Branchement du capteur de proximité -LJC18A3 H Z/BX

Posted by taratata

|

Branchement du capteur de proximité -LJC18A3 H Z/BX April 10, 2016 05:08AM |

Registered: 8 years ago Posts: 85 |

bonjour à tous

Marlin RCBugFix "Default_version.h"

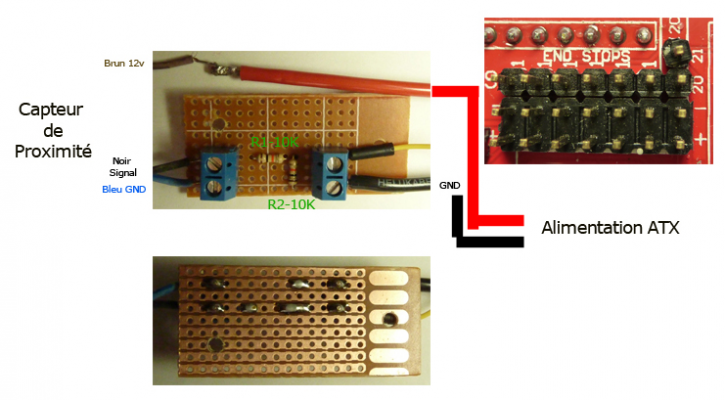

j'ai brancher la capteur de proximité LJC18A3 H Z/BX comme ceci

Le fil jaune est brancher sur le PIN Signale min-Z Ramps1.4

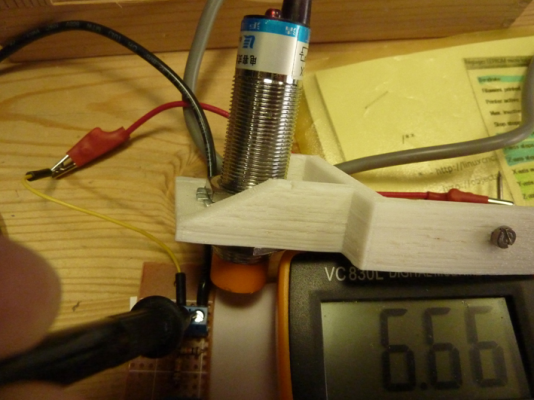

J'ai bien une tension de 6.64v aux bornes (Jaune/Noir à droite de l'image) sans détection

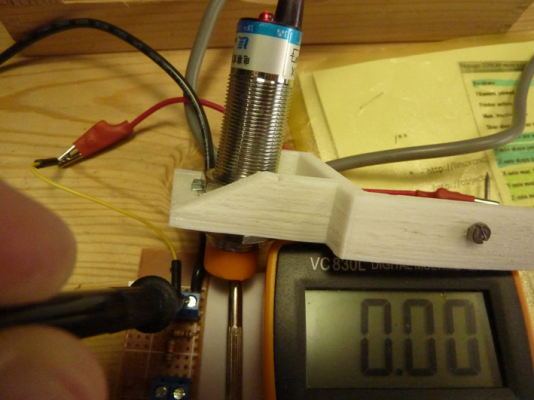

J'ai bien une tension de 0v aux bornes (Jaune/Noir à droite de l'image) avec détection (tournvis métal)

J'en déduis qu'il est toujours alimenté en position de non détection.

Si j'ai bien compris, le capteur de proximité remplace le EndStop mécanique Z.

Sous Repetier-Host,

M119 donne bien "Open" sur les 3 axes lorsqu'ils sont situés sur un point de l'axe

M119 donne bien "Triggered" sur l'axe Z lorsqu'ils lorsqu'il est en mode de détection

Voici comment j'ai configuré

Une fois sous Repetier-Host en mode "Essais à vide" ou pas, la commande G29 renvoie echo:Home X/Y before Z (rien ne bouge)

Si je fais Home Z, l'axe descend est force.

auriez-vous une idée svp... merci

Marlin RCBugFix "Default_version.h"

#define SHORT_BUILD_VERSION "1.1.0-RC5" #define DETAILED_BUILD_VERSION "1.1.0-RC5 From Archive" #define STRING_DISTRIBUTION_DATE "2016-04-01 12:00"

j'ai brancher la capteur de proximité LJC18A3 H Z/BX comme ceci

Le fil jaune est brancher sur le PIN Signale min-Z Ramps1.4

J'ai bien une tension de 6.64v aux bornes (Jaune/Noir à droite de l'image) sans détection

J'ai bien une tension de 0v aux bornes (Jaune/Noir à droite de l'image) avec détection (tournvis métal)

J'en déduis qu'il est toujours alimenté en position de non détection.

Si j'ai bien compris, le capteur de proximité remplace le EndStop mécanique Z.

Sous Repetier-Host,

M119 donne bien "Open" sur les 3 axes lorsqu'ils sont situés sur un point de l'axe

M119 donne bien "Triggered" sur l'axe Z lorsqu'ils lorsqu'il est en mode de détection

Voici comment j'ai configuré

Editer Configuration.h

Définir la configuration physique de l'état du contacteur mécanique de fin de course

[NC]=False ou [NO]=True

const bool Z_MIN_ENDSTOP_INVERTING = true;

Permet de dépasser la valeur de la variable Z_HOME_POS

#define min_software_endstops false

Active le mode Auto Bed Leveling

#define AUTO_BED_LEVELING_FEATURE

#define FIX_MOUNTED_PROBE

Activer l'utilisation de la grille

#define AUTO_BED_LEVELING_GRID

#define LEFT_PROBE_BED_POSITION 15

#define RIGHT_PROBE_BED_POSITION 170

#define FRONT_PROBE_BED_POSITION 20

#define BACK_PROBE_BED_POSITION 170

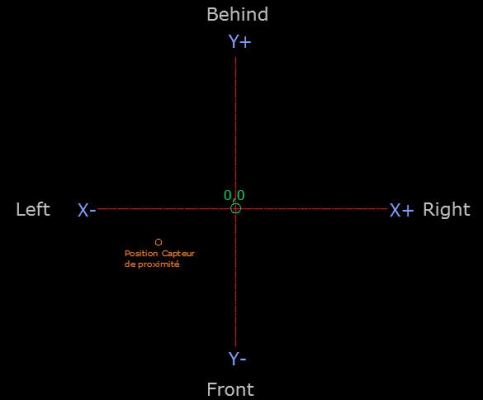

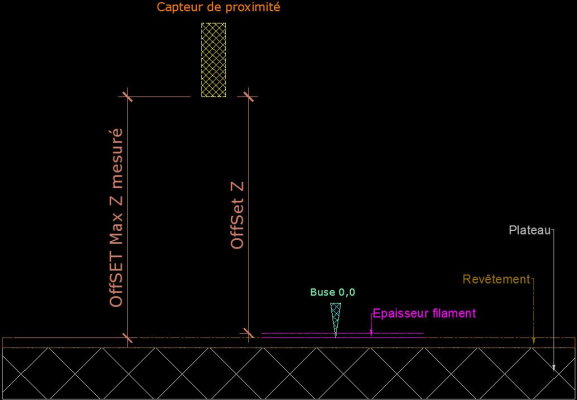

Détermine la distance entre la tête d'impression et le capteur de proximité

#define X_PROBE_OFFSET_FROM_EXTRUDER 10

#define Y_PROBE_OFFSET_FROM_EXTRUDER 10

#define Z_PROBE_OFFSET_FROM_EXTRUDER 0

Enregistrer la nouvelle configuration

Mettre à jour le firmware

Tracer les deux diagonales du plateau pour obtenir son centre.

