Skienforge help, Huxley bowden fix, New hot tip

Posted by owism8

|

Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 06:28AM |

Registered: 13 years ago Posts: 248 |

Hello All,

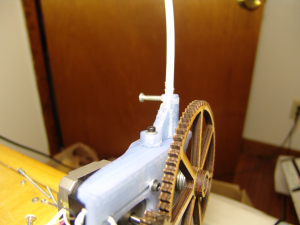

Ive finally got my huxley to print a decent part. But to fix that I had to purchase a totally different type of hot tip, mentioned on the Below post. Also I had to put screws on each end of the bowden to ensure the cable doesnt release.

All in all, Im trying to print out a prusa as soon as I can before this huxley dies on me so I at least get my money's worth. I wasted 600$ with techzone.

Please dont make the same mistake I did...

Here is the post! [omemon.wordpress.com]

Anyone Who can help me make the screw holes nicer, please let me know which setting I should change in Skienforge.

Also this print took 3 hours. Any way to increase the speed without giving up on the decent print? I notice it speeds up while filling, but while printing it is slower. Any tips?

Also in the beginning skienforge raised my tip a little. Where is the setting for that?

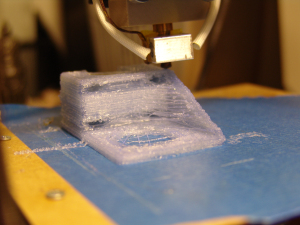

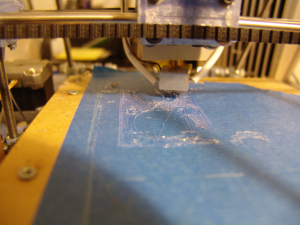

here is my first layer:

Thanks all!

[omemon.wordpress.com]

Ive finally got my huxley to print a decent part. But to fix that I had to purchase a totally different type of hot tip, mentioned on the Below post. Also I had to put screws on each end of the bowden to ensure the cable doesnt release.

All in all, Im trying to print out a prusa as soon as I can before this huxley dies on me so I at least get my money's worth. I wasted 600$ with techzone.

Please dont make the same mistake I did...

Here is the post! [omemon.wordpress.com]

Anyone Who can help me make the screw holes nicer, please let me know which setting I should change in Skienforge.

Also this print took 3 hours. Any way to increase the speed without giving up on the decent print? I notice it speeds up while filling, but while printing it is slower. Any tips?

Also in the beginning skienforge raised my tip a little. Where is the setting for that?

here is my first layer:

Thanks all!

[omemon.wordpress.com]

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 07:32AM |

Registered: 13 years ago Posts: 226 |

Hi,

I too had the problem where the tip raises slightly at the beginning - and I believe (please correct me if i'm wrong Skeinforge experts) that the Bottom module has to be turned off. At least that's what worked for me.

Also, if the Raft module is turned on then the first layer will print slower, unless you change the rate (I forget the exact name of the parameter at the moment). Have a look in the Limit module whether your overall mm/s is limited. Finally, if the Cool module is turned on and set to "Slow Down" this can also affect how fast a layer prints.

Hope this helps.

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

I too had the problem where the tip raises slightly at the beginning - and I believe (please correct me if i'm wrong Skeinforge experts) that the Bottom module has to be turned off. At least that's what worked for me.

Also, if the Raft module is turned on then the first layer will print slower, unless you change the rate (I forget the exact name of the parameter at the moment). Have a look in the Limit module whether your overall mm/s is limited. Finally, if the Cool module is turned on and set to "Slow Down" this can also affect how fast a layer prints.

Hope this helps.

Gary

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 07:52AM |

Registered: 13 years ago Posts: 248 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 08:08AM |

Registered: 13 years ago Posts: 818 |

I believe OOzebane is just for DC motor extruders, so leave it off.

You should have extruder reversal set to at least 2mm. I use 3mm in my Bowden and get nice clean prints (It's not a Huxley though).

