

.................. it's only a xenophobic remark that only fuels prejudice and hate and also classist smear because those things are consumed by the lower classes .....................

While I could report you for the implied threat of violence, I won't because I believe that high emotions and even strong opinions have no place in this forum. Finishing with yet another quote

Quote

King James Bible

First, remove the beam out of your own eye, and then you can see clearly to remove the speck out of your brother's eye.

Mike

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 05:43PM |

Registered: 2 years ago Posts: 22 |

you live in a class society just like any hierarchy or caste based society, you are either high class, middle class or low class.

yes i will proudly use my right to commit an act of physical violence against anyone invading my space or public space with hate speech as it happened in uk during the battle of cable street, and i know that you are using this argument as an hyperbole to silence me or get me banned

what's your reason behind defending a racist comment or try to find twisted arguments to deny talking about racism?

Edited 1 time(s). Last edit at 08/14/2021 05:45PM by ayozek.

yes i will proudly use my right to commit an act of physical violence against anyone invading my space or public space with hate speech as it happened in uk during the battle of cable street, and i know that you are using this argument as an hyperbole to silence me or get me banned

what's your reason behind defending a racist comment or try to find twisted arguments to deny talking about racism?

Edited 1 time(s). Last edit at 08/14/2021 05:45PM by ayozek.

|

Re: recycled plastics,metals and geopolymers, biopolymers for numerical machines (extended) August 14, 2021 06:00PM |

Admin Registered: 16 years ago Posts: 13,884 |

... before this dispute gets out of control (or ist it already?) I'll close this thread and will observe the further development ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, you can't reply to this topic. It has been closed.