Lancer Repetier-Host

Positionner la tête d'impression au centre du plateau X,Y

Descendre finement la buse sur une feuille 80g/m2 (s'il reste encore espace et que l'axe est en bout de course, alors modifier la sensibilité du capteur de proximité).

Exécuter G92 X0 Y0 Z0

Placer l'extruder sur le centre du plateau Axe X

Placer l'extruder sur le centre du plateau Axe Y

Descendre en Z jusqu'à que le LED s'allume

X=58.00 Y=-7.0 Z=-0.23

Déconnecter Repetier-Host

Editer Configuration.h

Détermine la distance entre la tête d'impression et le capteur de proximité

#define X_PROBE_OFFSET_FROM_EXTRUDER -58

#define Y_PROBE_OFFSET_FROM_EXTRUDER -7

#define Z_PROBE_OFFSET_FROM_EXTRUDER 0.23

Enregistrer la nouvelle configuration

Mettre à jour le firmware

Lancer Repetier-Host

Slic3r Introduire la commande de mise ne position absolue

Onglet "Trancheur\Configuration\Printer Settings\Custom G-Code\Start G-code"

G28 ; Home all axis

G29 ; Auto leveling

puis enregistrer

Une fois sous Repetier-Host en mode "Essais à vide" ou pas, la commande G29 renvoie echo:Home X/Y before Z (rien ne bouge)

Si je fais Home Z, l'axe descend est force.

auriez-vous une idée svp... merci

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX April 10, 2016 06:07AM |

Registered: 9 years ago Posts: 150 |

Descendre en Z jusqu'à que la LED s'allume... en manuel

si ce n'est pas le cas le capteur est trop haut et la buse touchera le plateau avant sa détection

Edited 1 time(s). Last edit at 04/11/2016 02:42PM by gab91.

Prusa i3 rework homemade , E3D V6 homemade.

Smartrapcore 200 x 300 ,axes 8mm .

si ce n'est pas le cas le capteur est trop haut et la buse touchera le plateau avant sa détection

Edited 1 time(s). Last edit at 04/11/2016 02:42PM by gab91.

Prusa i3 rework homemade , E3D V6 homemade.

Smartrapcore 200 x 300 ,axes 8mm .

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX April 11, 2016 03:33AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 05, 2016 03:53PM |

Registered: 8 years ago Posts: 22 |

Bonjour,

Je fais remonter le sujet car j'ai le même capteur et un petit souci avec.

Les branchement on été effectués tel que décris sur le schéma.

Quand je fais un M119, tous les 3 axes sont OPEN.

Je fais détecter le capteur (il s'allume) et si je refais un M119, rien n'a bougé, toujours sur OPEN

Une idée?

Je fais remonter le sujet car j'ai le même capteur et un petit souci avec.

Les branchement on été effectués tel que décris sur le schéma.

Quand je fais un M119, tous les 3 axes sont OPEN.

Je fais détecter le capteur (il s'allume) et si je refais un M119, rien n'a bougé, toujours sur OPEN

Une idée?

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 06, 2016 04:15AM |

Registered: 8 years ago Posts: 85 |

vérifie :

Le fil jaune est brancher sur le PIN Signale min-Z

Définir la configuration physique de l'état du capteur de proximité [NC]=False [NO]=True

const bool Z_MIN_ENDSTOP_INVERTING = true;

Permet de dépasser la valeur de la variable Z_HOME_POS

#define min_software_endstops false

const bool Z_MIN_ENDSTOP_INVERTING = true;

const bool Z_MAX_ENDSTOP_INVERTING = true;

const bool Z_MIN_PROBE_ENDSTOP_INVERTING = false;

// Position des EndStops par rapport à l'axe

// X=0 Home --> -1=MIN -- X=Max --> 1=MAX

// :[-1,1]

#define X_HOME_DIR -1

#define Y_HOME_DIR 1

#define Z_HOME_DIR -1

Le fil jaune est brancher sur le PIN Signale min-Z

Définir la configuration physique de l'état du capteur de proximité [NC]=False [NO]=True

const bool Z_MIN_ENDSTOP_INVERTING = true;

Permet de dépasser la valeur de la variable Z_HOME_POS

#define min_software_endstops false

const bool Z_MIN_ENDSTOP_INVERTING = true;

const bool Z_MAX_ENDSTOP_INVERTING = true;

const bool Z_MIN_PROBE_ENDSTOP_INVERTING = false;

// Position des EndStops par rapport à l'axe

// X=0 Home --> -1=MIN -- X=Max --> 1=MAX

// :[-1,1]

#define X_HOME_DIR -1

#define Y_HOME_DIR 1

#define Z_HOME_DIR -1

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 06, 2016 06:04AM |

Registered: 8 years ago Posts: 22 |

Bon j'ai trouvé pourquoi cela ne fonctionnait pas.

En faite avec le capteur LJC18A3 H Z/BX NPN NO, il n'y a pas besoin des résistances.

Le fil marron sur le 12V, le fil bleu sur la masse et le fil noir directement sur le signal.

Là c'est ok, le capteur passe bien de OPEN à TRIGGERED.

Avec G28 le Home-Z se fait bien au centre du plateau.

Le G29 se passe bien aussi, palpage des 4 coins du plateau.

Mais, et oui il y a un mais quand je veux imprimer, la buse se trouve toujours au dessus du plateau.

Je n'ai pas encore trouver la solution.

Je suis preneur de toutes idées...

En faite avec le capteur LJC18A3 H Z/BX NPN NO, il n'y a pas besoin des résistances.

Le fil marron sur le 12V, le fil bleu sur la masse et le fil noir directement sur le signal.

Là c'est ok, le capteur passe bien de OPEN à TRIGGERED.

Avec G28 le Home-Z se fait bien au centre du plateau.

Le G29 se passe bien aussi, palpage des 4 coins du plateau.

Mais, et oui il y a un mais quand je veux imprimer, la buse se trouve toujours au dessus du plateau.

Je n'ai pas encore trouver la solution.

Je suis preneur de toutes idées...

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 06, 2016 09:30AM |

Registered: 8 years ago Posts: 489 |

Salut,

Est ce que la distance entre ta buse et ton plateau change ?

Ou est ce tout le temps la même ?

Car si c'est tout le temps la même, tu n'as juste qu'à mettre un offset en z et c'est réglé

@++

Ma Prusa i3 (ancienne imprimante, transformé en Itopie depuis)

Mon Itopie

Mon thingiverse

[TUTO] Lcd full graphic avec firmware Marlin

--

Possibilité de vous imprimer des pièces, n'hésitez pas à demander en MP

Est ce que la distance entre ta buse et ton plateau change ?

Ou est ce tout le temps la même ?

Car si c'est tout le temps la même, tu n'as juste qu'à mettre un offset en z et c'est réglé

@++

Ma Prusa i3 (ancienne imprimante, transformé en Itopie depuis)

Mon Itopie

Mon thingiverse

[TUTO] Lcd full graphic avec firmware Marlin

--

Possibilité de vous imprimer des pièces, n'hésitez pas à demander en MP

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 06, 2016 05:13PM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 09:22AM |

Registered: 8 years ago Posts: 22 |

J'ai toujours mon problème et je n'arrive pas à le régler.