[richrap.blogspot.com]

You should have extruder reversal set to at least 2mm. I use 3mm in my Bowden and get nice clean prints (It's not a Huxley though).

[richrap.blogspot.com]

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 08:15AM |

Registered: 13 years ago Posts: 226 |

I don't use oozebane, rather I use the option to retract the filament mechanically using the Dimension module.

I'm actually part way through building a Huxley class printer, using parts from the various designs that are floating around (emaker, techzone, mini-mendel, huxley). I'm about to embark on the Xcarriage and hotend design and would be interested to hear more about the problems you had with the bowden cable. Was it the stability of the cable in the extruder and hot end that causes the problem, or does the whole setup have inherent problems?

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

I'm actually part way through building a Huxley class printer, using parts from the various designs that are floating around (emaker, techzone, mini-mendel, huxley). I'm about to embark on the Xcarriage and hotend design and would be interested to hear more about the problems you had with the bowden cable. Was it the stability of the cable in the extruder and hot end that causes the problem, or does the whole setup have inherent problems?

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 11:48AM |

Admin Registered: 12 years ago Posts: 2,569 |

I also am a lil bit disappointed about the techzone huxley kit, I will post a sum up once I got it fully built - that is if I can.

Question : wasn't the inner size of the bowden ptfe cable provided by techzone a problem for you ?

Myself got one with inner diameter being exactly 3 mm, while the filament you can find around - and even the one they provide - have a diameter which is variating slightly, sometime passing a lil bit over that average 3 mm dimension.

I bought a replacement tube from the german reprap foundation, which is 3.2 mm, just a bit bigger but should avoid the filament pushing the tube - didn't have time to fully test it yet.

Question : wasn't the inner size of the bowden ptfe cable provided by techzone a problem for you ?

Myself got one with inner diameter being exactly 3 mm, while the filament you can find around - and even the one they provide - have a diameter which is variating slightly, sometime passing a lil bit over that average 3 mm dimension.

I bought a replacement tube from the german reprap foundation, which is 3.2 mm, just a bit bigger but should avoid the filament pushing the tube - didn't have time to fully test it yet.

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 02:56PM |

Registered: 13 years ago Posts: 248 |

Hey Gary,

Do you use Relative or Absolute?

The bowden is working fine now but the problem was that the cable always got pushed out due to the pressure of the extrusion.

You can see where I put the nails in to keep the cable from slipping. [omemon.wordpress.com]

Besides that , you just have to find out how you want the extruder to sit on the table since its separate from the rest of the machine. I have it sitting in a clamp.

Thanks for your help

Do you use Relative or Absolute?

The bowden is working fine now but the problem was that the cable always got pushed out due to the pressure of the extrusion.

You can see where I put the nails in to keep the cable from slipping. [omemon.wordpress.com]

Besides that , you just have to find out how you want the extruder to sit on the table since its separate from the rest of the machine. I have it sitting in a clamp.

Thanks for your help

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 02:57PM |

Registered: 13 years ago Posts: 248 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 03:34PM |

Registered: 13 years ago Posts: 226 |

@owism8 I use absolute. Here are the rest of my Dimension settings if it helps:

dimension

Activate Dimension : True

Absolute Extrusion Distance : True

Relative Extrusion Distance : False

Extruder Retraction Speed (mm/s): : 15.0

Filament Diameter (mm): : 2.8

Filament Packing Density (ratio): : 1.0

Retraction Distance (millimeters): : 1.5

Restart Extra Distance (millimeters): : 0.0

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

dimension

Activate Dimension : True

Absolute Extrusion Distance : True

Relative Extrusion Distance : False

Extruder Retraction Speed (mm/s): : 15.0

Filament Diameter (mm): : 2.8

Filament Packing Density (ratio): : 1.0

Retraction Distance (millimeters): : 1.5

Restart Extra Distance (millimeters): : 0.0

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 27, 2011 06:16PM |

Registered: 13 years ago Posts: 248 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 28, 2011 12:48AM |

Registered: 13 years ago Posts: 226 |

From my understanding the retraction is usually very short (~2-5mm) and so it doesn't get a chance to get to full speed anyway.

