porbleme leveling delta (capteur tactile)

Posted by rialevent

|

porbleme leveling delta (capteur tactile) December 12, 2017 01:57PM |

Registered: 10 years ago Posts: 103 |

bonjour,

je me suis monter une delta resemant et j'y ais mis un capter tactil pour le leveling

le problème est que ça ne marche pas, j'ai le message d'erreur err: ZPROBE

pouvez vous m'aider ?

j'ai mis ma cofigue en lien

si non, voici le bout de configure que me semble importent :

merci d'avance pour votre aide.

je me suis monter une delta resemant et j'y ais mis un capter tactil pour le leveling

le problème est que ça ne marche pas, j'ai le message d'erreur err: ZPROBE

pouvez vous m'aider ?

j'ai mis ma cofigue en lien

si non, voici le bout de configure que me semble importent :

//=========================================================================== //============================== Delta Settings ============================= //=========================================================================== // Enable DELTA kinematics and most of the default configuration for Deltas #define DELTA #if ENABLED(DELTA) // Make delta curves from many straight lines (linear interpolation). // This is a trade-off between visible corners (not enough segments) // and processor overload (too many expensive sqrt calls). #define DELTA_SEGMENTS_PER_SECOND 200 // After homing move down to a height where XY movement is unconstrained //#define DELTA_HOME_TO_SAFE_ZONE // Delta calibration menu // uncomment to add three points calibration menu option. // See [minow.blogspot.com] //#define DELTA_CALIBRATION_MENU // uncomment to add G33 Delta Auto-Calibration (Enable EEPROM_SETTINGS to store results) #define DELTA_AUTO_CALIBRATION // NOTE NB all values for DELTA_* values MUST be floating point, so always have a decimal point in them #if ENABLED(DELTA_AUTO_CALIBRATION) // set the default number of probe points : n*n (1 -> 7) #define DELTA_CALIBRATION_DEFAULT_POINTS 5 #endif #if ENABLED(DELTA_AUTO_CALIBRATION) || ENABLED(DELTA_CALIBRATION_MENU) // Set the radius for the calibration probe points - max DELTA_PRINTABLE_RADIUS*0.869 for non-eccentric probes #define DELTA_CALIBRATION_RADIUS 70 // mm // Set the steprate for papertest probing #define PROBE_MANUALLY_STEP 0.025 #endif // Print surface diameter/2 minus unreachable space (avoid collisions with vertical towers). #define DELTA_PRINTABLE_RADIUS 80.0 // mm // Center-to-center distance of the holes in the diagonal push rods. #define DELTA_DIAGONAL_ROD 217.0 // mm // height from z=0 to home position #define DELTA_HEIGHT 164.90 // get this value from auto calibrate #define DELTA_ENDSTOP_ADJ { -1.0, 0.0, -2.0 } // get these from auto calibrate // Horizontal distance bridged by diagonal push rods when effector is centered. #define DELTA_RADIUS 84.0 //mm Get this value from auto calibrate // Trim adjustments for individual towers // tower angle corrections for X and Y tower / rotate XYZ so Z tower angle = 0 // measured in degrees anticlockwise looking from above the printer #define DELTA_TOWER_ANGLE_TRIM { 0.0, 0.0, 0.0 } // get these values from auto calibrate // delta radius and diaginal rod adjustments measured in mm //#define DELTA_RADIUS_TRIM_TOWER { 0.0, 0.0, 0.0 } //#define DELTA_DIAGONAL_ROD_TRIM_TOWER { 0.0, 0.0, 0.0 } #endif