J'ai 0.6mm d'écart entre la buse et le capteur. J'ai donc renseigné dans le Marlin comme ça:

#define Z_PROBE_OFFSET_FROM_EXTRUDER -0.6

Quand j’essaie d'imprimer, je suis légèrement trop haut ce qui fait que ma première couche n'accroche pas.

quand je fais un G29, voici ce que j'ai dans le terminal

00:12:06.664 : Plateau x: 20.00 y: 15.00 z: -0.21

00:12:12.045 : Plateau x: 180.00 y: 15.00 z: -0.36

00:12:16.954 : Plateau x: 180.00 y: 125.00 z: -0.37

00:12:22.294 : Plateau x: 20.00 y: 125.00 z: -0.28

00:12:22.294 : Eqn coefficients: a: -0.00 b: -0.00 d: -0.21

00:12:22.294 : planeNormal x: 0.00 y: 0.00 z: 1.00

00:12:22.294 : echo:endstops hit: Z:-0.28

C'est comme si la valeur Z-0.28 n'était pas prise en compte.

Comment puis-je mettre un décalage afin que la buse vienne bien au bon niveau?

J'ai 0.6mm d'écart entre la buse et le capteur. J'ai donc renseigné dans le Marlin comme ça:

#define Z_PROBE_OFFSET_FROM_EXTRUDER -0.6

Quand j’essaie d'imprimer, je suis légèrement trop haut ce qui fait que ma première couche n'accroche pas.

quand je fais un G29, voici ce que j'ai dans le terminal

00:12:06.664 : Plateau x: 20.00 y: 15.00 z: -0.21

00:12:12.045 : Plateau x: 180.00 y: 15.00 z: -0.36

00:12:16.954 : Plateau x: 180.00 y: 125.00 z: -0.37

00:12:22.294 : Plateau x: 20.00 y: 125.00 z: -0.28

00:12:22.294 : Eqn coefficients: a: -0.00 b: -0.00 d: -0.21

00:12:22.294 : planeNormal x: 0.00 y: 0.00 z: 1.00

00:12:22.294 : echo:endstops hit: Z:-0.28

C'est comme si la valeur Z-0.28 n'était pas prise en compte.

Comment puis-je mettre un décalage afin que la buse vienne bien au bon niveau?