One thing I have noticed on my extruders is that, over time, the hexagonal hole that secures the bolt to the large gear wears down a little, and a slight delay comes into play when the retraction happens. I remedied this by wrapping the bolt head in plumbing tape (the thin, white vinyl -type stuff used to make the threads on pipes watertight) which seems to work well so far. I mention this because perhaps a higher retraction speed causes more stress on the bolt and gear - but it's only a hypothesis.

In short: I don't think going to 50mm/s would bring any advantage.

Cheers,

G.

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

One thing I have noticed on my extruders is that, over time, the hexagonal hole that secures the bolt to the large gear wears down a little, and a slight delay comes into play when the retraction happens. I remedied this by wrapping the bolt head in plumbing tape (the thin, white vinyl -type stuff used to make the threads on pipes watertight) which seems to work well so far. I mention this because perhaps a higher retraction speed causes more stress on the bolt and gear - but it's only a hypothesis.

In short: I don't think going to 50mm/s would bring any advantage.

Cheers,

G.

------------------------------------------

garyhodgson.com/reprap | reprap.development-tracker.info | thingtracker.net

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 28, 2011 04:10AM |

Registered: 12 years ago Posts: 1,611 |

Here's a picture of my setup (it has toothed belts now, much more accurate!), which has a Bowden cable held at each end by an M5 nut countersunk into the wood, with wide washers holding them in. I used PT1/8x3/16 tubing from [www.adtech.co.uk] . I also ordered some thicker-walled tubing, 3.2mm ID by 6.4mm OD, though it was easier to work with the smaller tubing, which performs fine. This German Reprap foundation page sells PTFE tubing for Bowden cables: [shop.grrf.de] and is specified the same as the adtech tubing I am using at 1/8" ID x 3/16" OD or Internal Diameter: 3.2mm, External Diameter: 4.72mm metric. This wiki page [www.reprap.org] has links to various thingiverse items that can act as clamps.

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 28, 2011 07:02AM |

Registered: 13 years ago Posts: 248 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 29, 2011 03:28AM |

Glad to know I'm not the only one with a problematic huxley from Techzone. I agree with your plan, print a mendel and quit using the piece of junk. Its been nothing but trouble from the start. Worse, it took them over two weeks to send me the filament I ordered. I see most people seem to be having trouble with the bowden tube pushing out, but when I built mine I followed the advice on the build wiki and put the two M6 nuts on the end. Unfortunately, the extruder is pushing out the hot end from the X carriage. This is frustrating since its already damaged by (brand new, unused) heated bed. I blame this however on the software they suggested (RepSnapper).

Also, the build wiki said the monolithic electronics come with the firmware installed. This is only partially true. The opto end stops they provide are inverting, but the firmware is set for non-inverting, so you have to edit the firmware and re-install it. I'm hoping to have all this fixed soon so I can just give up and build a mendel, or maybe making my own (big) repstrap.

Also, the build wiki said the monolithic electronics come with the firmware installed. This is only partially true. The opto end stops they provide are inverting, but the firmware is set for non-inverting, so you have to edit the firmware and re-install it. I'm hoping to have all this fixed soon so I can just give up and build a mendel, or maybe making my own (big) repstrap.

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 29, 2011 07:43AM |

Registered: 13 years ago Posts: 248 |

Yeah the hot tip needs to also be screwedin from the top. See the photo here:

The hot tip will die very soon as Ive had two die on me so far because of the plastic oozing the brass tip out of the PTFE.

So I purchased another from a reprap user Cdnreprap for $45, and it works great.

The firmware is also not prepared for the latest skeinforge.

The hot tip will die very soon as Ive had two die on me so far because of the plastic oozing the brass tip out of the PTFE.

