Part-cooling fan for PLA

Posted by qrp-gaijin

|

Part-cooling fan for PLA September 26, 2021 07:10AM |

Registered: 3 years ago Posts: 93 |

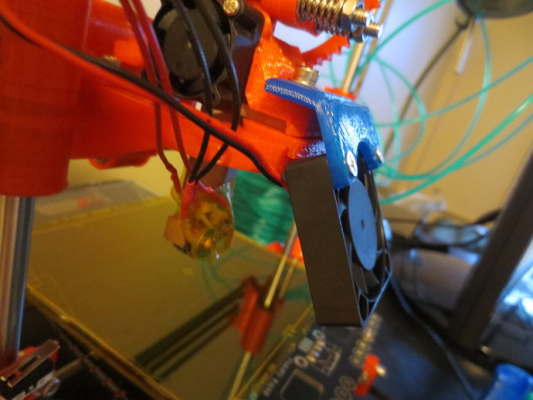

I'm planning on adding a part-cooling fan to my Portabee printer as follows:

[www.thingiverse.com]

Now, I recall reading that the fan should cool the part, and not the hot end. Do you think I need to make some kind of a duct to channel the air only to the tip of the hot end, or will the above setup likely work well enough as shown? I'm now using a V6 clone hot end.

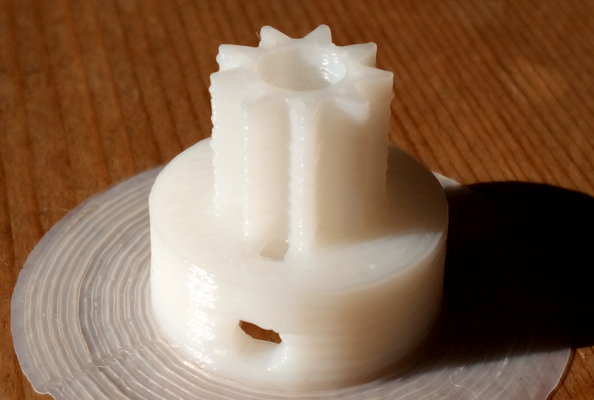

My goal for adding the fan is to allow me to print small detailed parts like this gear with small teeth. Currently, to print this gear, I have to print 2 copies in opposite corners of the print bed, to allow for passive cooling as the print head moves from one copy to the other. Without this, the layers for the gear teeth are laid down too fast before the previous layers can cool, leading to a blobby, melted mess.

[web.archive.org]

Edited 1 time(s). Last edit at 09/26/2021 07:11AM by qrp-gaijin.

[www.thingiverse.com]

Now, I recall reading that the fan should cool the part, and not the hot end. Do you think I need to make some kind of a duct to channel the air only to the tip of the hot end, or will the above setup likely work well enough as shown? I'm now using a V6 clone hot end.

My goal for adding the fan is to allow me to print small detailed parts like this gear with small teeth. Currently, to print this gear, I have to print 2 copies in opposite corners of the print bed, to allow for passive cooling as the print head moves from one copy to the other. Without this, the layers for the gear teeth are laid down too fast before the previous layers can cool, leading to a blobby, melted mess.

[web.archive.org]

Edited 1 time(s). Last edit at 09/26/2021 07:11AM by qrp-gaijin.

|

Re: Part-cooling fan for PLA September 26, 2021 09:21PM |

Registered: 7 years ago Posts: 321 |

Ideally, yes. It saves extra stress on the heater block keeping a steady temperature.

You can look for shroud designs on Thingiverse or wherever.

A silicone sock on the heating block insulates the block. Alternative approach (some do both).

But it will probably work as is, just not as efficiently as it might work.

You can look for shroud designs on Thingiverse or wherever.

A silicone sock on the heating block insulates the block. Alternative approach (some do both).

But it will probably work as is, just not as efficiently as it might work.

|

Re: Part-cooling fan for PLA September 27, 2021 07:36PM |

Registered: 11 years ago Posts: 5,780 |

Axial fans do not work well with nozzles because they can't produce pressure to get air flowing through the duct/nozzle. Look into radial fans which work better against the back pressure produced by a duct/nozzle.