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 09:27AM |

Registered: 8 years ago Posts: 85 |

si cela peut t'aider

/** * Marlin 3D Printer Firmware * Copyright (C) 2016 MarlinFirmware [https://github.com/MarlinFirmware/Marlin] * * Based on Sprinter and grbl. * Copyright (C) 2011 Camiel Gubbels / Erik van der Zalm * * This program is free software: you can redistribute it and/or modify * it under the terms of the GNU General Public License as published by * the Free Software Foundation, either version 3 of the License, or * (at your option) any later version. * * This program is distributed in the hope that it will be useful, * but WITHOUT ANY WARRANTY; without even the implied warranty of * MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the * GNU General Public License for more details. * * You should have received a copy of the GNU General Public License * along with this program. If not, see [www.gnu.org]. * */ /** * Configuration.h * * Basic settings such as: * * - Type of electronics * - Type of temperature sensor * - Printer geometry * - Endstop configuration * - LCD controller * - Extra features * * Advanced settings can be found in Configuration_adv.h * */ /** * Here are some standard links for getting your machine calibrated: * * [reprap.org] * [youtu.be] * [calculator.josefprusa.cz] * [reprap.org] * [www.thingiverse.com] * [sites.google.com] * [www.thingiverse.com] */ //=========================================================================== //== ..:: Version Marlin "Default_Version.h" ::.. "1.1.0-RC5 From Archive" == //=========================================================================== #ifndef CONFIGURATION_H #define CONFIGURATION_H #include "boards.h" #include "macros.h" //=========================================================================== //========= ID Imprimante type cartésien =========== //=========================================================================== // This configuration file contains the basic settings. // Advanced settings can be found in Configuration_adv.h // BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration // #if ENABLED(USE_AUTOMATIC_VERSIONING) #include "_Version.h" #else #include "Default_Version.h" #endif // User-specified version info of this build to display in [Pronterface, etc] terminal window during // startup. Implementation of an idea by Prof Braino to inform user that any changes made to this // build by the user have been successfully uploaded into firmware. #define STRING_CONFIG_H_AUTHOR "TechWan2003 - Marlin 1.1.0-RC3 for Prusa i3 M505" #define SHOW_BOOTSCREEN #define STRING_SPLASH_LINE1 SHORT_BUILD_VERSION // will be shown during bootup in line 1 //#define STRING_SPLASH_LINE2 STRING_DISTRIBUTION_DATE // will be shown during bootup in line 2 // SERIAL_PORT selects which serial port should be used for communication with the host. // This allows the connection of wireless adapters (for instance) to non-default port pins. // Serial port 0 is still used by the Arduino bootloader regardless of this setting. // :[0,1,2,3,4,5,6,7] #define SERIAL_PORT 0 // This determines the communication speed of the printer // :[2400,9600,19200,38400,57600,115200,250000] #define BAUDRATE 115200 // Enable the Bluetooth serial interface on AT90USB devices //#define BLUETOOTH // The following define selects which electronics board you have. // Please choose the name from boards.h that matches your setup #ifndef MOTHERBOARD #define MOTHERBOARD BOARD_RAMPS_14_EFB #endif // Optional custom name for your RepStrap or other custom machine // Displayed in the LCD "Ready" message #define CUSTOM_MACHINE_NAME "TechWan2003" // Define this to set a unique identifier for this printer, (Used by some programs to differentiate between machines) // You can use an online service to generate a random UUID. (eg [www.uuidgenerator.net]) //#define MACHINE_UUID "00000000-0000-0000-0000-000000000000" //// The following define selects which power supply you have. Please choose the one that matches your setup // 1 = ATX // 2 = X-Box 360 203Watts (the blue wire connected to PS_ON and the red wire to VCC) // :{1:'ATX',2:'X-Box 360'} #define POWER_SUPPLY 1 // Define this to have the electronics keep the power supply off on startup. If you don't know what this is leave it. //#define PS_DEFAULT_OFF //=========================================================================== //========= Paramétrage Thermiques - Général ============= //=========================================================================== // This defines the number of extruders // :[1,2,3,4] #define EXTRUDERS 1 // Offset of the extruders (uncomment if using more than one and relying on firmware to position when changing). // The offset has to be X=0, Y=0 for the extruder 0 hotend (default extruder). // For the other hotends it is their distance from the extruder 0 hotend. //#define EXTRUDER_OFFSET_X {0.0, 20.00} // (in mm) for each extruder, offset of the hotend on the X axis //#define EXTRUDER_OFFSET_Y {0.0, 5.00} // (in mm) for each extruder, offset of the hotend on the Y axis // //--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table // //// Temperature sensor settings: // -3 is thermocouple with MAX31855 (only for sensor 0) // -2 is thermocouple with MAX6675 (only for sensor 0) // -1 is thermocouple with AD595 // 0 is not used // 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup) // 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup) // 3 is Mendel-parts thermistor (4.7k pullup) // 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !! // 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (4.7k pullup) // 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup) // 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup) // 71 is 100k Honeywell thermistor 135-104LAF-J01 (4.7k pullup) // 8 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup) // 9 is 100k GE Sensing AL03006-58.2K-97-G1 (4.7k pullup) // 10 is 100k RS thermistor 198-961 (4.7k pullup) // 11 is 100k beta 3950 1% thermistor (4.7k pullup) // 12 is 100k 0603 SMD Vishay NTCS0603E3104FXT (4.7k pullup) (calibrated for Makibox hot bed) // 13 is 100k Hisens 3950 1% up to 300°C for hotend "Simple ONE " & "Hotend "All In ONE" // 20 is the PT100 circuit found in the Ultimainboard V2.x // 60 is 100k Maker's Tool Works Kapton Bed Thermistor beta=3950 // 70 is the 100K thermistor found in the bq Hephestos 2 // // 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k // (but gives greater accuracy and more stable PID) // 51 is 100k thermistor - EPCOS (1k pullup) // 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup) // 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan & J-Head) (1k pullup) // // 1047 is Pt1000 with 4k7 pullup // 1010 is Pt1000 with 1k pullup (non standard) // 147 is Pt100 with 4k7 pullup // 110 is Pt100 with 1k pullup (non standard) // 998 and 999 are Dummy Tables. They will ALWAYS read 25°C or the temperature defined below. // Etat désactivé = Valeur 0 #define TEMP_SENSOR_0 11 // #define TEMP_SENSOR_1 0 // #define TEMP_SENSOR_2 0 // #define TEMP_SENSOR_3 0 #define TEMP_SENSOR_BED 11 // This makes temp sensor 1 a redundant sensor for sensor 0. If the temperatures difference between these sensors is to high the print will be aborted. //#define TEMP_SENSOR_1_AS_REDUNDANT #define MAX_REDUNDANT_TEMP_SENSOR_DIFF 10 // Actual temperature must be close to target for this long before M109 returns success #define TEMP_RESIDENCY_TIME 10 // (seconds) #define TEMP_HYSTERESIS 3 // (degC) range of +/- temperatures considered "close" to the target one #define TEMP_WINDOW 1 // (degC) Window around target to start the residency timer x degC early. // The minimal temperature defines the temperature below which the heater will not be enabled It is used // to check that the wiring to the thermistor is not broken. // Otherwise this would lead to the heater being powered on all the time. #define HEATER_0_MINTEMP 5 #define BED_MINTEMP 5 // When temperature exceeds max temp, your heater will be switched off. // This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure! // You should use MINTEMP for thermistor short/failure protection. #define HEATER_0_MAXTEMP 250 #define BED_MAXTEMP 120 // If you want the M105 heater power reported in watts, define the BED_WATTS, and (shared for all extruders) EXTRUDER_WATTS //#define EXTRUDER_WATTS (12.0*12.0/6.7) // P=U^2/R //#define BED_WATTS (12.0*12.0/1.1) // P=U^2/R //=========================================================================== //========== Paramétres Thermique - PID Extruders ============ //=========================================================================== // PID Tuning Guide here: [reprap.org] // Comment the following line to disable PID and enable bang-bang. #define PIDTEMP #define BANG_MAX 255 // limits current to nozzle while in bang-bang mode; 255=full current #define PID_MAX BANG_MAX // limits current to nozzle while PID is active (see PID_FUNCTIONAL_RANGE below); 255=full current #if ENABLED(PIDTEMP) //#define PID_AUTOTUNE_MENU // Add PID Autotune to the LCD "Temperature" menu to run M303 and apply the result. //#define PID_DEBUG // Sends debug data to the serial port. //#define PID_OPENLOOP 1 // Puts PID in open loop. M104/M140 sets the output power from 0 to PID_MAX //#define SLOW_PWM_HEATERS // PWM with very low frequency (roughly 0.125Hz=8s) and minimum state time of approximately 1s useful for heaters driven by a relay //#define PID_PARAMS_PER_EXTRUDER // Uses separate PID parameters for each extruder (useful for mismatched extruders) // Set/get with gcode: M301 E[extruder number, 0-2] #define PID_FUNCTIONAL_RANGE 10 // If the temperature difference between the target temperature and the actual temperature // is more then PID_FUNCTIONAL_RANGE then the PID will be shut off and the heater will be set to min/max. #define PID_INTEGRAL_DRIVE_MAX PID_MAX //limit for the integral term #define K1 0.95 //smoothing factor within the PID // Prusia M505 - Perso #define DEFAULT_Kp 17.46 #define DEFAULT_Ki 1.13 #define DEFAULT_Kd 67.38 // Pour PID // #define DEFAULT_Kp 22.2 // #define DEFAULT_Ki 1.08 // #define DEFAULT_Kd 114 // Autotune PID --> "M303 E0 C8 S220" #endif // PIDTEMP //this prevents dangerous Extruder moves, i.e. if the temperature is under the limit //can be software-disabled for whatever purposes by #define PREVENT_DANGEROUS_EXTRUDE //if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately. #define PREVENT_LENGTHY_EXTRUDE // Température minimum à laquelle le moteur est autorisé à fonctionner – // Cela évite toutes