//=========================================================================== //============================== Endstop Settings =========================== //=========================================================================== //#define USE_XMIN_PLUG //#define USE_YMIN_PLUG #define USE_ZMIN_PLUG // a Z probe #define USE_XMAX_PLUG #define USE_YMAX_PLUG #define USE_ZMAX_PLUG // coarse Endstop Settings //#define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors #if DISABLED(ENDSTOPPULLUPS) // fine endstop settings: Individual pullups. will be ignored if ENDSTOPPULLUPS is defined //#define ENDSTOPPULLUP_XMAX //#define ENDSTOPPULLUP_YMAX //#define ENDSTOPPULLUP_ZMAX //#define ENDSTOPPULLUP_XMIN //#define ENDSTOPPULLUP_YMIN #define ENDSTOPPULLUP_ZMIN //#define ENDSTOPPULLUP_ZMIN_PROBE #endif // Mechanical endstop with COM to ground and NC to Signal uses "false" here (most common setup). #define X_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Y_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Z_MIN_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define X_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Y_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Z_MAX_ENDSTOP_INVERTING true // set to true to invert the logic of the endstop. #define Z_MIN_PROBE_ENDSTOP_INVERTING true // set to true to invert the logic of the probe. // Enable this feature if all enabled endstop pins are interrupt-capable. // This will remove the need to poll the interrupt pins, saving many CPU cycles. //#define ENDSTOP_INTERRUPTS_FEATURE

//===========================================================================

//============================= Z Probe Options =============================

//===========================================================================

#define Z_MIN_PROBE_USES_Z_MIN_ENDSTOP_PIN

//#define Z_MIN_PROBE_ENDSTOP

//#define PROBE_MANUALLY

//#define FIX_MOUNTED_PROBE

//#define Z_ENDSTOP_SERVO_NR 0 // Defaults to SERVO 0 connector.

//#define Z_SERVO_ANGLES {70,0} // Z Servo Deploy and Stow angles

//#define BLTOUCH

#if ENABLED(BLTOUCH)

//#define BLTOUCH_DELAY 375 // (ms) Enable and increase if needed

#endif

//#define PROBING_HEATERS_OFF // Turn heaters off when probing

//#define PROBING_FANS_OFF // Turn fans off when probing

//#define DELAY_BEFORE_PROBING 200 // (ms) To prevent vibrations from triggering piezo sensors

// A probe that is deployed and stowed with a solenoid pin (SOL1_PIN)

//#define SOLENOID_PROBE

// A sled-mounted probe like those designed by Charles Bell.

//#define Z_PROBE_SLED

//#define SLED_DOCKING_OFFSET 5 // The extra distance the X axis must travel to pickup the sled. 0 should be fine but you can push it further if you'd like.

#define X_PROBE_OFFSET_FROM_EXTRUDER 0 // X offset: -left +right [of the nozzle]

#define Y_PROBE_OFFSET_FROM_EXTRUDER -3.6 // Y offset: -front +behind [the nozzle]

#define Z_PROBE_OFFSET_FROM_EXTRUDER -3.5 // Z offset: -below +above [the nozzle]

// X and Y axis travel speed (mm/m) between probes

#define XY_PROBE_SPEED 4000

// Speed for the first approach when double-probing (with PROBE_DOUBLE_TOUCH)

#define Z_PROBE_SPEED_FAST HOMING_FEEDRATE_Z

// Speed for the "accurate" probe of each point

#define Z_PROBE_SPEED_SLOW (Z_PROBE_SPEED_FAST / 2)

// Use double touch for probing

//#define PROBE_DOUBLE_TOUCH

/**

* Allen key retractable z-probe as seen on many Kossel delta printers - [reprap.org]

* Deploys by touching z-axis belt. Retracts by pushing the probe down. Uses Z_MIN_PIN.

*/

#define Z_PROBE_ALLEN_KEY

//=========================================================================== //=============================== Bed Leveling ============================== //=========================================================================== //#define AUTO_BED_LEVELING_3POINT #define AUTO_BED_LEVELING_LINEAR //#define AUTO_BED_LEVELING_BILINEAR //#define AUTO_BED_LEVELING_UBL //#define MESH_BED_LEVELING

merci d'avance pour votre aide.

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 01:15AM |

Registered: 9 years ago Posts: 145 |

Hello, ta delta est sur quelle ramps?

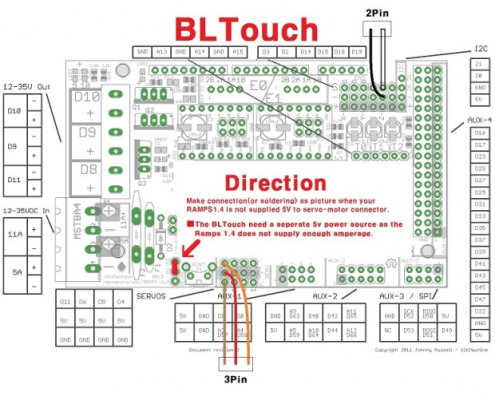

as tu bien connecté le bltouch sur les pin's qui gèrent les servos? et as tu bien connecté le cable 5v qui alimente le bltouch?