Or, just tilt that fan to direct air downward. I had a cubex printer that used two or three fans without any ducts- it seemed to work fine but took up a lot of space. The hot-end was insulated in that printer.

Whatever you settle on for a fan/duct, rerun the PID temperature control tuning on the hot-end with the fan running.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Or, just tilt that fan to direct air downward. I had a cubex printer that used two or three fans without any ducts- it seemed to work fine but took up a lot of space. The hot-end was insulated in that printer.

Whatever you settle on for a fan/duct, rerun the PID temperature control tuning on the hot-end with the fan running.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Part-cooling fan for PLA September 29, 2021 10:07AM |

Registered: 11 years ago Posts: 5,780 |

Here's an example of the way axial fans behave with ducts/nozzles: [vimeo.com] When I posted that video to reddit a couple years ago, and suggested that people check their axial fan nozzles for air flow, a bunch of people said it had to be fake, so I shot another video: [vimeo.com]

The response was as ridiculous as you'd expect from reddit. Someone said there are thousands of designs for axial fan ducts on Thingiverse and that I was making an extraordinary claim so I had to provide extraordinary proof. I suggested that he tape up a piece of paper and try t it himself, but apparently that was not his responsibility- I had to prove it (I'm not sure what the videos were), not him. Another dope went as far as claiming that he showed the videos to his dad who used to design jet engines for Boeing and he said it was impossible so my videos must be fake.

The lunatics have taken over the assylum.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The response was as ridiculous as you'd expect from reddit. Someone said there are thousands of designs for axial fan ducts on Thingiverse and that I was making an extraordinary claim so I had to provide extraordinary proof. I suggested that he tape up a piece of paper and try t it himself, but apparently that was not his responsibility- I had to prove it (I'm not sure what the videos were), not him. Another dope went as far as claiming that he showed the videos to his dad who used to design jet engines for Boeing and he said it was impossible so my videos must be fake.

The lunatics have taken over the assylum.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Part-cooling fan for PLA September 29, 2021 10:58AM |

Registered: 3 years ago Posts: 93 |

Thanks for the advice gentlemen about a silicone sock, radial fans, ducts, and PID retuning. For a first try I may just use a small axial fan that I happen to have lying around (it's the old axial barrel fan from my old hot end, no longer needed since I upgraded to a newer V6 hot end) and see how much of an effect it has. Later I can then buy a radial fan and try printing a duct.

|

Re: Part-cooling fan for PLA September 29, 2021 04:06PM |

Registered: 7 years ago Posts: 321 |

|

Re: Part-cooling fan for PLA September 29, 2021 11:03PM |

Registered: 10 years ago Posts: 11 |

Actually the jet engines used by Boeing do have axial compressors as they are more efficient at the sort of power and compression ratio needed, many thousands of KW and pr of up to 50. They also have development costs in the millions now nudging billions. Smaller turboprop compressors are usually centrifigal for a whole heap of reasons cost and clearances being the main ones.

Turbochargers are all centifigal

Turbochargers are all centifigal

|

Re: Part-cooling fan for PLA October 06, 2021 01:47PM |

Registered: 3 years ago Posts: 92 |

Wow, great video. I wouldn't have expected it to go fully backward.Quote

the_digital_dentist

Here's an example of the way axial fans behave with ducts/nozzles: [vimeo.com] When I posted that video to reddit a couple years ago, and suggested that people check their axial fan nozzles for air flow, a bunch of people said it had to be fake, so I shot another video: [vimeo.com]

The big difference between this and jet engine compressors is the low blade coverage and lack of stationary blades, i.e. lots of room for air to flow backward between the blades.

The reddit response doesn't surprise me one bit

That place is the distilled concentrate of people who worship science as a religion, yet deny any actual scientific evidence that goes against their beliefs. As you've experienced, they do their best to run anyone else off.