destructions de la buse encore froide et d'endommager le filament. #define EXTRUDE_MINTEMP 170 #define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances. // Sens de rotation du moteur Extruder #define INVERT_E0_DIR false // #define INVERT_E1_DIR false // #define INVERT_E2_DIR false // #define INVERT_E3_DIR false // - Désactive tous les extruder #define DISABLE_E false //- Désactive les extruder inactif #define DISABLE_INACTIVE_EXTRUDER true //=========================================================================== //========== Paramétres Thermique - PID Plateau chauffant ============ //=========================================================================== // Select PID or bang-bang with PIDTEMPBED. If bang-bang, BED_LIMIT_SWITCHING will enable hysteresis // // Uncomment this to enable PID on the bed. It uses the same frequency PWM as the extruder. // If your PID_dT is the default, and correct for your hardware/configuration, that means 7.689Hz, // which is fine for driving a square wave into a resistive load and does not significantly impact you FET heating. // This also works fine on a Fotek SSR-10DA Solid State Relay into a 250W heater. // If your configuration is significantly different than this and you don't understand the issues involved, you probably // shouldn't use bed PID until someone else verifies your hardware works. // If this is enabled, find your own PID constants below. // Active le contrôleur PID #define PIDTEMPBED //#define BED_LIMIT_SWITCHING // This sets the max power delivered to the bed, and replaces the HEATER_BED_DUTY_CYCLE_DIVIDER option. // all forms of bed control obey this (PID, bang-bang, bang-bang with hysteresis) // setting this to anything other than 255 enables a form of PWM to the bed just like HEATER_BED_DUTY_CYCLE_DIVIDER did, // so you shouldn't use it unless you are OK with PWM on your bed. (see the comment on enabling PIDTEMPBED) // Limite de puissance de chauffe (limits duty cycle to bed; 255=full current) #define MAX_BED_POWER 255 #if ENABLED(PIDTEMPBED) //#define PID_BED_DEBUG // Sends debug data to the serial port. #define PID_BED_INTEGRAL_DRIVE_MAX MAX_BED_POWER //limit for the integral term // MK2B - Perso #define DEFAULT_bedKp 64.09 #define DEFAULT_bedKi 8.81 #define DEFAULT_bedKd 116.56 // Pour PID //#define DEFAULT_bedKp 266.49 //#define DEFAULT_bedKi 49.29 //#define DEFAULT_bedKd 360.23 // Autotune PID --> "M303 E-1 C8 S90" #endif // PIDTEMPBED //=========================================================================== //======================== Thermal Runaway Protection ======================= //=========================================================================== /** * Thermal Protection protects your printer from damage and fire if a * thermistor falls out or temperature sensors fail in any way. * * The issue: If a thermistor falls out or a temperature sensor fails, * Marlin can no longer sense the actual temperature. Since a disconnected * thermistor reads as a low temperature, the firmware will keep the heater on. * * If you get "Thermal Runaway" or "Heating failed" errors the * details can be tuned in Configuration_adv.h */ #define THERMAL_PROTECTION_HOTENDS // Enable thermal protection for all extruders #define THERMAL_PROTECTION_BED // Enable thermal protection for the heated bed //=========================================================================== //========== Mécanique ============ //=========================================================================== // Uncomment this option to enable CoreXY kinematics //#define COREXY // Uncomment this option to enable CoreXZ kinematics //#define COREXZ // Enable this option for Toshiba steppers //#define CONFIG_STEPPERS_TOSHIBA // Dimensions des axes disponibles (mm) #define X_MIN_POS 0 #define X_MAX_POS 255 #define Y_MIN_POS 0 #define Y_MAX_POS 221 #define Z_MIN_POS 0 #define Z_MAX_POS 205 // Calibrage des axes XYZE // #define DEFAULT_AXIS_STEPS_PER_UNIT {100,100,1600,114.82} #define DEFAULT_AXIS_STEPS_PER_UNIT {100,100,1600,114.82} // Prusa i3 // Vitesse de déplacement à l'origine #define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min) // Vitesse de déplacement #define DEFAULT_MAX_FEEDRATE {400, 400, 2, 50} // (mm/sec) // Vitesse d'accélération // X, Y, Z and E acceleration in mm/s^2 for printing moves #define DEFAULT_ACCELERATION 400 // Vitesse maximum d'accélération // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for Skeinforge 40+, for older versions raise them a lot. #define DEFAULT_MAX_ACCELERATION {3000,3000,100,10000} // E acceleration in mm/s^2 for retracts #define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z acceleration in mm/s^2 for travel (non printing) moves #define DEFAULT_TRAVEL_ACCELERATION 400 //=========================================================================== //========== Capteurs de fin de course ============ //=========================================================================== // Position physique des détecteurs de fin de course #define USE_XMIN_PLUG // #define USE_YMIN_PLUG #define USE_ZMIN_PLUG // #define USE_XMAX_PLUG #define USE_YMAX_PLUG // #define USE_ZMAX_PLUG // Active l'ensemble de contacteurs de fin de course mécanique #define ENDSTOPPULLUPS // Active l'un des contacteurs de fin de course - Il faut désactiver ENDSTOPPULLUPS #if DISABLED(ENDSTOPPULLUPS) //#define ENDSTOPPULLUP_XMAX //#define ENDSTOPPULLUP_YMAX //#define ENDSTOPPULLUP_ZMAX //#define ENDSTOPPULLUP_XMIN //#define ENDSTOPPULLUP_YMIN //#define ENDSTOPPULLUP_ZMIN //#define ENDSTOPPULLUP_ZMIN_PROBE #endif // Définir la configuration physique de l'état du contacteur mécanique de fin de course [NC]=False ou [NO]=True const bool X_MIN_ENDSTOP_INVERTING = true; const bool X_MAX_ENDSTOP_INVERTING = true; const bool Y_MIN_ENDSTOP_INVERTING = true; const bool Y_MAX_ENDSTOP_INVERTING = true; const bool Z_MIN_ENDSTOP_INVERTING = true; const bool Z_MAX_ENDSTOP_INVERTING = true; const bool Z_MIN_PROBE_ENDSTOP_INVERTING = false; // Position des EndStops par rapport à l'axe // X=0 Home --> -1=MIN -- X=Max --> 1=MAX // :[-1,1] #define X_HOME_DIR -1 #define Y_HOME_DIR 1 #define Z_HOME_DIR -1 #define min_software_endstops false // If true, axis won't move to coordinates less than HOME_POS. #define max_software_endstops true // If true, axis won't move to coordinates greater than the defined lengths below. // Invertion de la direction des moteurs #define INVERT_X_DIR false #define INVERT_Y_DIR false #define INVERT_Z_DIR true //=========================================================================== //============================= Z Probe Options ============================= //=========================================================================== // Enable Z_MIN_PROBE_ENDSTOP to use _both_ a Z Probe and a Z-min-endstop on the same machine. // With this option the Z_MIN_PROBE_PIN will only be used for probing, never for homing. // // *** PLEASE READ ALL INSTRUCTIONS BELOW FOR SAFETY! *** // // To continue using the Z-min-endstop for homing, be sure to disable Z_SAFE_HOMING. // Example: To park the head outside the bed area when homing with G28. // // To use a separate Z probe, your board must define a Z_MIN_PROBE_PIN. // // For a servo-based Z probe, you must set up servo support below, including // NUM_SERVOS, Z_ENDSTOP_SERVO_NR and SERVO_ENDSTOP_ANGLES. // // - RAMPS 1.3/1.4 boards may be able to use the 5V, GND, and Aux4->D32 pin. // - Use 5V for powered (usu. inductive) sensors. // - Otherwise connect: // - normally-closed switches to GND and D32. // - normally-open switches to 5V and D32. // // Normally-closed switches are advised and are the default. // // The Z_MIN_PROBE_PIN sets the Arduino pin to use. (See your board's pins file.) // Since the RAMPS Aux4->D32 pin maps directly to the Arduino D32 pin, D32 is the // default pin for all RAMPS-based boards. Some other boards map differently. // To set or change the pin for your board, edit the appropriate pins_XXXXX.h file. // // WARNING: // Setting the wrong pin may have unexpected and potentially disastrous consequences. // Use with caution and do your homework. // //#define Z_MIN_PROBE_ENDSTOP // Enable Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN to use the Z_MIN_PIN for your Z_MIN_PROBE. // The Z_MIN_PIN will then be used for both Z-homing and probing. #define Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN // To use a probe you must enable one of the two options above! // This option disables the use of the Z_MIN_PROBE_PIN // To enable the Z probe pin but disable its use, uncomment the line below. This only affects a // Z probe switch if you have a separate Z min endstop also and have activated Z_MIN_PROBE_ENDSTOP above. // If you're using the Z MIN endstop connector for your Z probe, this has no effect. //#define DISABLE_Z_MIN_PROBE_ENDSTOP // For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1 // :{0:'Low',1:'High'} #define X_ENABLE_ON 0 #define Y_ENABLE_ON 0 #define Z_ENABLE_ON 0 #define E_ENABLE_ON 0 // For all extruders // Disables axis stepper immediately when it's not being used. // WARNING: When motors turn off there is a chance of losing position accuracy! #define DISABLE_X false #define DISABLE_Y false #define DISABLE_Z false // Warn on display about possibly reduced accuracy //#define DISABLE_REDUCED_ACCURACY_WARNING // @section homing //#define MIN_Z_HEIGHT_FOR_HOMING 4 // (in mm) Minimal z height before homing (G28) for Z clearance above the bed, clamps, ... // Be sure you have this distance over your Z_MAX_POS in case. //=========================================================================== //============================ Mesh Bed Leveling ============================ //=========================================================================== //#define MESH_BED_LEVELING // Enable mesh bed leveling. #if ENABLED(MESH_BED_LEVELING) #define MESH_MIN_X 10 #define MESH_MAX_X (X_MAX_POS - (MESH_MIN_X)) #define MESH_MIN_Y 10 #define MESH_MAX_Y (Y_MAX_POS - (MESH_MIN_Y)) #define MESH_NUM_X_POINTS 3 // Don't use more than 7 points per axis, implementation limited. #define MESH_NUM_Y_POINTS 3 #define MESH_HOME_SEARCH_Z 4 // Z after Home, bed somewhere below but above 0.0. //#define MANUAL_BED_LEVELING // Add display menu option for bed leveling. #if ENABLED(MANUAL_BED_LEVELING) #define MBL_Z_STEP 0.025 // Step size while manually probing Z axis. #endif // MANUAL_BED_LEVELING #endif // MESH_BED_LEVELING //=========================================================================== //========== G29 Capteur de proximité Auto Bed Leveling =========== //=========================================================================== // Active Auto Bed Leveling #define AUTO_BED_LEVELING_FEATURE #define DEBUG_LEVELING_FEATURE // Dédouble chacune mesure en utilisant une vitesse plus basse lors de la 2ème mesure afin d'augmenter la précision de mesure #define Z_MIN_PROBE_REPEATABILITY_TEST #if ENABLED(AUTO_BED_LEVELING_FEATURE) // Note: this feature generates 10KB extra code size. // Mode Grille #define AUTO_BED_LEVELING_GRID #if ENABLED(AUTO_BED_LEVELING_GRID) // Détermine les limites de la grille //Les distances de limite X sont calculées depuis l'origine physique 0,0 de l'imprimante, ce qui détermine la position du capteur #define LEFT_PROBE_BED_POSITION 59 //35 "décalage origine physique coin Bas plateau" + 18/2 "diametre capteur" 15 Marge #define RIGHT_PROBE_BED_POSITION 182 // 35 (décalage origine physique coin Bas gauche plateau) + 220 largeur plateau - (58 OffSet X + 10 Marge) //Les distances de limite Y sont calculées depuis l'origine physique 0,0 de l'imprimante et du "EndStop - Y_MAX_POS", ce qui détermine la position de la tête d'impression #define BACK_PROBE_BED_POSITION 176 // 220 largeur du plateau - (8 "Décalage origine physique coin bas gauche plateau" + 7 OffSet + 9 "diametre capteur" + 20 Marge) #define FRONT_PROBE_BED_POSITION 10 // Détermine une marge par rapport au bord du plateau #define MIN_PROBE_EDGE 2 // Spécifie la densité de point en XY // Une densité de 4 équivaut à 16 pointages. #define AUTO_BED_LEVELING_GRID_POINTS 4 #else // Mode 3 Points arbitraire #endif // ..:: (Configuration OffSet = Ecartement) ::.. // Position du capteur par rapport à la tête d'impression // #define X_PROBE_OFFSET_FROM_EXTRUDER -58 #define Y_PROBE_OFFSET_FROM_EXTRUDER -7 // Alu - Kapton // #define Z_PROBE_OFFSET_FROM_EXTRUDER -1.8 // Verre - Laque #define Z_PROBE_OFFSET_FROM_EXTRUDER -1.21 // ..:: F I N ::.. // // Vitesse de déplacement en X Y entre chaque pointage (mm/min) #define XY_TRAVEL_SPEED 8000 // Hauteur à prendre avant l'exécution de la commande G29 (mm) #define Z_RAISE_BEFORE_PROBING 15 // Hauteur à prendre pour le déplacement entre deux pointages #define Z_RAISE_BETWEEN_PROBINGS 5 // Hauteur à prendre après l'exécution de la commande G29 (mm) #define Z_RAISE_AFTER_PROBING 20 //#define Z_PROBE_END_SCRIPT "G1 Z10 F12000\nG1 X15 Y330\nG1 Z0.5\nG1 Z10" // These commands will be executed in the end of G29 routine. // Useful to retract a deployable Z probe. // Probes are sensors/switches that need to be activated before they can be used // and deactivated after the use. // Allen Key Probes, Servo Probes, Z-Sled Probes, FIX_MOUNTED_PROBE, ... . //You have to activate one of these for the AUTO_BED_LEVELING_FEATURE // A fix mounted probe, like the normal inductive probe, must be deactivated to go below Z_PROBE_OFFSET_FROM_EXTRUDER // when the hardware endstops are active. // Type de Capteur de proximité #define FIX_MOUNTED_PROBE // A Servo Probe can be defined in the servo section below. // An Allen Key Probe is currently predefined only in the delta example configurations. //#define Z_PROBE_SLED // Enable if you have a Z probe mounted on a sled like those designed by Charles Bell. //#define SLED_DOCKING_OFFSET 5 // The extra distance the X axis must travel to pickup the sled. 0 should be fine but you can push it further if you'd like. // If you've enabled AUTO_BED_LEVELING_FEATURE and are using the Z Probe for Z Homing, // it is highly recommended you leave Z_SAFE_HOMING enabled! #define Z_SAFE_HOMING // Use the z-min-probe for homing to z-min - not the z-min-endstop. // This feature is meant to avoid Z homing with Z probe outside the bed area. // When defined, it will: // - Allow Z homing only after X and Y homing AND stepper drivers still enabled. // - If stepper drivers timeout, it will need X and Y homing again before Z homing. // - Position the Z probe in a defined XY point before Z Homing when homing all axis (G28). // - Block Z homing only when the Z probe is outside bed area. #if ENABLED(Z_SAFE_HOMING) // Déterminer Home Z suite à la commande G28 "Home All" // Les distances sont calculées par rapport aux limites externes de la grille. // Centre du plateau #define Z_SAFE_HOMING_X_POINT ((35+110)-58) #define Z_SAFE_HOMING_Y_POINT ((110+8)-(7+8)) #endif #endif // AUTO_BED_LEVELING_FEATURE // @section homing // The position of the homing switches //#define MANUAL_HOME_POSITIONS // If defined, MANUAL_*_HOME_POS below will be used //#define BED_CENTER_AT_0_0 // If defined, the center of the bed is at (X=0, Y=0) // Manual homing switch locations: // For deltabots this means top and center of the Cartesian print volume. #if ENABLED(MANUAL_HOME_POSITIONS) #define MANUAL_X_HOME_POS 0 #define MANUAL_Y_HOME_POS 0 #define MANUAL_Z_HOME_POS 0 //#define MANUAL_Z_HOME_POS 402 // For delta: Distance between nozzle and print surface after homing. #endif // The speed change that does not require acceleration (i.e. the software might assume it can be done instantaneously) #define DEFAULT_XYJERK 20.0 // (mm/sec) #define DEFAULT_ZJERK 0.4 // (mm/sec) #define DEFAULT_EJERK 5.0 // (mm/sec) //=========================================================================== //========================= Filament Runout Sensor ========================== //=========================================================================== //#define FILAMENT_RUNOUT_SENSOR // Uncomment for defining a filament runout sensor such as a mechanical or opto endstop to check the existence of filament // In RAMPS uses servo pin 2. Can be changed in pins file. For other boards pin definition should be made. // It is assumed that when logic high = filament available // when logic low = filament ran out #if ENABLED(FILAMENT_RUNOUT_SENSOR) const bool FIL_RUNOUT_INVERTING = true; // Should be uncommented and true or false should assigned #define ENDSTOPPULLUP_FIL_RUNOUT // Uncomment to use internal pullup for filament runout pins if the sensor is defined. #define FILAMENT_RUNOUT_SCRIPT "M600" #endif //============================================================================= //============================= Additional Features =========================== //============================================================================= // @section more // Custom M code points #define CUSTOM_M_CODES #if ENABLED(CUSTOM_M_CODES) #if ENABLED(AUTO_BED_LEVELING_FEATURE) #define CUSTOM_M_CODE_SET_Z_PROBE_OFFSET 851 #define Z_PROBE_OFFSET_RANGE_MIN -20 #define Z_PROBE_OFFSET_RANGE_MAX 20 #endif #endif // @section extras // EEPROM // The microcontroller can store settings in the EEPROM, e.g. max velocity... // M500 - stores parameters in EEPROM // M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily). // M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to. //define this to enable EEPROM support //#define EEPROM_SETTINGS #if ENABLED(EEPROM_SETTINGS) // To disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out: #define EEPROM_CHITCHAT // Please keep turned on if you can. #endif // // Host Keepalive // // By default Marlin will send a busy status message to the host // every 10 seconds when it can't accept commands. // //#define DISABLE_HOST_KEEPALIVE // Enable this option if your host doesn't like keepalive messages. // // M100 Free Memory Watcher // //#define M100_FREE_MEMORY_WATCHER // uncomment to add the M100 Free Memory Watcher for debug purpose // @section temperature // Preheat Constants #define PLA_PREHEAT_HOTEND_TEMP 180 #define PLA_PREHEAT_HPB_TEMP 70 #define PLA_PREHEAT_FAN_SPEED 0 // Insert Value between 0 and 255 #define ABS_PREHEAT_HOTEND_TEMP 240 #define ABS_PREHEAT_HPB_TEMP 110 #define ABS_PREHEAT_FAN_SPEED 0 // Insert Value between 0 and 255 //==============================LCD and SD support============================= // @section lcd // Define your display language below. Replace (en) with your language code and uncomment. // en, pl, fr, de, es, ru, bg, it, pt, pt_utf8, pt-br, pt-br_utf8, fi, an, nl, ca, eu, kana, kana_utf8, cn, cz, test // See also language.h #define LANGUAGE_INCLUDE GENERATE_LANGUAGE_INCLUDE(en) // Choose ONE of these 3 charsets. This has to match your hardware. Ignored for full graphic display. // To find out what type you have - compile with (test) - upload - click to get the menu. You'll see two typical lines from the upper half of the charset. // See also [github.com] #define DISPLAY_CHARSET_HD44780_JAPAN // this is the most common hardware //#define DISPLAY_CHARSET_HD44780_WESTERN //#define DISPLAY_CHARSET_HD44780_CYRILLIC //#define ULTRA_LCD //general LCD support, also 16x2 //#define DOGLCD // Support for SPI LCD 128x64 (Controller ST7565R graphic Display Family) //#define SDSUPPORT // Enable SD Card Support in Hardware Console // Changed behaviour! If you need SDSUPPORT uncomment it! //#define SPI_SPEED SPI_HALF_SPEED // (also SPI_QUARTER_SPEED, SPI_EIGHTH_SPEED) Use slower SD transfer mode (not normally needed - uncomment if you're getting volume init error) //#define SD_CHECK_AND_RETRY // Use CRC checks and retries on the SD communication //#define ENCODER_PULSES_PER_STEP 1 // Increase if you have a high resolution encoder //#define ENCODER_STEPS_PER_MENU_ITEM 5 // Set according to ENCODER_PULSES_PER_STEP or your liking //#define REVERSE_MENU_DIRECTION // When enabled CLOCKWISE moves UP in the LCD menu //#define ULTIMAKERCONTROLLER //as available from the Ultimaker online store. //#define ULTIPANEL //the UltiPanel as on Thingiverse //#define SPEAKER // The sound device is a speaker - not a buzzer. A buzzer resonates with his own frequency. //#define LCD_FEEDBACK_FREQUENCY_DURATION_MS 100 // the duration the buzzer plays the UI feedback sound. ie Screen Click //#define LCD_FEEDBACK_FREQUENCY_HZ 1000 // this is the tone frequency the buzzer plays when on UI feedback. ie Screen Click // 0 to disable buzzer feedback. Test with M300 S P // PanelOne from T3P3 (via RAMPS 1.4 AUX2/AUX3) // [reprap.org] //#define PANEL_ONE // The MaKr3d Makr-Panel with graphic controller and SD support // [reprap.org] //#define MAKRPANEL // The Panucatt Devices Viki 2.0 and mini Viki with Graphic LCD // [panucatt.com] // ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [github.com] //#define VIKI2 //#define miniVIKI // This is a new controller currently under development. [github.com] // // ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [github.com] //#define ELB_FULL_GRAPHIC_CONTROLLER //#define SD_DETECT_INVERTED // The RepRapDiscount Smart Controller (white PC// [reprap.org] //#define REPRAP_DISCOUNT_SMART_CONTROLLER // The GADGETS3D G3D LCD/SD Controller (blue PC