So I purchased another from a reprap user Cdnreprap for $45, and it works great.

The firmware is also not prepared for the latest skeinforge.

|

Re: Skienforge help, Huxley bowden fix, New hot tip June 29, 2011 07:09PM |

Registered: 12 years ago Posts: 179 |

From what I've seen, TechZone's hot end is the weakest point in their design. It's got two problems that I can see.

First is that it uses a very specialized thermocouple interface chip to read the hot end's temperature. The serial communications needed to read that chip are easily disrupted by timing issues within the microcontroller, and by noise from the heater MOSFET. I've seen my hotend go well above the set temperature when MOSFET noise is messing it up.

Second, the nozzle, heater and thermal mass are all the same piece (a 7mm brass tube). This means that changing the nozzle requires a complete rebuild of the hot end.

It's use of PEEK as a structural element also concerns me, because PEEK doesn't hold up well to an overheated hot end. I can't say that there are any good alternatives though - using stainless bolts to transfer forces around the PEEK simply results in conducting heat around the PEEK.

First is that it uses a very specialized thermocouple interface chip to read the hot end's temperature. The serial communications needed to read that chip are easily disrupted by timing issues within the microcontroller, and by noise from the heater MOSFET. I've seen my hotend go well above the set temperature when MOSFET noise is messing it up.

Second, the nozzle, heater and thermal mass are all the same piece (a 7mm brass tube). This means that changing the nozzle requires a complete rebuild of the hot end.

It's use of PEEK as a structural element also concerns me, because PEEK doesn't hold up well to an overheated hot end. I can't say that there are any good alternatives though - using stainless bolts to transfer forces around the PEEK simply results in conducting heat around the PEEK.

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 01, 2011 09:35AM |

Registered: 16 years ago Posts: 824 |

I wouldn't be so quick to blame everything on Techzone. Yes, their kits are challenging to build, and tune, and the documentation may be all over the place, but keep in mind that there is a significant learning curve to RepRap, even for those of us who build and sell kits.

The likely cause of the nozzle pushing out is too much force being produced by the Bowden extruder. I mean, look how big that gear is! The stepper motor probably does not need to work very hard to drive that filament through, so there is no way to release excess tension if the amount extruded is not keeping up with the feed into the nozzle. When this is the case, only two things can occur:

1. The plastic will find other ways to escape, i.e. Oozing up and out the sides of the thermal barrier.

2. Push out the nozzle.

The first remedy to try is to reduce the stepper motor current to just above the point where the motor stalls. The ideal setting allows the stepper motor to backlash when too much tension is built up, without stripping the filament. You will see this as the big gear turning backwards rapidly at intervals during extrusion.

If it not possible to induce tension release in this manner, you may need a bigger nozzle opening. Not the best solution, but look at what the alternative is. You either let the plastic out the way it's supposed to come out, or you let it make its own exit.

I've made this offer in the past to Techzone owners with one taker so far: If you want me to have a look, and fix up your machine, send it to me, or bring it by (if you are in Southern California). I'll make whaterever repairs you want and demonstrate the results. I've got a couple of IP cameras that you can view if you are far from me.

If it's too far for you. Maybe you can post a request to someone local. It would be a real waste to not use that machine after such effort has been put into maiking it work, and I don't believe that there is a fundamental flaw that will prevent it from working reliably.

Regards,

-Wildseyed-

The likely cause of the nozzle pushing out is too much force being produced by the Bowden extruder. I mean, look how big that gear is! The stepper motor probably does not need to work very hard to drive that filament through, so there is no way to release excess tension if the amount extruded is not keeping up with the feed into the nozzle. When this is the case, only two things can occur:

1. The plastic will find other ways to escape, i.e. Oozing up and out the sides of the thermal barrier.

2. Push out the nozzle.

The first remedy to try is to reduce the stepper motor current to just above the point where the motor stalls. The ideal setting allows the stepper motor to backlash when too much tension is built up, without stripping the filament. You will see this as the big gear turning backwards rapidly at intervals during extrusion.