That place is the distilled concentrate of people who worship science as a religion, yet deny any actual scientific evidence that goes against their beliefs. As you've experienced, they do their best to run anyone else off.For the gear printing, another option is to use lower speed to give the layers more time to cool, and lower nozzle temperature so there's less cooling to be done. There's a CNC Kitchen video on youtube that everyone cites as proof that no cooling fan=stronger prints, but it always aggravates me that he never controls for print quality. The cooled ones look great and the un-cooled ones are all saggy. I'm fairly sure the sagginess itself is what causes the strength increase. That is, the layers have more contact area and more time to melt together before solidifying. If you increase the nozzle temperature enough to produce similar sagging with the cooling fan, and reduce temperature to get good quality without it, you'll probably get opposite strength results.

|

Re: Part-cooling fan for PLA December 12, 2021 12:44AM |

Registered: 3 years ago Posts: 93 |

Quote

dekutree64

For the gear printing, another option is to use lower speed to give the layers more time to cool, and lower nozzle temperature so there's less cooling to be done.

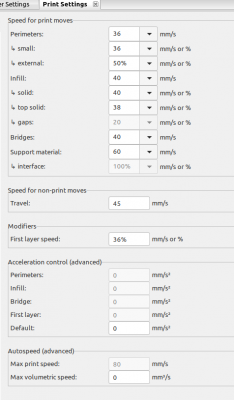

Thanks for the tip! That worked well. For the below print, print temperature was set to 175 degrees, slic3r was set to "slow down if layer print time is below: 30 seconds", with "min print speed: 0.5 mm/s".

The result obviously isn't perfect, but it's probably about the same quality as was obtained with my previous strategy of printing multiple copies, and the small visual defects don't affect the performance.

As for my planned radial cooling fan, I'm still shopping around for an appropriate one.

|

Re: Part-cooling fan for PLA December 12, 2021 06:50AM |

Registered: 8 years ago Posts: 1,671 |

|

Re: Part-cooling fan for PLA December 12, 2021 07:37AM |

Registered: 3 years ago Posts: 93 |

Quote

MechaBits

I would have thought the slow down function would mean its touching the print for longer, or does it move away & wait?

It doesn't move away and wait, so the print head is indeed touching the print longer, but that's why I lowered the temperature to 175 degrees C -- maybe even a lower temperature would work. When the printer is drawing out the zig-zag pattern of the gear teeth, it's crawling around the perimeter at extremely slow speed. If we consider for example the left-most gear tooth and the right-most gear tooth, the print head lays down some filament at the left-most side of the gear, then continues laying down more filament for the other teeth as the print head crawls slowly around to the right-most side of the gear, taking say 15 seconds to do so. Then the print head continues printing and crawling slowly back around towards the left-most side of the gear, finally arriving at the starting point a full 30 seconds later. So each point on the print perimeter basically has almost 30 seconds to cool, and the reduced temperature setting helps prevents the heat from creeping around and softening nearby plastic.

Now, I do remember trying this slow-down approach about half a year ago when I was using a different hot end and some old filament. At that time, I recall having problems with under-extrusion at very low speeds -- problems that did not occur when printing at higher speeds. However, my old hot end and my old filament both may have had problems (maybe the hot end was partially clogged; maybe the filament had absorbed moisture). With my new V6-clone hot end and a new roll of filament, I no longer observe any problems with under-extrusion at low speeds.

I recall reading another post here on the forum about someone printing very small gears for DC motors by using a low temperature of 160 degrees: [reprap.org] . For print speed, that author used a "10 mm/s feed rate" in slic3r, but I'm not sure exactly what the author meant by that. My version of slic3r doesn't allow setting a "feed rate" as such, but instead allows setting a "speed for print moves". There is a setting for "max volumetric speed", which perhaps is what the author was referring to? I suppose, in any event, that the author chose a somewhat low print speed to aid in cooling.

Edited 1 time(s). Last edit at 12/12/2021 07:40AM by qrp-gaijin.

Sorry, only registered users may post in this forum.