// [reprap.org] //#define G3D_PANEL // The RepRapDiscount FULL GRAPHIC Smart Controller (quadratic white PC

// [reprap.org] // // ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [github.com] //#define REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER // The RepRapWorld REPRAPWORLD_KEYPAD v1.1 // [reprapworld.com] //#define REPRAPWORLD_KEYPAD //#define REPRAPWORLD_KEYPAD_MOVE_STEP 10.0 // how much should be moved when a key is pressed, eg 10.0 means 10mm per click // The Elefu RA Board Control Panel // [www.elefu.com] // REMEMBER TO INSTALL LiquidCrystal_I2C.h in your ARDUINO library folder: [github.com] //#define RA_CONTROL_PANEL // The MakerLab Mini Panel with graphic controller and SD support // [reprap.org] //#define MINIPANEL /** * I2C Panels */ //#define LCD_I2C_SAINSMART_YWROBOT //#define LCM1602 // LCM1602 Adapter for 16x2 LCD // PANELOLU2 LCD with status LEDs, separate encoder and click inputs // // This uses the LiquidTWI2 library v1.2.3 or later ( [github.com] ) // Make sure the LiquidTWI2 directory is placed in the Arduino or Sketchbook libraries subdirectory. // (v1.2.3 no longer requires you to define PANELOLU in the LiquidTWI2.h library header file) // Note: The PANELOLU2 encoder click input can either be directly connected to a pin // (if BTN_ENC defined to != -1) or read through I2C (when BTN_ENC == -1). //#define LCD_I2C_PANELOLU2 // Panucatt VIKI LCD with status LEDs, integrated click & L/R/U/P buttons, separate encoder inputs //#define LCD_I2C_VIKI // SSD1306 OLED generic display support // ==> REMEMBER TO INSTALL U8glib to your ARDUINO library folder: [github.com] //#define U8GLIB_SSD1306 // Shift register panels // --------------------- // 2 wire Non-latching LCD SR from: // [bitbucket.org] // LCD configuration: [reprap.org] //#define SAV_3DLCD // @section extras // Increase the FAN PWM frequency. Removes the PWM noise but increases heating in the FET/Arduino //#define FAST_PWM_FAN // Use software PWM to drive the fan, as for the heaters. This uses a very low frequency // which is not as annoying as with the hardware PWM. On the other hand, if this frequency // is too low, you should also increment SOFT_PWM_SCALE. //#define FAN_SOFT_PWM // Incrementing this by 1 will double the software PWM frequency, // affecting heaters, and the fan if FAN_SOFT_PWM is enabled. // However, control resolution will be halved for each increment; // at zero value, there are 128 effective control positions. #define SOFT_PWM_SCALE 0 // Temperature status LEDs that display the hotend and bet temperature. // If all hotends and bed temperature and temperature setpoint are < 54C then the BLUE led is on. // Otherwise the RED led is on. There is 1C hysteresis. //#define TEMP_STAT_LEDS // M240 Triggers a camera by emulating a Canon RC-1 Remote // Data from: [www.doc-diy.net] //#define PHOTOGRAPH_PIN 23 // SkeinForge sends the wrong arc g-codes when using Arc Point as fillet procedure //#define SF_ARC_FIX // Support for the BariCUDA Paste Extruder. //#define BARICUDA //define BlinkM/CyzRgb Support //#define BLINKM /*********************************************************************\ * R/C SERVO support * Sponsored by TrinityLabs, Reworked by codexmas **********************************************************************/ // Number of servos // // If you select a configuration below, this will receive a default value and does not need to be set manually // set it manually if you have more servos than extruders and wish to manually control some // leaving it undefined or defining as 0 will disable the servo subsystem // If unsure, leave commented / disabled // //#define NUM_SERVOS 3 // Servo index starts with 0 for M280 command // Servo Endstops // // This allows for servo actuated endstops, primary usage is for the Z Axis to eliminate calibration or bed height changes. // Use M851 to set the Z probe vertical offset from the nozzle. Store that setting with M500. // //#define X_ENDSTOP_SERVO_NR 1 //#define Y_ENDSTOP_SERVO_NR 2 //#define Z_ENDSTOP_SERVO_NR 0 //#define SERVO_ENDSTOP_ANGLES {{0,0}, {0,0}, {70,0}} // X,Y,Z Axis Extend and Retract angles // Servo deactivation // // With this option servos are powered only during movement, then turned off to prevent jitter. //#define DEACTIVATE_SERVOS_AFTER_MOVE #if ENABLED(DEACTIVATE_SERVOS_AFTER_MOVE) // Delay (in microseconds) before turning the servo off. This depends on the servo speed. // 300ms is a good value but you can try less delay. // If the servo can't reach the requested position, increase it. #define SERVO_DEACTIVATION_DELAY 300 #endif /**********************************************************************\ * Support for a filament diameter sensor * Also allows adjustment of diameter at print time (vs at slicing) * Single extruder only at this point (extruder 0) * * Motherboards * 34 - RAMPS1.4 - uses Analog input 5 on the AUX2 connector * 81 - Printrboard - Uses Analog input 2 on the Exp1 connector (version B,C,D,E) * 301 - Rambo - uses Analog input 3 * Note may require analog pins to be defined for different motherboards **********************************************************************/ // Uncomment below to enable //#define FILAMENT_WIDTH_SENSOR #define DEFAULT_NOMINAL_FILAMENT_DIA 3.00 //Enter the diameter (in mm) of the filament generally used (3.0 mm or 1.75 mm) - this is then used in the slicer software. Used for sensor reading validation #if ENABLED(FILAMENT_WIDTH_SENSOR) #define FILAMENT_SENSOR_EXTRUDER_NUM 0 //The number of the extruder that has the filament sensor (0,1,2) #define MEASUREMENT_DELAY_CM 14 //measurement delay in cm. This is the distance from filament sensor to middle of barrel #define MEASURED_UPPER_LIMIT 3.30 //upper limit factor used for sensor reading validation in mm #define MEASURED_LOWER_LIMIT 1.90 //lower limit factor for sensor reading validation in mm #define MAX_MEASUREMENT_DELAY 20 //delay buffer size in bytes (1 byte = 1cm)- limits maximum measurement delay allowable (must be larger than MEASUREMENT_DELAY_CM and lower number saves RAM) #define DEFAULT_MEASURED_FILAMENT_DIA DEFAULT_NOMINAL_FILAMENT_DIA //set measured to nominal initially //When using an LCD, uncomment the line below to display the Filament sensor data on the last line instead of status. Status will appear for 5 sec. //#define FILAMENT_LCD_DISPLAY #endif #include "Configuration_adv.h" #include "thermistortables.h" #endif //CONFIGURATION_H

