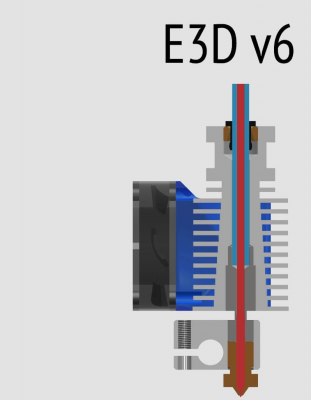

PTFE fumes: poor assembly order for E3D-v6 hot end?

Posted by qrp-gaijin

|

PTFE fumes: poor assembly order for E3D-v6 hot end? November 23, 2021 02:52AM |

Registered: 3 years ago Posts: 93 |

The instructions for the E3D-v6 hot end assembly [wiki.e3d-online.com] direct you to first assemble everything including the PTFE tube, then to do hot tightening at 285 degrees C. This means that the PTFE tube, being flush against the nozzle, will be subjected to 285 degree heat.

However, this thread [reprap.org] says that above 260 degrees, PTFE will "start to give off nasties".

This would imply that it would be better to do hot tightening without the PTFE tube in place, and only after everything has been tightened and cooled to finally insert the PTFE tube.

Any comments?

However, this thread [reprap.org] says that above 260 degrees, PTFE will "start to give off nasties".

This would imply that it would be better to do hot tightening without the PTFE tube in place, and only after everything has been tightened and cooled to finally insert the PTFE tube.

Any comments?

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 23, 2021 04:06AM |

Admin Registered: 13 years ago Posts: 6,998 |

"In the 1.75mm versions the PTFE tube actually runs through the Heat Sink and into the Heat Break, "

The PTFE does not go into the hot end and is kept cool in the cooling fins section

The PTFE does not go into the hot end and is kept cool in the cooling fins section

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 23, 2021 04:30AM |

Registered: 9 years ago Posts: 893 |

IIRC, the PTFE tubing does go into a recess in the top of the heat-break, so that it lines up correctly with the filament hole. However, it is still on the cool end of the heat-break and shouldn't reach dangerous temperatures - unless the fan fails and the heatsink fails to keep the cool end cool.

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 24, 2021 06:32AM |

Registered: 3 years ago Posts: 93 |

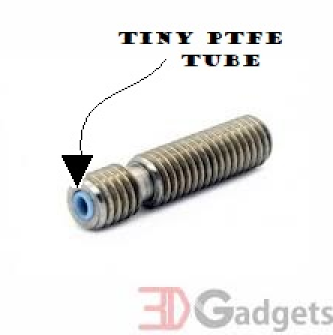

Somewhat interestingly, the image shown in this other recent thread at [reprap.org] seems to show a PTFE tube extending all the way into the hot end of the heat break, where the PTFE tube will then, it seems, then be flush against the hot nozzle and subject to temperatures that could start to decompose the PTFE.

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 24, 2021 06:42AM |

Admin Registered: 13 years ago Posts: 6,998 |

your taking things out of context

[3dgadgets.my]

"E3D V6 Direct Feed Compatible PTFE Lined Heat Break - 1.75mm"

Is not a real E3dv6

[3dgadgets.my]

"E3D V6 Direct Feed Compatible PTFE Lined Heat Break - 1.75mm"

Is not a real E3dv6

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 24, 2021 06:51AM |

Registered: 3 years ago Posts: 93 |

It seems that my V6 clone hot end came with a number of different heat breaks, some with a PTFE lining, some without. (I'm not sure which I have currently installed in my printer, but it seems to be working OK.)

What is the purpose of the extra PTFE lining? And if it's PTFE, then this does seem to imply a risk of it burning/giving off fumes during hot tightening at 285 degrees C. In this case, since the PTFE lining is permanently affixed to the heat break, there's no way to avoid the overheating of the PTFE. I suppose the size of the PTFE and the length of overheating would lead to "minimal" fumes being generated, but it still bothers me a bit that this plastic is (by design?) subject to overheating.