SI oui quand tu enclenche l’imprimante est ce que tu le vois s'allumer en rouge et le capteur fait haut bas 2X?

A plus

Edited 1 time(s). Last edit at 12/13/2017 01:15AM by maximeh.

as tu bien connecté le bltouch sur les pin's qui gèrent les servos? et as tu bien connecté le cable 5v qui alimente le bltouch?

SI oui quand tu enclenche l’imprimante est ce que tu le vois s'allumer en rouge et le capteur fait haut bas 2X?

A plus

Edited 1 time(s). Last edit at 12/13/2017 01:15AM by maximeh.

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 06:28AM |

Registered: 10 years ago Posts: 103 |

j'ai une ramp 1.4 et j'ai fais le même cablage que préconisé par le vendeur

pour la led, je ne sais pas (je regarde se soir) . aucun mouvement du capteur.

l'or de la commande G33, la delta se met à l'origine (Zmaz). Ce posissionne en Xmax (si je ne me trompe pas d'axe) et dessend.

à mis parcour elle se déplace en -x et s'arrete avec le message d'erreur.

pour la led, je ne sais pas (je regarde se soir) . aucun mouvement du capteur.

l'or de la commande G33, la delta se met à l'origine (Zmaz). Ce posissionne en Xmax (si je ne me trompe pas d'axe) et dessend.

à mis parcour elle se déplace en -x et s'arrete avec le message d'erreur.

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 09:55AM |

Registered: 9 years ago Posts: 145 |

Re

Alors avant de lancer le G33 tu dois contrôler si le capteur donne bien l'info au microncontroleur mais petite subtilité, mais juste avant tu fois lancer M280 P0 S60 pour activer bltouch pour envoyer le signal comme un endstop, en faisant M119 tu dois voir normalement Probe =0 ou 1 quand tu monte ou descend le capteur, donc 0 si il est descendu et 1 quand il est en haut.

Bon pour moi j'ai acheté la version original et pas chinoise

mais je pense qu'au niveau de la led qui s'allume quand on démarre l'imprimante est aussi dans la version copie, donc si elle ne s'allume pas et aussi que le check ne se fait pas en haut en bas 2 X il doit y avoir un problème de d'alimentation. Donc question es tu sur d'être en 5v et pas 3.3.

De plus regarde bien la fonction M280 sur le net c'est depuis cette commande que tu peux contrôler le capteur, genre haut, bas alarme, désactivation alarme, active fonction endstop afin de déterminer le bon fonctionnement du capteur.

Edited 1 time(s). Last edit at 12/13/2017 10:15AM by maximeh.

Alors avant de lancer le G33 tu dois contrôler si le capteur donne bien l'info au microncontroleur mais petite subtilité, mais juste avant tu fois lancer M280 P0 S60 pour activer bltouch pour envoyer le signal comme un endstop, en faisant M119 tu dois voir normalement Probe =0 ou 1 quand tu monte ou descend le capteur, donc 0 si il est descendu et 1 quand il est en haut.

Bon pour moi j'ai acheté la version original et pas chinoise

mais je pense qu'au niveau de la led qui s'allume quand on démarre l'imprimante est aussi dans la version copie, donc si elle ne s'allume pas et aussi que le check ne se fait pas en haut en bas 2 X il doit y avoir un problème de d'alimentation. Donc question es tu sur d'être en 5v et pas 3.3.

De plus regarde bien la fonction M280 sur le net c'est depuis cette commande que tu peux contrôler le capteur, genre haut, bas alarme, désactivation alarme, active fonction endstop afin de déterminer le bon fonctionnement du capteur.

Edited 1 time(s). Last edit at 12/13/2017 10:15AM by maximeh.

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 12:35PM |

Registered: 10 years ago Posts: 103 |

merci beaucoup, je me demandé qu'elle était cette histoire de 5V

je n'avais pas vue le pond à mètre.