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 09:30AM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 09:43AM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 10:54AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 10:57AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 07, 2016 06:58PM |

Registered: 8 years ago Posts: 22 |

Victoire

Victoire

Enfin ça fonctionne.

J'étais avec la version Marlin 1.0.2 Il doit y avoir des bugs, car impossible de faire positionner la buse correctement. De plus, parfois entre 2 essais, la commande G29 ne fonctionnait plus et la buse entrait en contacte avec le plateau.

Donc j'ai téléchargé la version Marlin 1.1.0-RC3, repris mes paramètres et du 1er coup ça imprime.

Pour 0.4 j'ai 0.35 en moyenne. Léger décalage de 0.05mm que je vais peaufiner.

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 08, 2016 03:20AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 08, 2016 04:18AM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 08, 2016 05:55AM |

Registered: 8 years ago Posts: 85 |

G30 - Single Z probe, probe bed at current XY location (lance un pointage sur les coordonnées cournate en XY)

test sur repeiter-Host.

Personnellement, j'ai commencé sur Repetier-Host puis je suis passé sur Simplify 3D car algorithme de remplissage est mieux pensé et donne de meilleure résultat à l'impression

[reprap.org]

[www.mmsonline.com]

...

test sur repeiter-Host.

Personnellement, j'ai commencé sur Repetier-Host puis je suis passé sur Simplify 3D car algorithme de remplissage est mieux pensé et donne de meilleure résultat à l'impression

[reprap.org]

[www.mmsonline.com]

...

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 08, 2016 07:20AM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 08, 2016 08:59AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 09, 2016 03:51PM |

Registered: 8 years ago Posts: 22 |

Hello,

J'ai encore un bug quelque part...

Quand je lance une impression, le G28 se passe très bien (le Z est bien détecté), il passe au G29 et là, c'est comme si le capteur de ne déclenchait pas, la buse continue droit dans le plateau.

Le pire, c'est que si je coupe l'alim, rebranche et relance l'impression, tout marche bien. J'ai fais le test avec 3 impressions différentes et à chaque fois j'ai eu le même résultat.

Une idée de se qui se passe?

J'ai encore un bug quelque part...

Quand je lance une impression, le G28 se passe très bien (le Z est bien détecté), il passe au G29 et là, c'est comme si le capteur de ne déclenchait pas, la buse continue droit dans le plateau.

Le pire, c'est que si je coupe l'alim, rebranche et relance l'impression, tout marche bien. J'ai fais le test avec 3 impressions différentes et à chaque fois j'ai eu le même résultat.

Une idée de se qui se passe?

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 09, 2016 04:01PM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 09, 2016 04:13PM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 09, 2016 04:14PM |

Registered: 8 years ago Posts: 394 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 09, 2016 04:30PM |

Registered: 8 years ago Posts: 22 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 10, 2016 03:34AM |

Registered: 8 years ago Posts: 85 |

dans Slic3r ajoute ceci

Onglet "printer Setings"

Option "Custom G-Code"

Champ "Start G-code"

G1 Z20 F5000 ; Remonte la tête d'impression si sa position initiale est sous le plateau

G28 X0 Y0 ; Home XY

G29 ; Lance le processus de pointage

Champ "End G-code"

M104 S0 ; turn off temperature

G28 X0 ; home X axis

M84 ; disable motors

Onglet "printer Setings"

Option "Custom G-Code"

Champ "Start G-code"

G1 Z20 F5000 ; Remonte la tête d'impression si sa position initiale est sous le plateau

G28 X0 Y0 ; Home XY

G29 ; Lance le processus de pointage

Champ "End G-code"

M104 S0 ; turn off temperature

G28 X0 ; home X axis

M84 ; disable motors

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 10, 2016 03:36AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 10, 2016 03:38AM |

Registered: 8 years ago Posts: 85 |

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 10, 2016 04:24AM |

Registered: 8 years ago Posts: 22 |

Oui j'avais la tension, j'avais 4.8V et 0V quand il détectait.

Là, j'ai recompilé le firmware, avec Arduino 1.0.5 (avant j'avais la 1.5.8), j'ai aussi augmenté Z_RAISE_BEFORE_PROBING et Z_RAISE_BETWEEN_PROBINGS de 2 à 5.

Je viens de faire 2 essais et le problème n'est pas apparu.

Je croise les doigts pour que ça dure dans le temps.

Là, j'ai recompilé le firmware, avec Arduino 1.0.5 (avant j'avais la 1.5.8), j'ai aussi augmenté Z_RAISE_BEFORE_PROBING et Z_RAISE_BETWEEN_PROBINGS de 2 à 5.

Je viens de faire 2 essais et le problème n'est pas apparu.

Je croise les doigts pour que ça dure dans le temps.

|

Re: Branchement du capteur de proximité -LJC18A3 H Z/BX May 10, 2016 04:26AM |

Registered: 8 years ago Posts: 85 |

Sorry, only registered users may post in this forum.