If it not possible to induce tension release in this manner, you may need a bigger nozzle opening. Not the best solution, but look at what the alternative is. You either let the plastic out the way it's supposed to come out, or you let it make its own exit.

I've made this offer in the past to Techzone owners with one taker so far: If you want me to have a look, and fix up your machine, send it to me, or bring it by (if you are in Southern California). I'll make whaterever repairs you want and demonstrate the results. I've got a couple of IP cameras that you can view if you are far from me.

If it's too far for you. Maybe you can post a request to someone local. It would be a real waste to not use that machine after such effort has been put into maiking it work, and I don't believe that there is a fundamental flaw that will prevent it from working reliably.

Regards,

-Wildseyed-

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 01, 2011 09:51AM |

Registered: 13 years ago Posts: 248 |

Thanks for the feedback.

Ive been trying to do some Bridge calibration with Skeinforge using [www.thingiverse.com]

I set the Bridge feed rate multiplyer to 2.5 and its still sagging. Any tips? Other changes i can make in skeinforge?

Thanks

Ive been trying to do some Bridge calibration with Skeinforge using [www.thingiverse.com]

I set the Bridge feed rate multiplyer to 2.5 and its still sagging. Any tips? Other changes i can make in skeinforge?

Thanks

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 01, 2011 12:41PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 02, 2011 05:47AM |

Registered: 13 years ago Posts: 248 |

nozzle is .5mm

layer thickness is .35mm

I was told in the chat to try with a fan and I did but it seems that skeinforge is making the connection a little weird so the bridge actually doesnt fully contact the other side. So its just a flaw in the calibration model. I'll try with a hollow cube which is on thingiverse.

Also How can I tell skeinforge to bring my machine back to home after the print is done? I get tense over this and watch my machine for hours just to make sure I press the home buttons .

.

Thanks!

layer thickness is .35mm

I was told in the chat to try with a fan and I did but it seems that skeinforge is making the connection a little weird so the bridge actually doesnt fully contact the other side. So its just a flaw in the calibration model. I'll try with a hollow cube which is on thingiverse.

Also How can I tell skeinforge to bring my machine back to home after the print is done? I get tense over this and watch my machine for hours just to make sure I press the home buttons

.

. Thanks!

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 14, 2011 02:06AM |

Registered: 13 years ago Posts: 1,918 |

owism8 Wrote:

-------------------------------------------------------

> Also How can I tell skeinforge to bring my machine

> back to home after the print is done? I get tense

> over this and watch my machine for hours just to

> make sure I press the home buttons .

.

>

> Thanks!

You just have to put "G28" into the alteration file end.gcode. Then it appends this command to your G-Code.

-------------------------------------------------------

> Also How can I tell skeinforge to bring my machine

> back to home after the print is done? I get tense

> over this and watch my machine for hours just to

> make sure I press the home buttons

.

. >

> Thanks!

You just have to put "G28" into the alteration file end.gcode. Then it appends this command to your G-Code.

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 14, 2011 05:27AM |

Registered: 13 years ago Posts: 248 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 14, 2011 06:50AM |

Registered: 13 years ago Posts: 1,780 |

You shouldn't put this command, G28, into your end.gcode file. You might crash the head into the part that you just printed. Just move the Y axis all the way to the end or near the end and leave it there. For the Mendel, it would be G1 Y200.0 F3000.0.

Edited 1 time(s). Last edit at 07/14/2011 06:51AM by brnrd.

Edited 1 time(s). Last edit at 07/14/2011 06:51AM by brnrd.

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 14, 2011 07:24AM |

Registered: 14 years ago Posts: 3,742 |

I agree - I personally use

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

G1 X100.0 Y200.0 F2000.0

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 14, 2011 01:55PM |

Registered: 13 years ago Posts: 248 |

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 14, 2011 02:19PM |

Registered: 14 years ago Posts: 3,742 |

You can find the GCodes reference on the wiki.