Mais le palpeur ne sort pas avec la commande M280

M119 me renvoi :

READ: x_max: open

READ: y_max: open

READ: z_min: open

READ: z_max: open

je vais voir se que j'ai mal configuré

Edited 1 time(s). Last edit at 12/13/2017 12:36PM by rialevent.

je n'avais pas vue le pond à mètre.

Mais le palpeur ne sort pas avec la commande M280

M119 me renvoi :

READ: x_max: open

READ: y_max: open

READ: z_min: open

READ: z_max: open

je vais voir se que j'ai mal configuré

Edited 1 time(s). Last edit at 12/13/2017 12:36PM by rialevent.

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 01:17PM |

Registered: 9 years ago Posts: 145 |

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 01:36PM |

Registered: 10 years ago Posts: 103 |

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 01:40PM |

Registered: 9 years ago Posts: 145 |

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 01:51PM |

Registered: 9 years ago Posts: 145 |

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 03:14PM |

Registered: 10 years ago Posts: 103 |

oui, c'est ce que je pence aussiQuote

maximeh

donc problème servo

pour le moment, il ne se passe rien quand je fait cette commandeQuote

maximeh

désolé recherche toutes les commandes M280, tu peux avec cette commande commandé haut et bas, ce qui est le teste parfait

j'ai vérifier le pin, du servo :

#define SERVO0_PIN 11

se qui correspond au câblage

le bon servo moteur est défini

#define NUM_SERVOS 0

aprés je n'est pas décomenté les deux lignes : (sa fais planter la compilation)

//#define Z_ENDSTOP_SERVO_NR 0 // Defaults to SERVO 0 connector.

//#define Z_SERVO_ANGLES {70,0} // Z Servo Deploy and Stow angles

maximeh : tu a utilisé le même capteur que moi, est ce que tu pourai me montré t'on fichier de configuration, voir les paramètre que tu a mis (et peut être trouver l'erreur)

Edited 3 time(s). Last edit at 12/13/2017 03:19PM by rialevent.

|

Re: porbleme leveling delta (capteur tactile) December 13, 2017 03:27PM |

Registered: 9 years ago Posts: 145 |

|

Re: porbleme leveling delta (capteur tactile) May 12, 2018 07:31AM |

Registered: 10 years ago Posts: 103 |

bonjour, je reviens vers vous car je n'y arrive toujours pas avec mon bed leveling

j'ai résolu un problème : les câbles était trop fin et il devait y avoir une perturbation du signal

la commande M280 P0 S60 : me renvoi : OK

mais rien ne ce passe au niveau du servomoteur

la commande M119 me renvoie :

j'ai réussi à activé les ligne de commande :

quelque fois au l'or ce que je branche l’imprimante, l’initialisation du capteur ce passe mal et il clignote

alors la commande M119 me renvoie :

merci d'avance pour vos retour

j'ai résolu un problème : les câbles était trop fin et il devait y avoir une perturbation du signal

la commande M280 P0 S60 : me renvoi : OK

mais rien ne ce passe au niveau du servomoteur

la commande M119 me renvoie :

READ: x_max: open READ: y_max: open READ: z_min: TRIGGERED READ: z_max: open

j'ai réussi à activé les ligne de commande :

#define Z_ENDSTOP_SERVO_NR 0 // Defaults to SERVO 0 connector.

#define Z_SERVO_ANGLES {70,0} // Z Servo Deploy and Stow angles

et j'ai passé le nombre de servomoteur à 1 :#define NUM_SERVOS 1

quelque fois au l'or ce que je branche l’imprimante, l’initialisation du capteur ce passe mal et il clignote

alors la commande M119 me renvoie :

READ: x_max: open READ: y_max: open READ: z_min: open READ: z_max: open

merci d'avance pour vos retour

|

Re: porbleme leveling delta (capteur tactile) May 12, 2018 03:19PM |

Registered: 10 years ago Posts: 103 |

|

Re: porbleme leveling delta (capteur tactile) May 13, 2018 07:24AM |

Registered: 7 years ago Posts: 509 |

Sorry, only registered users may post in this forum.