bed leveling with CNC-methods

Posted by pickedtransmitted

|

bed leveling with CNC-methods January 13, 2022 05:45PM |

Registered: 2 years ago Posts: 2 |

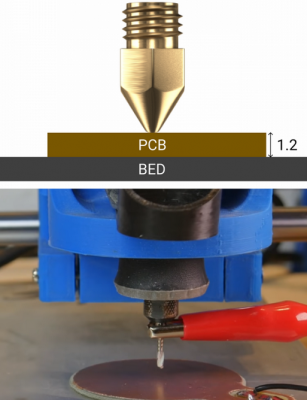

I've recently used the same method as CNC hobbyists use to zero out their work-piece (see picture below), by using my printers nozzle as a probe that lights up an LED as soon as it touches a PCB.

That worked extremely well, however I am puzzled as to how it ended up working - by sheer logic I would need to subtract the Z-height at which I was calibrating, which in my case was at Z1.2, so I assumed I would have to G206 a Z1.2 in marlin to correct for that..

However that ended up being way too close to the bed (even though my printer has a Z0.30 start g-code) - what ended up working was Z0.15, which is half of the Z0.30 set by my printer.

I'm close to believing it was marlin always z-stop'ing that dictated this, but why wouldn't it be then 1.2 off the bed still?

Does anyone have a clue / theory how that ended up working?

Thanks so much for any ideas!

That worked extremely well, however I am puzzled as to how it ended up working - by sheer logic I would need to subtract the Z-height at which I was calibrating, which in my case was at Z1.2, so I assumed I would have to G206 a Z1.2 in marlin to correct for that..

However that ended up being way too close to the bed (even though my printer has a Z0.30 start g-code) - what ended up working was Z0.15, which is half of the Z0.30 set by my printer.

I'm close to believing it was marlin always z-stop'ing that dictated this, but why wouldn't it be then 1.2 off the bed still?

Does anyone have a clue / theory how that ended up working?

Thanks so much for any ideas!

|

Re: bed leveling with CNC-methods January 14, 2022 05:43PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: bed leveling with CNC-methods January 14, 2022 07:54PM |

Registered: 2 years ago Posts: 2 |

|

Re: bed leveling with CNC-methods January 24, 2022 07:10AM |

Registered: 8 years ago Posts: 1,671 |

are you using 3 or 4 screws, either way 1.5 is about half your extrusion diam with a little squish, but the good thing is when its working you can forget about it & worry about something else, I start leveling my printer touching the bed, some z offset seems to raise things a little, but sometimes can be too close or too far, but either way I think it remembers where it was on its last jog

Sorry, only registered users may post in this forum.