M104: Set Extruder Temperature (Fast)

Example: M104 S190

M140: Bed Temperature (Fast)

Example: M140 S55

Set the temperature of the build bed to 55oC and return control to the host immediately (i.e. before that temperature has been reached by the bed).

M141: Chamber Temperature (Fast)

Example: M141 S30

Set the temperature of the chamber to 30oC and return control to the host immediately (i.e. before that temperature has been reached by the chamber).

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

M104: Set Extruder Temperature (Fast)

Example: M104 S190

M140: Bed Temperature (Fast)

Example: M140 S55

Set the temperature of the build bed to 55oC and return control to the host immediately (i.e. before that temperature has been reached by the bed).

M141: Chamber Temperature (Fast)

Example: M141 S30

Set the temperature of the chamber to 30oC and return control to the host immediately (i.e. before that temperature has been reached by the chamber).

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 16, 2011 05:40PM |

What are all the settings in skienforge? I was using techzones 3dtoolchain site to convert my .stl and there site is always up and down.

Also I have attached a bracket to the top of my huxley and shortened the tube lenght to only about 12 inches with better print quality due to there being less slop but still not perfect.

Also I have attached a bracket to the top of my huxley and shortened the tube lenght to only about 12 inches with better print quality due to there being less slop but still not perfect.

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 19, 2011 11:12AM |

Registered: 12 years ago Posts: 9 |

I attach my Skeinforge settings for printing in PLA. I found that most of the defaults work will, but I had two major issues.

First, The firmware way needs to be calibrated before using with skeinforge. The biggest problem calibration issue was regarding the extrude steps. The default is something like 12 and the actual number I ended up using was 166.

Second, I had issues with my z axis not moving because it was get in commands to move to fast. I had to use the limit pluggin with a low limit and To add some bogus homing code to "isolate the z axis". see this forum for more info if you have this problem

[forums.reprap.org]

Aside those issues

I am using the skirt plug to get my extruder flowing

My Feed rate = my flow rate = my travel feed rate

I am using dimensions to get my E commands and using a retract of 4 mm at 10 mm/s

--- I still get string but I have had trouble with the pla getting stuck in the boden cable (not the hotend) so I'm leary of to much movement

I am using multiply at round 50 x and y to get my peices centered.

I am print without a raft but with the raft setting on and no raft layers (to slow down the first pring)

I am currently testing out the comb pluging lower string in holes

First, The firmware way needs to be calibrated before using with skeinforge. The biggest problem calibration issue was regarding the extrude steps. The default is something like 12 and the actual number I ended up using was 166.

Second, I had issues with my z axis not moving because it was get in commands to move to fast. I had to use the limit pluggin with a low limit and To add some bogus homing code to "isolate the z axis". see this forum for more info if you have this problem

[forums.reprap.org]

Aside those issues

I am using the skirt plug to get my extruder flowing

My Feed rate = my flow rate = my travel feed rate

I am using dimensions to get my E commands and using a retract of 4 mm at 10 mm/s

--- I still get string but I have had trouble with the pla getting stuck in the boden cable (not the hotend) so I'm leary of to much movement

I am using multiply at round 50 x and y to get my peices centered.

I am print without a raft but with the raft setting on and no raft layers (to slow down the first pring)

I am currently testing out the comb pluging lower string in holes

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 20, 2011 01:29PM |

Registered: 13 years ago Posts: 248 |

I found this to be the best from the Gcodes reference from the forum:

[objects.reprap.org]

G28 X0 Y72.3

This will move X and Y back home but will leave Z where it is.

I will try this out.

[objects.reprap.org]

G28 X0 Y72.3

This will move X and Y back home but will leave Z where it is.

I will try this out.

|

Re: Skienforge help, Huxley bowden fix, New hot tip July 20, 2011 03:18PM |

Registered: 13 years ago Posts: 1,780 |

Sorry, only registered users may post in this forum.