extrusion problem

Posted by yoonus_rox

|

extrusion problem November 22, 2021 12:53AM |

Registered: 3 years ago Posts: 19 |

hi, recently i took out my 3d printer which i havent used in a long time and when i started prining with it the filament gets blocked in the hotend.

i tried everything the internet has told me and none of th m have fixed the problem.

what i did:

i use an e3d v6 hotend 0.4 mm nozzle with esun pla plus blue filament

can someone please help.

i tried everything the internet has told me and none of th m have fixed the problem.

what i did:

- increasing hotend temperature

- reduced hotend temperature

- increase fan speed to max

- changed the heatsink cooling fan air flow direction twice

- tighten the extruder

- loosen the extruder

- made sure that the nozzle isnt too close to the bed

- shorten the ptfe tube

- reassembled the hotend properly

- reduced the flow rate

- increased the flow rate

- checked the extruder steps per mm

i use an e3d v6 hotend 0.4 mm nozzle with esun pla plus blue filament

can someone please help.

|

Re: extrusion problem November 22, 2021 03:53AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: extrusion problem November 22, 2021 08:43AM |

Registered: 4 years ago Posts: 285 |

|

Re: extrusion problem November 22, 2021 01:46PM |

Registered: 3 years ago Posts: 92 |

Yeah, old filament could be trouble. At the very least it probably needs to be dehydrated. Push some through by hand and see if you can see or hear any snap-crackle-pop of bubbles forming.

Clean the nozzle if you haven't already (or buy a new one). I just hold it in a fire with pliers until all the plastic burns into white powder and then wash under running water, using a needle to scrape around inside. Clean the heatbreak as well if it has any plastic in it.

Whatever the case, it should be fixable. 3D printers aren't particularly complicated machines, and if it heats up properly and you were able to measure the extruder steps per mm, then there's nothing left to go wrong that would cost much to replace.

Edited 1 time(s). Last edit at 11/22/2021 01:50PM by dekutree64.

Clean the nozzle if you haven't already (or buy a new one). I just hold it in a fire with pliers until all the plastic burns into white powder and then wash under running water, using a needle to scrape around inside. Clean the heatbreak as well if it has any plastic in it.

Whatever the case, it should be fixable. 3D printers aren't particularly complicated machines, and if it heats up properly and you were able to measure the extruder steps per mm, then there's nothing left to go wrong that would cost much to replace.

Edited 1 time(s). Last edit at 11/22/2021 01:50PM by dekutree64.

|

Re: extrusion problem November 22, 2021 08:39PM |

Registered: 3 years ago Posts: 93 |

Is there a possibility of damaging a brass nozzle with this method?Quote

dekutree64

Clean the nozzle if you haven't already (or buy a new one). I just hold it in a fire with pliers until all the plastic burns into white powder and then wash under running water, using a needle to scrape around inside.

How exactly would you do that? Same method -- burn off the plastic into powder, then scrape/poke it out?Quote

dekutree64

Clean the heatbreak as well if it has any plastic in it.

Fortunately I haven't had any really bad jams yet, but it can't hurt to be prepared.

|

Re: extrusion problem November 23, 2021 01:48AM |

Registered: 3 years ago Posts: 92 |

Yes and yes. But unless your needle is super sharp, it will take some effort to scratch brass. Toothpicks are also useful to scrape around everywhere except the tiny hole, and to push a bit of paper towel through the heatbreak to sweep it out.

I've never had a full clog, but plenty of partial clogs causing inconsistent extrusion problems. One thing that helps is to use a binder clip to hold a piece of cloth around the filament between the spool and extruder, so any dust gets wiped off before going into the bowden tube/nozzle.

I've never had a full clog, but plenty of partial clogs causing inconsistent extrusion problems. One thing that helps is to use a binder clip to hold a piece of cloth around the filament between the spool and extruder, so any dust gets wiped off before going into the bowden tube/nozzle.

|

Re: extrusion problem November 23, 2021 02:38AM |

Registered: 3 years ago Posts: 93 |

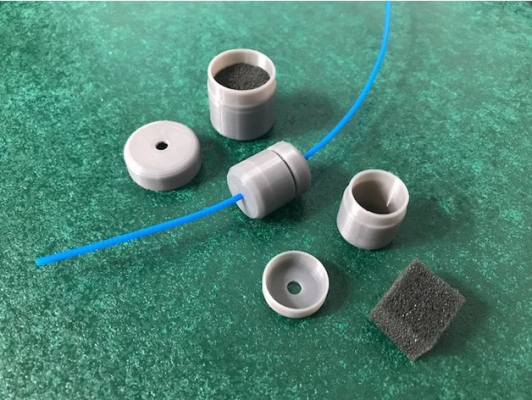

Yeah, I've been recently using this for the same purpose:Quote

dekutree64

One thing that helps is to use a binder clip to hold a piece of cloth around the filament between the spool and extruder, so any dust gets wiped off before going into the bowden tube/nozzle.

[www.thingiverse.com]

About clogs, what I'm really worried about is if molten plastic (PLA in my case) leaks into the heater block and all around the threads. By heating up the heater block normally, I assume that I would still be able to unscrew and disassemble everything -- but then there still would be melted plastic all on the inside of the heater block's threads that would need to be cleaned up, where it's difficult to get at since it's inside of the small hole. Another thread suggested either re-tapping or using chemicals to clean the threads. [reprap.org] Sounds like a bit of a chore to clean up in this case.

|

Re: extrusion problem November 23, 2021 12:00PM |

Registered: 3 years ago Posts: 92 |

|

Re: extrusion problem November 24, 2021 06:57PM |

Registered: 9 years ago Posts: 483 |

Sorry, only registered users may post in this forum.

So much easier than trying to deal with plastic. But do scrape off what molten plastic you can with a toothpick before burning, to reduce the amount of smoke and residue produced. And yes, use the printer's own heater for disassembly.

So much easier than trying to deal with plastic. But do scrape off what molten plastic you can with a toothpick before burning, to reduce the amount of smoke and residue produced. And yes, use the printer's own heater for disassembly.