What is the purpose of the extra PTFE lining? And if it's PTFE, then this does seem to imply a risk of it burning/giving off fumes during hot tightening at 285 degrees C. In this case, since the PTFE lining is permanently affixed to the heat break, there's no way to avoid the overheating of the PTFE. I suppose the size of the PTFE and the length of overheating would lead to "minimal" fumes being generated, but it still bothers me a bit that this plastic is (by design?) subject to overheating.

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 25, 2021 02:40PM |

Registered: 7 years ago Posts: 321 |

Ummm... No. You don't have a V6 E3D.

What you have is an V6 Lite clone.

[e3d-online.com]

And it's not supposed to work that hot.

?

PTFE tube decreases friction in the cold end. It might be OK for high temperatures with a titanium heatbreak and shorter PTFE tube.

What you have is an V6 Lite clone.

[e3d-online.com]

And it's not supposed to work that hot.

?

PTFE tube decreases friction in the cold end. It might be OK for high temperatures with a titanium heatbreak and shorter PTFE tube.

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 25, 2021 06:25PM |

Registered: 3 years ago Posts: 93 |

Thanks for the clarification. The linked documentation for the Lite6 hot end indicates that "The PTFE lining in a Lite6 HotEnd is very important for printing successfully. Make sure that your tubing is all the way in the hotend and butting up against your nozzle (this is different from a V6,where the tubing stops above the heat break)."

It is specifically stated that in a V6, the tubing stops above the heat break.

But, my V6 (?) clone came with 2 types of heat breaks: one type that was all metal, and another type with a PTFE liner. Apparently, this is non-standard for a V6 hot end to use a PTFE liner, but many sites sell heat breaks with PTFE liners for V6 hot ends.

Moreover, the official assembly documentation for the Lite6 hot end states that hot tightening for the Lite6 which uses the PTFE liner flush against the nozzle should be done at 240 degrees, not 285 degrees. This apparently then avoids subjecting the PTFE to excessive temperatures where it can start to emit fumes.

Because the V6 hot end (apparently) was not designed for use with a PTFE liner (that is inside the heat break and extends down to touch the nozzle), its official documentation of course makes no mention of it. But because the clone makers are selling V6 heat breaks with PTFE liners, using such a heat break, with the PTFE liner flush against the nozzle, and following the official E3D V6 hot tightening instructions (which assume no PTFE liner is present), the PTFE liner will be subject to excessive heat and release of noxious fumes.

Yikes. From now on, I will be sure to use only 240 degrees for hot tightening when a PTFE liner is in use and is flush against the nozzle. For that matter, what is the difference between hot tightening at 240 degrees and hot tightening at 285 degrees? Why not always tighten at the lower, safer temperature of 240 degrees?

Edited 2 time(s). Last edit at 11/25/2021 07:39PM by qrp-gaijin.

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 26, 2021 08:21AM |

Registered: 8 years ago Posts: 1,671 |

Might be a little late to avoid c-8 exposure

[theintercept.com]

Edited 1 time(s). Last edit at 11/26/2021 08:22AM by MechaBits.

[theintercept.com]

Edited 1 time(s). Last edit at 11/26/2021 08:22AM by MechaBits.

|

Re: PTFE fumes: poor assembly order for E3D-v6 hot end? November 26, 2021 11:24AM |

Registered: 11 years ago Posts: 5,780 |

Sometimes it's just not worth the time and intellectual effort to try to make a silk purse out of a sow's ear. For about $15 you can get a good, all-metal hotend and not have to be concerned about PTFE fumes. I've been using one of these in UMMD for 3 years with no problems other than replacing the crappy fan with a good sunon fan for an additional $8 or so. It has several advantages over the E3D V6.

Here's an old blog post about it- the extruder has been replaced with a Bondtech BMG...

Edited 1 time(s). Last edit at 11/26/2021 11:31AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's an old blog post about it- the extruder has been replaced with a Bondtech BMG...

Edited 1 time(s). Last edit at 11/26/2021 11:31AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.